Chubais black suitcase

At Dozhd, Alexei Navalny and Anatoly Chubais debated about the effectiveness of Rusnano. In support of his position in the final debate, the head of Rusnano presented Navalny with a black suitcase full of nanotechnology. A photo of the contents of the suitcase Navalny posted on the blog. I figured out what these artifacts are, why they are needed, and where does nanotechnology work. Suitcase transfer process

Let's start with a simple one: a large metal piece on top at number 1 is polysilicon. It consists of small silicon crystallites. It occupies an intermediate position between amorphous silicon, in which there is no long-range order, and single-crystal silicon. Polycrystalline silicon of electronic quality is mainly used to produce cylindrical crystals for electronics using the Czochralski method and crucible free zone melting.

Polysilicon is used in solar energy. Saudi Arabia, which wants to be the first in the field of solar energy , plans to supply a plant for its production on the Persian Gulf in order to supply plants for the production of solar power plants with necessary material.

RUSNANO was going to build its own production of this material in order to create a complete production cycle of solar panels in Russia. But from 2008 to 2012, world prices for polysilicon fell from $ 400 to $ 16 per kilogram, and in 2013 it was announced that the project would be closed due to unprofitability. Rusnano sold its stake in Nitola.

In parallel, Rusnano worked with the Havel company . It produces photovoltaic modules and builds turnkey solar power plants. In February 2015, the company launched the first full-cycle plant for the production of solar modules in Russia.

On Geektimes published photos from the current production Hevel.

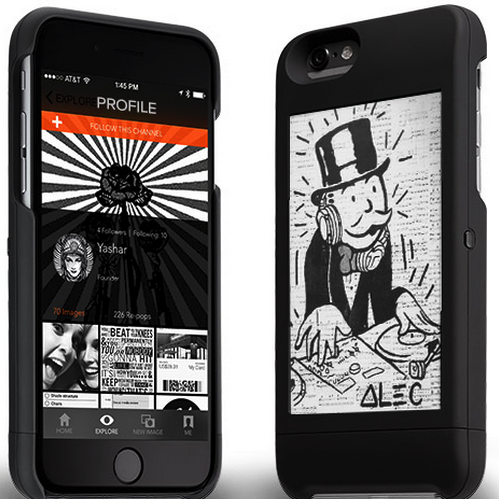

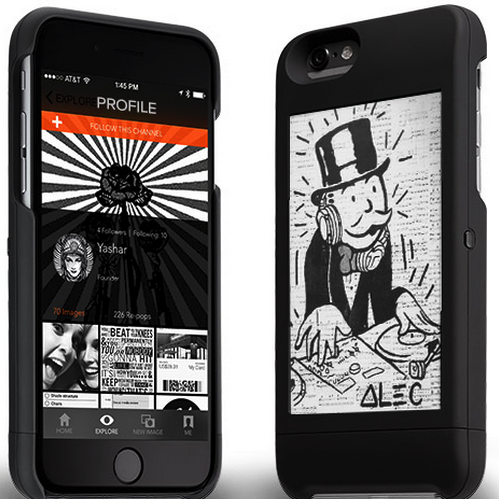

On the right at number 2 in the image is a case with a PopSlate screen. PopSlate startup sells such cases for iPhone 6, equipped with a 4-inch display on which you can change screensavers, install cards or read books. The device’s screen is made by Plastic Logic, the company in which Rusnano invested $ 150 million. In addition to RUSNANO, Intel Capital, Bank of America, Siemens Venture Capital, Oak Investment Partners, Tudor Intestments invested in Plastic Logic.

Since 2000, Plastic Logic has developed and patented a number of technologies.allowing to create electronic components on a non-silicon basis using polymers. In 2013, the company had difficulties with introducing technologies to the market; the construction of a plant in Zelenograd was stopped. The factory in Dresden was redesigned for the contract manufacturing of electronics. California design center employees have been relocated to the R&D center in Cambridge. The company began to look not for end users, but for manufacturers who would use screens in their devices.

According to some sources, Yota Devices is testing Plastic Logic screens and plans to use them in new smartphone models. During the debate on Dozhd, Anatoly Chubais said that “YotaPhone received exactly the same screens from us under the contract, this is a way out into the commercial sphere of the first flexible electronics”.

On the left in the photo (number 3) is a composite material cured using a nanomodified polymer.

The Prepreg-SCM project company in Dubna produces carbon fiber fabrics of various types of weaving - as an alternative to the most common standard types. Now these fabrics are being tested by automakers Lamborghini and Ferrari and Chanel fashion house. Composite materials have been used in the automotive industry since 1954 . BMW uses a carbon composite in its i3 and i8 electric models to lighten the design to increase driving time on a single battery charge.

In Novosibirsk, the Russian production company OCSIAL. The main competitive advantage and the main merit of OCSIAL is that they were the first in the world to learn how to produce carbon nanotubes in industrial volumes at a very low cost. According to Rosnano, the cost of nanotubes was reduced by this company by almost 100 times. The result of this work - TUBALL - can be bought in the online store of the company .

TUBALL (numbered 4) is a universal additive that simultaneously improves the strength, electrical and thermal conductivity of most materials. It is used to improve the quality of lithium-ion batteries, composite materials, transparent conductive films, tires and rubber, polymers.

In the center photo, there are examples of materials improved with TUBALL nanotubes: rubber with increased wear resistance (ring, number 5), bars - electrically conductive rubber (6), light objects (7 and 8) - an example of transparent electrically conductive polymer materials.

OCSIAL representative offices operate in the USA, Europe, Korea and Russia. One plant - in Novosibirsk.

HRSEM photo TUBALL

Polysilicon

Let's start with a simple one: a large metal piece on top at number 1 is polysilicon. It consists of small silicon crystallites. It occupies an intermediate position between amorphous silicon, in which there is no long-range order, and single-crystal silicon. Polycrystalline silicon of electronic quality is mainly used to produce cylindrical crystals for electronics using the Czochralski method and crucible free zone melting.

Polysilicon is used in solar energy. Saudi Arabia, which wants to be the first in the field of solar energy , plans to supply a plant for its production on the Persian Gulf in order to supply plants for the production of solar power plants with necessary material.

RUSNANO was going to build its own production of this material in order to create a complete production cycle of solar panels in Russia. But from 2008 to 2012, world prices for polysilicon fell from $ 400 to $ 16 per kilogram, and in 2013 it was announced that the project would be closed due to unprofitability. Rusnano sold its stake in Nitola.

In parallel, Rusnano worked with the Havel company . It produces photovoltaic modules and builds turnkey solar power plants. In February 2015, the company launched the first full-cycle plant for the production of solar modules in Russia.

On Geektimes published photos from the current production Hevel.

Plastic logic

On the right at number 2 in the image is a case with a PopSlate screen. PopSlate startup sells such cases for iPhone 6, equipped with a 4-inch display on which you can change screensavers, install cards or read books. The device’s screen is made by Plastic Logic, the company in which Rusnano invested $ 150 million. In addition to RUSNANO, Intel Capital, Bank of America, Siemens Venture Capital, Oak Investment Partners, Tudor Intestments invested in Plastic Logic.

Since 2000, Plastic Logic has developed and patented a number of technologies.allowing to create electronic components on a non-silicon basis using polymers. In 2013, the company had difficulties with introducing technologies to the market; the construction of a plant in Zelenograd was stopped. The factory in Dresden was redesigned for the contract manufacturing of electronics. California design center employees have been relocated to the R&D center in Cambridge. The company began to look not for end users, but for manufacturers who would use screens in their devices.

According to some sources, Yota Devices is testing Plastic Logic screens and plans to use them in new smartphone models. During the debate on Dozhd, Anatoly Chubais said that “YotaPhone received exactly the same screens from us under the contract, this is a way out into the commercial sphere of the first flexible electronics”.

Unfortunately, this company is against disclosing their suppliers. However, you probably saw the device itself and you know it well. @plushev

- Anatoly Chubays (@achubays) May 27, 2015

Composite Materials

On the left in the photo (number 3) is a composite material cured using a nanomodified polymer.

The Prepreg-SCM project company in Dubna produces carbon fiber fabrics of various types of weaving - as an alternative to the most common standard types. Now these fabrics are being tested by automakers Lamborghini and Ferrari and Chanel fashion house. Composite materials have been used in the automotive industry since 1954 . BMW uses a carbon composite in its i3 and i8 electric models to lighten the design to increase driving time on a single battery charge.

TUBALL (in a jar)

In Novosibirsk, the Russian production company OCSIAL. The main competitive advantage and the main merit of OCSIAL is that they were the first in the world to learn how to produce carbon nanotubes in industrial volumes at a very low cost. According to Rosnano, the cost of nanotubes was reduced by this company by almost 100 times. The result of this work - TUBALL - can be bought in the online store of the company .

TUBALL (numbered 4) is a universal additive that simultaneously improves the strength, electrical and thermal conductivity of most materials. It is used to improve the quality of lithium-ion batteries, composite materials, transparent conductive films, tires and rubber, polymers.

In the center photo, there are examples of materials improved with TUBALL nanotubes: rubber with increased wear resistance (ring, number 5), bars - electrically conductive rubber (6), light objects (7 and 8) - an example of transparent electrically conductive polymer materials.

OCSIAL representative offices operate in the USA, Europe, Korea and Russia. One plant - in Novosibirsk.

HRSEM photo TUBALL