Up box

I have a story with Up 3D printers. Firstly, I found one of them on the sidelines, dusted with rain. While he was figuring out whether he was a worker, he got acquainted with all the service companies in Moscow (and a couple in Siberia, hello to them) and with the many offices that sell these devices in Moscow (then there were no more than 20).

Now I have the honor to write most likely the very first review of the UP BOX novelty (at the time of writing, I did not find any English-language reviews).

The Chinese also tried this time. They invited Italian designers and now the printer does not look like a sewing machine, it is very stylish (which is the graceful slope of the front panel), they packed their 8 years of experience in creating industrial 3d printers in this BOX, made a bold visual interface and took care to equip the printer with a system filtering (and heating) the air and minimized noise to the cooler level on the laptop. A plus sign in karma to Chinese engineers.

The UP mini, UP Plus and UP Plus 2 3D printers have been and remain great workhorses. Many prototyping agencies bought half a dozen printers, put them in a row on shelves of several floors, and printed without stopping.

Here are some awards from MAKE Magazine:

(as well as MakeFare 2015 prizes at NewYork and an audience prize at the 3D Print Expo in Paris)

About company

Beijing Tiertime Technology Co., Ltd. (Tiertime) is Asia's largest 3D printer manufacturer. Offices in Beijing, California and New York.

It was founded in 2003 and produced industrial 3d printers. In 2012, they launched the desktop printer Up Plus.

Industrial printers

Industrial models:

Inspire S Series, Inspire D Series, Inspire A Series

Production UP Plus (aka Afinia)

UP BOX

Announcement:

It all started with the New York exhibition in September 2014, where the Chinese presented a working example of a new 3d printer:

But they really didn’t take a picture of the printer, there were only studio photo

Vase printed on UP mini and UP BOX

Appearance:

more stylish photos

And just recently, the very first Up Box arrived in Russia:

The first thing that impressed was the size: 485 (W) x 520 (H) x 495 (D) mm, weight - 20 kg.

The second is noiselessness.

The third is the interface, namely three buttons and the lack of a familiar display, all the info is displayed in the analogue way - progress bar and color of the bulbs. No language discrimination.

And here is the instruction for decoding the signals:

What is remarkable, with an error, each letter carries its message.

Here are the control buttons. There are three of them, but you can click on them in different ways.

All basic control functions are located on the printer. It can be controlled without even connecting to a computer. For example, you can start printing the previous printed model by pressing only 2 buttons.

The instruction is located on the top cover, which can be opened even during printing:

Soon the instructions will be translated into Russian.

This is what you see when you open the top cover:

Boards, cables, axes - everything was done perfectly. Each loop and part is marked with TierTime

But what can be seen when the printer is working:

Now the printer is more like MakerBot and Ultimaker - the platform moves only along the Z axis

But the front door cannot be opened during printing. Inside there is a powerful “hair dryer” that heats the insides.

This is actually not a hairdryer, but the “Air HEPA smart system” - a unique air filtration system that absorbs all the unpleasant odors and fumes that may occur during printing.

The system of uniform distribution and stabilization of temperature in the camera, borrowed from the TierTime line of industrial 3d printers, makes print quality even better, helps to avoid most of the main printing problems, such as plastic sticking from the platform, cracks, deformations.

Further, what is surprising is the size of the platform (255mm x 205mm), and the build area is 255 x 205 x 205 mm

. Compared to platforms with UP plus and UP Plus 2

Fully automated calibration of the platform in all axes. No manual intervention required.

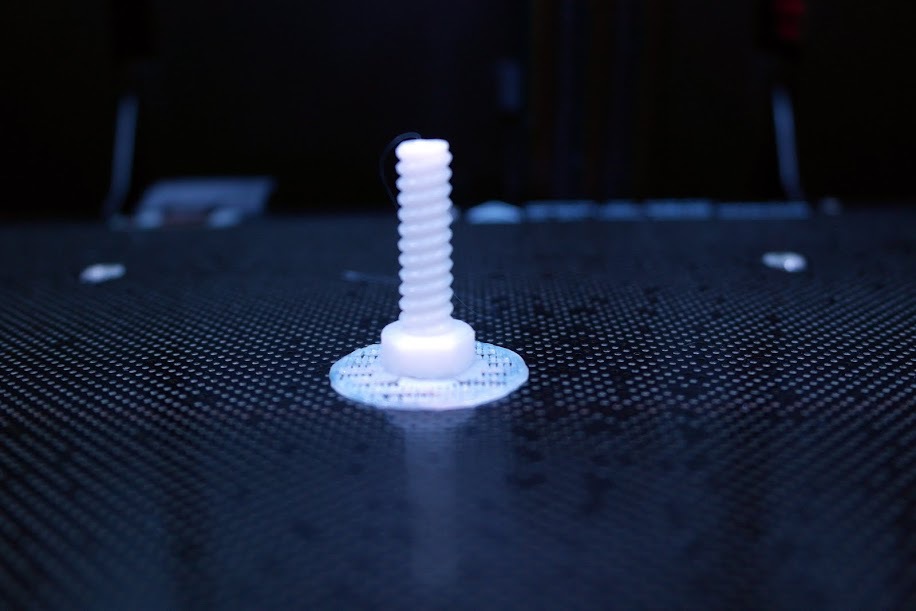

A perforated Teflon-coated platform (patented TierTime invention) further enhances adhesion (from Latin adhaesio - adhesion) and, therefore, the stability and stability of the model.

A new mechanism for fixing the platform, now there is no need to use clothespins:

Bolts are not fully tightened, and the platform is attached like a Soviet shelf to the wall

Modified extruder with a removable nozzle. It gives a layer thickness of 0.1 / 0.15 / 0.20 /0.25 /0.30 /0.35 /0.40 mm:

Unusually and stylishly placed a reel with plastic. On the right wall:

Reduces the risk of “chewing” a foreign object from the desktop, and the cat will not attack the coil.

The power supply is still huge (110-240VAC, 50-60 Hz, 180W).

The back panel cannot be opened just like that, but in There are three keys in the kit:

But what was hidden behind the back wall is the updated brains.

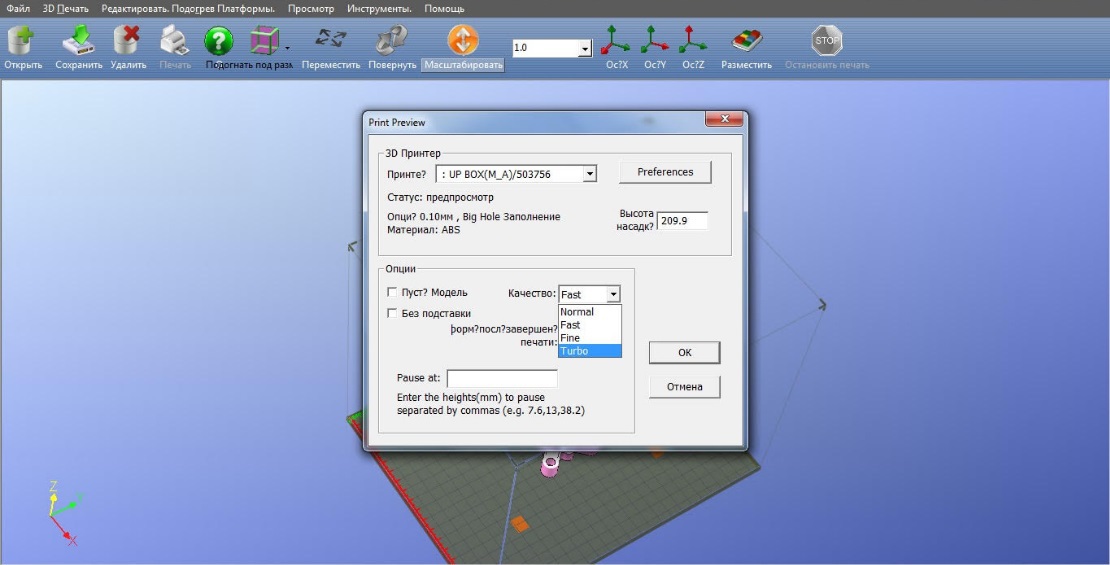

The software has remained almost the same (available in Russian):

Added the mode "Turbo". This is a function of superfast printing for creating fast “sketches”, it prints at the fastest speed and without filling. Only the outline of the model.

And the platform size has increased:

<

img src = " habrastorage.org/files/87b/7fd/764/87b7fd764b0b493588dfb41a4cc06de8.jpg " />

"Smart Support Technology" is a smart support technology, a patented algorithm that allows you to calculate and build support only in the most necessary places, easily print the most complex objects and easily separate the supporting structure.

A few more words about software:

- Proprietary software. Simplicity and at the same time multifunctional. Suitable for beginners 3D printing experts.

- It has a built-in slicer (that is, all the necessary tools are collected in one software, and not scattered over several different programs). Designed for Windows (the latest version of the software has built-in drivers for Win 8.1, which allows you to get started right away), and for Mac OSX.

- Automated creation of supports and substrates, allowing you to print even the most complex models

- Unique Surface mode for incredibly thin wall printing

- Adjustable print speed: 10 to 130 cm3 / h

- Ability to adjust model fill and material flow

- Ability to adjust print quality

- It prints equally well not only with ABS and PLA plastic, but also with special materials such as rubber, plastic with the effect of “cement”, “wood”, HIPS, Nylon, etc.!

- Ability to change the color of plastic during printing, which makes it possible to create multi-color models

- Universal thread thickness - 1.75mm

- The kit includes a reel with white ABS plastic (0.5kg)

Conclusion

- Design, noiseless, air filtration and closed chamber. Now 3D printers can be safely put in schools, offices and design studios

- Platform size, temperature support and automatic platform adjustment. And that means you can print even the most complex samples at a very high level.

- Simple software, “smart” support, ease of nozzle and platform change. Simple, fast, minimal maintenance

- Once again, design, lighting and ease of operation. All closer to the ideal.

- Price - 139,000 rubles

Thank 3DPhome - TierTime official representative in Russia and CIS for providing for the review of the printer.