This is kind of magic: about the Tion Magic Air concept

About a year and a half ago, we started working on the Magic Air smart climate system. The release of the first version of the product will be in 2016, and this fall its prototype won the international Red Dot Design Award 2015 in the Design Concept nomination. This category directly evaluates the product concept. We’ll tell about him.

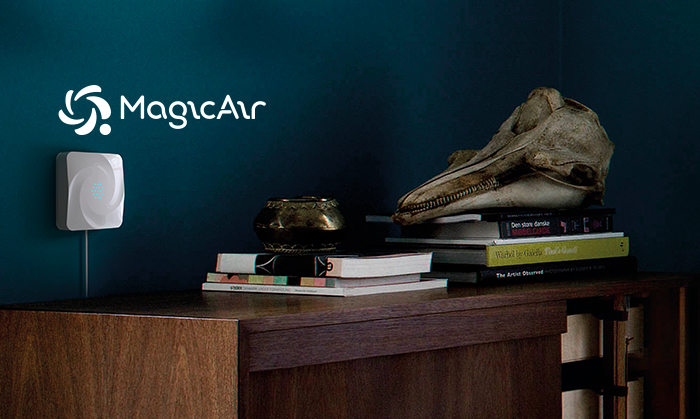

Briefly about Magic Air. This is an automatic control system for household climate equipment. The small box (about 10 cm across) in the picture is the base station of this system. Power station - via a USB network adapter. Inside the station there are several types of air sensors, a Wi-Fi module for communication with a cloud server and an RF module for communication with peripheral modules and actuators. Magic Air evaluates the air condition, analyzes the data and, based on it, controls actuators (breather, air conditioning, etc.).

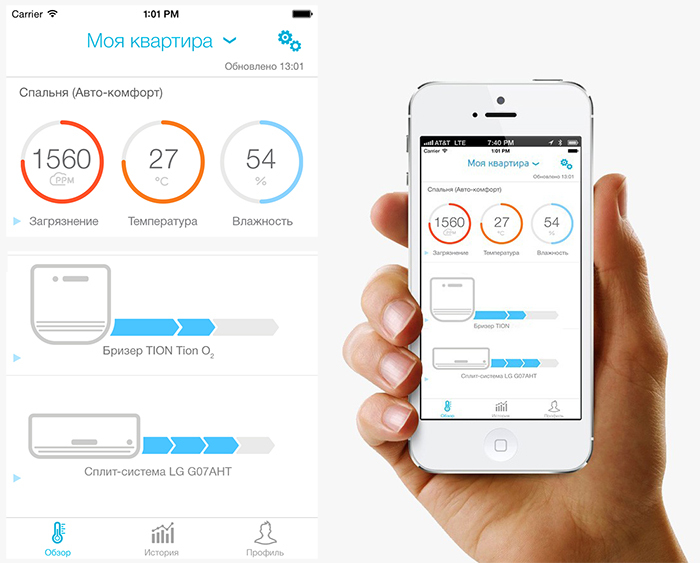

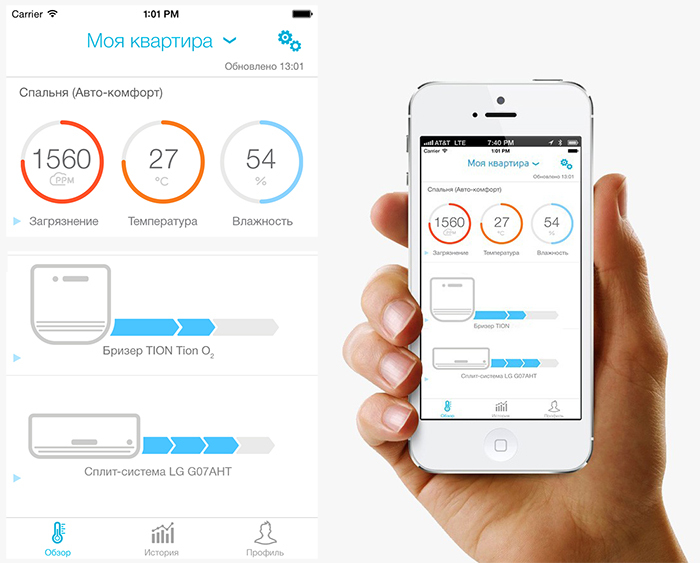

The usual smart home system is an expensive engineering solution; deploying and setting up a “smart home”, as a rule, is beyond the power of a “housewife”. The compact Magic Air is a full-fledged replacement for such a system, while it occupies a square decimeter of the wall, works wirelessly (except for power) and costs about 10,000 rubles. Instead of a separate computer with special software - a front-end on a smartphone (free Magic Air application) and a cloud back-end.

Our professional areas are ventilation and air purification / disinfection. We, like our many “colleagues in the shop”, are developing solutions for creating a healthy indoor climate. Our common efforts in the modern market are devices for “fixing” almost any microclimate deficiency: breathers, air conditioners, humidifiers, cleaners, heating systems, etc. We install the necessary devices, configure them correctly - and the room has a healthy microclimate. All this is good, but there are two problems.

Problem number 1: we can not adequately assess the state of the air in order to properly configure the devices.

Temperature and humidity can still be estimated "by touch." But in the air there is often an excess of pollutants without color and odor: CO2, CO, radon and other toxic gases, as well as PM2.5 and PM10 particles. No odors, no smoke. Our biological sensors are silent: there are no alarms, but there is danger.

Problem number 2: the more devices, the more difficult it is to monitor them.

The conditions are constantly changing. And depending on them, it is necessary to change the operating mode of the climate technology. Everyone left home, the level of CO2 fell - we switch the ventilation to the minimum speed (or close the window). Came home - turn on intensive airing. It has become damp - turn off the humidifier, dry - turn it on. Hot or cold - we regulate air conditioning and heating devices. Manually changing the “climate system” configuration daily is not the best option. And not only and not so much from the point of view of convenience, but for reasons of energy efficiency. An improperly configured climate system means excessive energy consumption.

The solution to the first problem is a correctly selected set of sensors for an accurate assessment of indoor air. The solution to the second problem is automatic “smart” control of all devices from one point. We decided to make a device that would allow both.

What has been invented before us

What is our idea

? Conventional sensors "dump" information on the state of the microclimate on the user. Not every user has enough knowledge / skills / patience to understand it. We decided to create a system that not only monitors the microclimate, but also flexibly regulates it. To do this, we need an automated climate system for a smart home. In a standard representation, such a system is complex: with a large central hub, complex architecture and wires throughout the premises. The order of value is hundreds of thousands of rubles.

We decided to create an analogue of such a system, only with the transfer of complex engineering to the cloud back-end. At the front-end, there is only a simple and compact gadget. Cost is much lower. Immersion in physical / technical nuances is minimal, control is intuitive, through a mobile application.

We deliberately did not immediately begin to tamper with the sensing of all microclimate parameters. The smart decision is to start with the most basic. This greatly speeds up and simplifies the process of creating the final product. For Magic Air v.1.0, we selected three main parameters: air temperature, humidity, and CO2 level (carbon dioxide is the main indicator of ventilation operation ).

From the idea to the first layout, we did not go long. More than a year ago, Skoltech students under the direction of Denis Volkov, head of the development department of the Tion company, created the first simple model of Magic Air based on Arduino. It measures the CO2 level in the room and automatically controls the breather. The guys attached a CO2 sensor and an IR module to the breather to control the breadboard. There was no cloud server yet; the breadboard was communicating with a desktop computer via wire. It took just a few weeks to create the layout. It looks very simple and very different from the serial product.

The next stage of development, from the layout to the serial product, was much longer - more than a year. We completed the prototype this year. What have we done by this time?

What does the general configuration of the Magic Air system look like?

Such a system can easily “cover” not only an apartment, but also a small floor of an office building, a business center, several classrooms in a school or kindergarten. The system can be controlled manually from a smartphone, as from a remote control. And you can set automatic control. In this case, it is enough to set the target parameters, and Magic Air will decide how to control the climate equipment. Algorithms will provide the most energy-efficient mode of operation of the system: with saving both energy and resource of executive devices (filters, cartridges, etc.).

With the Magic Air system, we initially relied not only on the Russian, but also on the international market. Therefore, the design of the device had to comply with international standards. Understanding the importance of this issue, we immediately decided to give the task to specialists. The choice was made in favor of the contractor LOGEEKs, since we already worked with them when creating the Tion Clever air purifier. We know that the guys have a sense of beauty, experience in industrial design, and a high level of professionalism.

The standard phrase of any customer upon receipt of the first sketch: “Can I see everyone?” And we are no exception. LOGEEKs, as a responsible artist, has provided us with several design options for Magic Air. But when the likelihood of endless coordination of the design layout loomed on the horizon, LOGEEKs head Igor Krasovsky made a move with his knight. He “poked a finger” into the main version and said: “With this design we will win the Red Dot. I give a tooth! ”The

statement is loud, we agreed, but we remembered the tooth :) We accepted the proposed concept and“ exhaled ”. And we must pay tribute to the guys, they kept their word, and Red Dot was taken. Respect!

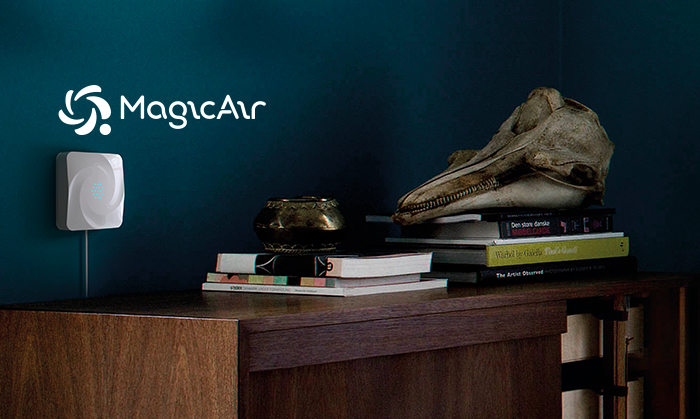

The design of Magic Air turned out to be simple but tasty. Before starting work, LOGEEKs chose a concept that they described in two words: cleanly and honestly. In their opinion, this is exactly what the approach to Tion products should be: laconic appearance, easy understanding, functionality without unnecessary frills. You can read more about Magic Air design on the blog of PROTOTYPSTER , a subsidiary of LOGEEKs. There is also information about some of the nuances of participating in Red Dot.

Finally - a couple of words about the immediate plans. Now we are completing alpha tests and getting ready to roll out on beta. After the beta, the “craft” will go: preparation for production, equipment, logistics. The release of the first version of Magic Air is scheduled for 2016.

In the next version of Magic Air, we plan to expand the range of sensors: for PM2.5, PM10, VOC (volatile organic compounds), radon. All sensors can be purchased separately, like the IR module, in the form of peripheral modules in addition to the Magic Air base station. In the future, we will expand the pool of actuators. After all, the resulting platform, in fact, can manage anything if “anything” is provided with an RF module or there is an opportunity to “mine” IR control codes. We can tell you more about the filling after the completion of all patent work. Follow our blog, we will definitely write about Magic Air. Or sign up for Magic Air news here .

Briefly about Magic Air. This is an automatic control system for household climate equipment. The small box (about 10 cm across) in the picture is the base station of this system. Power station - via a USB network adapter. Inside the station there are several types of air sensors, a Wi-Fi module for communication with a cloud server and an RF module for communication with peripheral modules and actuators. Magic Air evaluates the air condition, analyzes the data and, based on it, controls actuators (breather, air conditioning, etc.).

The usual smart home system is an expensive engineering solution; deploying and setting up a “smart home”, as a rule, is beyond the power of a “housewife”. The compact Magic Air is a full-fledged replacement for such a system, while it occupies a square decimeter of the wall, works wirelessly (except for power) and costs about 10,000 rubles. Instead of a separate computer with special software - a front-end on a smartphone (free Magic Air application) and a cloud back-end.

How the idea of Magic Air was born

Our professional areas are ventilation and air purification / disinfection. We, like our many “colleagues in the shop”, are developing solutions for creating a healthy indoor climate. Our common efforts in the modern market are devices for “fixing” almost any microclimate deficiency: breathers, air conditioners, humidifiers, cleaners, heating systems, etc. We install the necessary devices, configure them correctly - and the room has a healthy microclimate. All this is good, but there are two problems.

Problem number 1: we can not adequately assess the state of the air in order to properly configure the devices.

Temperature and humidity can still be estimated "by touch." But in the air there is often an excess of pollutants without color and odor: CO2, CO, radon and other toxic gases, as well as PM2.5 and PM10 particles. No odors, no smoke. Our biological sensors are silent: there are no alarms, but there is danger.

Problem number 2: the more devices, the more difficult it is to monitor them.

The conditions are constantly changing. And depending on them, it is necessary to change the operating mode of the climate technology. Everyone left home, the level of CO2 fell - we switch the ventilation to the minimum speed (or close the window). Came home - turn on intensive airing. It has become damp - turn off the humidifier, dry - turn it on. Hot or cold - we regulate air conditioning and heating devices. Manually changing the “climate system” configuration daily is not the best option. And not only and not so much from the point of view of convenience, but for reasons of energy efficiency. An improperly configured climate system means excessive energy consumption.

The solution to the first problem is a correctly selected set of sensors for an accurate assessment of indoor air. The solution to the second problem is automatic “smart” control of all devices from one point. We decided to make a device that would allow both.

What has been invented before us

- Affordable and affordable CO2 sensors, thermometers, hygrometers and other household sensors (examples: Green Eye , Master Kit )

- Universal stationary remote controls for household appliances (example: Orvibo AllOne )

- Smart climate control systems (example: Google Nest )

- Adaptive ventilation engineering systems (DCV) - for automatic control of central ventilation in office buildings and industrial facilities by CO2 level. More details

What is our idea

? Conventional sensors "dump" information on the state of the microclimate on the user. Not every user has enough knowledge / skills / patience to understand it. We decided to create a system that not only monitors the microclimate, but also flexibly regulates it. To do this, we need an automated climate system for a smart home. In a standard representation, such a system is complex: with a large central hub, complex architecture and wires throughout the premises. The order of value is hundreds of thousands of rubles.

We decided to create an analogue of such a system, only with the transfer of complex engineering to the cloud back-end. At the front-end, there is only a simple and compact gadget. Cost is much lower. Immersion in physical / technical nuances is minimal, control is intuitive, through a mobile application.

From idea to product

We deliberately did not immediately begin to tamper with the sensing of all microclimate parameters. The smart decision is to start with the most basic. This greatly speeds up and simplifies the process of creating the final product. For Magic Air v.1.0, we selected three main parameters: air temperature, humidity, and CO2 level (carbon dioxide is the main indicator of ventilation operation ).

From the idea to the first layout, we did not go long. More than a year ago, Skoltech students under the direction of Denis Volkov, head of the development department of the Tion company, created the first simple model of Magic Air based on Arduino. It measures the CO2 level in the room and automatically controls the breather. The guys attached a CO2 sensor and an IR module to the breather to control the breadboard. There was no cloud server yet; the breadboard was communicating with a desktop computer via wire. It took just a few weeks to create the layout. It looks very simple and very different from the serial product.

The next stage of development, from the layout to the serial product, was much longer - more than a year. We completed the prototype this year. What have we done by this time?

- Own electronic platform (do not make the same serial product on Arduino)

- Back-end: a cloud server for storing data from sensors and communicating with the front-end

- Front-end: Arello Mobile Magic Air mobile application (in the first version it will be available only for Android and iOS, in the future we will expand to other OSs)

- Base station industrial design (from LOGEEKs )

- Debug interaction between back-end and base station

What does the general configuration of the Magic Air system look like?

- In one room is the base station. It is tied to a personal user profile on a cloud server. The base station processor decides what to do with the breather, air conditioning, and other actuators. Commands are determined based on user settings.

- The remaining rooms are located peripheral sensors. They communicate with the base station via RF channel

- Communication of the base station with Tion actuators - also via RF channel through the built-in radio module

- Communication with third-party devices through the IR module, which can be purchased additionally. The IR module itself is also a peripheral device that communicates with the base station through the same RF module

- Wi-Fi back-end and base station connectivity

- Communication back-end and front-end through any communication channel through which the smartphone goes to the Internet: Wi-Fi, 3G, etc.

- A personal user profile is saved on the cloud server, all microclimate parameters, information about the system architecture and the state of all executive devices are collected. Big data is analyzed right away, correlations for learning computational algorithms are tracked

- Management of executive devices from a smartphone is carried out indirectly through the back-end throughout the chain: front - internet - back - internet - Wi-Fi - RF

Such a system can easily “cover” not only an apartment, but also a small floor of an office building, a business center, several classrooms in a school or kindergarten. The system can be controlled manually from a smartphone, as from a remote control. And you can set automatic control. In this case, it is enough to set the target parameters, and Magic Air will decide how to control the climate equipment. Algorithms will provide the most energy-efficient mode of operation of the system: with saving both energy and resource of executive devices (filters, cartridges, etc.).

A few words about design

With the Magic Air system, we initially relied not only on the Russian, but also on the international market. Therefore, the design of the device had to comply with international standards. Understanding the importance of this issue, we immediately decided to give the task to specialists. The choice was made in favor of the contractor LOGEEKs, since we already worked with them when creating the Tion Clever air purifier. We know that the guys have a sense of beauty, experience in industrial design, and a high level of professionalism.

The standard phrase of any customer upon receipt of the first sketch: “Can I see everyone?” And we are no exception. LOGEEKs, as a responsible artist, has provided us with several design options for Magic Air. But when the likelihood of endless coordination of the design layout loomed on the horizon, LOGEEKs head Igor Krasovsky made a move with his knight. He “poked a finger” into the main version and said: “With this design we will win the Red Dot. I give a tooth! ”The

statement is loud, we agreed, but we remembered the tooth :) We accepted the proposed concept and“ exhaled ”. And we must pay tribute to the guys, they kept their word, and Red Dot was taken. Respect!

The design of Magic Air turned out to be simple but tasty. Before starting work, LOGEEKs chose a concept that they described in two words: cleanly and honestly. In their opinion, this is exactly what the approach to Tion products should be: laconic appearance, easy understanding, functionality without unnecessary frills. You can read more about Magic Air design on the blog of PROTOTYPSTER , a subsidiary of LOGEEKs. There is also information about some of the nuances of participating in Red Dot.

Finally - a couple of words about the immediate plans. Now we are completing alpha tests and getting ready to roll out on beta. After the beta, the “craft” will go: preparation for production, equipment, logistics. The release of the first version of Magic Air is scheduled for 2016.

In the next version of Magic Air, we plan to expand the range of sensors: for PM2.5, PM10, VOC (volatile organic compounds), radon. All sensors can be purchased separately, like the IR module, in the form of peripheral modules in addition to the Magic Air base station. In the future, we will expand the pool of actuators. After all, the resulting platform, in fact, can manage anything if “anything” is provided with an RF module or there is an opportunity to “mine” IR control codes. We can tell you more about the filling after the completion of all patent work. Follow our blog, we will definitely write about Magic Air. Or sign up for Magic Air news here .