3D printer for working in outer space

Made In Space announced a significant advance in the development of the Zero-G printer , which had previously successfully passed trials at the International Space Station under microgravity conditions. Now the printer has learned to print things not only on board the ISS, but also overboard. That is, he can work in outer space.

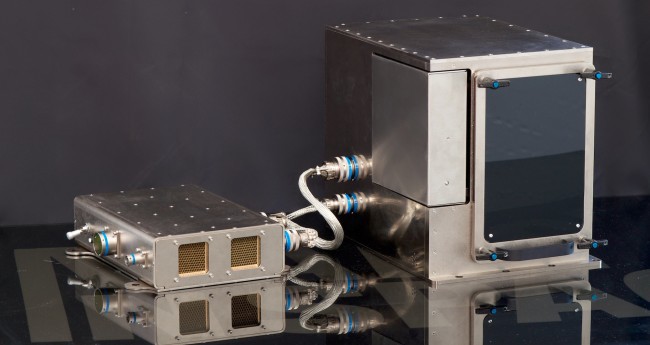

In July, Made In Space conducted a series of tests and made sure that the Zero-G really functions normally in a vacuum. Testing in a vacuum chamber continued for a week. Various parts were manufactured from aerospace-level thermopolymers. Engineers carefully studied the features of the extrusion heads of the printer in a vacuum.

Now the printed parts will be studied and compared with the same printed in normal atmospheric conditions.

During last year’s testing on the ISS, the printer manufactured 24 spare parts, they were later returned to Earth for analysis. This was a preparatory mission before the final test of the Additive Manufacturing Facility (AMF) commercial device, which will take place before the end of this year again at the ISS.

“We believe that in a year and a half we will be ready to test the printer of its current design in orbit,” said Mike Snyder, lead engineer in Made In Space, “These preliminary tests, together with our experience in microgravity, demonstrate that direct production of structures in space is possible using Made In Space technologies. Soon, in space, structures will be produced that are much larger in size than can be accommodated in a cargo ship for lifting from Earth. They will be designed for microgravity, not to withstand overloads at startup. Full structural optimization is now possible right in space. ”