How the General Electric Smart Plant Works

Tools of Industry 4.0 are comprehensively used by major global manufacturers today. Such "factories of the future" represent the prototype of the model on the basis of which the production of the Fourth Industrial Revolution will be organized, and there are more and more such enterprises. We will talk about the amazing prospects of a new industrial concept on the example of the “smart” factory of General Electric, where today are used:

- laser technology and robots;

- supermaterials;

- additive technology;

- internet of things.

The industrial area on the outskirts of Greenville, South Carolina, is not the most obvious place to go to see the future. But there, behind the railroad tracks and box-shaped factories, you can find the new advanced plant of GE Power, which opened in April 2016. This place changes the very idea of how things can be created.

Step into the future No. 1: laser technology and robotics

An enterprise covering more than two football fields looks like a huge toolbox from the future, adorned with a giant GE monogram. An elegant laser cutter based on MicroJet technology directs the laser beam through a thin stream of water and cuts shapes on strong metals, making it so accurate that they look like something unearthly. The factory has installed industrial 3D printers and argon furnaces in rows for processing spare parts made of lightweight and heat-resistant supermaterial - ceramic matrix composites (KKM).

This laser device based on MicroJet technology uses a thin stream of water to focus the laser beam (ruby glow inside the mechanism). It was originally developed for use in the diamond industry, but GE Power adapted it to create the most accurate cooling holes in the turbine blades and other details (see below). Photo GE Power

Somewhere on the side - a robot named Autonomous Prime after the Transformers character Optimus Prime scans its work area with the built-in LIDAR laser locator technology - the same technology Google used to create self-driving cars - and maintains a computer-controlled milling machine management. Most of the technologies presented here use built-in sensors that transfer data to the cloud via secure industrial Internet channels for analysis and processing.

General Electric engineer Vinson Blenton stands next to Autonomous Prime. This robot is equipped with eyes with integrated LIDAR laser locator technology to move heavy parts around the factory. The engineer says: “He is studying space. He can actually see us. ” At the new plant, robots perform "dirty, complex, dangerous and boring tasks." Photo GE Power

Step into the future No. 2: supermaterials

During a visit to the plant by the GE Reports team, the machines made wavy compressor blades for the world's largest jet engine, ceramic caps for gas turbines and other parts of the most complex shapes and from the latest materials , the creation of which was difficult to imagine a couple of years ago. According to Kurt Goodwin, the GE manager who runs the plant, “this venture is a bridge between the laboratory and reality. This is an incubator. “We work with engineers to enable them to implement their ambitious plans and help integrate their results into mass production at a reasonable cost.”

Goodwin, a man who wears glasses, a gray beard and behaves like a friendly university professor, says: “Leonardo da Vinci brought the idea of a helicopter into the world, but it took 400 years for Igor Sikorsky to bring it to life. We have everything to help our inventors create here and now and without delay to introduce development into mass production . ”

Parts of ceramic materials composites in furnaces and autoclaves can be made at the plant, as in the photo above. Photo GE Power

GE Power has invested $ 75 million in the construction of the plant. It is located next to the company's huge facility in Greenville, where GE Power produces the world's largest gas turbines, weighing hundreds of tons, the details of which are made with precision comparable to the thickness of a human hair. At the new plant, engineers and their colleagues from other GE departments, such as GE Oil & Gas and GE Global Research, will test new models and designs, create prototypes in a short time, and then look for ways to mass produce the best models. GE calls this knowledge and technology sharing project GE Store.

A 3D scanner with blue light technology allows engineers to monitor with maximum accuracy how complex parts, such as turbine blades, change over time after they are put into operation. Photo GE Power

Step into the future No. 3: additive technologies

The second such company General Electric - Improvement Center additive technology (Center for Additive Technology Advancement) in Pittsburgh that helps companies implement methods of additive manufacturing, among which is dominated by the 3D-press.

According to Goodwin, a high-tech plant was necessary for the company to keep up with the needs of consumers. “It's incredible how fast the world is changing,” he says. - Expectations for improvements offered by the market are staggering. Our neighbor is the largest in the world, and it is already optimized for the production of gas turbines at the limit of their capacity. The workers of this plant have many grand ideas and no time for games. ”

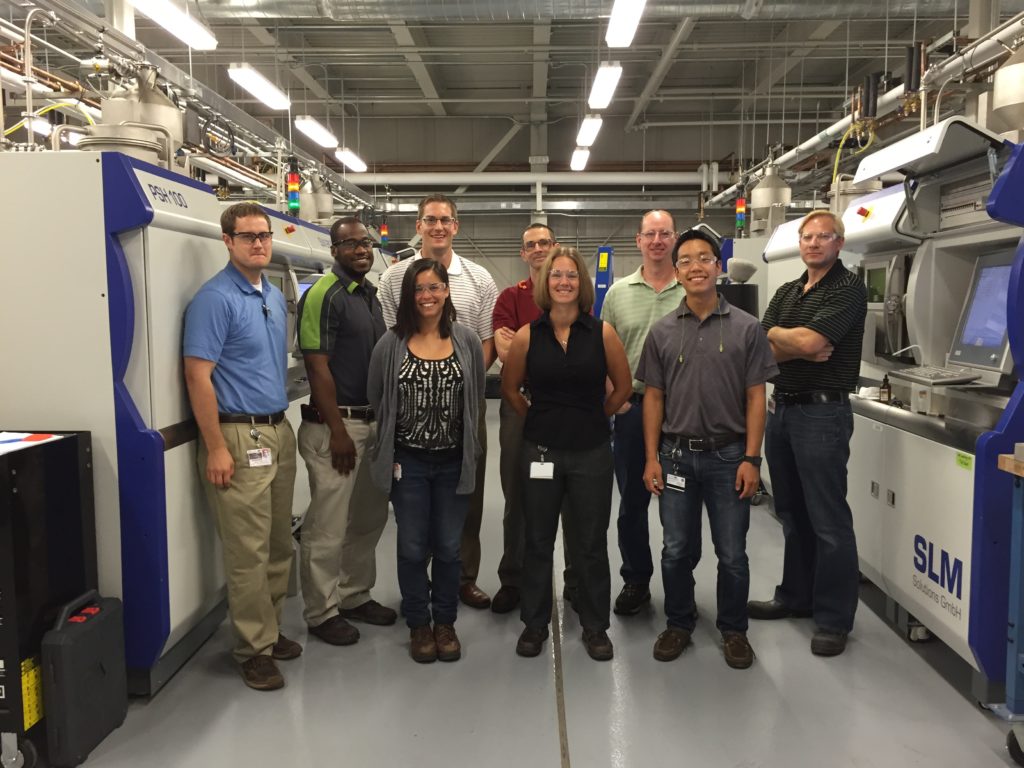

Engineers gave SLM Solutions additive installations nicknames such as Poison Ivy and Catwoman. Industrial 3D printing is still an innovation, and each device behaves differently. These 3D printers will be involved in mass production. Photo GE Power

The latest machines and devices for analyzing large volumes of data are installed here, but the main thing is the right people. The plant, where 80 employees will work, has already hired materials scientists with a doctoral degree, engineers and mechanics who have been honing their skills for decades. “We carefully selected a team of inventive people who are focused on finding solutions and don’t panic when something goes wrong,” says Goodwin. “They know what it means to fail quickly.” Together they can solve any problem. ”

Parts for the world's largest jet engine, gas turbines and other products of the most complex shapes and from the latest materials, the creation of which was difficult to imagine a couple of years ago, are made at the General Electric factory in Greenville.

Work begins when a three-dimensional CAD model of the first prototype arrives at workstations via the Internet. “We want designers to show us their“ unpretentious brainchild ”- a model that is only 80 percent complete,” says Blake Fulton, a materials engineer at the plant. “We realized that at this stage they are much more prepared for feedback.” Then Fulton and his colleagues set about creating a 3D model of the structure. It can be printed from plastic or metal , or even carved from wood.

Additive manufacturing engineer Chad Dulkevich with 3D printed test samples. Photo GE Power

Previously, designers sent their archives through an express delivery service to contractors who made models and sent them back weeks later. Thanks to the direct transfer of data to 3D printers, designers in just a few days create many options for drawings and immediately see how they will look in real life. “This is what we call rapid prototyping,” says Fulton.

In addition, Goodwin employees test all manufacturing processes. GE Aviation already uses 3D-printed parts in jet engines, but when Goodwin got the idea to apply the same technology to gas turbines (they include many of the same parts as jet engines, but much larger), on obstacles appeared on his way.

GE Aviation used Direct 3D Laser Melting based 3D printing technology. It consists in the fact that the laser beam fuses layers of pure metal powder, creating parts from scratch. But Goodwin's details were too large and took a very long time to print on DMLM machines, which turned out to be economically impractical.

Gas and jet turbines operate under extremely high temperatures. Engineers have developed a sophisticated cooling hole system to maintain the most efficient level of performance. MicroJet technology allows them to create new models, the production of which was previously impossible. Photo GE Aviation

Goodwin instructed his team to find a more economical car. Because 3D printing is still an innovation, the only faster device they could find was the SLM Solutions 3D laser printer with two laser beams, which had not yet been released to the market. “We bought three,” Goodwin says.

It was a risky move, and difficulties soon began to arise. “We followed the instructions, but the product quality was unsatisfactory.” The team spent four months analyzing 200 different software parameters and made 400 hardware modifications before the devices were debugged. Finally, they were used to optimize the design.3D-printed fuel nozzle for the latest General Electric gas turbine and for putting it into production. The new design lowers nitrogen oxide emissions while increasing power output and productivity. “We were able to complete 10 design options in just a few months, and then four months later send the final version to production,” Goodwin says. “It usually takes a year.”

Step into the future No. 4: the Internet of things

GE uses the Predix software platform to stream data over the industrial Internet to the cloud, analyze it, and transfer problems and solutions to the team.

These feedback loops are part of the GE concept called digital thread. Clay Johnson, director of information technology at GE Power, says the plant still only shows some of what is expected in the future. According to him, the “digital stream” will constantly transfer data from customers and suppliers to GE and vice versa.

“The system will receive real-time feedback through sensors located on the parts inside the devices,” says Johnson. - In the future, the part will itself “understand” that it is becoming unusable, automatically order a reconfiguration and appoint a service technician who will install the update. This is real Uber for the industry. ”

But technology will not solve all the problems. Steve Bolze, CEO of GE Power, said after the opening ceremony: “We have robotics and 3D printers, but the main thing is our people who trust each other enough to risk and create the future together.”

This massive machine makes compressor blades for the world's largest GE9X jet engine. Photo GE Power

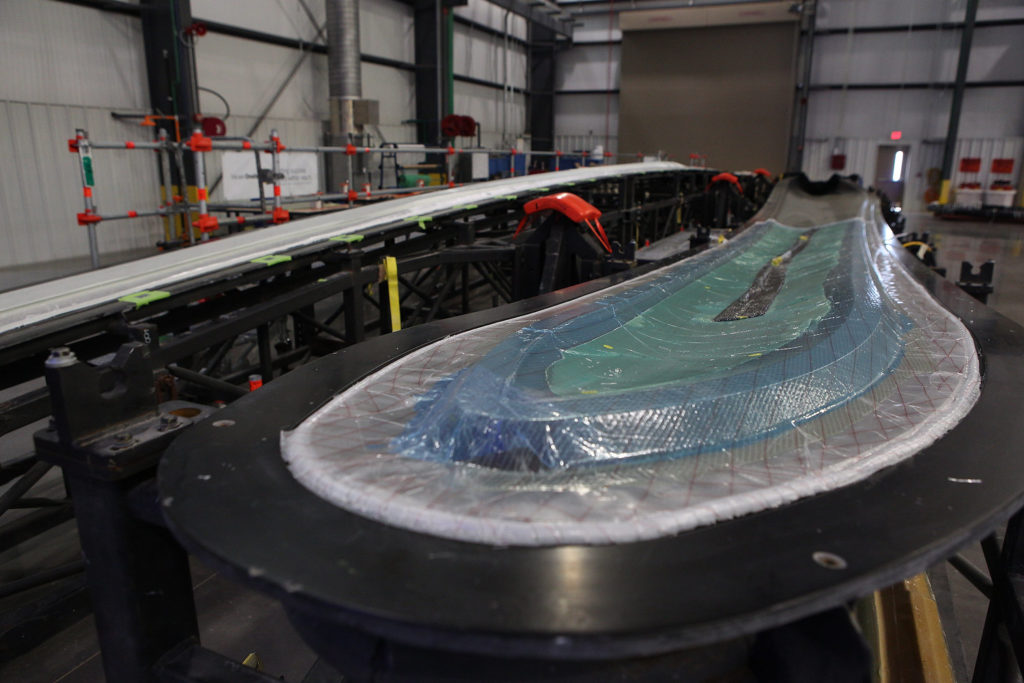

Material scientists at GE Power use these two models of wind turbine blades to develop more durable and accurate parts from modern polymers. The manufactured blades can be tested here on a test machine. Photo by GE Power

Posted by Thomas Kellner, ge.com. Translation from English.