Presentation of GOM Atos 5 / 5X 3D scanners at Top 3D Expo

We present the performance of Sergey Morgun from the OIM company at the Top 3D Expo , telling about the new generation GOM ATOS scanners and a specially created educational complex for training in 3D scanning systems in the industry.

Video

Performance

The company Optical Measuring Machines represents on the territory of Russia and the CIS the company GOM: optical scanners of this company, which are called Atos, systems of analysis of dynamic deformations and displacements of Aramis, equipment that is used to analyze stampability and formability of materials.

The presentation is divided into two parts: the first is devoted to a novelty, a completely new generation of scanners, and the second to a comprehensive solution for educational institutions.

Modern metrology is not a tactile machine, but a transition to optical 3D scanners. They completely replace the previous generation, equipped with sensors, probes, are innovative, precision-precise, and provide a qualitatively new approach to measuring the geometry of objects, as well as quality control in production at all steps - from the start of product development to quality control of finished parts and diagnostics in during operation.

The new equipment absorbed all of GOM's unique developments: this is the principle of Triple Scan projection, stereo camera system, precision accurate calibration, built-in self-diagnostics, measurement process, tracking an object in space during measurement, as well as electronic marking and projection functions, replaceable measurement volumes, use photogrammetry at work - to measure large objects of the order of 10-20 meters or more, the combination of contact and contactless methods - using a probe together with optical with a measuring machine, as well as the possibility of using it both in manual and automated mode.

So, we present to you the fifth generation of Athos scanners: they are called ATOS 5 and 5x.

ATOS 5 and 5x

ATOS 5 Series Features

- Blue light equalizer;

- Incoherent homogeneous, rayless light;

- Low noise level;

- Full coverage of complex geometry;

- High detail and resolution;

- Projection of very small stripes per unit area;

- Bright LED source;

- 1.5 times brighter;

- Fast data processing;

- Fiber optic transmission with industrial connectors;

- Screening;

- Resistance to surrounding electromagnetic fields;

- High data throughput;

- Cable lengths up to 30m;

- Smart communication between sensors;

- Active temperature monitoring;

- Prices: on request .

ATOS 5X Features

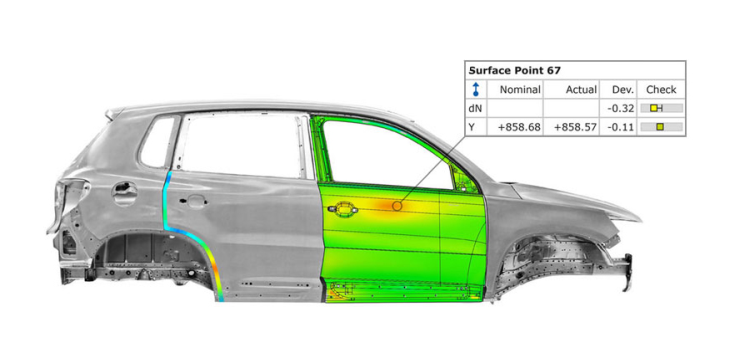

ATOS 5X is designed for automated control of auto body geometry. The device allows you to do wide-angle scanning at maximum speed automatically. Together with ATOS, ScanBox is an ideal tool for automakers and body builders.

These are completely updated systems with specific innovations, both hardware and software, which have a great effect on the workplace as a whole.

Now these systems allow even faster scanning, use a blue EQ to obtain precision data, can scan objects of a larger area with the same detail as before, use fiber optic data cables, provide reliable measurement accuracy and are used as metrological equipment by workers of any qualification.

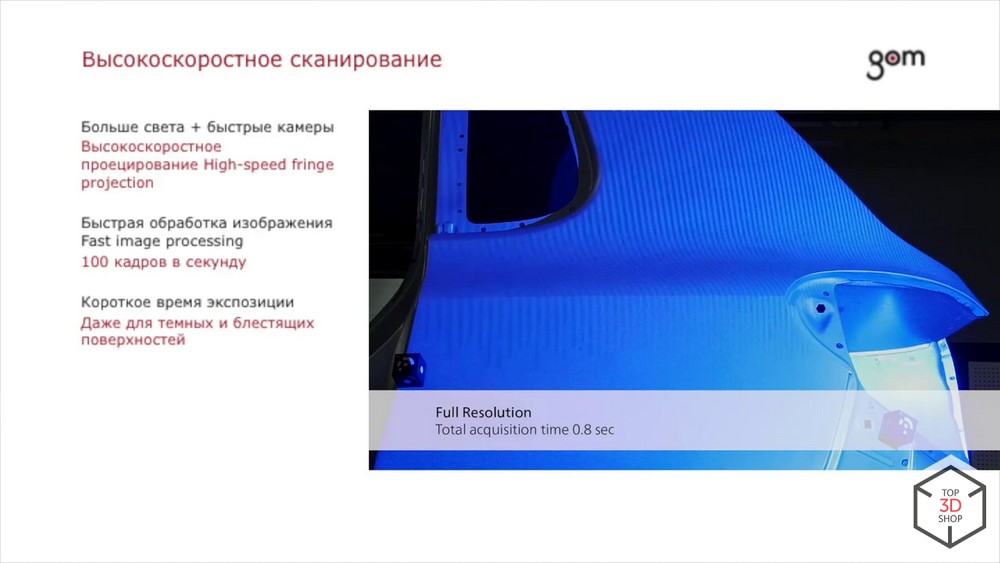

Now, it takes only 0.2 seconds for one scan, that is, moving the scanner or changing the position of the scanned object is much longer than the measurement process itself.

Scanning process

The system projects more light onto the object, which allows scanning faster than 100 frames per second.

Equipment can scan black and shiny objects, including glossy ones. The blue equalizer allows you to receive data of even higher quality, you can use it to produce detailed objects with complex geometry: small radii, edges - to get them with absolutely low noise and accurately cover this geometry, convert it into a three-dimensional view.

Now it's all a half times brighter and faster. The illustration shows a blade scan with full gripping of the edges.

Improve the quality of the data also allows the laser compressor, which uses a super-bright light source. The Atos 5x modification uses a laser diode with an equalizer and a specialized projector. This system allows you to produce 8 times more light than similar existing systems, and allows you to quickly scan with fields up to one meter - with the same detail as before, you will receive much larger areas of objects, and therefore much faster to scan them.

Now, it will take 2.5-3 times less time to scan a car body. Acceleration of the measurement process also contributes to the use of fiber optic data transmission lines. Optics allows you to make cables longer and use the scanner away from the computer itself.

Reliability and accuracy are also ensured by the performance of the sensor itself - now it is a case protected from external influences, such as dust and splashes, protected optics, and assembled separately sealed unit for electronics with external cooling.

All components now have industrial moisture and dustproof connectors.

The system also recognizes a change in the field of view, that is - as soon as you change the optics, the system automatically recognizes everything. There is a built-in active temperature control sensor.

Atos has incorporated: high-speed scanning, a blue equalizer, a laser radiation compressor, high-precision scanning of large areas, optical fiber for data transmission and reliability for use in industrial production.

Educational solution

We decided to create a common set for universities, schools and technical schools, which would allow educational institutions to get not only high-quality equipment and high technological level, but also allow them to train people to work with this equipment. After all, each student, in the future - a specialist, worker, leader in an enterprise where such technologies can be used.

Having knowledge of three-dimensional scanning, working on CNC machines, and reverse engineering, it is much easier then to turn on their workflow.

We took the Atos Core industrial scanner as a basis and on its basis formed a solution for training, and called it: Atos For Education.

This is a kit that allows you to train people to work directly in production.

It is a set for theoretical and practical training in schools, colleges and universities, contains industrial software and hardware, lecture and teaching materials for teaching and practical exercises.

The set includes: a scanner with a fixed field of view, a tripod, a table, a demonstration training sample, a computer with scanning and inspection software.

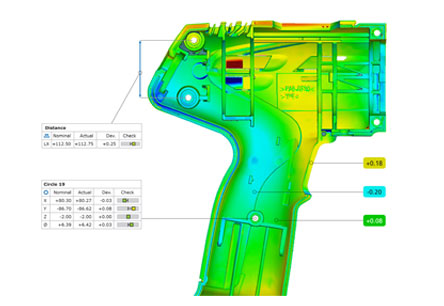

Industrial scanner software allows you to immediately receive high-level data, ready for reverse engineering and industrial use, for inspection, for quality control in production conditions.

The kit includes lecture materials with complete reference information in Russian, the software interface is also in Russian.

There is also support from our specialists: for working with software, operation and maintenance of the scanner, practical courses on teaching.

The program includes training materials, the course consists of several modules: this is an introduction to optical metrology, preparation of objects for measurements, control of the geometry of objects, creation of reports.

All material is supplemented with video tutorials and recommendations for the teacher. Based on this module, you can create additional specialized modules for training by industry.

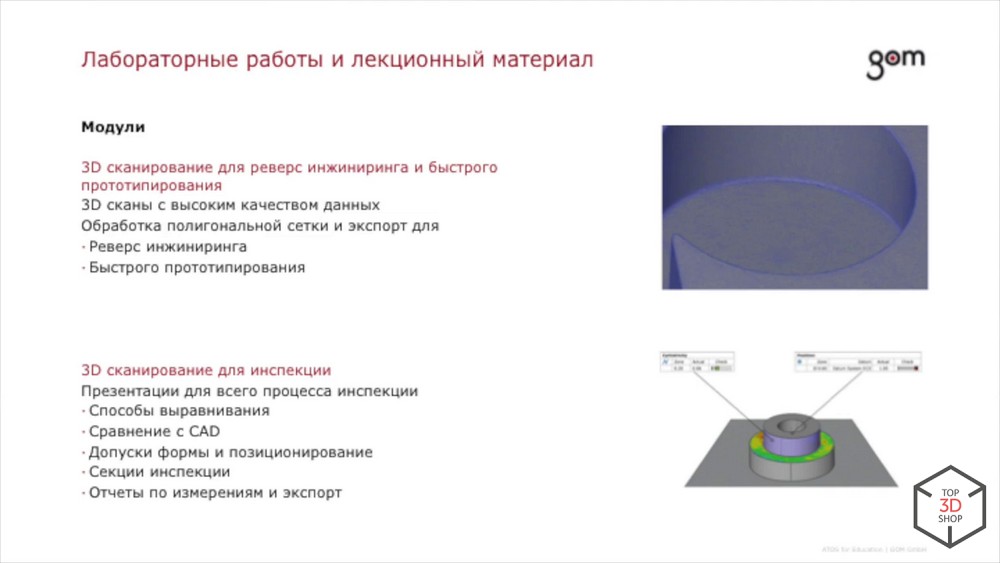

The basic module, which is included in the package, is a three-dimensional scanning module for reverse engineering and rapid prototyping. It contains a library of high-quality ready-made 3D scans. You can make scans directly by the scanner, with this set of equipment, to adapt the course in this way to your specificity.

The module also includes polygonal mesh processing, export for reverse engineering and rapid prototyping.

The next module is a scan for inspection.

It also contains all the necessary presentations, methods of combining with a mathematical model, simple alignment of scanned data, analysis of shape tolerances and positioning, control over sections, as well as creating reports and exporting these reports.

We also examined the areas where this package can be applied: universities and any educational institutions that train specialists for the automotive industry, aerospace production, energy and consumer goods production, as well as any industries where digital production tools are used.

As an addition to this kit, we also offer software that allows analyzing deformations, moving objects, components and components in dynamics, using the same hardware - the Atos sensor, which will be used as a dynamic optical non-contact deformation analysis machine.

The kit also includes, along with the software, a set of lab manuals, lecture material and video tutorials.

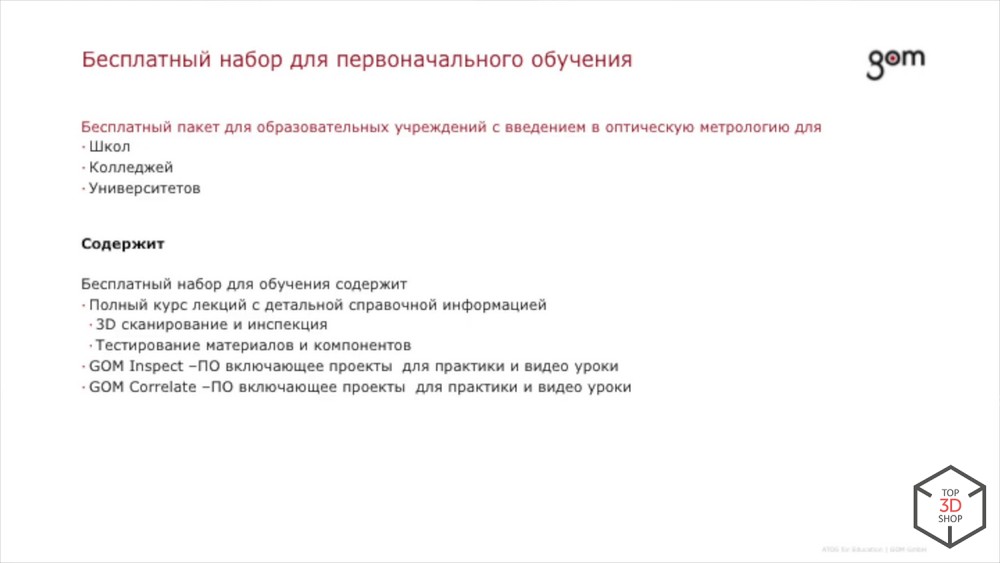

We also offer a simple free kit for educational institutions, which can be downloaded by contacting us on the site.

It contains free lecture courses with detailed reference information on scanning, testing materials of components, as well as GOM Inspect and GOM Correlate software designed to monitor the geometry of linear angular values and analyze the deformation and movement of components.

Upon request, in exchange for your contacts, we will send you this information, which can be used to teach students and schoolchildren.

For the selection of 3D-scanning equipment and integrated solutions, contact Top 3D Shop.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks: