Meet the 3D printer - your personal assistant in jewelry

Jewelry has always been considered special things, not only because of their material value. They served as a reflection of the essence of man and were used as amulets that were endowed with special mystical power. Along with the development of civilization, the style of jewelry craftsmanship has changed, as well as our attitude to jewelry.

Swarovski crystals, for example, almost overshadowed the brilliance of diamonds, and three-dimensional printing, in turn, brought the design in its purest form onto the stage. Precious materials and unique skills compete with pure intelligence and computer technology: now it’s enough to create an electronic model of the jewelry and immediately send it to print, choosing the right material.

Oxytocin, or the hormone of love, in the form of a silver pendant created using 3d printing.

Three-dimensional printing changes jewelry production and helps single artists to compete with major market players. 57 years ago, this was completely unthinkable; now, you don’t have to invest a lot of money in production and attract labor from abroad. No need to calculate the number of copies that will actually be sold, as well as try to sell them as quickly as possible. Everything that was not for sale immediately sinks too expensive on the heart of the jewelry manufacturer - those who had to start jewelry production from scratch had to take these forced risks.

3D printing makes it possible to create jewelry on demand.without fear of overproduction, use an individual approach, do it all quickly and cheaper than the “classic” familiar way. Naturally, with the change in technology, the design has changed. What can be done using 3d printing cannot be done by traditional casting or forging methods. Three-dimensional printing also opened up a huge field for imagination: there certainly is a place for designers to take a walk!

Production speed and costs directly affect the result in any production. In this sense, loners are now even benefiting: it is more difficult for large companies to rebuild established processes. It is not surprising that all exhibitions of jewelry production in recent years are to a large extent devoted to the use of 3d opportunities. Changing technology gives a chance to create a completely new jewelry design. This applies not only to printing jewelry 3d models directly from silver or gold - the classic casting method also received its bonuses from 3d printing. The manufacture of waxes (blanks) for further casting of jewelry has now been greatly simplified.

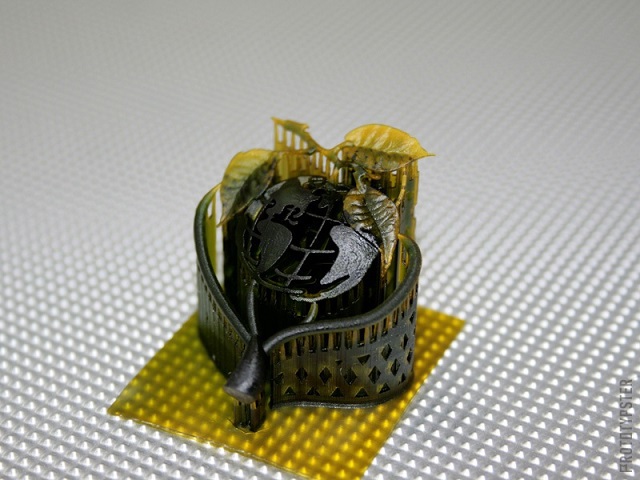

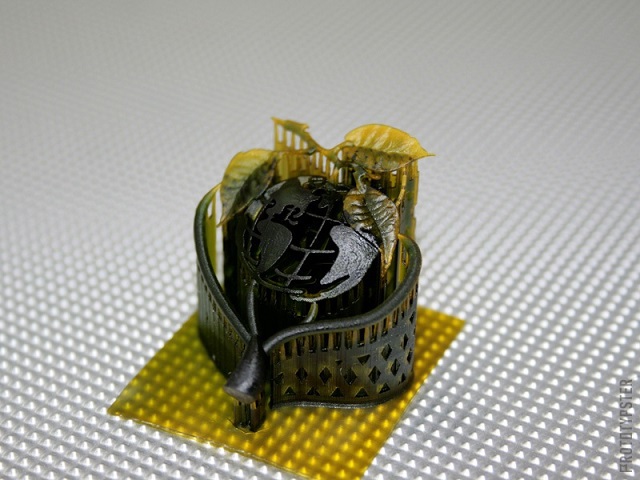

Stencil made using 3D printing from photopolymer.

On our Prototypester 3d printing service, for example, you can immediately print wax models and use them for further production: wax and yellow photopolymer are ideal for this , as they have a high degree of detail, are excellent for printing small items and have low ash content.

Andrea Anastrella, founder of Protofusione , said in an interview with David Cher:

“From manual labor, we switched to an almost completely digital process. The new technology allows us to stay afloat, in spite of the terrible economic situation, and remain competitive in the global market. If I had not switched to 3d printing, I would have closed for a long time, like many in this sector. Of the 2600 brands that were a few years ago, only 400 survived. Today we make jewelry that could not be made a few years ago. Moreover, all this is much faster and the price is constantly falling. ”

The companies that have left the market are being replaced by literally an army of single designers who can create 3d masterpieces anywhere in the world and sell them everywhere. At the same time, they do not need to be monsters of the jewelry industry for this. Now independent jewelers have a great competitive advantage that jewelry corporations have not yet arrogated to themselves - this is a unique design and speed of production. The technical leap complicates the confrontation between new and classic jewelry: familiar forms with precious stones compete with voluminous weaving, the finest nets and complex cutouts inside the metal.

If you are a designer, then you have various ways to sell your design: you can sell a “clean design” without going into details about how the final consumer will receive the jewelry for which he paid. The buyer, of course, is more convenient to get everything at once: choose, for example, the model of the bracelet, material, find out the final price and print. Obviously, for the buyer, the collaboration of designers with the 3D printing service simplifies the purchase. Everything that simplifies the purchase is good for the business, and this is also obvious. By the way, our designers can immediately open their store and sell there not only jewelry, but also home decor.

If you are the same end-user, now you can print any 3d model in Russia. On prototypster.ruYou can choose a finished model or upload your own, choose a material and immediately get a price. And it doesn’t matter where the designer of your ring lives: in Hong Kong, Paris or Australia. In addition to the usual gold and silver, you can choose brass or even titanium, which seems even more fashionable.

Jewelry art combines advanced technology with the most relevant forms. The 21st century has really changed a lot and continues to change, and with 3d printing, much less time now passes from the design idea to its implementation. With full 3d-printing of jewelry, a little post-processing is still needed - and this is the only moment of using manual labor. Yes, those who do not have time to rebuild leave the market, but those who manage to rebuild or “join” the stream play by the new rules.

Swarovski crystals, for example, almost overshadowed the brilliance of diamonds, and three-dimensional printing, in turn, brought the design in its purest form onto the stage. Precious materials and unique skills compete with pure intelligence and computer technology: now it’s enough to create an electronic model of the jewelry and immediately send it to print, choosing the right material.

Oxytocin, or the hormone of love, in the form of a silver pendant created using 3d printing.

Three-dimensional printing changes jewelry production and helps single artists to compete with major market players. 57 years ago, this was completely unthinkable; now, you don’t have to invest a lot of money in production and attract labor from abroad. No need to calculate the number of copies that will actually be sold, as well as try to sell them as quickly as possible. Everything that was not for sale immediately sinks too expensive on the heart of the jewelry manufacturer - those who had to start jewelry production from scratch had to take these forced risks.

3D printing makes it possible to create jewelry on demand.without fear of overproduction, use an individual approach, do it all quickly and cheaper than the “classic” familiar way. Naturally, with the change in technology, the design has changed. What can be done using 3d printing cannot be done by traditional casting or forging methods. Three-dimensional printing also opened up a huge field for imagination: there certainly is a place for designers to take a walk!

Production speed and costs directly affect the result in any production. In this sense, loners are now even benefiting: it is more difficult for large companies to rebuild established processes. It is not surprising that all exhibitions of jewelry production in recent years are to a large extent devoted to the use of 3d opportunities. Changing technology gives a chance to create a completely new jewelry design. This applies not only to printing jewelry 3d models directly from silver or gold - the classic casting method also received its bonuses from 3d printing. The manufacture of waxes (blanks) for further casting of jewelry has now been greatly simplified.

Stencil made using 3D printing from photopolymer.

On our Prototypester 3d printing service, for example, you can immediately print wax models and use them for further production: wax and yellow photopolymer are ideal for this , as they have a high degree of detail, are excellent for printing small items and have low ash content.

Andrea Anastrella, founder of Protofusione , said in an interview with David Cher:

“From manual labor, we switched to an almost completely digital process. The new technology allows us to stay afloat, in spite of the terrible economic situation, and remain competitive in the global market. If I had not switched to 3d printing, I would have closed for a long time, like many in this sector. Of the 2600 brands that were a few years ago, only 400 survived. Today we make jewelry that could not be made a few years ago. Moreover, all this is much faster and the price is constantly falling. ”

The companies that have left the market are being replaced by literally an army of single designers who can create 3d masterpieces anywhere in the world and sell them everywhere. At the same time, they do not need to be monsters of the jewelry industry for this. Now independent jewelers have a great competitive advantage that jewelry corporations have not yet arrogated to themselves - this is a unique design and speed of production. The technical leap complicates the confrontation between new and classic jewelry: familiar forms with precious stones compete with voluminous weaving, the finest nets and complex cutouts inside the metal.

If you are a designer, then you have various ways to sell your design: you can sell a “clean design” without going into details about how the final consumer will receive the jewelry for which he paid. The buyer, of course, is more convenient to get everything at once: choose, for example, the model of the bracelet, material, find out the final price and print. Obviously, for the buyer, the collaboration of designers with the 3D printing service simplifies the purchase. Everything that simplifies the purchase is good for the business, and this is also obvious. By the way, our designers can immediately open their store and sell there not only jewelry, but also home decor.

If you are the same end-user, now you can print any 3d model in Russia. On prototypster.ruYou can choose a finished model or upload your own, choose a material and immediately get a price. And it doesn’t matter where the designer of your ring lives: in Hong Kong, Paris or Australia. In addition to the usual gold and silver, you can choose brass or even titanium, which seems even more fashionable.

Jewelry art combines advanced technology with the most relevant forms. The 21st century has really changed a lot and continues to change, and with 3d printing, much less time now passes from the design idea to its implementation. With full 3d-printing of jewelry, a little post-processing is still needed - and this is the only moment of using manual labor. Yes, those who do not have time to rebuild leave the market, but those who manage to rebuild or “join” the stream play by the new rules.