Samsung Solid State Drives: Boosting Speed

As time goes on, everything around is changing and technology is no exception. If a few years ago, hosting on solid-state drives was a novelty, but now this is the norm. Not so long ago, SSDs of even a small volume cost good money, because hosters, as a rule, provided “hybrid” SSD hosting for the sake of economy: they placed customer databases on solid-state drives, and the rest of the site files on ordinary hard drives. When SSDs became more affordable, companies began to switch their hosting infrastructure entirely to solid state drives. High throughput and low transaction latency dictate many data centers to choose to use solid-state drives (SSD), instead of hard drives (HDD). In turn, this avoids a delay in performance, increases the efficiency and reliability of the server farm, and also makes it possible to reduce operating costs. We were no exception and for quite some time we have been providing virtual hosting on ultra-fast SSD storage.

Often, choosing the right SSD for the data center is a long and complicated process, you need to study and evaluate many different suppliers, types of SSDs, since it is known that not all NAND flash drives and types of flash memory available on the market are the same. The wrong choice of solid state drives for long-term use on server farms is fraught not only with financial negative consequences. The drive may fail prematurely, a constant write speed will decrease, while delays in the drive array, on the contrary, will increase.

Many of our servers that we provide to our customers use Samsung SSDs. Back in 2014, Samsung Electronics announced the start of mass production of the first 3D NAND flash memory (known as V-NAND) in the 850 Pro and 850 EVO SATA SSD series. SSD 850 Pro became the first serial flash drive, which was made on the basis of 32-layer technology MLC 3D V-NAND.

Until 2013, Samsung Electronics was the only manufacturer of SSDs on the TLC NAND. The well-known 840 EVO model with 19 nm TLC NAND and a 128 Gb crystal density has successfully occupied high market positions since 2011. At the moment, the company is deservedly not only the leader in the production of consumer SSDs, but also the main innovator in this field. It is safe to say that over the past few years, Samsung has conquered this market. According to Trendfocus, the company’s share reached nearly 40% of the global solid-state drive market.

The SSD 830 (2011) and 840 Pro (2014) were among the first solid-state drives that brought Samsung's product to the so-called “gold standard”. These products quickly occupied their niche and received the title of the best SATA SSD for high-performance personal computers of the upper price segment. For mass users were released drives series 840 and 840 EVO. The innovation was the use of three-bit TLC NAND in drives. Thanks to the use of this technology, the cost of the product was significantly reduced, and the company was ahead of its competitors by a couple of years. The MDX controller and TLC NAND developed by the company ensured the high performance of the 840 PRO.

Over time, Samsung launched a three-dimensional flash memory, known as 3D V-NAND, into serial production. Thanks to it, the problem of scalability of flash memory crystals was solved, and a further increase in the data storage density in crystals became possible by placing cells in three planes. As already mentioned, in 2014, Samsung Electronics announced the start of mass production of the first 3D NAND flash memory in the 850 Pro and 850 EVO SATA SSD series. In turn, the SSD 850 Pro became the first serial flash drive, which was made on the basis of 32-layer technology MLC 3D V-NAND.

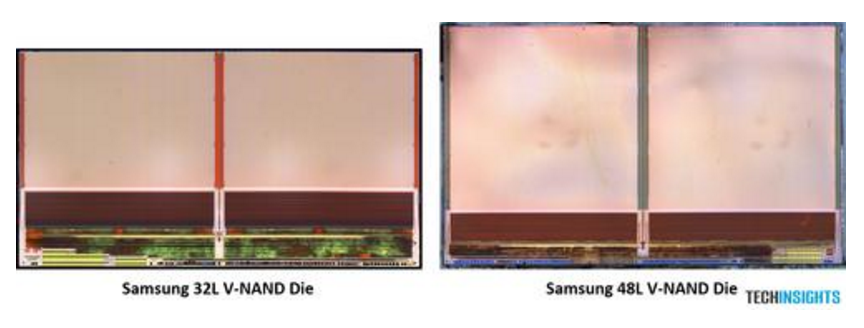

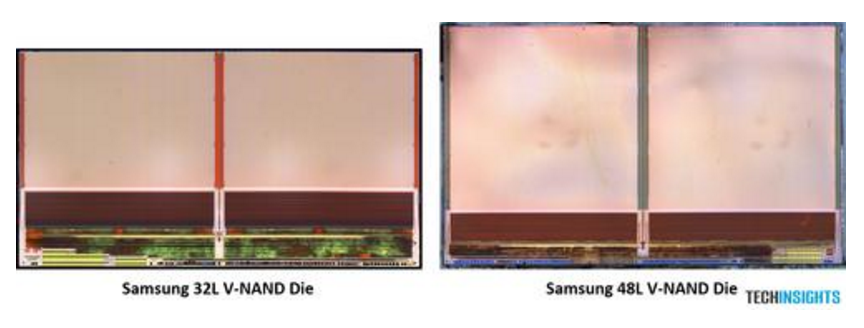

During use, 3D V-NAND technology has shown its best side, thanks to the location of the memory cells in the stack, the chip area is used more efficiently, and more memory cells can be placed on the chip. The first generation of V-NAND has 24 vertically folded layers of memory cells, the second generation is 32, and the third generation is 48. By the way, the use of SSDs based on V-NAND first generation improved performance by 20 percent and doubled reliability. This was the impetus for the next innovative developments of the second and third generation V-NAND.

The 850 Pro SSD (based on the 32-layer MLC 3D V-NAND) is characterized by a significant increase in performance and reliability. If we talk about its value, then it is quite high. Therefore, the company began developing a mass product that could combine high performance, reliability, but at the same time remain affordable. So saw the light of the 850 Series EVO SSD, whose three-dimensional flash memory combined the multi-layer 3D V-NAND and TLC NAND architecture.

At the moment, 850 PRO and 850 EVO senior volumes are two different products. The 850 PRO uses two-bit MLC memory, and the 850 EVO uses a three-bit TLC.

The 850 series of solid state drives is constantly evolving; in 2015, the company released a 2 TB SSD. The capacity of the 32-layer MLC V-NAND used in the 850 Pro semiconductor crystals increased from 86 Gbps to 128 Gbps. In 850 EVO, the capacity remained the same -128 Gb. Such a capacity of crystals in 850 EVO was previously explained by the recording in each cell of not two, but three bits of information.

Later in 2015, Samsung announced the start of mass production of 256-Gb 3D V-NAND flash memory chips. They used the third-generation V-NAND - 48-layer three-bit TLC memory. Thanks to the use of used semiconductor crystals with a capacity of 256 Gbps on one substrate, it became possible to produce SSDs with a capacity of several terabytes. In early 2016, it was planned to transfer the existing 850 and 950 series to the new third generation V-NAND. But the transition to new technologies was not so quick in practice.

The 850 EVO series drives were updated with the new third-generation TLC 3D V-NAND of the third generation (the number of layers and the capacity of the crystals increased). It should be noted that for the production of the new TLC 3D V-NAND of the third generation, a finer process technology was applied.

The third-generation TLC 3D V-NAND flash memory chips of the third generation consume 30% less energy than their predecessors, but at the same time 40% smaller in size, which made it possible to reduce the cost of storage.

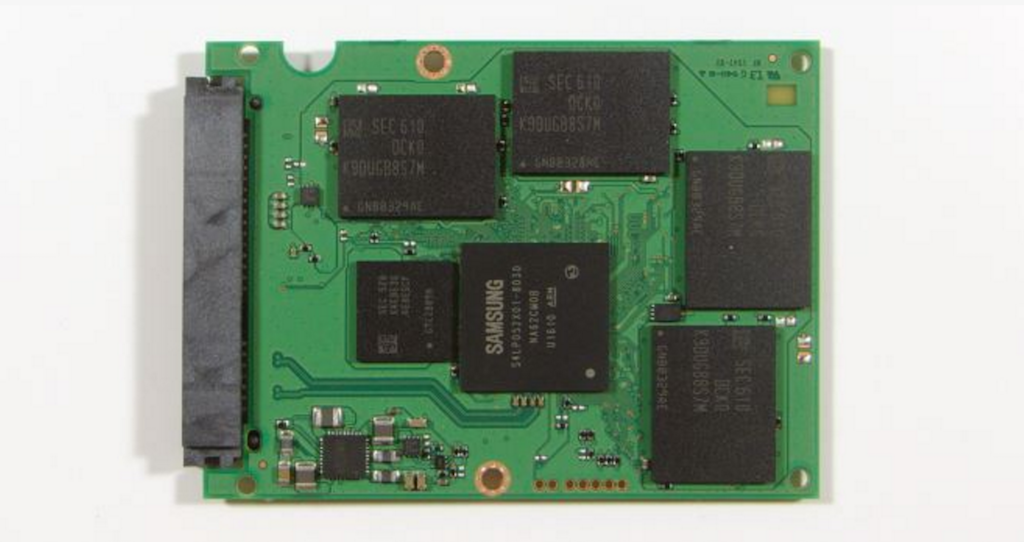

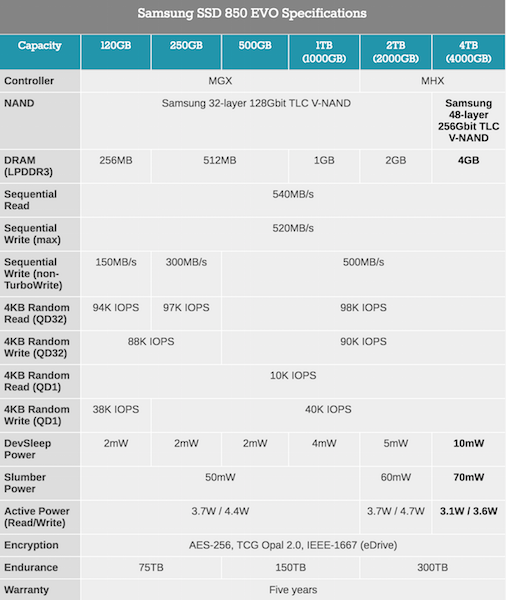

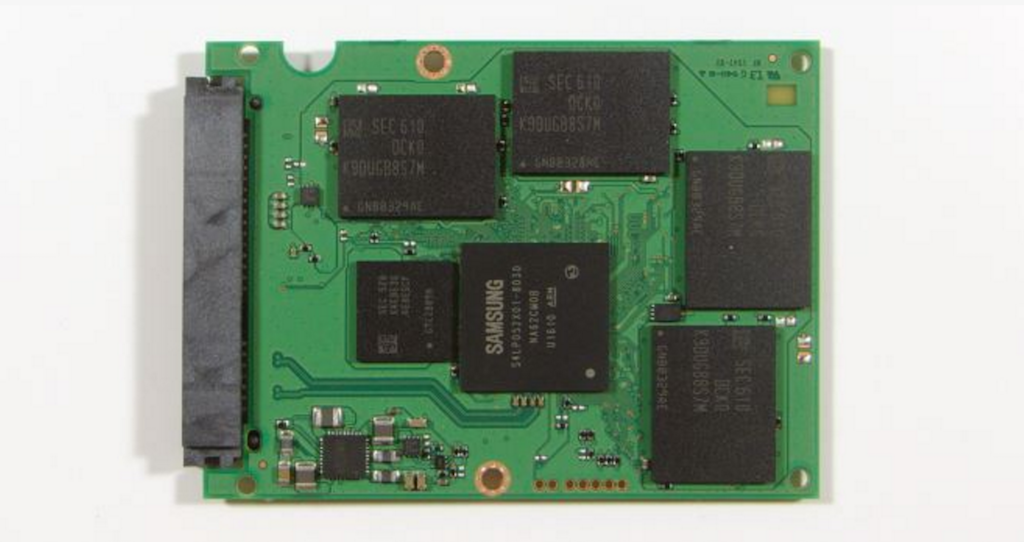

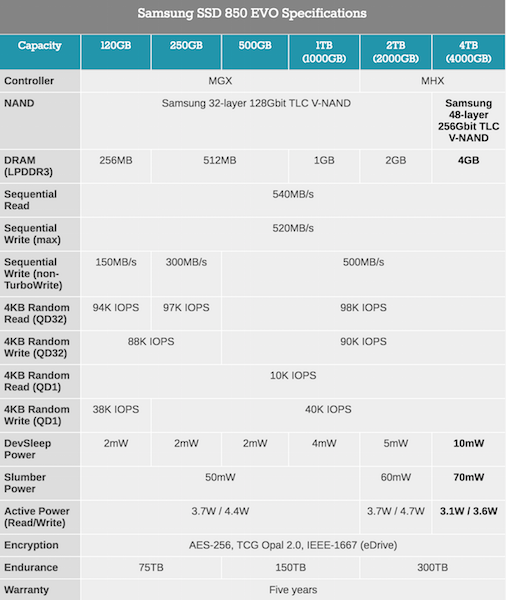

The use of the third generation 48-layer TLC 3D V-NAND of the third generation made it possible to increase the capacity of the solid-state drive to 4 TB while maintaining the familiar form factor (2.5 inches). The 850 Series SSDs with capacities up to 1 TB used the MGX controller, while 2 and 4 TB used the MHX. The MHX controller, which was used in the 850 TB 2 EVO SSD, supports 4 GB of DRAM, therefore it was also used in the 4 TB SSD 850 EVO. The 850 EVO v2 DRAM comes with a more modern type of memory standard LPDDR3. At the same time, its size remained the same, for every gigabyte of storage capacity there is 1 MB of buffer capacity.

It would seem that with the increase in the technical characteristics of the solid-state drive, namely, the capacity from 1 TB to 4 TB, the data transfer rate should also increase. But, as we see with the advent of 4 TB, the Samsung 850 EVO is able to read and write data at a speed close to the bandwidth limit of the SATA 6 Gb / s interface, which is identical to the 850 EVO with a capacity of 500 GB, 1 TB, and 2 TB. The maximum speed of arbitrary read / write at the level of 98000/90000 input / output operations per second (input / output operations per second) for blocks of 4 KB. The power consumption of such a drive is 3.1 / 3.6 W during active read / write operations.

A few words about the warranty resource of the SSD 850 EVO 4 TB drive. Samsung provides a 5-year warranty or 300 TB of recordings on these drives; it goes no more than on an SSD 850 EVO 2 TB, so there’s nothing to please users at this point. At the same time, thanks to the new third-generation V-NAND, four-terabyte solid-state drives will please some innovations. In addition to increasing the number of levels from 32 to 48, some changes have been made to the development called “charge-trap” used in V-NAND (a floating-gate transistor is used in the NAND planar flash memory) : added an additional metal layer between the compounds, the I / O placement area on the crystal became more thoughtful and compact, as a result of which the cell density increased from 1,

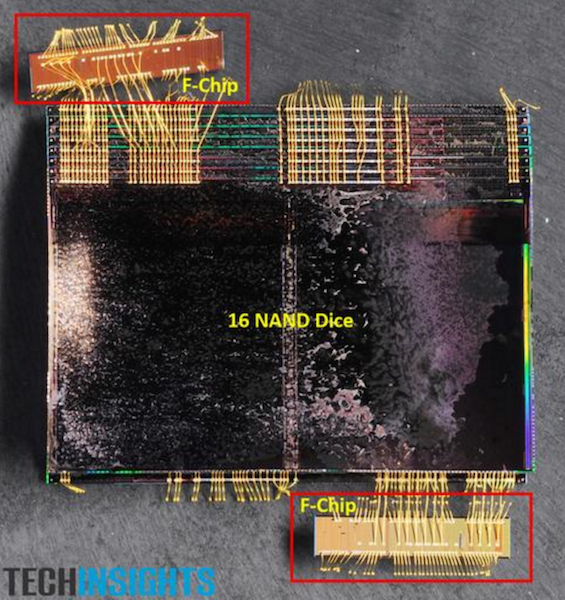

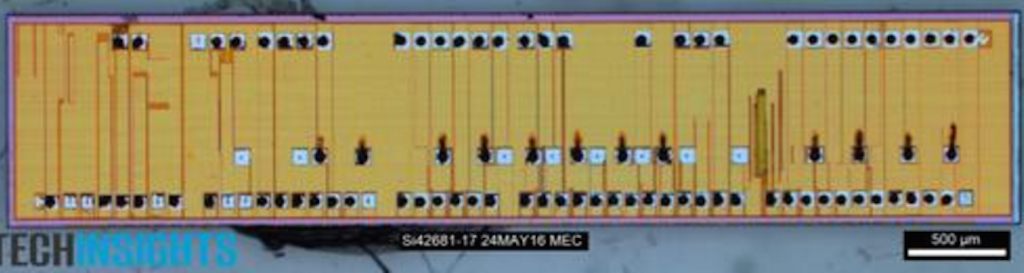

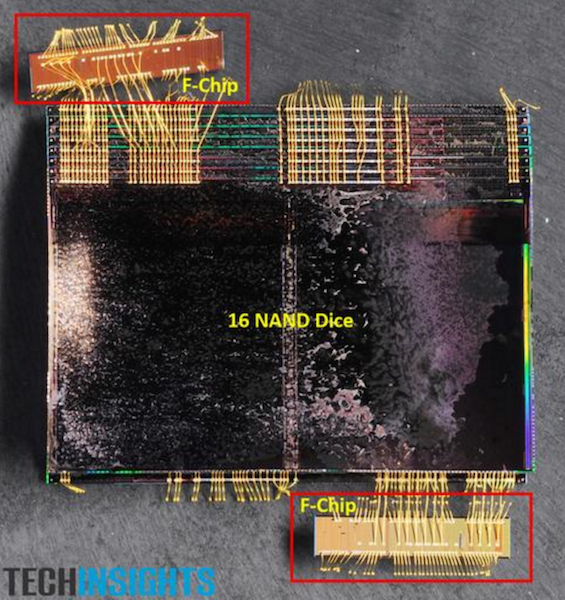

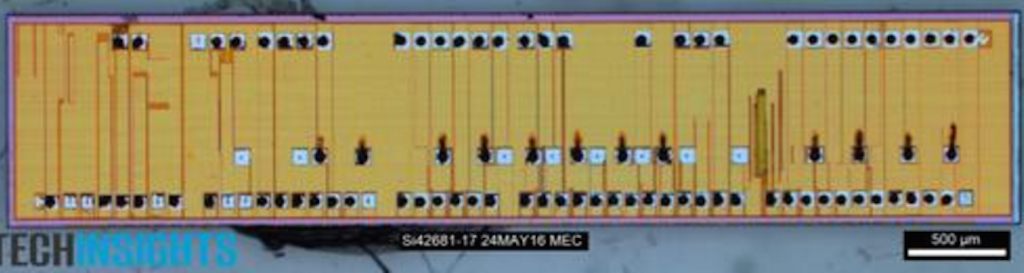

Another “trick” Samsung is F-Chip, which the company presented at the ISSCC in 2015. Basically, the hardware architecture of SSDs consists of a controller, NAND flash, and DRAM. F-Chip works on the same principle as FB-DIMMs (Fully Buffered Dual In-Line Memory Module) for DRAM. Recall that FB-DIMM is a new type of server memory that can significantly increase the frequency of the modules while reducing the number of conductors and, thanks to the serial interface, increase the total memory on the server, each FB-DIMM module contains an Advanced Memory Buffer chip, it provides high-speed buffering and conversion all signals, not only data but also address transmission. So, instead of directly connecting the SSD controller to the NAND chip stack using a multi-drop bus, F-Chip is used - an interface that connects SSDs with two groups of 4 NAND crystals. Due to the fact that the small F-Chip includes the same BGA package as the NAND stack, only 4 chips are used to connect to NAND instead of 8 or 16. The area occupied by the F-Chip is 0.057 mm ^ 2.

Compare it with corporate SSDs whose performance and indicators are an order of magnitude higher than that of consumer systems? It would also not be entirely true. Solid state drives of this capacity are usually designed for servers and data centers, they support a number of technologies that increase reliability and performance, and, consequently, the price for them is higher. For example, Samsung’s 3.84 TB Samsung-made PM863 (SATA) drive costs about $ 2,200, and PM1633 (SAS) 3.84 TB on the market starts at $ 3,092. It is no secret that the limit on the price of solid-state drives of greater performance, capacity and endurance can vary ("infinity is not the limit"). The companies have already introduced 2.5-inch SSDs with a capacity of over 10 TB on the market, the price, respectively, over $ 10,000, for $ 20,000 and more specialized solutions can be ordered.

Last year, Samsung announced its fourth generation 64-layer 3D NAND. This fourth-generation V-NAND is currently in mass production and will be available in many product segments in the coming months. Most products will use either 256 GB or 512 GB of TLC-matrix.

64-Gigabyte 256 Gb V-NAND and 1-TB M.2 SSD Chips

Compared to the third-generation 48-layer V-NAND, the 64-layer V-NAND provides the same read performance but offers 11% better write performance. Improved energy consumption. Samsung claims their 64-layer V-NAND TLC is designed for between 7,000 and 20,000 total read / write cycles. The manufacture of 64-layer 256 GB chips indicates that Samsung is currently increasing the production of its fourth-generation V-NAND chips, it is logical to expect new products based on such chips (for example, SSDs, memory cards, etc.).

Last week, Samsung announced the fifth-generation 96-layer V-NAND. Samsung’s fifth-generation flash memory is QLC NAND (can store four bits in one cell) with a capacity of 128 GB.

Samsung also introduced an updated version of Z-NAND memory, the advantage of which is to provide less latency than the existing flash memory. Modification of the existing 3D architecture of V-NAND based on SLC cells gives a reading latency of 3µs, which provides 15 times higher speed compared to V-NAND flash memory (MLC or TLC). Their first product built by Z-NAND is the Z-SSD SZ985 with a total read latency of less than 15µs. SZ985 Z-SSDs are 5.5 times faster than TLC-based high-performance enterprise-class SSDs. Samsung introduced the second generation of the Z-NAND, based on the MLC NAND instead of the SLC. Although the latency for reading operations is 5µs, instead of 3µs, a higher data storage density is provided. In addition to the promising new Z-NAND memory technology,

Among the presented SSDs (based on the aforementioned V-NAND technologies) is a 128-bit 2.5-inch SAS SSD based on QLC V-NAND. The crystals will be packed in 32-crystal structures (stacks), and such an SSD will be placed in a BGA-type case.

Samsung tentatively introduced the form factor for the enterprise-class SSD that it currently called NGSFF. A printed circuit board measuring 30.5 mm x 110 mm is significantly wider than the common M.2 form factors. Due to the fact that the printed circuit board is built on a metal base, hot-swappable storage is possible. Samsung demonstrated a 1U server codenamed “Mission Peak”, where the total capacity of 36 PM983 SSDs in the NGSFF form factor was 576TB, each 16TB SSD.

Samsung is developing a new key / value technology with which SSDs do not transform data into blocks during processing. The name of the technology itself speaks for itself - the “key” key provides the ability to directly address the location of the data, as a result we get scalable performance and capacity parameters, increasing the speed of data input and output. Samsung's Enterprice SSDs support the NVMe 1.3 Controller Memory Buffer and IO Determinism functions, which helps to avoid blocking operations with one set and operations with another set.

Time does not stand still, the creation and implementation of new technologies, respectively, too. In the market today, a variety of offers are presented that will optimally satisfy any user. Everything is limited only by your needs and capabilities.

As an advertisement. Stock! Only now get up to 4 months of free use of VPS (KVM) with dedicated drives in the Netherlands and the USA (configurations from VPS (KVM) - E5-2650v4 (6 Cores) / 10GB DDR4 / 240GB SSD or 4TB HDD / 1Gbps 10TB - $ 29 / month and above, options with RAID1 and RAID10 are available) , a full-fledged analogue of dedicated servers, when ordering for a period of 1-12 months, the terms of the action are here, existing subscribers can get 2 months as a bonus!

How to build the infrastructure of the building. class using Dell R730xd E5-2650 v4 servers costing 9,000 euros for a penny?

Often, choosing the right SSD for the data center is a long and complicated process, you need to study and evaluate many different suppliers, types of SSDs, since it is known that not all NAND flash drives and types of flash memory available on the market are the same. The wrong choice of solid state drives for long-term use on server farms is fraught not only with financial negative consequences. The drive may fail prematurely, a constant write speed will decrease, while delays in the drive array, on the contrary, will increase.

Many of our servers that we provide to our customers use Samsung SSDs. Back in 2014, Samsung Electronics announced the start of mass production of the first 3D NAND flash memory (known as V-NAND) in the 850 Pro and 850 EVO SATA SSD series. SSD 850 Pro became the first serial flash drive, which was made on the basis of 32-layer technology MLC 3D V-NAND.

Until 2013, Samsung Electronics was the only manufacturer of SSDs on the TLC NAND. The well-known 840 EVO model with 19 nm TLC NAND and a 128 Gb crystal density has successfully occupied high market positions since 2011. At the moment, the company is deservedly not only the leader in the production of consumer SSDs, but also the main innovator in this field. It is safe to say that over the past few years, Samsung has conquered this market. According to Trendfocus, the company’s share reached nearly 40% of the global solid-state drive market.

The SSD 830 (2011) and 840 Pro (2014) were among the first solid-state drives that brought Samsung's product to the so-called “gold standard”. These products quickly occupied their niche and received the title of the best SATA SSD for high-performance personal computers of the upper price segment. For mass users were released drives series 840 and 840 EVO. The innovation was the use of three-bit TLC NAND in drives. Thanks to the use of this technology, the cost of the product was significantly reduced, and the company was ahead of its competitors by a couple of years. The MDX controller and TLC NAND developed by the company ensured the high performance of the 840 PRO.

Over time, Samsung launched a three-dimensional flash memory, known as 3D V-NAND, into serial production. Thanks to it, the problem of scalability of flash memory crystals was solved, and a further increase in the data storage density in crystals became possible by placing cells in three planes. As already mentioned, in 2014, Samsung Electronics announced the start of mass production of the first 3D NAND flash memory in the 850 Pro and 850 EVO SATA SSD series. In turn, the SSD 850 Pro became the first serial flash drive, which was made on the basis of 32-layer technology MLC 3D V-NAND.

During use, 3D V-NAND technology has shown its best side, thanks to the location of the memory cells in the stack, the chip area is used more efficiently, and more memory cells can be placed on the chip. The first generation of V-NAND has 24 vertically folded layers of memory cells, the second generation is 32, and the third generation is 48. By the way, the use of SSDs based on V-NAND first generation improved performance by 20 percent and doubled reliability. This was the impetus for the next innovative developments of the second and third generation V-NAND.

The 850 Pro SSD (based on the 32-layer MLC 3D V-NAND) is characterized by a significant increase in performance and reliability. If we talk about its value, then it is quite high. Therefore, the company began developing a mass product that could combine high performance, reliability, but at the same time remain affordable. So saw the light of the 850 Series EVO SSD, whose three-dimensional flash memory combined the multi-layer 3D V-NAND and TLC NAND architecture.

At the moment, 850 PRO and 850 EVO senior volumes are two different products. The 850 PRO uses two-bit MLC memory, and the 850 EVO uses a three-bit TLC.

The 850 series of solid state drives is constantly evolving; in 2015, the company released a 2 TB SSD. The capacity of the 32-layer MLC V-NAND used in the 850 Pro semiconductor crystals increased from 86 Gbps to 128 Gbps. In 850 EVO, the capacity remained the same -128 Gb. Such a capacity of crystals in 850 EVO was previously explained by the recording in each cell of not two, but three bits of information.

Later in 2015, Samsung announced the start of mass production of 256-Gb 3D V-NAND flash memory chips. They used the third-generation V-NAND - 48-layer three-bit TLC memory. Thanks to the use of used semiconductor crystals with a capacity of 256 Gbps on one substrate, it became possible to produce SSDs with a capacity of several terabytes. In early 2016, it was planned to transfer the existing 850 and 950 series to the new third generation V-NAND. But the transition to new technologies was not so quick in practice.

The 850 EVO series drives were updated with the new third-generation TLC 3D V-NAND of the third generation (the number of layers and the capacity of the crystals increased). It should be noted that for the production of the new TLC 3D V-NAND of the third generation, a finer process technology was applied.

The third-generation TLC 3D V-NAND flash memory chips of the third generation consume 30% less energy than their predecessors, but at the same time 40% smaller in size, which made it possible to reduce the cost of storage.

The use of the third generation 48-layer TLC 3D V-NAND of the third generation made it possible to increase the capacity of the solid-state drive to 4 TB while maintaining the familiar form factor (2.5 inches). The 850 Series SSDs with capacities up to 1 TB used the MGX controller, while 2 and 4 TB used the MHX. The MHX controller, which was used in the 850 TB 2 EVO SSD, supports 4 GB of DRAM, therefore it was also used in the 4 TB SSD 850 EVO. The 850 EVO v2 DRAM comes with a more modern type of memory standard LPDDR3. At the same time, its size remained the same, for every gigabyte of storage capacity there is 1 MB of buffer capacity.

It would seem that with the increase in the technical characteristics of the solid-state drive, namely, the capacity from 1 TB to 4 TB, the data transfer rate should also increase. But, as we see with the advent of 4 TB, the Samsung 850 EVO is able to read and write data at a speed close to the bandwidth limit of the SATA 6 Gb / s interface, which is identical to the 850 EVO with a capacity of 500 GB, 1 TB, and 2 TB. The maximum speed of arbitrary read / write at the level of 98000/90000 input / output operations per second (input / output operations per second) for blocks of 4 KB. The power consumption of such a drive is 3.1 / 3.6 W during active read / write operations.

A few words about the warranty resource of the SSD 850 EVO 4 TB drive. Samsung provides a 5-year warranty or 300 TB of recordings on these drives; it goes no more than on an SSD 850 EVO 2 TB, so there’s nothing to please users at this point. At the same time, thanks to the new third-generation V-NAND, four-terabyte solid-state drives will please some innovations. In addition to increasing the number of levels from 32 to 48, some changes have been made to the development called “charge-trap” used in V-NAND (a floating-gate transistor is used in the NAND planar flash memory) : added an additional metal layer between the compounds, the I / O placement area on the crystal became more thoughtful and compact, as a result of which the cell density increased from 1,

Another “trick” Samsung is F-Chip, which the company presented at the ISSCC in 2015. Basically, the hardware architecture of SSDs consists of a controller, NAND flash, and DRAM. F-Chip works on the same principle as FB-DIMMs (Fully Buffered Dual In-Line Memory Module) for DRAM. Recall that FB-DIMM is a new type of server memory that can significantly increase the frequency of the modules while reducing the number of conductors and, thanks to the serial interface, increase the total memory on the server, each FB-DIMM module contains an Advanced Memory Buffer chip, it provides high-speed buffering and conversion all signals, not only data but also address transmission. So, instead of directly connecting the SSD controller to the NAND chip stack using a multi-drop bus, F-Chip is used - an interface that connects SSDs with two groups of 4 NAND crystals. Due to the fact that the small F-Chip includes the same BGA package as the NAND stack, only 4 chips are used to connect to NAND instead of 8 or 16. The area occupied by the F-Chip is 0.057 mm ^ 2.

Compare it with corporate SSDs whose performance and indicators are an order of magnitude higher than that of consumer systems? It would also not be entirely true. Solid state drives of this capacity are usually designed for servers and data centers, they support a number of technologies that increase reliability and performance, and, consequently, the price for them is higher. For example, Samsung’s 3.84 TB Samsung-made PM863 (SATA) drive costs about $ 2,200, and PM1633 (SAS) 3.84 TB on the market starts at $ 3,092. It is no secret that the limit on the price of solid-state drives of greater performance, capacity and endurance can vary ("infinity is not the limit"). The companies have already introduced 2.5-inch SSDs with a capacity of over 10 TB on the market, the price, respectively, over $ 10,000, for $ 20,000 and more specialized solutions can be ordered.

A few words about innovations from Samsung

2016 year

Last year, Samsung announced its fourth generation 64-layer 3D NAND. This fourth-generation V-NAND is currently in mass production and will be available in many product segments in the coming months. Most products will use either 256 GB or 512 GB of TLC-matrix.

64-Gigabyte 256 Gb V-NAND and 1-TB M.2 SSD Chips

Compared to the third-generation 48-layer V-NAND, the 64-layer V-NAND provides the same read performance but offers 11% better write performance. Improved energy consumption. Samsung claims their 64-layer V-NAND TLC is designed for between 7,000 and 20,000 total read / write cycles. The manufacture of 64-layer 256 GB chips indicates that Samsung is currently increasing the production of its fourth-generation V-NAND chips, it is logical to expect new products based on such chips (for example, SSDs, memory cards, etc.).

2017 year

Last week, Samsung announced the fifth-generation 96-layer V-NAND. Samsung’s fifth-generation flash memory is QLC NAND (can store four bits in one cell) with a capacity of 128 GB.

Samsung also introduced an updated version of Z-NAND memory, the advantage of which is to provide less latency than the existing flash memory. Modification of the existing 3D architecture of V-NAND based on SLC cells gives a reading latency of 3µs, which provides 15 times higher speed compared to V-NAND flash memory (MLC or TLC). Their first product built by Z-NAND is the Z-SSD SZ985 with a total read latency of less than 15µs. SZ985 Z-SSDs are 5.5 times faster than TLC-based high-performance enterprise-class SSDs. Samsung introduced the second generation of the Z-NAND, based on the MLC NAND instead of the SLC. Although the latency for reading operations is 5µs, instead of 3µs, a higher data storage density is provided. In addition to the promising new Z-NAND memory technology,

Among the presented SSDs (based on the aforementioned V-NAND technologies) is a 128-bit 2.5-inch SAS SSD based on QLC V-NAND. The crystals will be packed in 32-crystal structures (stacks), and such an SSD will be placed in a BGA-type case.

Samsung tentatively introduced the form factor for the enterprise-class SSD that it currently called NGSFF. A printed circuit board measuring 30.5 mm x 110 mm is significantly wider than the common M.2 form factors. Due to the fact that the printed circuit board is built on a metal base, hot-swappable storage is possible. Samsung demonstrated a 1U server codenamed “Mission Peak”, where the total capacity of 36 PM983 SSDs in the NGSFF form factor was 576TB, each 16TB SSD.

Samsung is developing a new key / value technology with which SSDs do not transform data into blocks during processing. The name of the technology itself speaks for itself - the “key” key provides the ability to directly address the location of the data, as a result we get scalable performance and capacity parameters, increasing the speed of data input and output. Samsung's Enterprice SSDs support the NVMe 1.3 Controller Memory Buffer and IO Determinism functions, which helps to avoid blocking operations with one set and operations with another set.

Time does not stand still, the creation and implementation of new technologies, respectively, too. In the market today, a variety of offers are presented that will optimally satisfy any user. Everything is limited only by your needs and capabilities.

As an advertisement. Stock! Only now get up to 4 months of free use of VPS (KVM) with dedicated drives in the Netherlands and the USA (configurations from VPS (KVM) - E5-2650v4 (6 Cores) / 10GB DDR4 / 240GB SSD or 4TB HDD / 1Gbps 10TB - $ 29 / month and above, options with RAID1 and RAID10 are available) , a full-fledged analogue of dedicated servers, when ordering for a period of 1-12 months, the terms of the action are here, existing subscribers can get 2 months as a bonus!

How to build the infrastructure of the building. class using Dell R730xd E5-2650 v4 servers costing 9,000 euros for a penny?