As in my Chevrolet Bolt electric car, under warranty, two battery modules were replaced, and the third was monitored

- Transfer

“Your case is unique, the chance to get into such a situation is one in a million,” Tim Greve told me over the phone (Chief Engineer for Electrical Power Plants at General Motors) reassuringly last week, “it's just awful what happened to you. And even though this is a very rare problem, we would not want it to repeat. ”

This is a long, sad story, the main points of which I tried to describe in detail here, according to the time frame in which they took place.

Nearly 43,000 Chevrolet Bolt electric vehicles were sold in the United States.

According to the company General Motors, only one of all these electric vehicles

under warranty needed to replace the battery is not one, but two times. And who was the winner of this unsuccessful lottery? I.

From the translator:

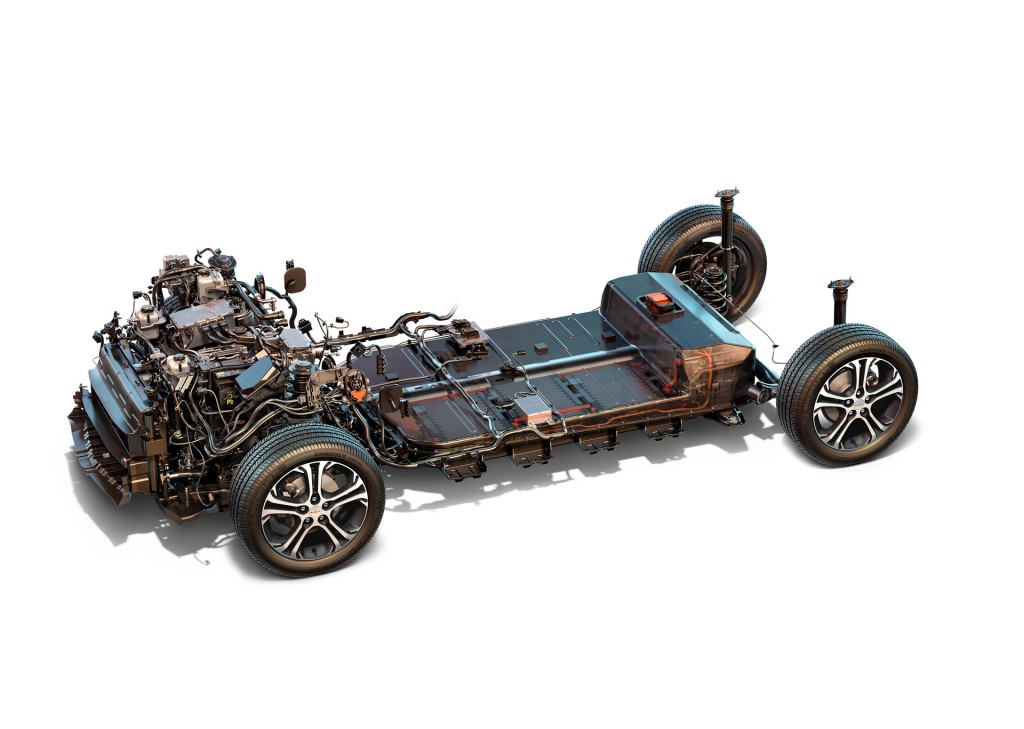

Chevrolet Bolt 2017 model year:

- electric motor power 150 kW (200 hp), torque 360 Nm, single-stage gearbox;

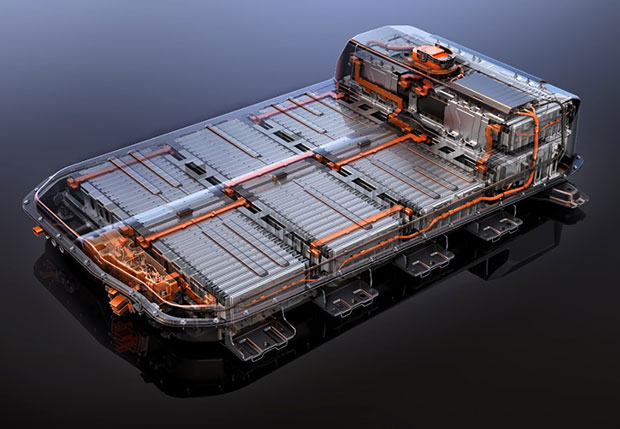

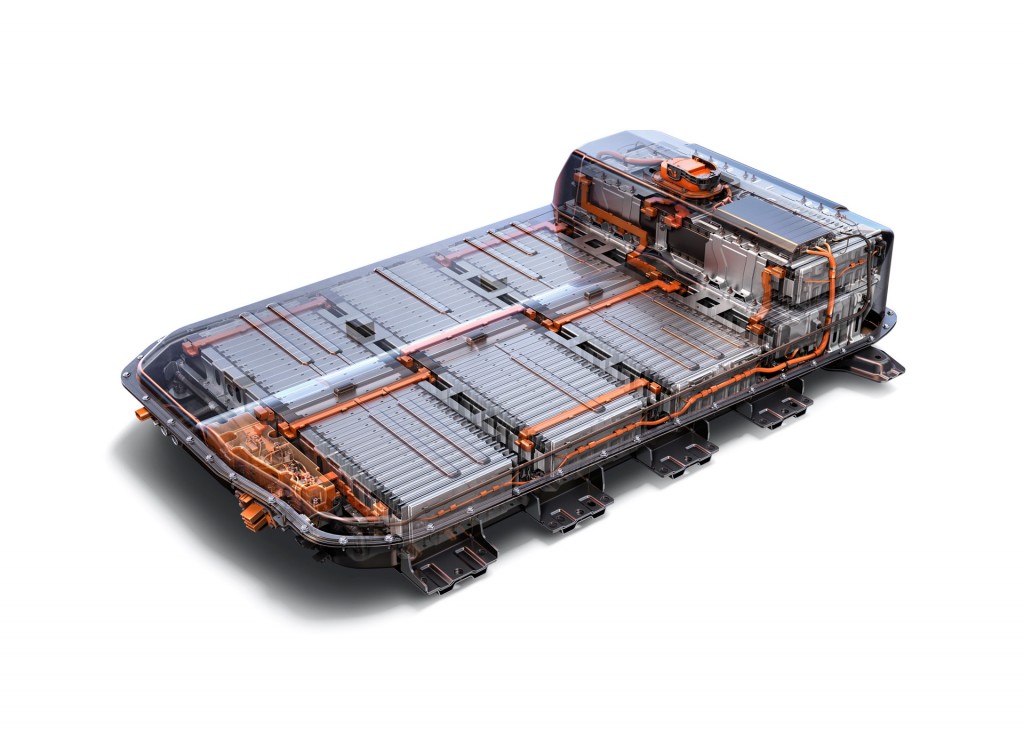

- lithium-ion rechargeable battery 60 kWh (288 cells arranged in 96 groups), the weight of the battery is 435 kg, the warranty on the battery is 8 years or 160,000 km of run.

- power reserve of 380 km at a speed of 60 km / h;

- The maximum speed of 145 km / h;

- dimensions: length - 4166 mm, width - 1765 mm, height - 1595 mm, wheelbase - 2600 mm, ground clearance - 115 mm;

- the weight of the electric car is 1625 kg due to the fact that its body is made of lightweight carbon fiber, and the doors and hood are made of aluminum;

- coefficient of aerodynamic drag (Cx) 0,308;

- cost as standard40905 USD (Manufacture Suggested Retail Price 2017 Chevrolet Bolt EV Premier FWD );

- place of production: state of Michigan, plant Orion Assembly.

The battery assembly for the Chevrolet Bolt was developed by GM in close collaboration with LG, which also manufactures other components for this electric vehicle: an electric climate control system, an integrated charger, an invertible module, power supply components, a high-voltage distribution module, and other elements electrical installations.

For charging from an ordinary electric outlet with a voltage of up to 240 V, the Chevrolet Bolt uses a specially designed device with a power of 7.2 kW. In two hours of recharging, the Chevrolet Bolt battery replenishes with energy that is enough for a distance of 80 km, but using the optional fast charging system (1500 USD) for the Chevrolet Bolt, the battery can be charged for 145 km (up to 50%) in 30 minutes.

Beginning of the story

March 6, 2017: My 2017 Chevrolet Bolt Premier is coming off the assembly line.

June 16, 2017: I fill out all the documents and get an electric car for a three-year rent.

August 8, 2017: In the process of driving my Chevy Bolt stops abruptly, creating a dangerous situation on the road.

August 22, 2017: GM diagnoses a problem in the battery in the battery; in cell No. 25 a reduced voltage level is detected. Under warranty, the entire battery pack is replaced with a new one. On my Chevy Bolt on the odometer 1,746 miles (2,800 km).

August 24, 2017: I publish a report on the situation that happened to me on PluginCars.com . Also additionally report on this sitethat GM warned about 100 Chevy Bolt owners that they might face a similar problem in the process.

September 11, 2017: GM Communications service informs me via e-mail that GM has made “improvements throughout the supply chain” to correct the problem of low voltage levels in battery cells.

September 18, 2017: I found out about other Chevy Bolt drivers (including a pregnant woman on a busy road in Los Angeles) who found themselves in the same situation as me on the side of the road, but were not notified by the company. At GM, they say that data for the OnStar service needs to be collected for some time to identify vehicles that are at risk of falling into a similar situation. Therefore, the new owners of Bolt (or cars at dealer sites) may face the same problem.

OnStar is a set of services developed in partnership with GM. The system consists of three components: a mobile terminal built into the machine; Software interaction of the machine with the service; The “clouds” controlling subscription, collecting data from the machine and accessing the machine from the outside.September 2017 - March 2018: Chevrolet Bolt electric cars with new (updated) batteries look more reliable in operation. GM works closely with LG Chem, the battery supplier, making the necessary changes to the battery manufacturing process. In the company GM consider that the problem with rechargeable batteries is solved.

Early warning software fixes

April 2, 2018: GM is holding a revocable company for the 2017 Chevrolet Bolt. Dealers in recalled Chevrolet Bolt are updating software, including providing more data on the problem of preventing any potential "low voltage conditions in cells" and a sudden loss of power. Adjustment in the software also allows electric vehicles to continue moving after a problem arises with a smaller power reserve, and does not block the operation of the electric vehicle, causing an immediate stop, as it was before.

April 17, 2018: It’s an interesting article that replaces batteries in a previously purchased Chevrolet Bolt.

May 11, 2018: GM releases a new software update for all Chevrolet Bolt owners (not only for 2017 models) to “provide additional alerts.” Later, GM informs me that the software "improves the accuracy of calculating the range of the course, in addition to obtaining additional data on the low charge state of the battery cells."

May 14, 2018: My Chevrolet Bolt receives software updates for April and May. GM tells me that it continues to collect diagnostic data from all Chevrolet Bolt, so that you can “inform the owner of electric vehicles in advance that they need to immediately service the batteries from the dealer as soon as the remote diagnostics of their systems confirm that the batteries have problem cells.”

Deja Vu or again twenty-five

October 2018: I begin to notice a decrease in the power reserve.

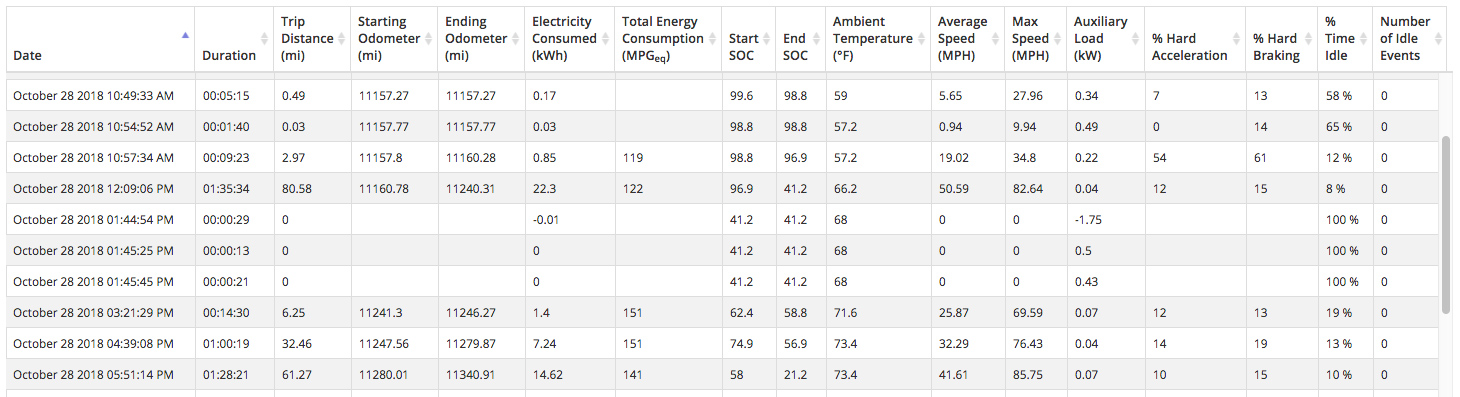

I am starting to use the solution from FleetCarma to collect and analyze data obtained from the diagnostic socket of my Chevrolet Bolt.

November 20, 2018: In an article on InsideEVs.com, I report details on the problem of reducing the range of my electric car after a trip to a distance of 184 miles (296 km) and further charging at the home station, after which, according to my calculations, it became clear that the battery capacity my Chevrolet Bolt has fallen from a standard 60 kWh to a value of 35 kWh.

November 21, 2018: I’ll warn GM about the problem. The GM Communications service responds: "Our engineers find out what could be causing your problem by using remote diagnostics." Later, I was informed that the data on the problem with my Chevrolet Bolt do the same “right up to the management” of the company.

December 3, 2018: I receive a standardized diagnostic warning from the OnStar service, which said: “One of the battery cells has characteristics below the threshold required for good performance. It is necessary to solve the problem, otherwise it may lead to a loss of speed during the process of movement. "

December 2018 - January 2019: I unsuccessfully try to argue with Chevrolet and my local dealer to convince them to pick up my electric car for battery maintenance. The Chevrolet Communications service tells me that my Chevrolet Bolt is safe to drive, albeit with a shorter range.

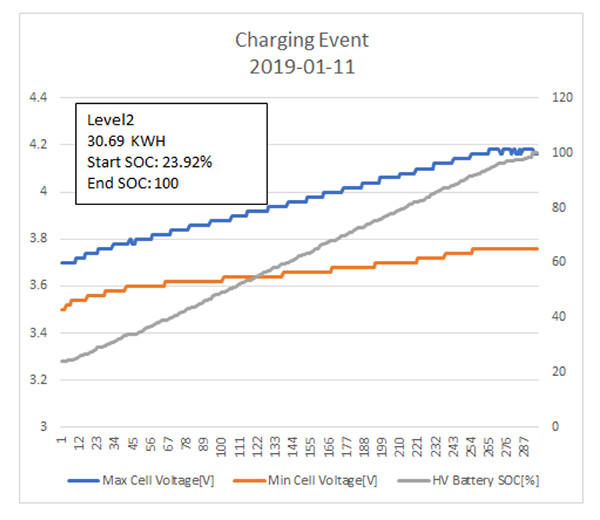

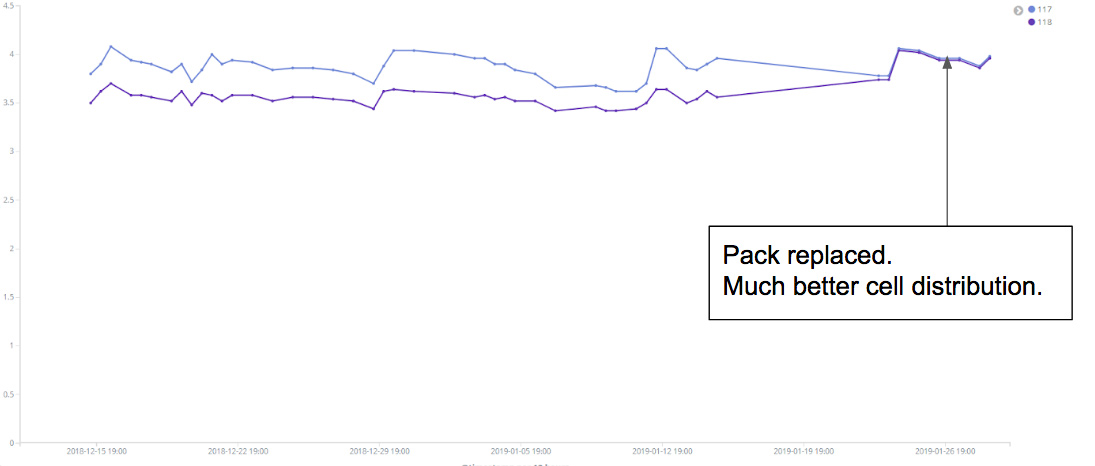

December 2018 - January 2019: I continue to receive and analyze data from the computer system of my Chevrolet Bolt, finding that in the range (from low to high) voltage thresholds on the cells, their permissible levels are exceeded.

Battery SOC (State Of Charge) is the state of charge of the battery.

January 16, 2019: I drive an electric car 25 miles to the nearest Chevy dealership. Diagnostics show that a reduced voltage level is detected in cell No. 68. My Chevrolet Bolt gets a third new battery.

My electric car has 11940 miles (19200 km) on the odometer .

My Chevrolet Bolt returned to the dealer in January to get the third battery:

January - February 2019: I continue to analyze the data from the electric car computer, so far everything indicates that the third battery is fully functional, and the range of the electric car has been restored to the proper level.

Trying to understand the problem

January 2019: After the diagnosis of the second malfunctioning cell in my electric car, GM, working closely with LG Chem, makes additional changes to the battery cell manufacturing process.

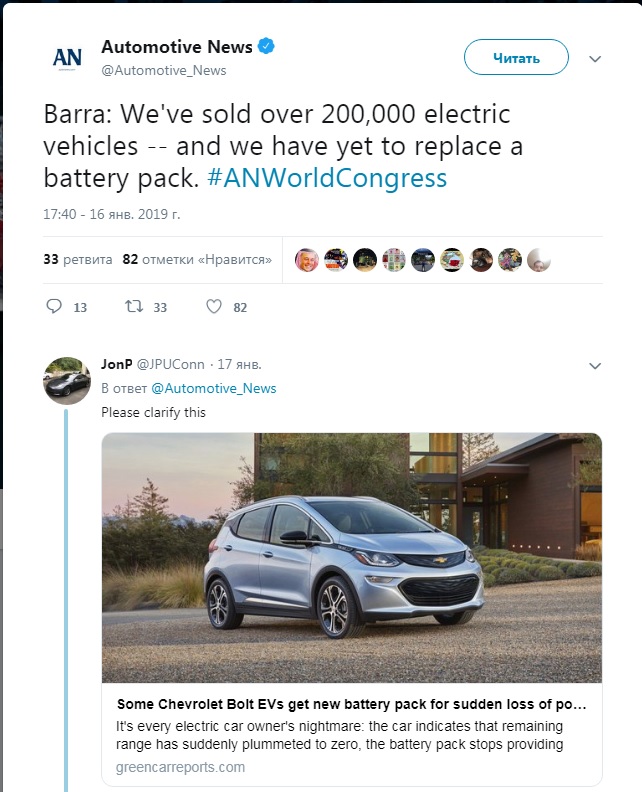

January 16, 2019: Six hours after I left my electric vehicle for the second battery replacement at the dealer, the quote from Automotive News published a quote from GM General Director Mary Barr: “We sold more than 200,000 electric vehicles - we have not yet had to replace batteries. "

Many Chev owners of electric cars on social networks claim that they also had their batteries replaced, some of which received this update in January 2019.

January 18, 2019: Chevrolet Communications Service informs me that “Mary’s initial statement was related to battery wear due to regular use. In fact, at the moment, due to the alleged wear and tear, less than 0.01% of the batteries in the number of sold electric vehicles have been replaced. ”

February 1, 2019: I talked to Tim Greve, chief electrical engineer for General Motors.

Interview with Tim Greve A

conversation with Tim Greve from GM lasted almost 40 minutes. Here are the most interesting moments from the conversation.

Me: Was it the same problem with the operating range of values between low and high cell voltage during incidents with my car in 2017 and 2018?

Tim Greve: Based on the results of the data and from other clients, this led to a decrease in the stroke range and an overall decrease in battery capacity. When you charge a 100% battery, and you have one cell with a voltage different from 4.1 V, and with a lower voltage of 3.8 V, it turns out that this cell does not match the parameters of other cells in the unit. This was not the same problem as the cell production process, although there is a correlation between these problems.

In my second battery, cell No. 68 had a low voltage, creating an imbalance and lowering the range:

I: Help me understand the difference between these two breakdowns in my batteries.

Tim Greve: We have 288 cells in the battery. This number and their placement are related to the size of the cell itself. Many processes occur within cells, which also consist of elements.

As you know, in our world everything is aging and changing accordingly. Batteries and their elements expand, contract and change their characteristics depending on temperature. This is electrochemistry. So, you have two problems that took some time to manifest. There were several very subtle events that occurred in our supply chain and in the process of assembling cells, which eventually led to irreparable changes within the cells.

I: Do you check each cell before it gets to the battery assembly?

Tim Greve: We are conducting intensive testing. When you have collected a cell, it is not yet charged. Then it goes through the formation stage (molding process). The formation phases of the anode and cathode take a long time. We use a quality assurance system, with the help of which we monitor all the processes of production of cell elements. Data on all stages of production are stored for processing and analysis so that even the smallest changes in the production process with the elements do not occur. We also have quality control systems that track the “phenomenon” that occurs with elements and cells before and after their compression.

Me: What do you mean by compression?

Tim Greve: We literally press them together. We fill the space between the elements of high-tech solution. Then we put them all together during the assembly process of the cell module. Each cell is under a certain verified pressure throughout its entire life cycle for a hot and cold state. Even in spite of all the monitoring that we perform in the production process, the indefinite negative “phenomenon” that occurs after such a compression process may affect the parameters of the cell after a sufficiently large amount of time after its production.

Me: When you say "phenomenon", do you mean that some kind of chemical process lowers the ability of the cell elements to hold a certain voltage?

Tim Greve: Yes. Thus, lowering the initial cruising range of 238 miles to 155 miles, as happened to you.

I: This is you about what happened the second time. The first time the system detected a problem, the program said “stop” and just stopped me. But the second time, the system simply recalculated the power reserve on the indicator?

Tim Greve: Exactly. Now, thanks to the preventive approach using the OnStar service, there is an adaptive change in the power reserve for an electric vehicle. Thus, literally, your article on the InsideEV resource was written just at the time when the system had already received the necessary data from your electric car and launched the process in order to be able to quickly resolve this issue with the dealer.

Me: Are you sure that in another month someone will not face the same problem and will not say: - “Hey, why did you not notify me?”

Tim Greve: Very sure. And I don't just say that. You are the only one I know in the second round with such a problem.

Me: There were several recall companies and special service notifications for dealers. Did I miss any of them?

Tim Greve: No We want to be confident, but we also want to be modest, because these are innovative things. We monitor your electric car with the OnStar system to keep track of your situation further. We were one of the first to start producing electric cars with a large stock of progress. We are doing additional predictive work to make sure that everything happens as we expect. We were very upset by your first problem and immediately did everything possible to minimize the number of customers who could have fallen into a similar situation, which would be just awful. From August 2017 to May 2018, we tried to solve the problem as quickly as possible in order to neutralize further such cases with electric vehicles and to stop the snowball effect on this issue.

Me: You say that in part my problem in 2017 led to the development of a new version of the software and a revocable company for all Chevrolet Bolt?

Tim Greve: Right.

Me: And yet, can you tell in more detail about the differences between what happened to me in the first and second cases?

Tim Greve: To create a battery cell, you need to perform hundreds of operations. You take aluminum. You take copper. You layer nickel, manganese and cobalt on the cathode material, and then you apply graphite to the anode. Then you have something called a “separator” that prevents these electrodes from touching each other. And then you must place many such plates in parallel, slowly assembling the elements of the cell. Between August 2017 and January 2019, there were various subtle manufacturing problems that caused the problem of electric vehicle power loss before the end of battery life. It’s not quite accurate to say that these were the same problems or different. They were hardly distinguishable for test equipment. Both problems led to a loss of power, but for very different reasons. This will require long technical explanations,

Me: So you found the place where the problem occurred?

Tim Greve: We know exactly what happened. Applying tools, maintenance schedules, and the like are very complex things. It was best practice with LG Chem. This was our best experience with previous battery versions. We needed to do some things differently. Not necessarily better, just different.

Me: Do you mean the packaging process?

Tim Greve: Production Process. The battery assembly lab is like a newspaper printing press. You start with these huge rolls of paper. In our case it is copper, and then it passes through this coating machine, and then you press it. Then you heat and cut. And then you put the cut elements into newspapers, and at some of these stages of the process there are very complex and inconspicuous things that can affect cell elements in different ways, up to the degradation of its properties over a long time.

Me: Have you made any changes to this process?

Tim Greve: 100 percent. We not only solved the problem, but also conducted additional monitoring to make sure that it will never happen again. In each case, we work directly with our supply chain. We fix it there and add the possibility of monitoring there after the fix.

Me: Can a similar problem occur somewhere else in one of the other hundreds of operations that have been heard above? And how do you do this additional monitoring, and also improve these operations?

Tim Greve: This was due to maintenance and monitoring schedules. We did not just study only one operation, which was the main cause of the problem with your cell. We studied the effect of this problem for all other similar operations and we improved them, and also increased the monitoring of these operations.

Me: These corrections occurred only after problems in 2017 or after a later event?

Tim Greve: We made some improvements in 2017 and 2018. But this was not enough. For example, now, according to our data, the cells in your new 2019 battery are superdense compared to the 2017 version. This will be proof that we finally nailed this thing. But we are going to continue monitoring with the OnStar system to make sure that this is true.

Me: About 100 people experienced the problem in 2017. Could one or more of these 100 people have a similar fault the second time, like mine?

Tim Greve: We found only one. You're special.

From the translator:

About the maintenance of electric vehicles.

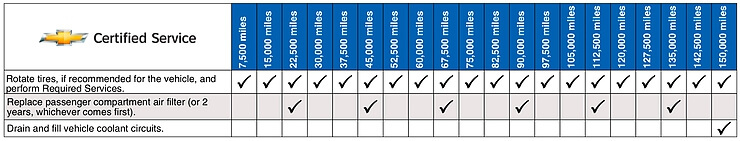

This is a list of service positions for servicing an electric Chevrolet Bolt. As you can see, in addition to checking the wheels, servicing the electric vehicle components and replacing the air filter - the amount of work is less than in cars with internal combustion engines.

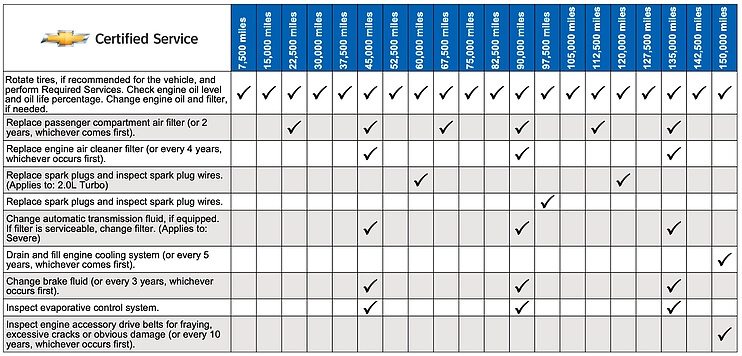

And here is a list of service positions for servicing Chevrolet Malibu.

By the way, manufacturers of hybrids also have similar problems, here is a very recent review of priuses in the Russian Federation from February 11. Very similar - the loss of power and stop.