Alkomat

Ivan Arnoldovich, I humbly ask you not to offer Sharikov beer.

Professor Preobrazhensky. "Dog's heart"

Somehow, traveling around the Internet, I saw the development of Rumbot . I always liked to manage something and in the end I got the idea to improve the development and bring new elements to it. The result was a project that included not only the development of hardware and software, but also 3D modeling of the case, an excursion into the manufacture of furniture, working with sound, some tricks of the work of bartenders and much more that accompanied the development. The result was a funny party machine with friends. The main thing was to go all the way from the idea to the development of the final product. The device allows you to make alcoholic cocktails for five people. I called it Alkomat.

Details below. Lots of great photos.

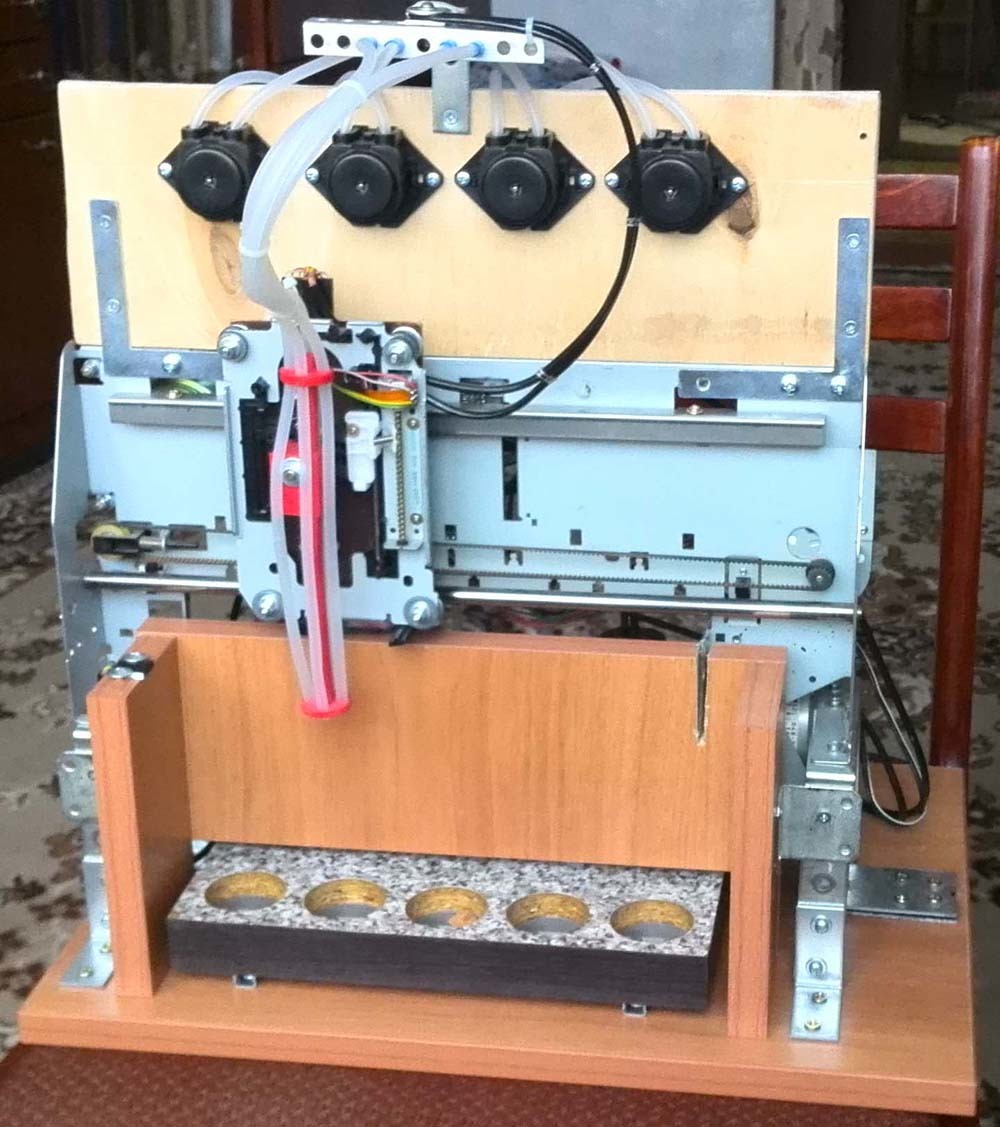

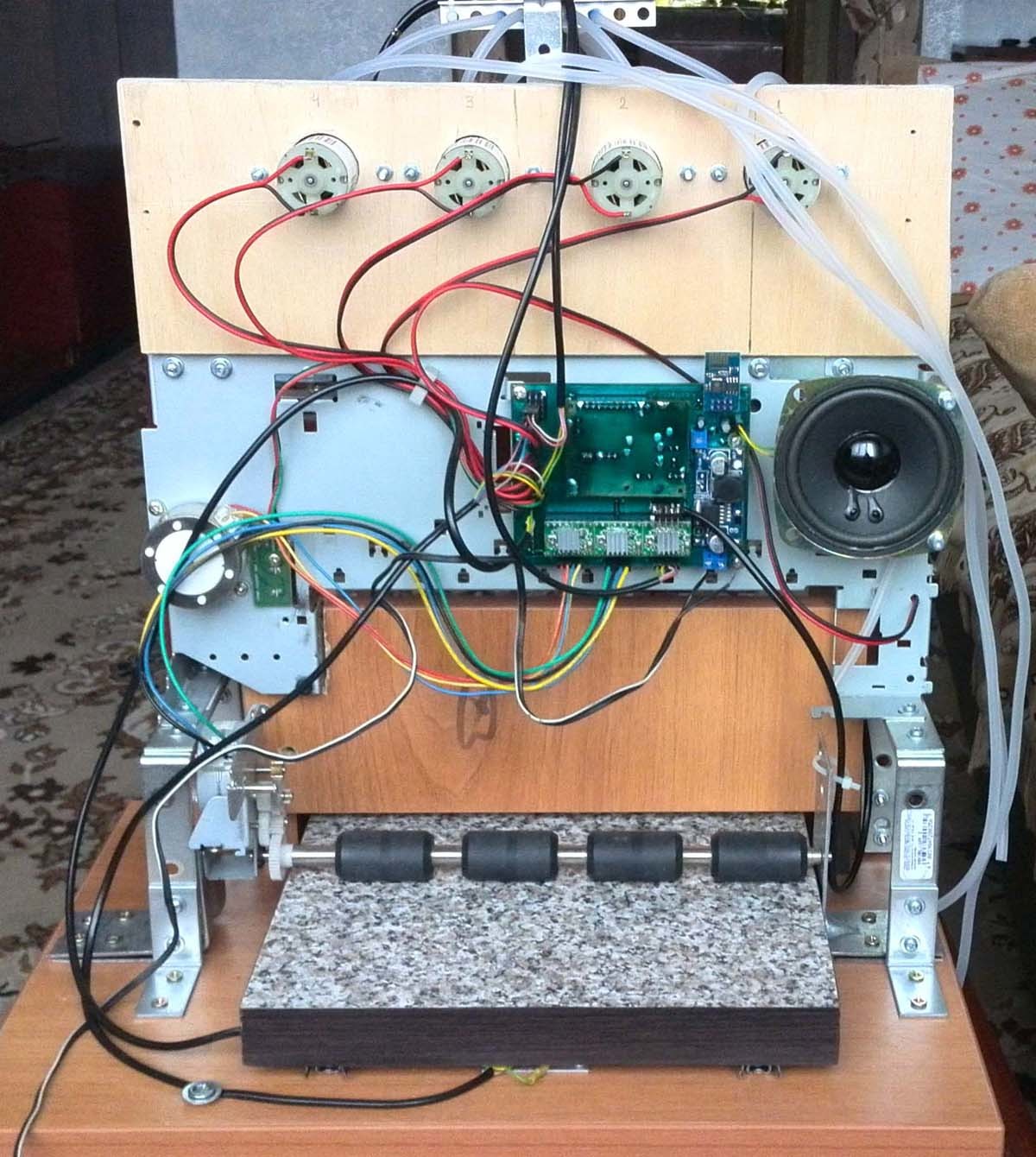

The basis was taken from the chassis of an old inkjet printer. The frame was just right for my needs. It was necessary to throw out everything except the carriage feed mechanism (X axis) and the paper feed mechanism (Y axis). The frame itself had to be raised higher, so that a table with installed glasses could easily fit under it.

The table is made from the rest of the countertop. Size 230x230. Edges trimmed with hem. The table includes landing holes for piles. I drilled the holes with a mill and then varnished. Such seats allow you to accurately determine the coordinates of the stacks, prevent the stack from falling during the movement of the table, as well as make lower lighting and place photosensors of the stack. In order not to pull a large number of wires to the controller, a local controller was installed, installed in the table itself. It collects data from all sensors and transfers information to the main controller via the serial port. In total, there are 4 wires from the table. Also on the side of the table brought a connector for programming the table controller. For the landing hole of the stack, a tab on which a photosensor and an LED for backlighting was installed was printed on a 3D printer.

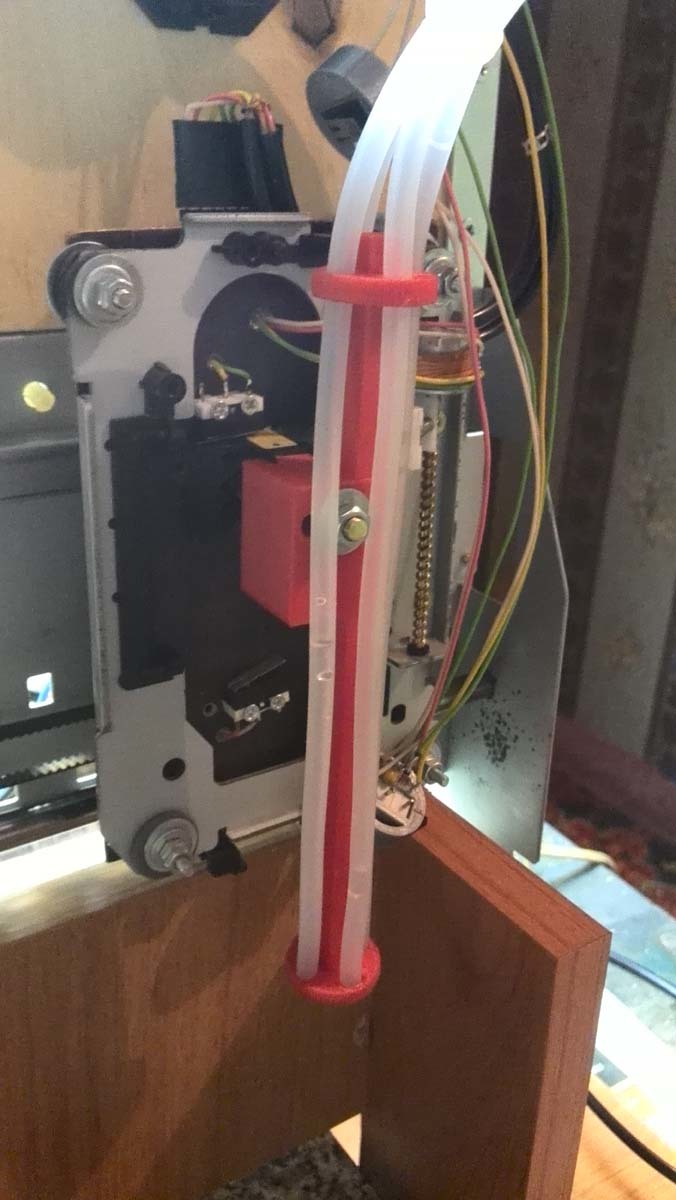

The nozzle can extend up to 4 cm (Z axis). To do this, I installed a platform from a 3.5 "drive on the carriage. I left only the frame, the stepper motor and the slider. I removed the laser module and fixed the holder printed on the 3D printer in its place. The holder at the end was made in the form of a nozzle. Initially, I wanted to make a nozzle with one tube into which different liquids are fed through the mixer, but then drove off this idea. Also, the device was conceived for the production of layered cocktails, when liquids with different densities are beautifully "laid" in a stack. For this, it is necessary to pour liquids very carefully, excluding their turbulent mixing. Bartenders do this by pouring along the blade of a knife or along the wall of the stack. I planned to pour drinks with a synchronous rise of the nozzle, but for this the nozzle stroke should be from the bottom of the stack to the top.

All axes have limit switches. The movement time is considered programmatically and, if this time is exceeded, a mechanism error message is issued. Mistakes mostly occur when curious friends try to stop the table during its movement. With the exclusion of the "human factor" there are no errors.

Peristaltic pumps are used to prevent contact of the mechanical parts of the pump with the pumped liquid. There are bottle compartments at the back of the case. At the bottom of each there are buttons for determining the presence of a bottle and an LED backlight.

The case was developed in a program for modeling furniture. According to the drawings, a chipboard was cut by an organization engaged in the production of furniture.

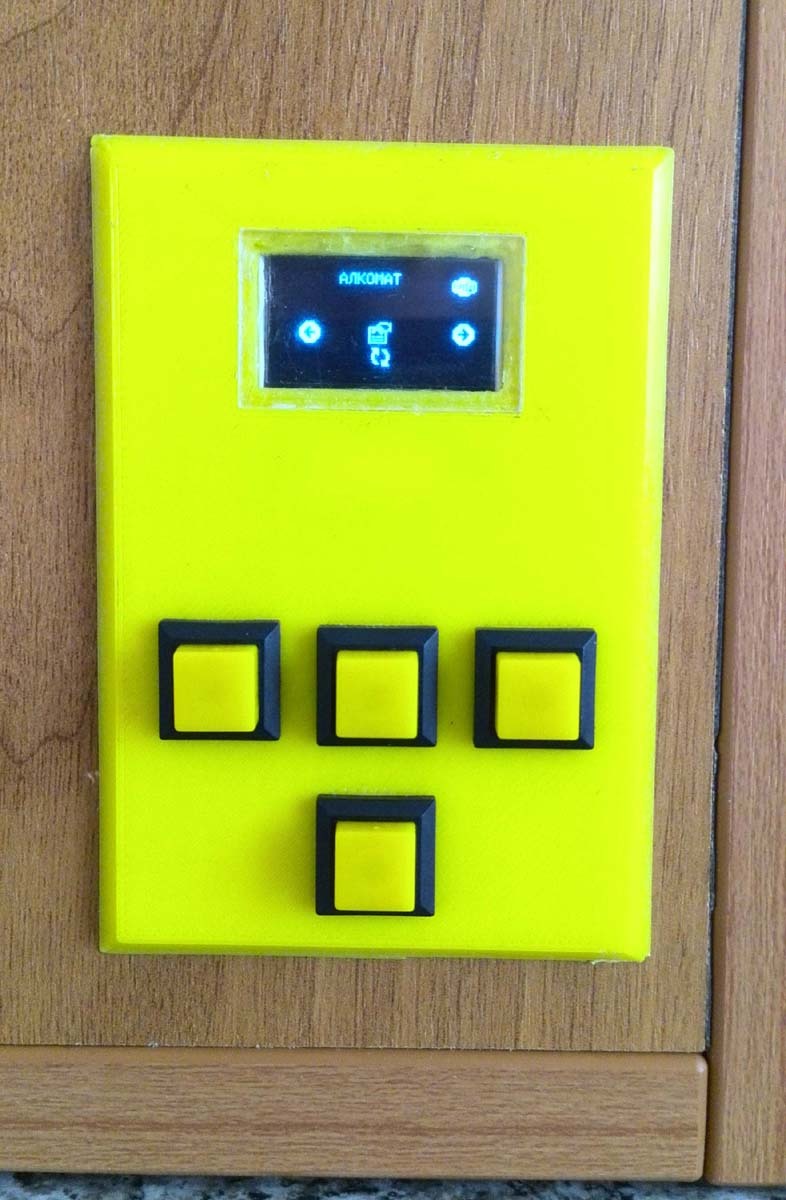

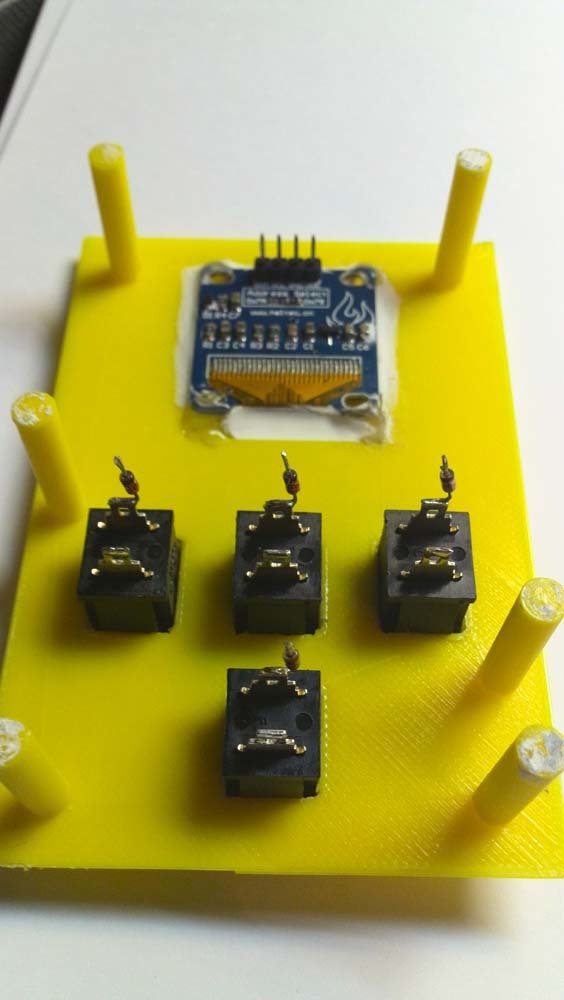

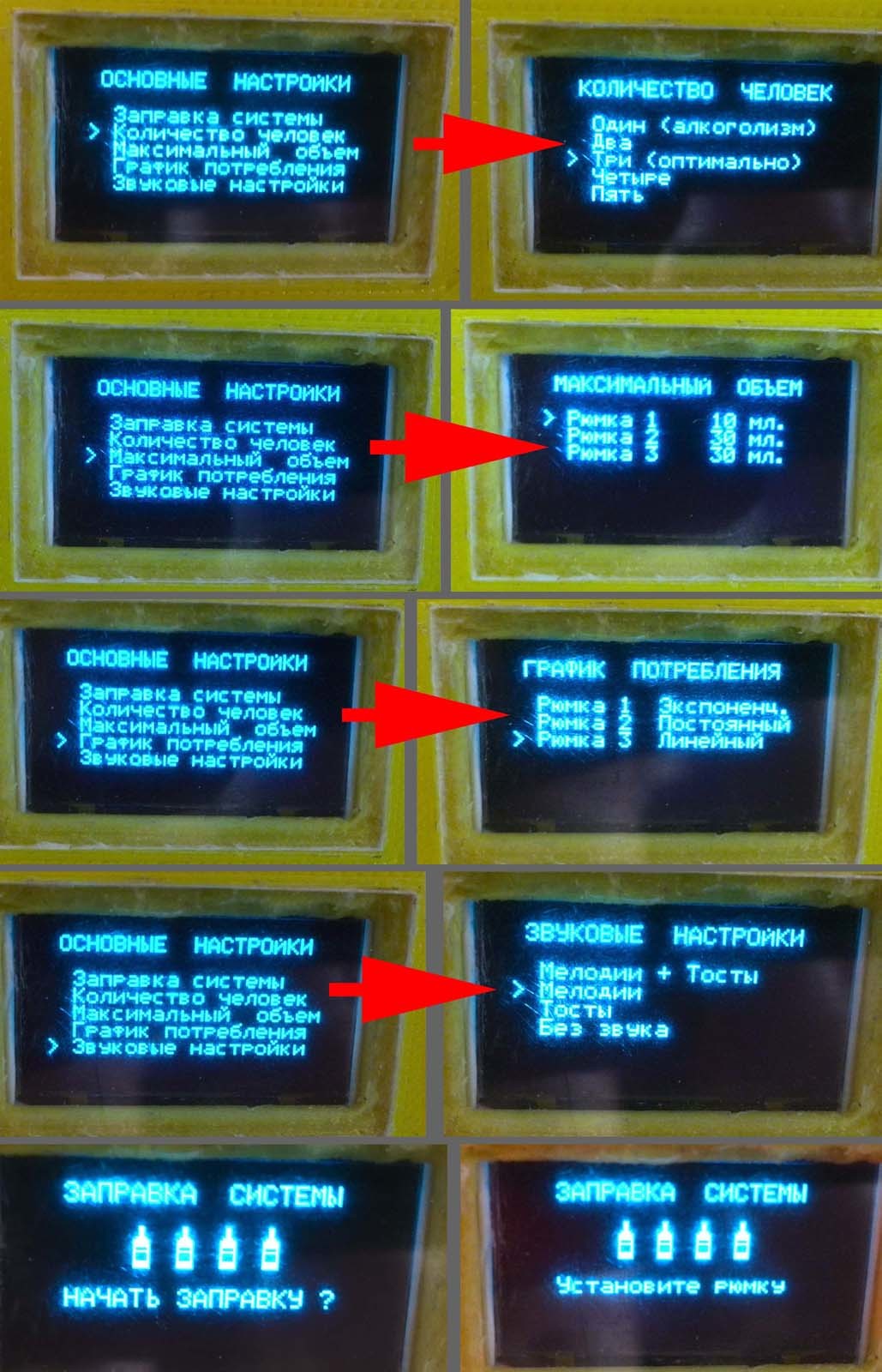

Management Alkomat occurs from the front panel. It is also printed on a 3D printer. Different menu items are displayed in the photo.

To get started, you need to fill the system of drinks with drinks. From the menu, select the appropriate item, after which the device will prompt you to set the stack. Then, in succession, choosing each drink, we pump the liquid through the tube until it pours out of the nozzle. When filling all drinks, the preparation process of the apparatus can be considered completed.

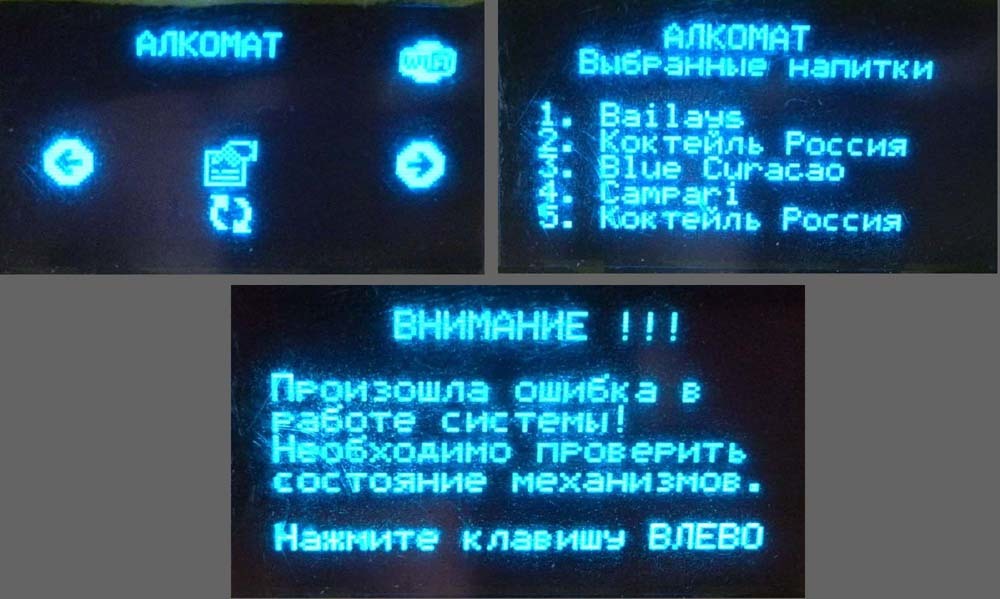

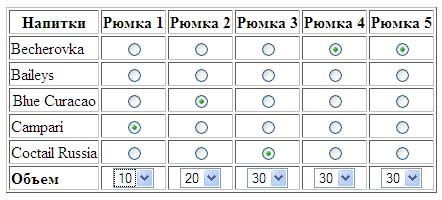

Selection of cocktails is carried out through a Web browser from any device connected to Alkomat via Wi-Fi. These are, of course, mainly smartphones. A Web server is launched on the ESP8266 module, which processes requests and issues a table of parameters to the main controller. Each client can choose for himself the name of the cocktail and the volume it needs in milliliters.

After the start of the spill process, Alkomat extends the table and waits for the stacks to be placed in the appropriate seats. As soon as the number of stacks installed is equal to the number of people involved in the process, Alkomat pushes the table and begins the spill process. For each pile, the pumps necessary for the selected cocktail are turned on and each ingredient is dosed in accordance with the recipe for this cocktail. Cocktail recipes include a table with the dosage of each drink in a cocktail.

After all the stacks have been poured, the machine extends the table, waits for all the stacks to be removed, and then pushes the table back. The first three toasts go automatically with a break of 1 minute. Further toasts go manually. All actions are accompanied by musical accompaniment. Toasts can be voiced with humorous phrases, for example, from films or a thematic melody.

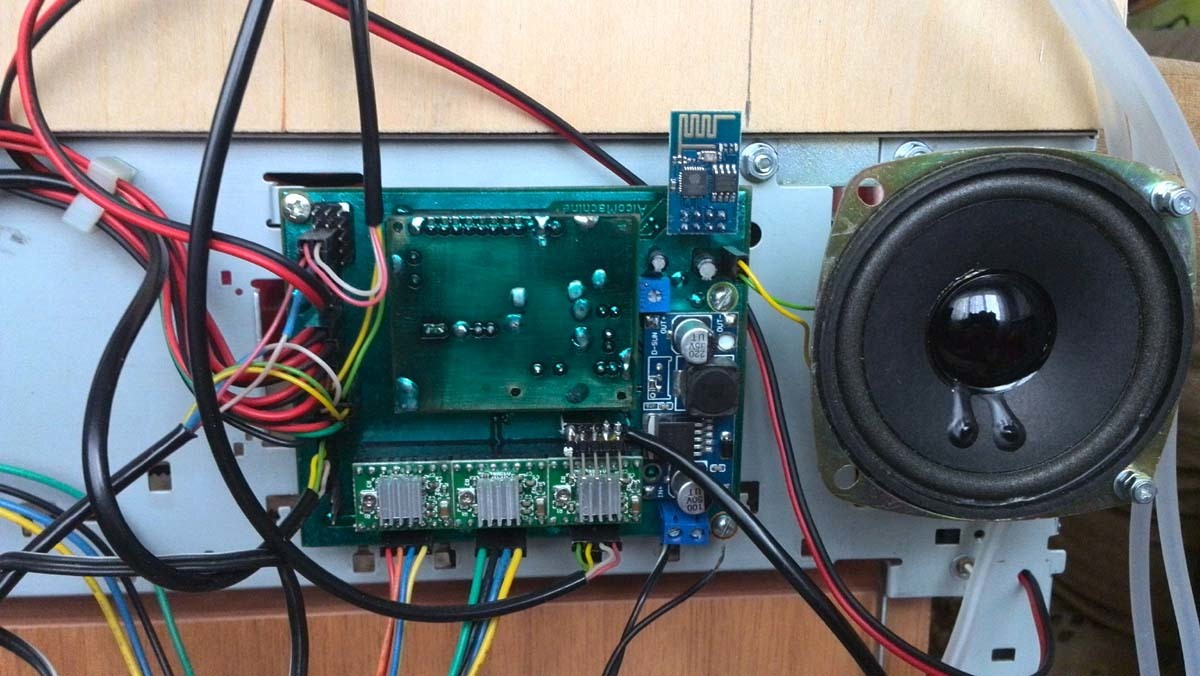

The electronics is simple and typical: a PIC controller, stepper motor drivers from a 3D printer, a buffer for controlling pumps ULN2003, an MP3 decoder VS1011k, a Wi-Fi module ESP8266, an OLED display. I wrote the program on HT-PICC. The hardest part was writing a menu system.

The web page for choosing cocktails is simple, due to the small amount of memory in the ESP8266, and there is no designer from me either. Now I’m mastering Android, I plan to write an application for Alcomat.

Video demonstrating the process.

The development took about 6 months and was carried out in stages, without haste, which in its free time is catastrophically small. There was a lot of things learned in the process, but the most pleasant thing was to see the finished product, which still works!

This development does not promote the use of alcoholic beverages, but reflects the complete process of translating ideas into iron.