The first Soviet AVM

In 1945 - 1946 under the leadership of L.I. Gutenmacher developed the first electronic analog machines with a repeat solution. But since 1949, the team of Soviet developers led by V. B. Ushakov and V.A. Trapeznikov, invented a series of direct current AVMs. This year began the history of the development of analog computing in the USSR. The use of operational amplifiers, which worked on the principle of automatic control systems with deep negative feedback, made it possible to carry out accurate modeling of mathematical operators, as well as parallel processing of information in real time when solving systems of differential equations.

In 1949, the laboratory of electro-modeling ITMiVT and the department of the chief designer of the Penza plant CAM B.A. Matkina was released electron-tube integrator ELI-12. It was intended to solve a system of differential equations of the 12th order with constant coefficients and constant right-hand sides. The process of solving the problem was automatically repeated, as a result of which the results of the solution were displayed, measured and photographed on a CRT screen.

After finalizing the circuits and design of the electron-tube integrator, as well as preparing for industrial production, the plant began mass production of ELI-12-1.

On its circuit-structural base, an integrator ELI-14 was developed, on which sixth-order differential equations were solved. There were 6 crucial blocks. For the manufacture of patch tubes, neuro-leukorite was used, which was distinguished by increased insulating properties.

In the years 1949-1950. in NII-885 by a team led by V. B. Ushakova created the first AVM, which were called DC integrators. In 1949, IPT-1, IPT-2, and IPT-3; in 1950, IPT-4 and IPT-5, which are mass-produced. These machines were designed to solve linear differential equations with constant and variable coefficients. Thanks to operational amplifiers, AVMs ensured the solution of the most important problems in various scientific and technical fields (aviation, rocket science, space research, defense industry, etc.).

The first AVMs with electronic tubes were created by the combined efforts of two teams: NII-855 MCI USSR and IAT AN USSR. Serial production of the AVM was organized at the Moscow, Penza and Chisinau factories of computer-analytical machines and a number of other factories of the radio industry.

Developed in 1952–1953. Under the guidance of VB Ushakov, AVMs were given the name "DC Modeling Units" (MPT). Serial AVM “MPT-9” were intended for solving linear differential equations, “MPT-11” - for solving non-linear differential equations.

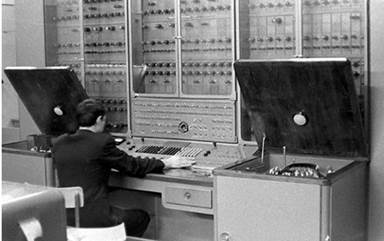

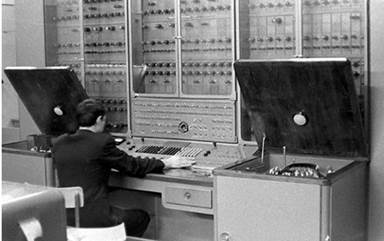

In 1955, the first Soviet high-power precision AVM “MN-8” was developed. It was the largest non-linear electronic mathematical machine of continuous operation. The development team was led by VB Ushakov. The machine had to solve differential equations of the sixteenth and higher order (32 integrating blocks). In the case of sixteenth order, half the linear part was used.

The electronic simulator consisted of 13 sections. Tasks were recruited using cord connections on the switching fields of the linear part. By means of a pair of control panels, two different tasks were simultaneously solved. The maximum duration of the integration process reached 10,000 seconds, and the power consumption was 25 kW.

“MN-8” carried out up to 48 operations of summing up 264 terms, 48 multiplications by a constant coefficient, 36 multiplications by a variable coefficient, 12 exact multiplications of the desired quantities. It was also possible to set 10 non-linear dependencies of the function on one variable, 40 non-linear dependencies of the signature type, 9 non-linear dependencies of typical characteristics (backlash, restrictions, dead zones).

In the car, there were 400 operational amplifiers with individual automatic zero stabilization and an advanced control circuit. Through powerful amplifiers with an economical output, interaction with real equipment took place. The control circuit had additional control.

Only three foreign models could compare with the Soviet model:

- American electro-modeling plant "Typhoon" (Typhoon), released in 1951;

- The English electro-modeling installation “Tridak” (“Trydac” - Three Dimensional Analogue Computer), was created in the period 1950 - 1954. It was an electronic-hydraulic simulator, with the help of which the control of shells was studied;

- the American installation “Convair” (Convair), released in 1954. A

feature of the MN-8 was that the duration of the processes studied by the installation in natural time scale could be either a small value (equal to several seconds) or very significant.

The circuit of the integrating unit accelerated the expansion process, it allowed to automatically change the time scale at the same time for all such installation units by 10 times.

In MN-8, precision multiplication blocks were used. They made it possible to obtain a static accuracy of the multiplication operation of about ± 0.01%. The number of blocks in the machine made it possible to obtain 12 operations of exact multiplication of variables.

The structure of MN-8 included 48 precise blocks for entering variable coefficients, which practically reproduced the graph of a variable coefficient by the method of piecewise linear approximation. And also included 40 special non-linear blocks for performing non-linear dependencies such as signatures. This improvement has greatly expanded the capabilities of the machine.

The Soviet electromodelling installation had an improved control scheme. Based on the decimal digital counter, an electronic block of the time meter was built. With its help, the synchronization of the work of all functional blocks was carried out. The decision process could be repeated periodically or stopped at predetermined time intervals.

“MN-8” used diode-triode electronic circuits for universal blocks, which were designed to reproduce nonlinear functions of one variable with an accuracy of the set of functions of ± 0.2.

The block allowed to dial very steep fronts of the function, as well as functions with sharp kinks.

The simulated system of equations was typed in accordance with the block diagram of the solution of the problem in the switching fields, which were located on sections of the linear units of the installation. The main lines between sections made it possible to use blocks of neighboring sections in one task. In "MN-8" there were no removable switching fields.

Registration and control of output values was carried out using six high-speed electronic potentiometers, an electronic-digital voltmeter, an electron-beam indicator, and other measuring instruments.

The MN-8 had 14 racks. Small-sized units were used in the design of the device, so that it was relatively compact. The circuit of the electro-modeling installation contained a lot of high-quality electrical parts (they significantly increased the accuracy of work). For example, about 8,000 germanium planar diodes were used in the power section circuit.

"MN-8" was serially produced by the Penza plant CAM.

In 1958, the MN-9 electronic simulator was launched. It was intended to study the dynamics of the main parts of the clockwork. The chief designer I.M. Wittenberg.

MN-9 had a bench construction. With the help of switches and handles located on the front panels of the machine, work modes were set.

"MN-9" solved a system of ordinary linear equations with variable coefficients. The device consisted of 5 blocks of a summing amplifier, 40 blocks of constant coefficients, and 9 blocks of a nonlinear function of one variable. MN-9 had 28 amplifiers with a centralized automatic setting of zeros according to a circuit with capacitors and is characterized by the presence of an electronic circuit for automatic switching of machine blocks as a function of the desired variable.

The electronic modeling installation "MN-9" was not produced in series.

In 1957, a new development of Soviet specialists was released - the small-sized non-linear tubeless modeling installation “MN-10”. It was the first analog computer with a circuit fully executed on semiconductor elements. Using the installation, problems that were described by ordinary nonlinear differential equations were solved and investigated. For example, this one:

where i = 1, 2, ..., 6.

Including the installation, it was possible to solve differential equations, which contained up to 6 non-linear dependencies of the form of a function on one variable or the product of two variables. The work could be carried out in real time. The results of the tasks were demonstrated on an electron-beam indicator of the type I-5 or I-4.

The MN-10 included 24 small-sized operational DC amplifiers. They performed the operations of integration, differentiation, summation and large-scale transformations. There are also 4 diode cells, which were used in circuits that reproduce typical nonlinear dependences of the type of hysteresis loop, the moment of dry friction, the deadband and the limitation.

The device occupied an area of 0.3 m 2 , weighed 75 kg. The range of variation of the installation variables ranged from 30 V to +30 V. The duration of the integration process was 200 seconds.

The MN-10 power was supplied from the ESV-10 unit, which is included in its kit. And the mains power was supplied by a single-phase alternating current voltage of 220 V, frequency 50 Hz. Power consumption was 100 watts.

In the 70s, the installation went through modernization and began to be mass-produced.

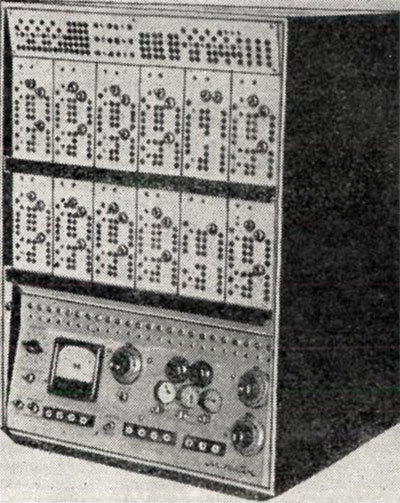

The MN-10M analog computing machine was developed by specialists at the Penza Plant. The model belonged to small-sized desktop machines of low power, with the help of which real dynamic systems were studied by the method of mathematical modeling. Also, “MN-10M” was intended to integrate ordinary differential equations of no higher than tenth order.

The dimensions of the machine were 460 × 615 × 445 mm., And the weight was 50 kg. The MN-10M included 24 operational amplifiers, as well as a set of 12 feedbacks.

Thanks to the set of operating units, it was possible to carry out various operations:

- integration operations with simultaneous summation (up to 10);

- invert or sum operations (up to 24);

- task on voltage dividers (up to 60 constant coefficients);

- reproduction of unambiguous continuous nonlinear functions of one variable with the simultaneous summation of several variables;

- the operation of multiplication or division with the simultaneous summation of several variables;

- reproduction of up to 6 typical non-linear dependencies of the type of dead zone, limitation, dry friction;

- conditional branch operations (up to 4).

More complex tasks were solved in parallel with two or three MN-10M machines. It was possible to observe and measure the result of the task using a turnout instrument of a machine or an external recording instrument (DRP, EPP-09, a loop oscilloscope). They were not part of the machine.

It was planned to pair with external equipment. The MN-10M power supply came from the ESV-4 unit, which was included in its kit. And the mains power was supplied by a single-phase alternating current voltage of 220 V, frequency 50 Hz. Power consumption was 250 watts. The circuit of the machine and the power source was completely built on semiconductor elements.

The machine solved ordinary differential equations. The range of variation of variables was from - 25 V to + 25 V. The duration of the integration process was 200 seconds.

The MN-10M unit included an electronic stabilized rectifier (ESV-4), an analog communication computer (AVM), communication channels with external equipment, with a second and third machine.

Over 100,000 AVMs were manufactured in the first 20 years. From simple to the most powerful, like the MN-8. At first, machines were used for the most part in the form of independent means of mathematical modeling of dynamic objects in real time. But around the 60-70s, progress in the field of digital electronics required the joint processing of information from the AVM and the digital computer.

Start of development

In 1949, the laboratory of electro-modeling ITMiVT and the department of the chief designer of the Penza plant CAM B.A. Matkina was released electron-tube integrator ELI-12. It was intended to solve a system of differential equations of the 12th order with constant coefficients and constant right-hand sides. The process of solving the problem was automatically repeated, as a result of which the results of the solution were displayed, measured and photographed on a CRT screen.

After finalizing the circuits and design of the electron-tube integrator, as well as preparing for industrial production, the plant began mass production of ELI-12-1.

On its circuit-structural base, an integrator ELI-14 was developed, on which sixth-order differential equations were solved. There were 6 crucial blocks. For the manufacture of patch tubes, neuro-leukorite was used, which was distinguished by increased insulating properties.

In the years 1949-1950. in NII-885 by a team led by V. B. Ushakova created the first AVM, which were called DC integrators. In 1949, IPT-1, IPT-2, and IPT-3; in 1950, IPT-4 and IPT-5, which are mass-produced. These machines were designed to solve linear differential equations with constant and variable coefficients. Thanks to operational amplifiers, AVMs ensured the solution of the most important problems in various scientific and technical fields (aviation, rocket science, space research, defense industry, etc.).

The first AVMs with electronic tubes were created by the combined efforts of two teams: NII-855 MCI USSR and IAT AN USSR. Serial production of the AVM was organized at the Moscow, Penza and Chisinau factories of computer-analytical machines and a number of other factories of the radio industry.

Developed in 1952–1953. Under the guidance of VB Ushakov, AVMs were given the name "DC Modeling Units" (MPT). Serial AVM “MPT-9” were intended for solving linear differential equations, “MPT-11” - for solving non-linear differential equations.

MN-8

In 1955, the first Soviet high-power precision AVM “MN-8” was developed. It was the largest non-linear electronic mathematical machine of continuous operation. The development team was led by VB Ushakov. The machine had to solve differential equations of the sixteenth and higher order (32 integrating blocks). In the case of sixteenth order, half the linear part was used.

The electronic simulator consisted of 13 sections. Tasks were recruited using cord connections on the switching fields of the linear part. By means of a pair of control panels, two different tasks were simultaneously solved. The maximum duration of the integration process reached 10,000 seconds, and the power consumption was 25 kW.

“MN-8” carried out up to 48 operations of summing up 264 terms, 48 multiplications by a constant coefficient, 36 multiplications by a variable coefficient, 12 exact multiplications of the desired quantities. It was also possible to set 10 non-linear dependencies of the function on one variable, 40 non-linear dependencies of the signature type, 9 non-linear dependencies of typical characteristics (backlash, restrictions, dead zones).

In the car, there were 400 operational amplifiers with individual automatic zero stabilization and an advanced control circuit. Through powerful amplifiers with an economical output, interaction with real equipment took place. The control circuit had additional control.

Only three foreign models could compare with the Soviet model:

- American electro-modeling plant "Typhoon" (Typhoon), released in 1951;

- The English electro-modeling installation “Tridak” (“Trydac” - Three Dimensional Analogue Computer), was created in the period 1950 - 1954. It was an electronic-hydraulic simulator, with the help of which the control of shells was studied;

- the American installation “Convair” (Convair), released in 1954. A

feature of the MN-8 was that the duration of the processes studied by the installation in natural time scale could be either a small value (equal to several seconds) or very significant.

The circuit of the integrating unit accelerated the expansion process, it allowed to automatically change the time scale at the same time for all such installation units by 10 times.

In MN-8, precision multiplication blocks were used. They made it possible to obtain a static accuracy of the multiplication operation of about ± 0.01%. The number of blocks in the machine made it possible to obtain 12 operations of exact multiplication of variables.

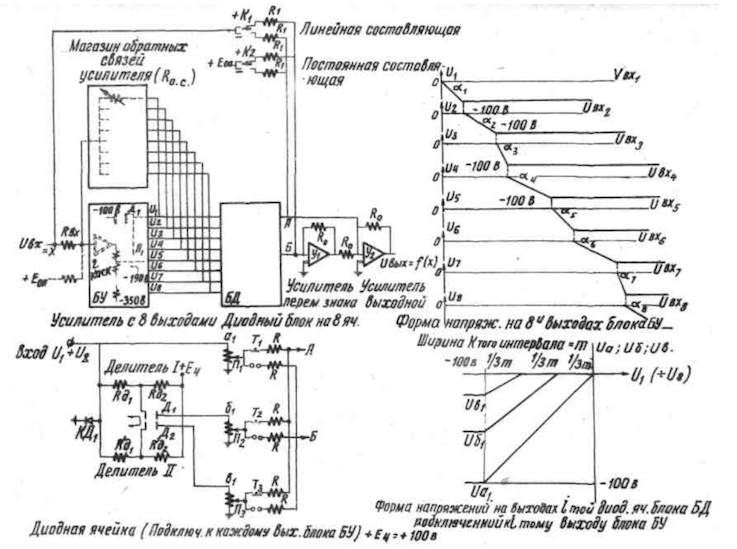

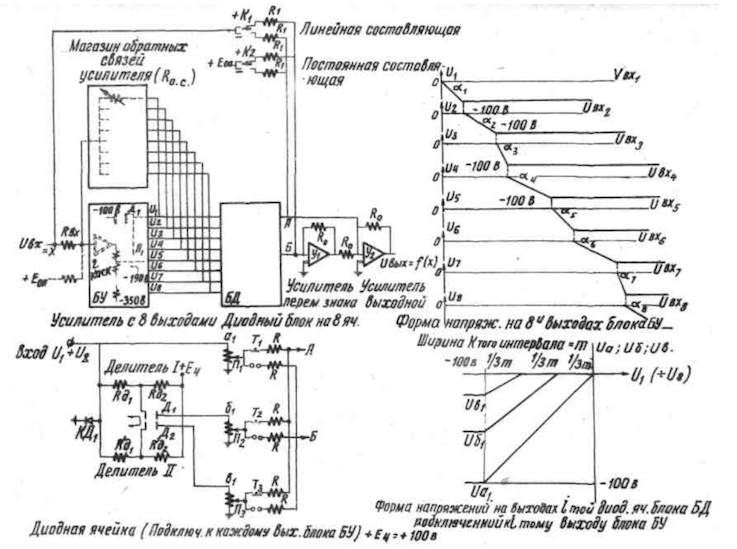

The structure of MN-8 included 48 precise blocks for entering variable coefficients, which practically reproduced the graph of a variable coefficient by the method of piecewise linear approximation. And also included 40 special non-linear blocks for performing non-linear dependencies such as signatures. This improvement has greatly expanded the capabilities of the machine.

The Soviet electromodelling installation had an improved control scheme. Based on the decimal digital counter, an electronic block of the time meter was built. With its help, the synchronization of the work of all functional blocks was carried out. The decision process could be repeated periodically or stopped at predetermined time intervals.

“MN-8” used diode-triode electronic circuits for universal blocks, which were designed to reproduce nonlinear functions of one variable with an accuracy of the set of functions of ± 0.2.

The block allowed to dial very steep fronts of the function, as well as functions with sharp kinks.

The simulated system of equations was typed in accordance with the block diagram of the solution of the problem in the switching fields, which were located on sections of the linear units of the installation. The main lines between sections made it possible to use blocks of neighboring sections in one task. In "MN-8" there were no removable switching fields.

Registration and control of output values was carried out using six high-speed electronic potentiometers, an electronic-digital voltmeter, an electron-beam indicator, and other measuring instruments.

The MN-8 had 14 racks. Small-sized units were used in the design of the device, so that it was relatively compact. The circuit of the electro-modeling installation contained a lot of high-quality electrical parts (they significantly increased the accuracy of work). For example, about 8,000 germanium planar diodes were used in the power section circuit.

"MN-8" was serially produced by the Penza plant CAM.

MN-9

In 1958, the MN-9 electronic simulator was launched. It was intended to study the dynamics of the main parts of the clockwork. The chief designer I.M. Wittenberg.

MN-9 had a bench construction. With the help of switches and handles located on the front panels of the machine, work modes were set.

"MN-9" solved a system of ordinary linear equations with variable coefficients. The device consisted of 5 blocks of a summing amplifier, 40 blocks of constant coefficients, and 9 blocks of a nonlinear function of one variable. MN-9 had 28 amplifiers with a centralized automatic setting of zeros according to a circuit with capacitors and is characterized by the presence of an electronic circuit for automatic switching of machine blocks as a function of the desired variable.

The electronic modeling installation "MN-9" was not produced in series.

MN-10

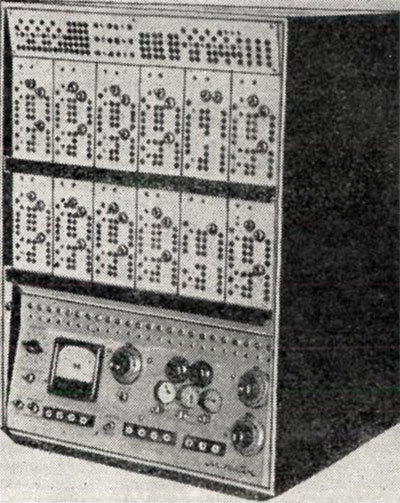

In 1957, a new development of Soviet specialists was released - the small-sized non-linear tubeless modeling installation “MN-10”. It was the first analog computer with a circuit fully executed on semiconductor elements. Using the installation, problems that were described by ordinary nonlinear differential equations were solved and investigated. For example, this one:

where i = 1, 2, ..., 6.

Including the installation, it was possible to solve differential equations, which contained up to 6 non-linear dependencies of the form of a function on one variable or the product of two variables. The work could be carried out in real time. The results of the tasks were demonstrated on an electron-beam indicator of the type I-5 or I-4.

The MN-10 included 24 small-sized operational DC amplifiers. They performed the operations of integration, differentiation, summation and large-scale transformations. There are also 4 diode cells, which were used in circuits that reproduce typical nonlinear dependences of the type of hysteresis loop, the moment of dry friction, the deadband and the limitation.

The device occupied an area of 0.3 m 2 , weighed 75 kg. The range of variation of the installation variables ranged from 30 V to +30 V. The duration of the integration process was 200 seconds.

The MN-10 power was supplied from the ESV-10 unit, which is included in its kit. And the mains power was supplied by a single-phase alternating current voltage of 220 V, frequency 50 Hz. Power consumption was 100 watts.

In the 70s, the installation went through modernization and began to be mass-produced.

MN-10M

The MN-10M analog computing machine was developed by specialists at the Penza Plant. The model belonged to small-sized desktop machines of low power, with the help of which real dynamic systems were studied by the method of mathematical modeling. Also, “MN-10M” was intended to integrate ordinary differential equations of no higher than tenth order.

The dimensions of the machine were 460 × 615 × 445 mm., And the weight was 50 kg. The MN-10M included 24 operational amplifiers, as well as a set of 12 feedbacks.

Thanks to the set of operating units, it was possible to carry out various operations:

- integration operations with simultaneous summation (up to 10);

- invert or sum operations (up to 24);

- task on voltage dividers (up to 60 constant coefficients);

- reproduction of unambiguous continuous nonlinear functions of one variable with the simultaneous summation of several variables;

- the operation of multiplication or division with the simultaneous summation of several variables;

- reproduction of up to 6 typical non-linear dependencies of the type of dead zone, limitation, dry friction;

- conditional branch operations (up to 4).

More complex tasks were solved in parallel with two or three MN-10M machines. It was possible to observe and measure the result of the task using a turnout instrument of a machine or an external recording instrument (DRP, EPP-09, a loop oscilloscope). They were not part of the machine.

It was planned to pair with external equipment. The MN-10M power supply came from the ESV-4 unit, which was included in its kit. And the mains power was supplied by a single-phase alternating current voltage of 220 V, frequency 50 Hz. Power consumption was 250 watts. The circuit of the machine and the power source was completely built on semiconductor elements.

The machine solved ordinary differential equations. The range of variation of variables was from - 25 V to + 25 V. The duration of the integration process was 200 seconds.

The MN-10M unit included an electronic stabilized rectifier (ESV-4), an analog communication computer (AVM), communication channels with external equipment, with a second and third machine.

Over 100,000 AVMs were manufactured in the first 20 years. From simple to the most powerful, like the MN-8. At first, machines were used for the most part in the form of independent means of mathematical modeling of dynamic objects in real time. But around the 60-70s, progress in the field of digital electronics required the joint processing of information from the AVM and the digital computer.