Overview of the high temperature 3D printer Intamsys FUNMAT HT

Hello! With you Top 3D Shop and in the next review of the latest equipment we will tell you about the Intamsys FUNMAT HT FDM printer .

Video

About the printer

Intamsys FUNMAT HT

Specifications

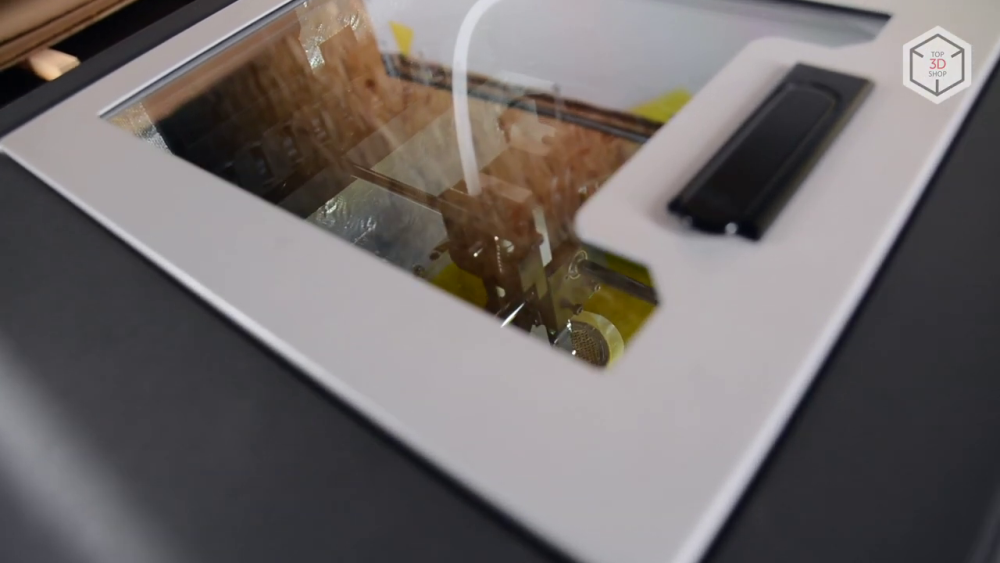

- Printing technology: FDM

- Number of extruders: 1

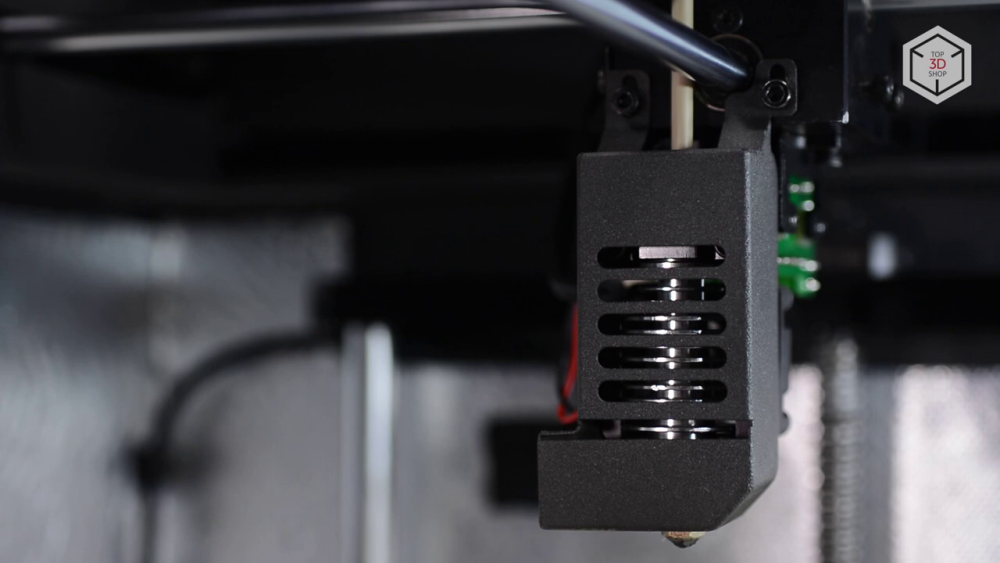

- Extruder temperature: up to 450˚C

- Table temperature: up to 160˚C

- Chamber temperature: up to 90˚C

- Layer thickness: from 50 microns

- Positioning accuracy: X / Y - 12.5 microns, Z - 1.25 microns

- Printing area: 260x260x260 mm

- Print speed: from 30 mm / s

- Plastic Type: PEEK, ULTEM, PPSU, PA / CF, PC, PA, ABS, Carbon, Metal-Filled, Fiberglass-Filled, ASA, PETG, ESD-Safe, HIPS, TPU, PLA

- Thread Diameter: 1.75 mm

- Interfaces: USB, SD cards

- OS: Windows, Mac OS, Linux

- Dimensions, weight: 540x500x650 mm, 43 kg

- Price: 462,000 rubles. (on 7.11.2018, check the current site)

Purpose

Fanmat HP Professional 3D Printer is manufactured by Inhamsis, headquartered in Shanghai. The capabilities of this device will be useful to a wide audience - it is a useful tool for both designers and manufacturers. Some of its characteristics are inherent in more advanced industrial-level 3D printers.

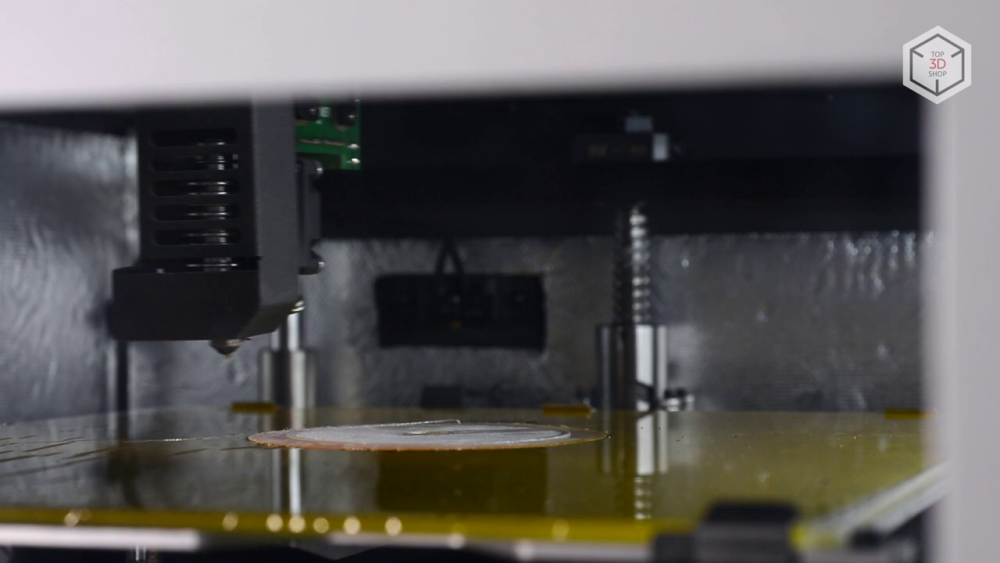

An extruder operating at a temperature of up to 450 degrees and a working chamber heated to 90 degrees allow Intamsys FUNMAT HT to be used to work with refractory materials such as PEEK or ULTEM. The same purpose is served by the possibility of heating the desktop up to 160 degrees.

Materials for printing

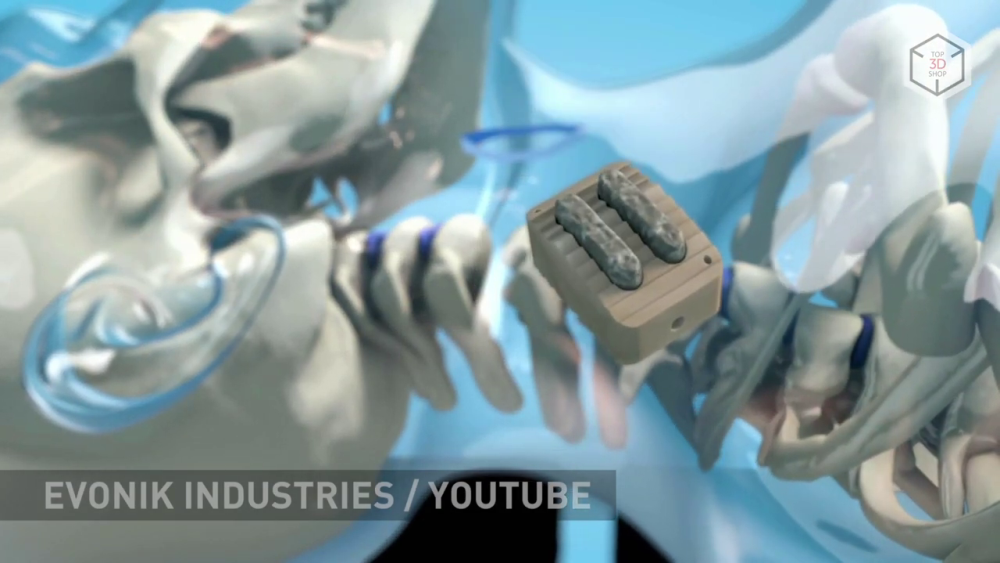

The increased interest of professional users in polyetheretherketone printing is the full name of the polymer, known as PEEK , due to its physical properties.

It is light, but at the same time strong and durable - PEEK, for example, is used in experimental medicine to repair damaged parts of the spine.

The range of materials with which the 3D-printer works also includes polycarbonate, nylon, thermoplastic polyurethane, carbon fiber reinforced plastics. Naturally, printing is also possible with more familiar ABS , PLA , HIPS .

Design features

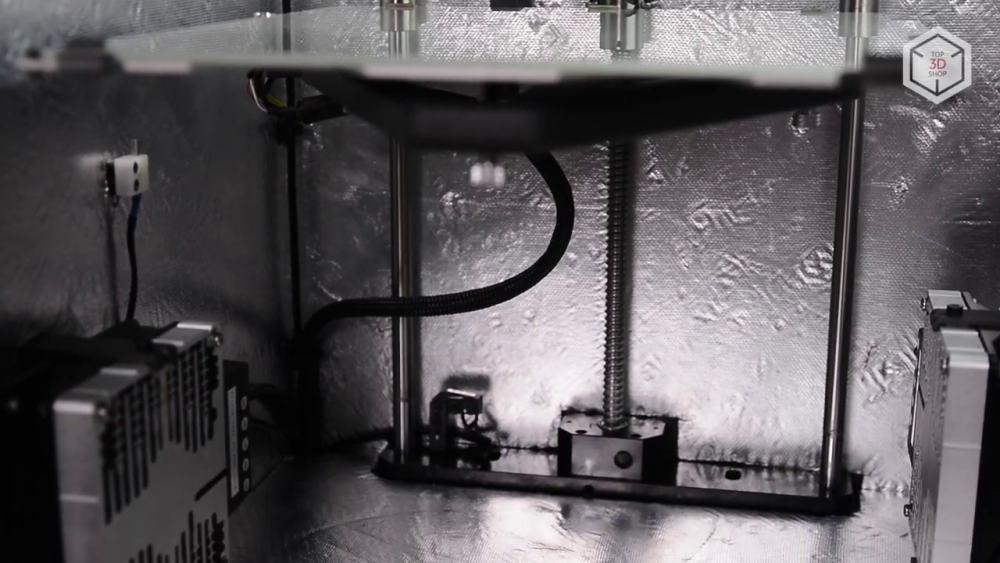

Rapid heating of the working chamber is carried out using two heating elements. The risk of violation of the temperature regime is reduced due to carefully thought-out thermal insulation.

The coil with plastic, for obvious reasons, is placed separately, in a compartment isolated from the working chamber.

The printer has a built-in system of notification of the end of the filament, which is very convenient in everyday use.

Practicality adds the ability to manipulate the touch screen, without removing the protective gloves.

By the way, additional protection when working with FUNMAT HT does not hurt - do not forget about the high operating temperatures.

One of the most unusual features of the Intamsys FUNMAT HT is the built-in backup power supply. Even completely disconnecting the printer from the network does not cause a malfunction - the extruder moves to a safe position until the printer is completely turned off. After the power has been restored and the operating temperature of the extruder, the table and the chamber has been reached, printing resumes.

FUNMAT HT is a relatively quiet device. The noise level at work does not exceed 59 decibels.

Software

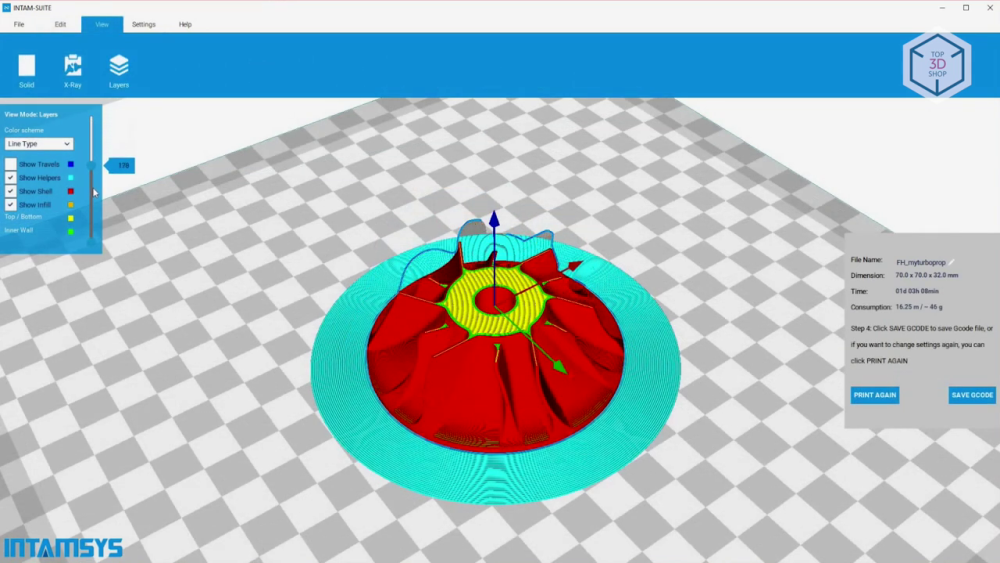

Preparation of 3D-models for printing is carried out using INTAMSUITE - control software, which is included in the package.

Other models

Model HT - the youngest in the lineup FUNMAT. In addition, Intamsis produces FUNMAT PRO and FUNMAT PRO HT . They differ from each other by the temperature, the volume of the working chamber and, of course, the price.

Total

In general, Intamsys FUNMAT HT can be recommended as a daily tool for additive manufacturing in the automotive industry, engineering, research, engineering, oil and gas, and medicine.

Are you choosing a 3D printer for high temperature engineering plastics? Write to us at sales@top3dshop.ru and we will select the best machine for your production.