The tiny and fast milliDelta origami robot from Harvard surprises with its speed

There are a great many robots. One of the families is delta robots, a type of parallel robots. Representatives of the family of three levers, which are attached via cardan joints to the base. A feature that can be called key is the use of parallelograms in the design of the manipulator. This allows you to save the spatial orientation of the actuator of the robot. The first such system was created in the early 1980s by Raymond Clavel.

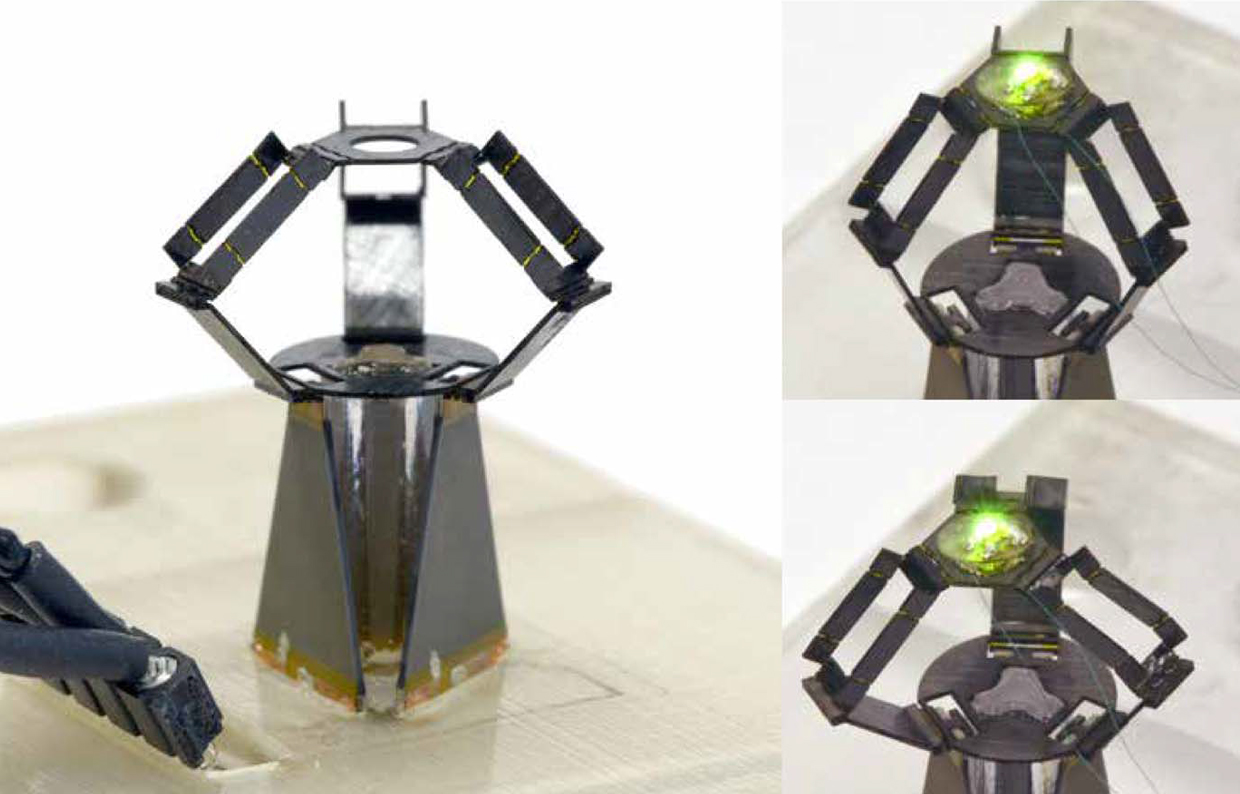

Recently, another robot created by a Harvard robot engineer ( Robert Wood Microrobotics Lab at Harvard) was introduced.) Hayley McClintock. The system is notable for being the smallest of the delta robots. Its dimensions are only 15 mm * 15 mm * 20 mm, and its weight is 430 milligrams. However, it can carry a payload of 1.3 grams. The accuracy of the movements of the robot is 5 micrometers.

But what is most surprising is the speed with which this robot is able to move: about 0.45 m / s, with an acceleration of 215 m / s 2 .

MilliDelta works thanks to piezoelectric actuators, which take effect when an electric current occurs. The rest in the design of the robot is a fixed body made of carbon fiber and additional elements that provide the special properties of the robot. The body is laser-cut because it is almost impossible to achieve such accuracy when using any other tool.

What can a baby do? For example, carry (very quickly) a payload, even a very small mass. It can be used in production, for the assembly of various kinds of miniature structures. It can also be used in microsurgery. For example, using it would be nice in eye surgery, where it would be most useful.

It is worth noting that Raymond Clavel made his device to work in a chocolate factory. The initial task was to pack small chocolates automatically. Prior to this, the work was performed by people or people “with the support” of semi-automatic machines. In order to achieve its goal, a very fast robot was needed, capable of moving without delay.

The first idea of engineers is to work with hydraulic motors as more powerful than everyone else. But they were not suitable for the intended purpose, since the candies weighed only ten grams each, and the powerful motor, with all its advantages, could not cope with such a baby. And then the idea came to use a robot with very light, but at the same time, maneuverable manipulators. It turned out to be a really good idea, which continues to develop today.

The structure of the robot, its design, was difficult to choose. “I had to work both at home and in the office, and with the usual improvised things, such as accessories for embroidery. This was required to create a structure that would just work, ”says the creator of the delta systems.

And the solution appeared in the form of a robot consisting of three manipulators that control an object of small size and weight. The idea was successful, and the design began to be used, if not everywhere, then quite widely. The robot has three translational and one rotational degrees of freedom. The ends of levers made of light materials are attached to a small base. The input connections during movement move the triangular platform in the X, Y or Z direction. The drive can be started using a linear or rotary motor.

In 1987, Demaurex bought a license for a robot that it began to use to create packaging. In 1991, Raymond Clavel presented his doctoral work, which was based on the results of testing robots. In 1999, he received a gold award for his contribution to the development of the delta robot. In the same 1999, ABB began selling a delta robot of its own design.

The miniature robot mentioned above can be used in industry, medicine, science and many other fields. True, for this, its developers will have to spend a little more time on the commercialization of their invention.