Slider for timelapse filming

I’ll start right away with the fact that this article should not be associated with a well-made project and direct hands)) This project is still being used as an alpha version and will still be completed, however, I think the very essence of the method and the constructive approach will be clear to everyone right now. It would be possible to buy a ready-made version * , but I would like to collect cheaper.

So, many of us know what TimeLapse is. Fast-flying clouds, the sun going into the sunset, etc. - all this is a time-lapse, that is, a set of photographs taken after a certain period of time and combined into a single video. However, if we can make a static time-lapse only with the help of a camera with a timer and a tripod, then for a more dynamic time-lapse (for example, moving the camera along any objects, etc.), we need to strain our heads and work with our hands.

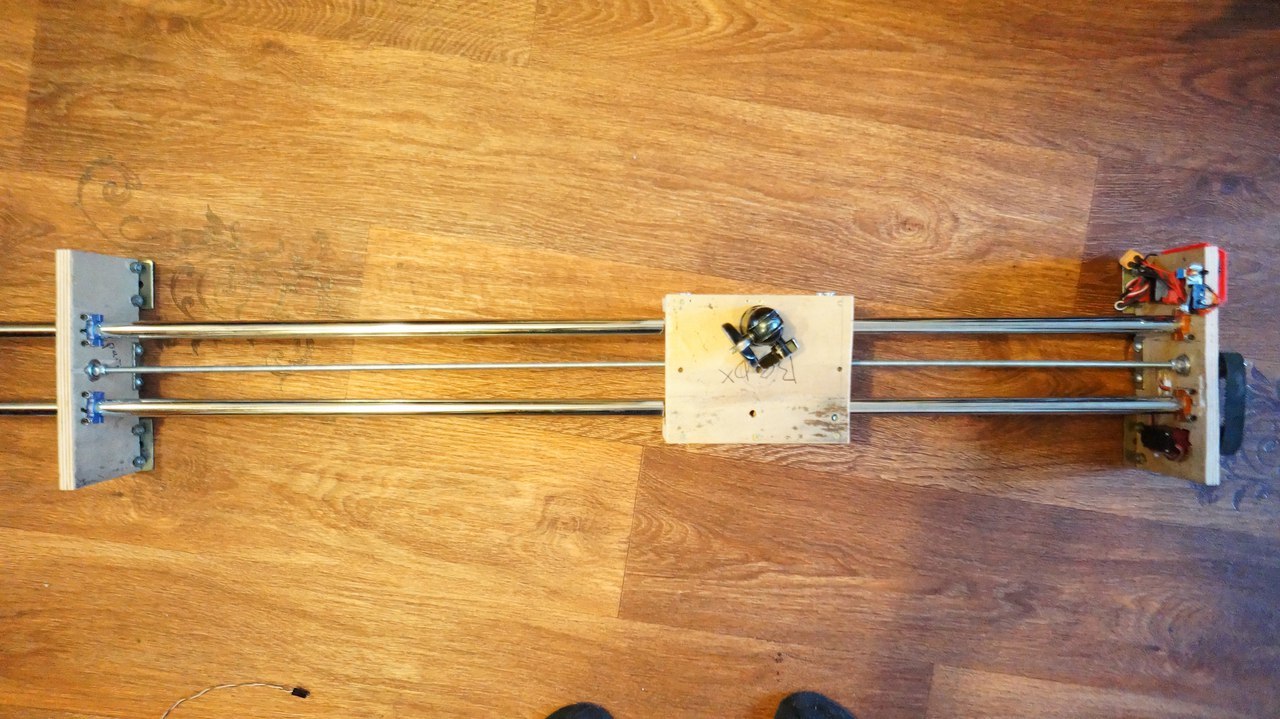

There are a lot of design options for timelapse in motion. However, I wanted to make a large time-lapse slider so that the camera could travel 2-3 meters, and at the same time it was collapsible for easy transportation. However, the idea failed. I can only say that it consisted in building up 16mm tubes through adapters that were inserted inside the tubes. At the junctions, the pipes were ground, and the adapters were specially machined to the internal diameter of the pipes, but the system was still shaky. The main problem was the deflection of the pipes (due to the fact that the camera tilted slightly) and the different planes of the two ends of the time-lapse. In other words, if one support stands at an angle of 0 degrees and the other 5 degrees, then the entire rail is already skewed and the system does not want to work as it should. Those. ideally, pipes with a diameter of 22 - 25 mm (depending on length) should be used. But then I thought that I would hardly need such a time-lapse (work for the sake of work) and I decided to make a simple meter-long time-lapse.

He looked at what YouTube would offer me, wrote down some good options, and did the following:

1) Pipes 16 mm 2 pieces (in a hardware store for 200 rubles each).

2) A piece of 10 mm plywood (got free).

3) 16 mm aluminum. Clamps + bolts 2.5 mm (left from the construction of copters).

4) Bearings 6x19 18 pieces (in the bike shop 30 pieces).

5) Bolts 6x45 6 pieces (10 rubles for everything in a hardware store).

6) Nuts 48 pcs. and washers 10 pcs. M6 (15 rubles for everything).

7) Other bolts and nuts to taste (depending on how to attach electronics).

8) Servo 360 degrees (left over from the construction of a 3-axis suspension).

9) Servotester (also found in the box).

10) Strap on pulleys (120 p. Bike shop).

11) Switches 2 pcs. (radio parts store 40p total).

12) Head for the camera (took from a friend).

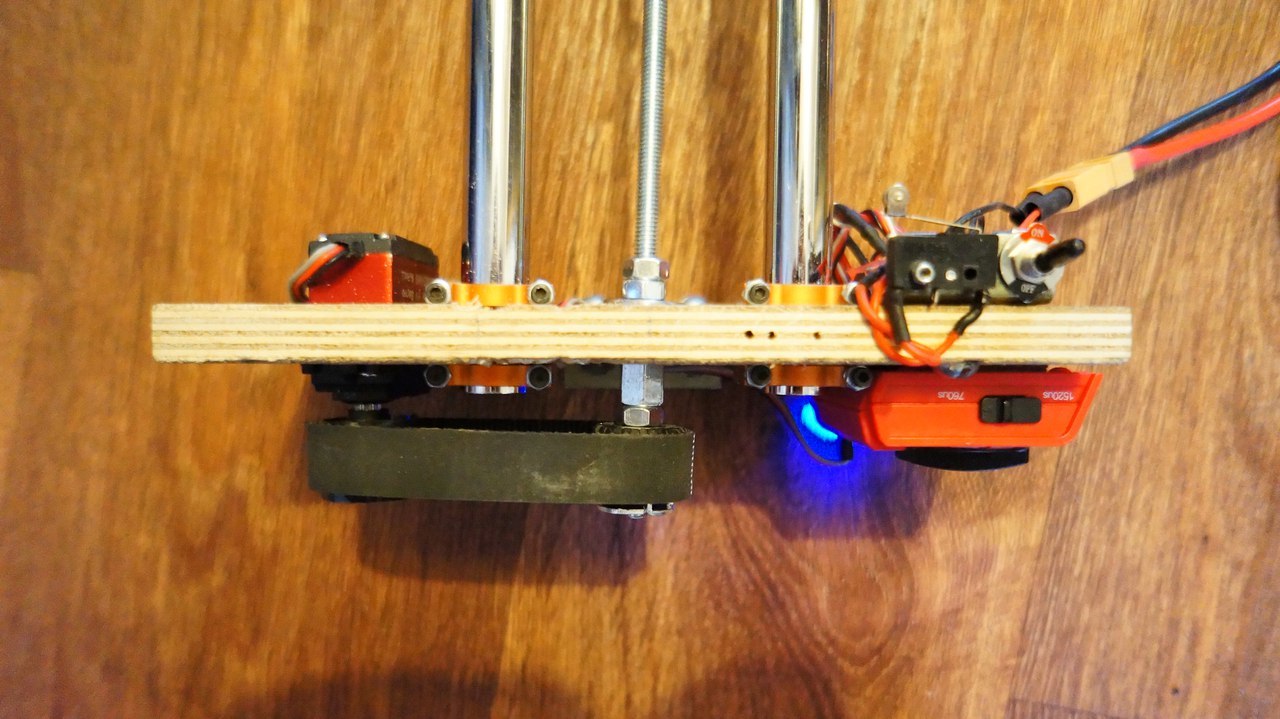

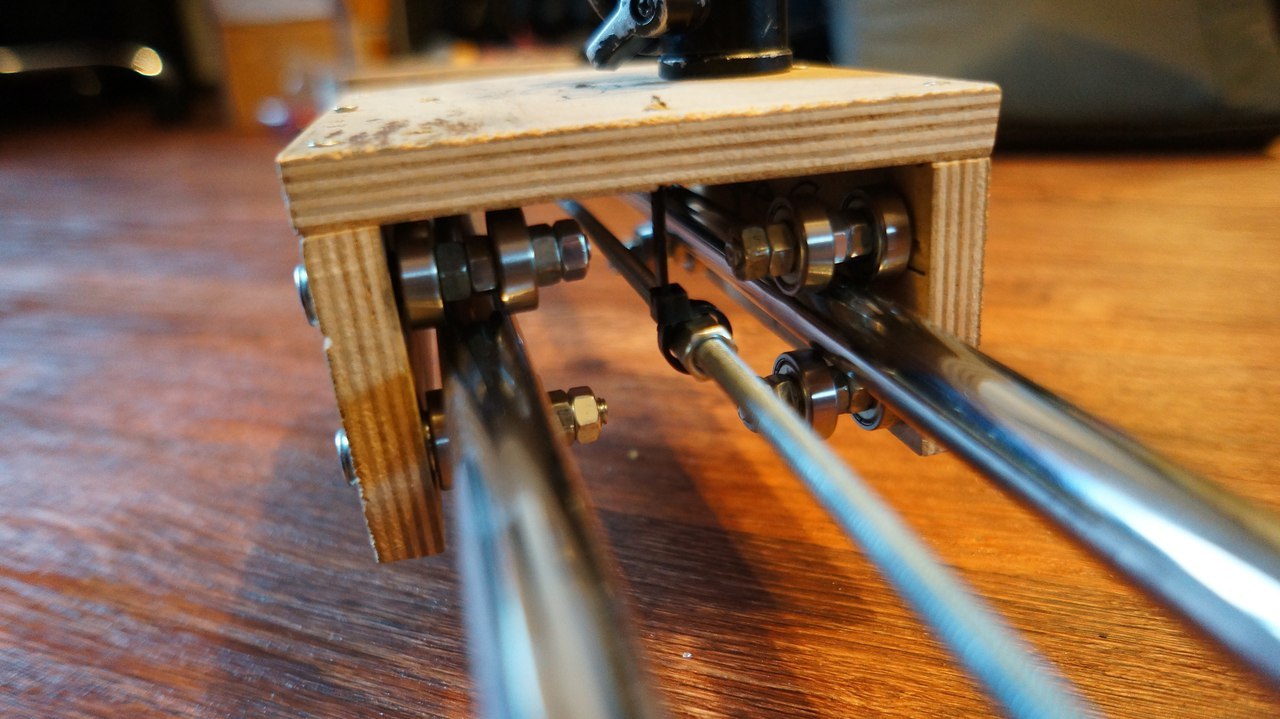

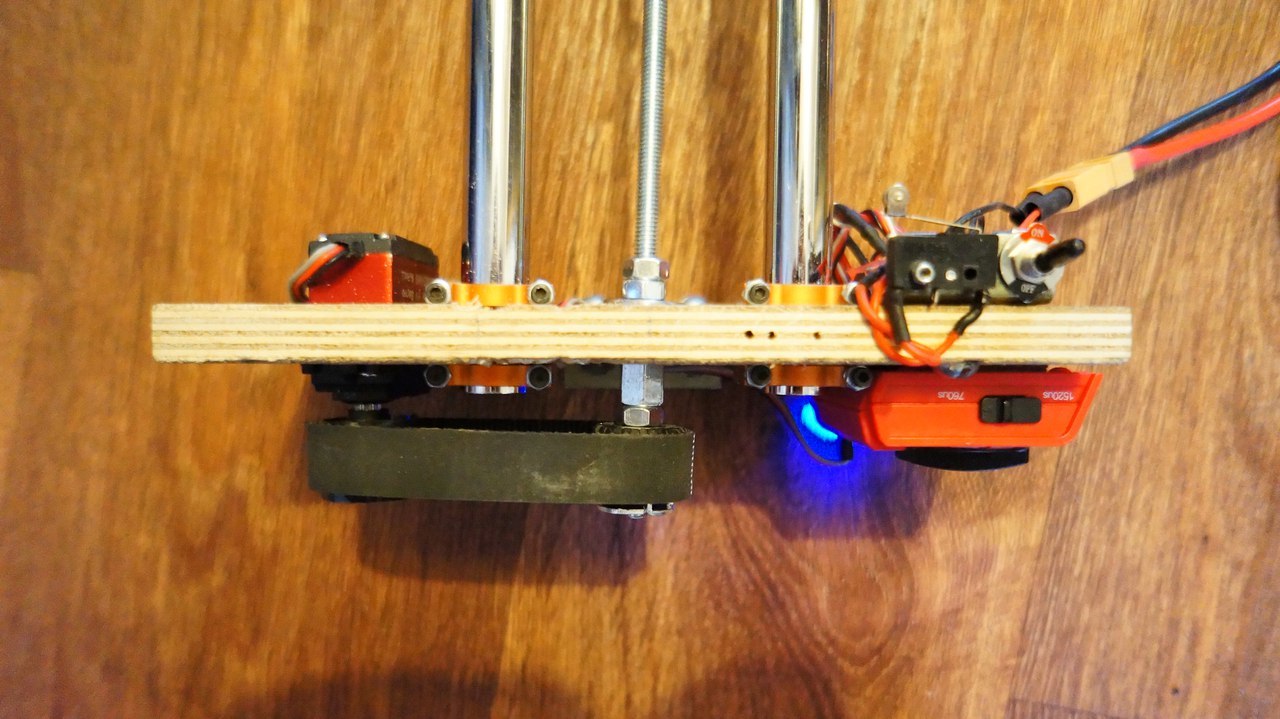

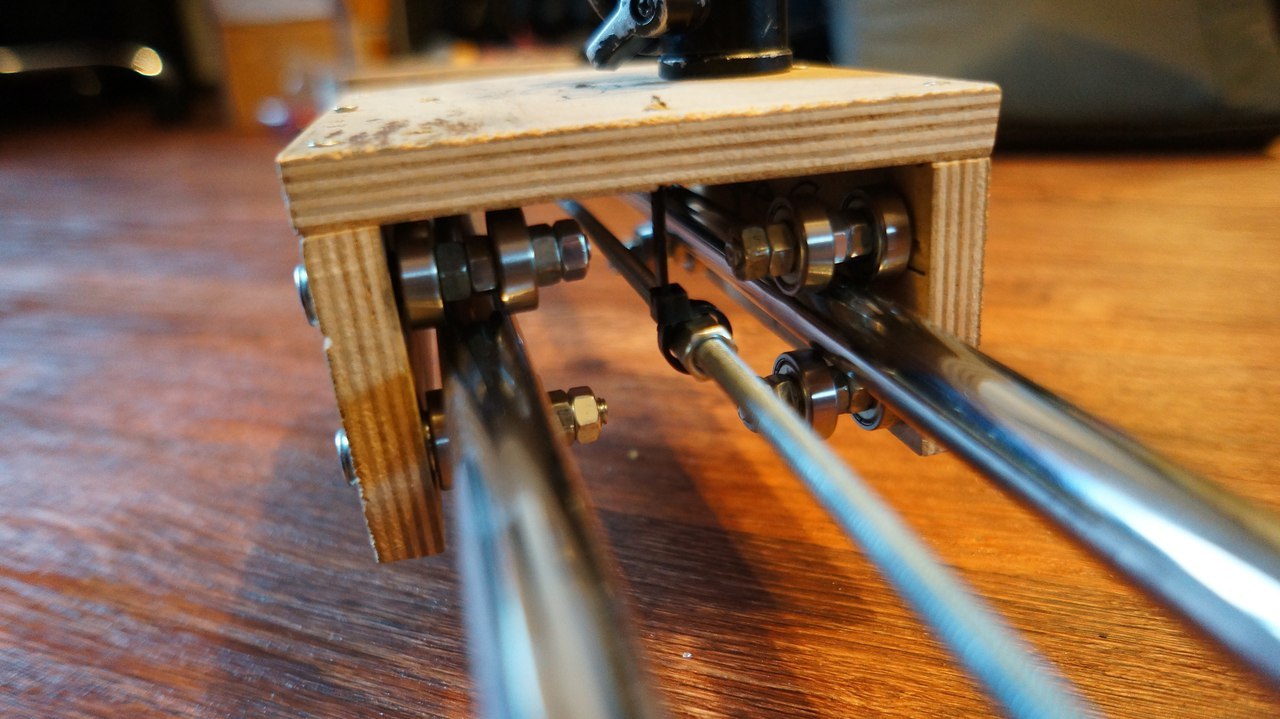

The photo shows what the carriage consists of. The bolts with bearings must be positioned so that a pipe can be inserted between them. However, it should be noted that the pipe must not pass with force or hang between the bearings.

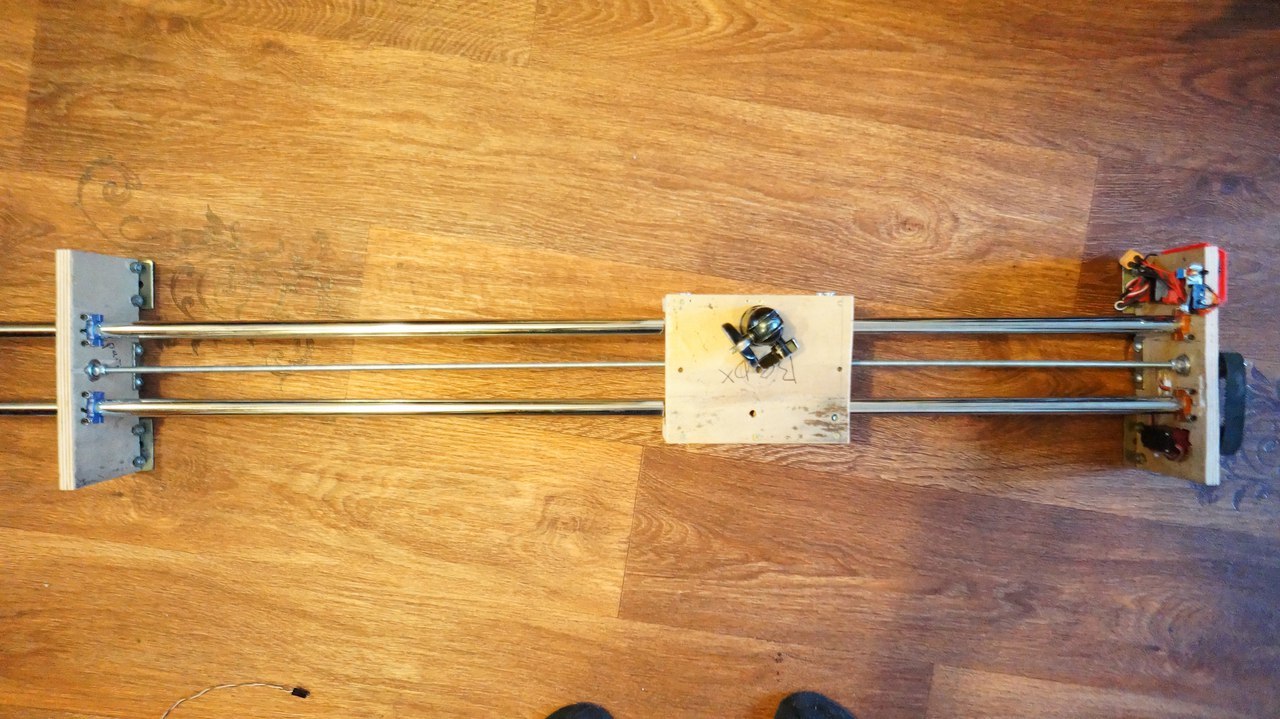

We fix the pipes with clamps on both sides of each support, which are also made of plywood. As a result, if everything is done correctly, the carriage will slide freely along the pipes. Theoretically, our slider is ready and necessary to make a drive that will pull the carriage along with the camera. (I apologize for the condition of the plywood. I did not find anything else in the garage)

Initially, the idea was to make a drive with a cable that would be tied to the carriage and pull it. However, I ran into a number of problems. Firstly, the movement will be only in one direction (of course, here you can turn the slider and rearrange the camera, and will pull it in the other direction), as well as wrapping the cable on the drum. Since the drum, in addition to the rotational movement, is not translational, the cable will periodically wind the coil around the coil and, as a result, jump to an empty spot. For shooting time-lapse, this is critical, because it will produce 1 normal frame, then a frame with a large shift (due to the larger radius of winding the cable) and then 2 identical frames (because the cable will jump off and not drag the carriage at that moment). Therefore, the best option is a worm gear. In this case, the “worm” will be the M6 hairpin,

In turn, one pulley will be mounted directly on the servo drive, the other on the stud. These pulleys are connected by a belt. Once again, I will remind you about the questions “what idiotic pulleys are, and who is drilling like that” - this is all assembled from improvised materials and drilled with a drill in the moonlight. :)

Servo control is through a servo tester, which makes it possible to change the speed of the carriage. Power supply from 12v. through back.

So, our drive works, and the pin rotates, it remains only to make the carriage move itself too. To do this, screw the M6 extension cord onto the hairpin and attach a plastic clamp to it (preferably glued in addition). By the way, it is better to take a hairpin not 6-ku but 8-ku ... it bends less and therefore less backlash. The movement is then smoother.

We make a hole in the carriage and insert the end of the clamp into it. I want to note that the extension cord on the stud is not specially fixed rigidly to the carriage, because the stud has a backlash. That is why it is better to make a “flexible” hitch. In addition, at any time, you can straighten the end of the clamp from the carriage, and shoot the video manually (this is an example).

Additionally installed two switches. One simply turns on the system, and the other acts as a trailer, i.e. as soon as the carriage reaches the end position, it presses the limit switch and the power turns off. In fact, since the carriage can move both left and right, it is better to install 2 limit switches (all the more so wires can be run through pipes).

I didn’t set any additional gearboxes, because the servo works with a load of 5 kg, and even more so the worm gear can pull even more, due to which this slider can be used in any plane.

I personally put canonmarkII and sonynex 5n on it. By the way, to make a time-lapse to kenon, I use such a joke * . But with Sony Nex more complicated. To do a time-lapse on it, read this .

That's all. As a result, such a slider cost me 1085 rubles. If you buy all the proposed components, then it will be somewhere around 4,500 p. (the main cost of the servo), but you can look for a cheap motor with a speed regulator.

Nowhere in China for such a price did I see a slider. Therefore, if you want to make cool time-lapses, then I hope I helped you with this article. :)

Of course, the racks and the carriage should be made of 10 mm PVC. and at least on a drilling machine so that everything is smooth, but that's another conversation. In time, such a slider with max. speeds 1 m in 2 minutes, with a minimum speed of 35 minutes. Unfortunately, I can’t immediately hit you with cool time-lapses, because something strange is happening on the street, called "autumn weather", so we are satisfied with what I can show.

In the video, 1 night time-lapse from the old version of the slider ... I think you will notice how the camera goes up - this is due to the deflection of the pipes ... it seems miserable, but noticeable in the picture (this is the only frame from the old slider).

ps Thanks to Victor for this material and experience.

pps * - links marked with a referral asterisk, so you can save extra by returning a cashback of up to 4%. More details at Dronk.ru/cashback/ or you can get 6.5% by purchasing them through the LetyShops cashback service .

That's all, with you there was a simple service for choosing complex Dronk.Ru equipment .

Do not forget to subscribe to our blog , there will be many more interesting things.

So, many of us know what TimeLapse is. Fast-flying clouds, the sun going into the sunset, etc. - all this is a time-lapse, that is, a set of photographs taken after a certain period of time and combined into a single video. However, if we can make a static time-lapse only with the help of a camera with a timer and a tripod, then for a more dynamic time-lapse (for example, moving the camera along any objects, etc.), we need to strain our heads and work with our hands.

There are a lot of design options for timelapse in motion. However, I wanted to make a large time-lapse slider so that the camera could travel 2-3 meters, and at the same time it was collapsible for easy transportation. However, the idea failed. I can only say that it consisted in building up 16mm tubes through adapters that were inserted inside the tubes. At the junctions, the pipes were ground, and the adapters were specially machined to the internal diameter of the pipes, but the system was still shaky. The main problem was the deflection of the pipes (due to the fact that the camera tilted slightly) and the different planes of the two ends of the time-lapse. In other words, if one support stands at an angle of 0 degrees and the other 5 degrees, then the entire rail is already skewed and the system does not want to work as it should. Those. ideally, pipes with a diameter of 22 - 25 mm (depending on length) should be used. But then I thought that I would hardly need such a time-lapse (work for the sake of work) and I decided to make a simple meter-long time-lapse.

He looked at what YouTube would offer me, wrote down some good options, and did the following:

1) Pipes 16 mm 2 pieces (in a hardware store for 200 rubles each).

2) A piece of 10 mm plywood (got free).

3) 16 mm aluminum. Clamps + bolts 2.5 mm (left from the construction of copters).

4) Bearings 6x19 18 pieces (in the bike shop 30 pieces).

5) Bolts 6x45 6 pieces (10 rubles for everything in a hardware store).

6) Nuts 48 pcs. and washers 10 pcs. M6 (15 rubles for everything).

7) Other bolts and nuts to taste (depending on how to attach electronics).

8) Servo 360 degrees (left over from the construction of a 3-axis suspension).

9) Servotester (also found in the box).

10) Strap on pulleys (120 p. Bike shop).

11) Switches 2 pcs. (radio parts store 40p total).

12) Head for the camera (took from a friend).

The photo shows what the carriage consists of. The bolts with bearings must be positioned so that a pipe can be inserted between them. However, it should be noted that the pipe must not pass with force or hang between the bearings.

We fix the pipes with clamps on both sides of each support, which are also made of plywood. As a result, if everything is done correctly, the carriage will slide freely along the pipes. Theoretically, our slider is ready and necessary to make a drive that will pull the carriage along with the camera. (I apologize for the condition of the plywood. I did not find anything else in the garage)

Initially, the idea was to make a drive with a cable that would be tied to the carriage and pull it. However, I ran into a number of problems. Firstly, the movement will be only in one direction (of course, here you can turn the slider and rearrange the camera, and will pull it in the other direction), as well as wrapping the cable on the drum. Since the drum, in addition to the rotational movement, is not translational, the cable will periodically wind the coil around the coil and, as a result, jump to an empty spot. For shooting time-lapse, this is critical, because it will produce 1 normal frame, then a frame with a large shift (due to the larger radius of winding the cable) and then 2 identical frames (because the cable will jump off and not drag the carriage at that moment). Therefore, the best option is a worm gear. In this case, the “worm” will be the M6 hairpin,

In turn, one pulley will be mounted directly on the servo drive, the other on the stud. These pulleys are connected by a belt. Once again, I will remind you about the questions “what idiotic pulleys are, and who is drilling like that” - this is all assembled from improvised materials and drilled with a drill in the moonlight. :)

Servo control is through a servo tester, which makes it possible to change the speed of the carriage. Power supply from 12v. through back.

So, our drive works, and the pin rotates, it remains only to make the carriage move itself too. To do this, screw the M6 extension cord onto the hairpin and attach a plastic clamp to it (preferably glued in addition). By the way, it is better to take a hairpin not 6-ku but 8-ku ... it bends less and therefore less backlash. The movement is then smoother.

We make a hole in the carriage and insert the end of the clamp into it. I want to note that the extension cord on the stud is not specially fixed rigidly to the carriage, because the stud has a backlash. That is why it is better to make a “flexible” hitch. In addition, at any time, you can straighten the end of the clamp from the carriage, and shoot the video manually (this is an example).

Additionally installed two switches. One simply turns on the system, and the other acts as a trailer, i.e. as soon as the carriage reaches the end position, it presses the limit switch and the power turns off. In fact, since the carriage can move both left and right, it is better to install 2 limit switches (all the more so wires can be run through pipes).

I didn’t set any additional gearboxes, because the servo works with a load of 5 kg, and even more so the worm gear can pull even more, due to which this slider can be used in any plane.

I personally put canonmarkII and sonynex 5n on it. By the way, to make a time-lapse to kenon, I use such a joke * . But with Sony Nex more complicated. To do a time-lapse on it, read this .

That's all. As a result, such a slider cost me 1085 rubles. If you buy all the proposed components, then it will be somewhere around 4,500 p. (the main cost of the servo), but you can look for a cheap motor with a speed regulator.

Nowhere in China for such a price did I see a slider. Therefore, if you want to make cool time-lapses, then I hope I helped you with this article. :)

Of course, the racks and the carriage should be made of 10 mm PVC. and at least on a drilling machine so that everything is smooth, but that's another conversation. In time, such a slider with max. speeds 1 m in 2 minutes, with a minimum speed of 35 minutes. Unfortunately, I can’t immediately hit you with cool time-lapses, because something strange is happening on the street, called "autumn weather", so we are satisfied with what I can show.

In the video, 1 night time-lapse from the old version of the slider ... I think you will notice how the camera goes up - this is due to the deflection of the pipes ... it seems miserable, but noticeable in the picture (this is the only frame from the old slider).

And you can be inspired by ready-made options on Ali

ps Thanks to Victor for this material and experience.

pps * - links marked with a referral asterisk, so you can save extra by returning a cashback of up to 4%. More details at Dronk.ru/cashback/ or you can get 6.5% by purchasing them through the LetyShops cashback service .

That's all, with you there was a simple service for choosing complex Dronk.Ru equipment .

Do not forget to subscribe to our blog , there will be many more interesting things.