Hercules Strong 3D Printer Review

Hello! The Top 3D Shop is with you, this time we will talk about our experience with the Hercules Strong 3D printer .

Specifications

This printer was immediately put into operation, right out of the box, so we did not begin to demonstrate the process of unpacking and what was inside. The packaging is standard: a solid box, all in a film, in polystyrene foam, there were no complaints. From the assembly - just connect the power cord, if necessary, put the desired nozzle and that's it. We immediately put a nozzle of 0.5 mm., Since we had to print precisely large models.

Description

Before the first printing, it was decided to immediately remove the top glass - for the convenience of changing the nozzle and refueling the plastic. This was our decision - the manufacturer recommends not to remove the glass, since when re-installing it, you can damage the plastic feed tube.

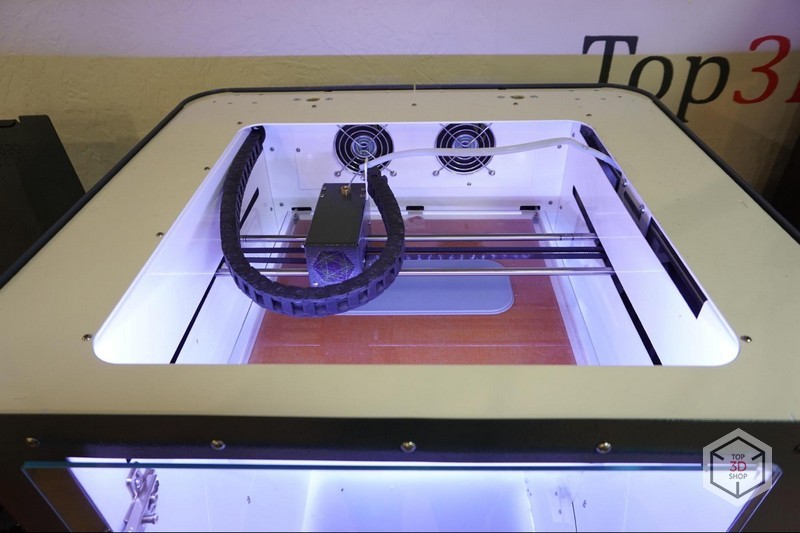

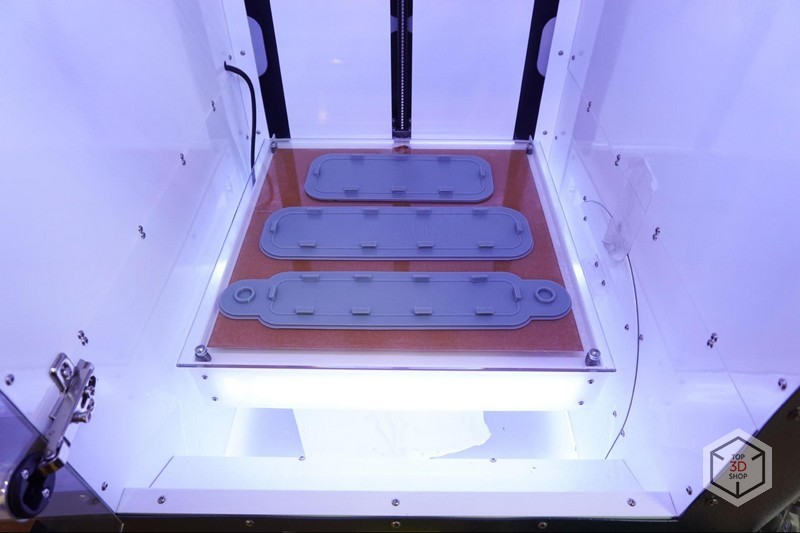

The Hercules Strong 3D printer is equipped with a heated glass platform 300 mm by 290 mm, which allows you to print large parts without dividing into segments, with a maximum height of 370 mm. Type of chamber - closed, with installed cooling system.

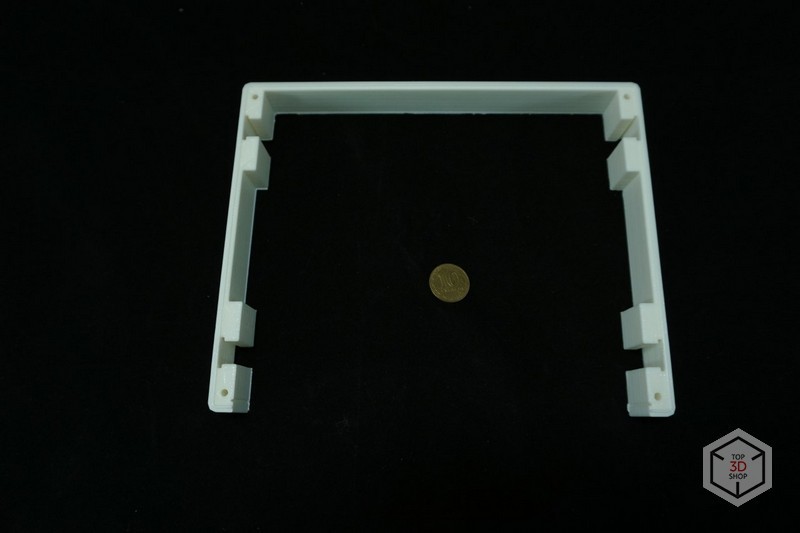

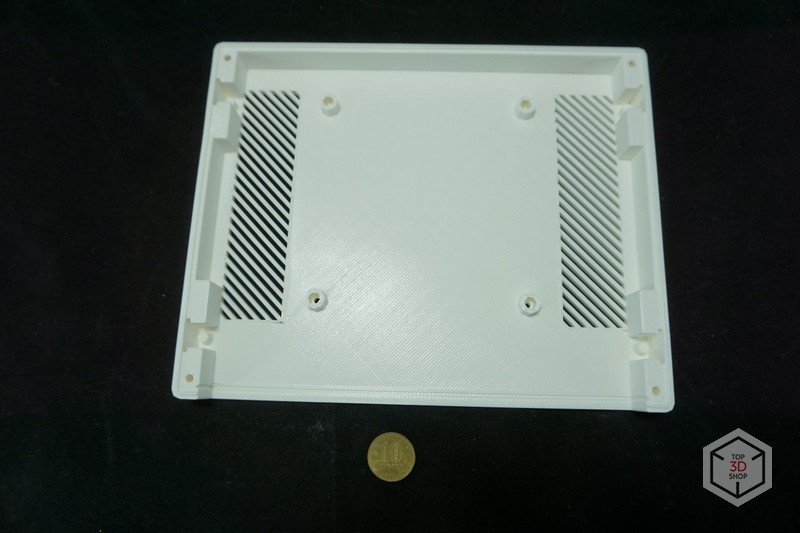

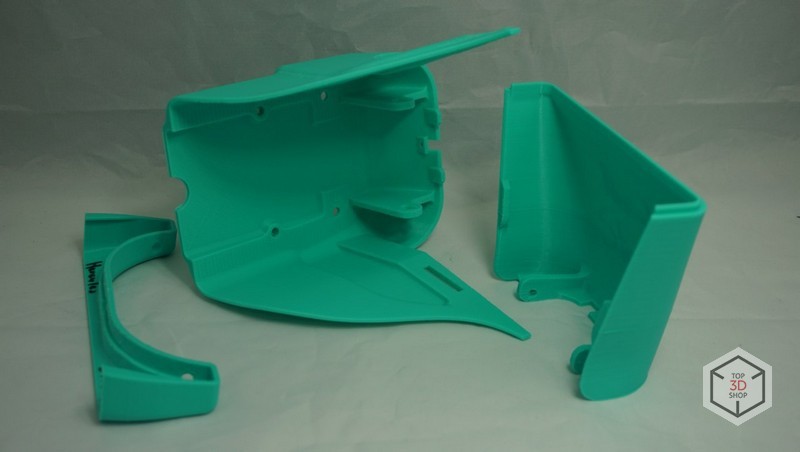

The results of the first printing experiments on Hecules Strong:

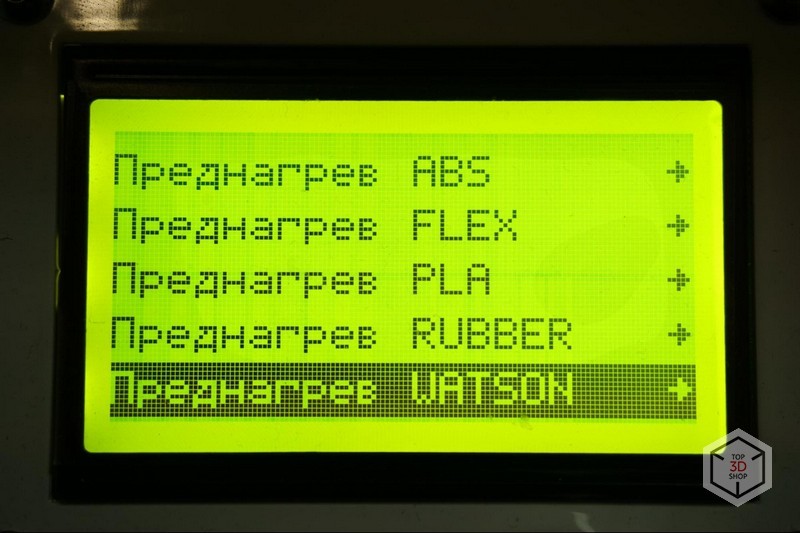

The successful design of the print head allows you to print without interruption with materials such as ABS, HIPS, PLA, Watson, Rubber, Flex.

The printer frame is made of 2 mm steel, 16 mm shafts are installed along the Z axis, the functional units are made of aluminum.

All this gives structural rigidity, which will not fail during prolonged loads, it also increases the life of the printer.

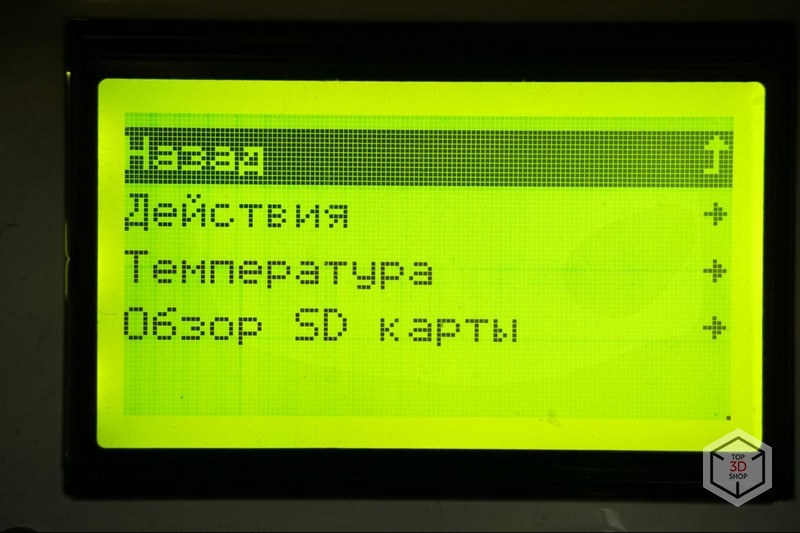

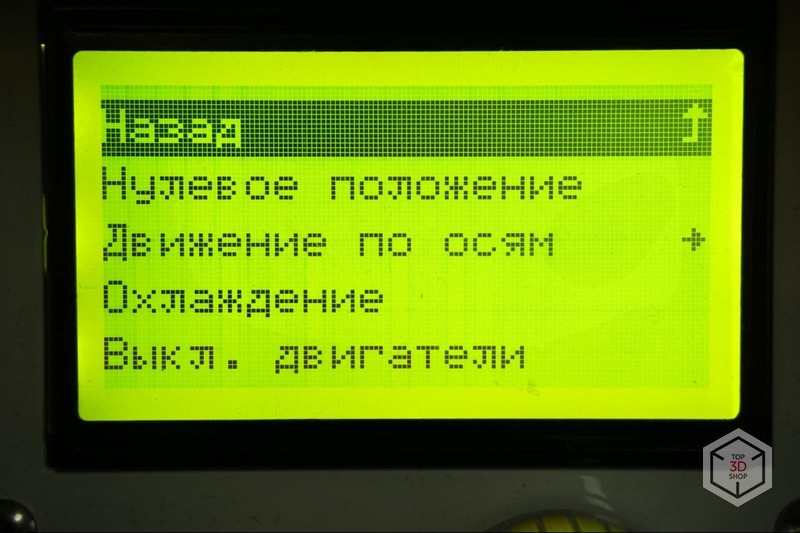

Governing bodies

Hercules Strong is equipped with a slot for a full-sized memory card. Navigation in the menu is carried out with the same familiar rotary knob.

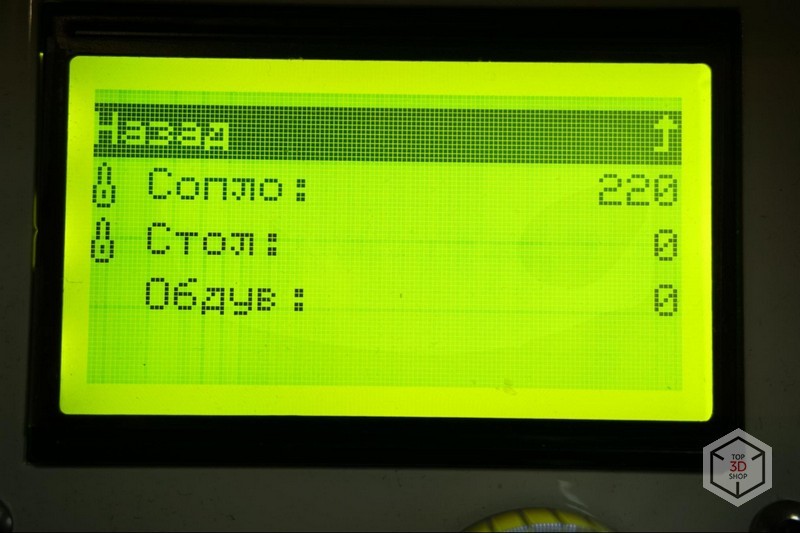

The menu contains the most necessary settings, nothing more: a large list of preheating for different materials, movement along the axes, return to zero point, manual control of temperatures and fan speed.

Work

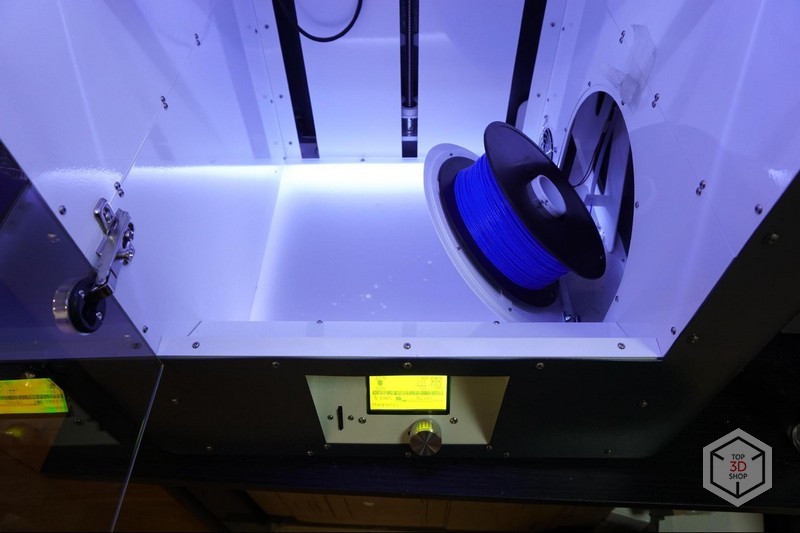

Table calibration is performed by four bolts located in the corners of the glass platform. The printer comes already calibrated, but just in case we calibrated ourselves after unpacking, we didn’t have to calibrate the printer for the next 2 months. A coil with plastic is installed inside the working chamber, in the right wall of the housing.

The plastic is fed into the extruder manually, the initial feed is regulated through the nozzle heating menu, and then through the “axis movement” menu. It is more convenient to perform this procedure with the upper glass removed: it is easier to get to the top of the extruder. In the future, when printing with ABS plastic, it is desirable to put the glass back in place, it is not necessary to fix the glass with screws - its own weight is enough to hold the plastic feed tube.

The manufacturer strongly recommends that the glass not be removed; we have already mentioned the reasons for this.

More samples:

There was a film on the surface of the platform for better adhesion, which turned out to be so good that the first models were removed with very great difficulty, despite the table completely cooling down.

Soon, when it came to large areas of printing, the film showed itself on the bad side: when the edges of the model began to bend, the film came off the table along with the folding plastic. It was decided to remove the film and print on the usual adhesive for us for FDM printing.

The PLA seal did not cause any problems, and before the ABS seal, large gaps on the camera door were alerted. But, oddly enough, the 10-hour print went well the first time. You can control the print speed right in the process, which adds convenience.

Results

Summarizing, I want to say: at the moment, Hercules Strong has only three minor minuses: not the most convenient filling and filament extraction; gaps between the camera door and the housing; when moving through the menu lines you have to turn the knob two clicks to move one position, it’s really difficult to get used to it.

The rest of the printer pleased us. When he first came to us, he was immediately put into work, we only checked the calibration, pulled up the nozzle and immediately began to fulfill our orders on it. For two months of work, almost non-stop, he did not give a single error, did not break a single print. This is an excellent apparatus for making large models: thanks to the nozzle diameter, volumetric working chamber and trouble-free operation, large parts are obtained especially well and print quickly.

When ordering Hercules Strong at the Top 3D Shop, you get not only a fair price for the printer, free shipping and training on how to use it, but also a 20% discount on supplies for the whole of 2017.

Come and see:

Take a closer look at this printer and its printed samples, as well as see it in your work, you will be one of the first - at the upcoming Top 3D Expo 2017 exhibition and conference , which will be held this week - April 14 in Moscow. Other 3D printers, consumables and other equipment will also be presented at the exhibition-conference.