Laboratory Automation

I am a graduate student of the Institute of Metallophysics, I am studying the properties of various metals and alloys. The measurement and analysis process is usually laborious and requires a lot of routine work. In this regard, the automation of the installation for studying the optical properties of metals was performed. I will tell about how it was later in the publication.

To develop software for managing the preparation and conduct of the experiment on an automated optical ellipsometer.

During the measurement process, the program must control the stepper drives by performing a two-dimensional scan. The minimum scanning step depends on the installation options. The number of dots per range is determined by the size of the range and the scan step.

The experimental parameters (measurement range, scanning step) do not change during the measurement. Scanning is discrete in steps.

Measurement is performed only when the drives are stopped. After the measurement is performed, a move command is given to the next step, and transport movement is performed. The voltage on the PMT is regulated using PWM .

I chose C # as the programming language, as it has out of the box many useful functions for working with USB, COM ports, native support for Microsoft Office, etc.

So, to receive data and send commands to the microcontroller, we will use the virtual COM port:

To convert the analog signal, I used the 16-bit ADC from ICP Das , for which there is an SDK on the official website, so reading data from the ADC is trivial:

A bit of math, calculating optical constants:

The function of determining the drift of "zero" signal:

The photoelectronic multiplier is terribly non-linear, therefore, it has different sensitivity in different parts of the spectrum and it is necessary to maintain a constant signal within the established limits (for our measurements, this is the range 300 - 850 mV with the optimal signal-to-noise ratio):

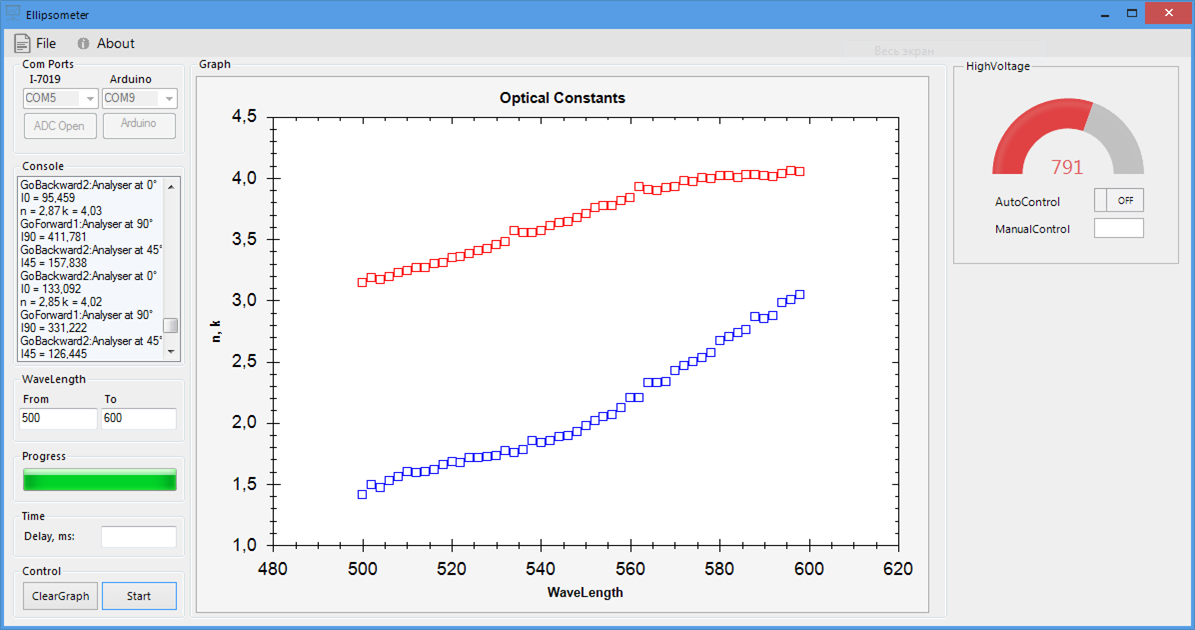

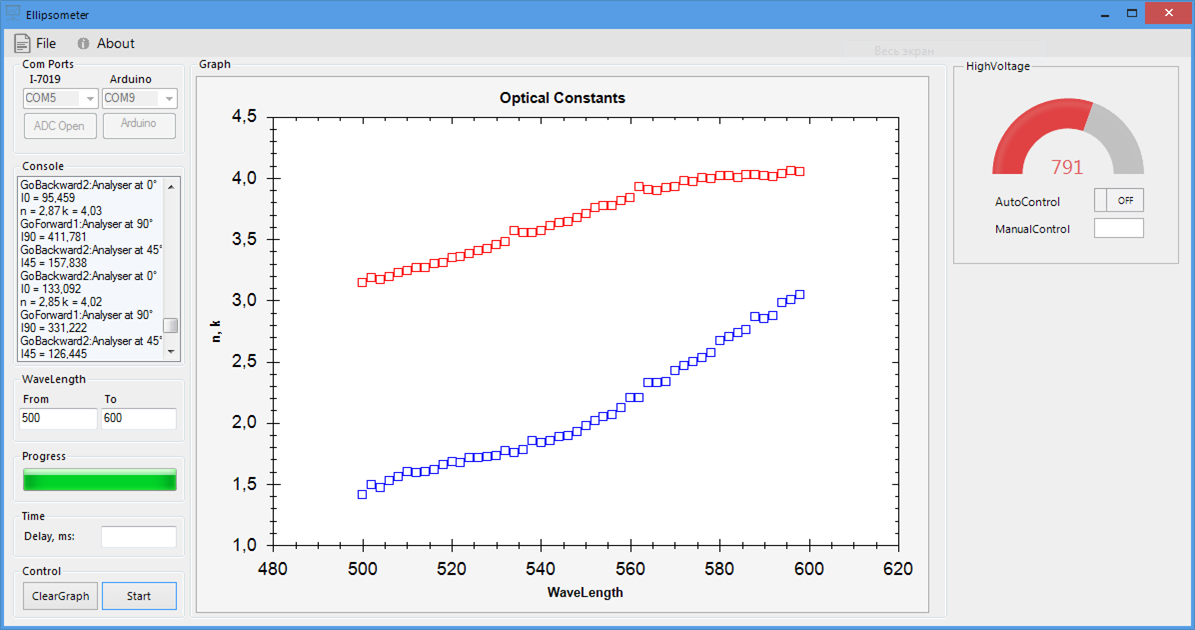

Displaying the measurement results in real time is a very important point, as it allows you to control the process and the correctness of the experiment. Having analyzed the article on Habr “ Graphing Tools for .NET,” I chose ZedGraph . Free, fast, simple and fairly functional library.

And finally, saving to a file:

A hardware-software complex designed to automate laboratory measurements based on WinForms has been developed. At the expense of the performance and relevance of choosing this particular PL for scientific computing, see the article .

PS This is part of the control hardware that I plan to write about in the next article:

Formulation of the problem

To develop software for managing the preparation and conduct of the experiment on an automated optical ellipsometer.

The software should provide an opportunity

- setting initial settings and experimental parameters;

- taking measurements of the optical characteristics of the samples;

- primary data set [data sets I (α) at a fixed wavelength λ and a fixed (constant) value of I (α) in a given wavelength range λmin ≤ λ ≤ λmax (where α is the analyzer azimuth) or arrays I (λ) at fixed azimuths of the analyzer α1, α2, α3, ... αn];

- processing arrays I (α) or I (λ) to calculate optical constants;

- control of the exposure time before measurements at a given point in the spectrum or azimuth of the analyzer to measure the steady-state signal level, as well as the duration of "standing" at a given point in the spectrum (azimuth) to "accumulate" the signal;

- visualization of measurement data;

- saving data to a file.

Experiment

During the measurement process, the program must control the stepper drives by performing a two-dimensional scan. The minimum scanning step depends on the installation options. The number of dots per range is determined by the size of the range and the scan step.

The experimental parameters (measurement range, scanning step) do not change during the measurement. Scanning is discrete in steps.

Measurement is performed only when the drives are stopped. After the measurement is performed, a move command is given to the next step, and transport movement is performed. The voltage on the PMT is regulated using PWM .

Software

I chose C # as the programming language, as it has out of the box many useful functions for working with USB, COM ports, native support for Microsoft Office, etc.

So, to receive data and send commands to the microcontroller, we will use the virtual COM port:

the code

// Open ADC Com

private void buttonADC_Click(object sender, EventArgs e)

{

String s = "";

if (comboBox1.Text != "")

{

s += comboBox1.Text;

}

try

{

hPort = PACNET.UART.Open(s + ",9600,N,8,1");

Log.Items.Add("Порт АЦП открыт");

buttonADC.Enabled = false;

comboBox1.Enabled = false;

}

catch

{

MessageBox.Show("Порт " + serialPort1.PortName +

"невозможно открыть!", "Ошибка!", MessageBoxButtons.OK, MessageBoxIcon.Warning);

Log.Item.add("Невозможно открыть порт!");

}

}

To convert the analog signal, I used the 16-bit ADC from ICP Das , for which there is an SDK on the official website, so reading data from the ADC is trivial:

the code

float readSequenceADC(int iChannel, int iterations)

{

float result = 0;

for (int i = 0; i < iterations; i++)

{

result += readADC(iChannel);

Thread.Sleep(150);

}

result /= iterations;

return result;

}

A bit of math, calculating optical constants:

the code

public void count(float a, float b, float c)

{

double x = a;

double y = b;

double z = c;

double ksi = Math.Atan(Math.Sqrt(x / z));

double delta = Math.Acos((x + z - 2 * y) / (2 * Math.Sqrt(x * z)));

double denominator = Math.Pow((1 - Math.Sin(2 * ksi) * Math.Cos(delta)), 2);

double numerator = Math.Pow(Math.Sin(phi), 2) * Math.Pow(Math.Tan(phi), 2) *

Math.Sin(2 * ksi) * Math.Cos(2 * ksi) * Math.Sin(delta);

double nk = numerator / denominator;

double numerator1 = Math.Pow(Math.Cos(2 * ksi), 2) - Math.Pow(Math.Sin(2 * ksi), 2) *

Math.Pow(Math.Sin(delta), 2);

double nk2 = Math.Pow(Math.Sin(phi), 2) + (Math.Pow(Math.Sin(phi), 2) * Math.Pow(Math.Tan(phi), 2) *

(numerator1 / denominator));

double x1 = 0;

double x2 = 0;

double D = nk2 * nk2 - 4 * ((-1) * nk * nk);

if (D < 0)

{

x1 = 0;

x2 = 0;

}

else if (D == 0)

{

x1 = -nk2 / 2;

x2 = -nk2 / 2;

}

else if (D > 0)

{

x1 = (-nk2 + Math.Sqrt(D)) / 2;

x2 = (-nk2 - Math.Sqrt(D)) / 2;

}

if (x1 < 0 && x2 < 0)

{

// "X1, x2 < 0"

}

else if (x1 > 0)

{

k = Math.Sqrt(x1);

}

else if (x2 > 0)

{

k = Math.Sqrt(x2);

}

n = Math.Sqrt(nk2 + k * k);

}

The function of determining the drift of "zero" signal:

the code

// Intensity Drifting Check

private void Worker3()

{

while (isWorking == true)

{

try

{

for (int i = 0; i < 1000; i++)

{

Thread.Sleep(200);

I = readADC(3);

Intensity.Add(I);

this.Invoke((MethodInvoker)(() => Log.Items.Add("I = " + I)));

DrawGraph(i, I, 0);

}

PrintExel.ExportText(Intensity);

ClearGraph();

isWorking = false;

}

catch (Exception e) { MessageBox.Show("Error:\n" + e.Message); }

}

}

The photoelectronic multiplier is terribly non-linear, therefore, it has different sensitivity in different parts of the spectrum and it is necessary to maintain a constant signal within the established limits (for our measurements, this is the range 300 - 850 mV with the optimal signal-to-noise ratio):

the code

private void maxControl()

{

double val = 1;

while (val > 0.85)

{

this.radRadialGauge1.Value -= 7;

serialPort1.Write("decrease");

val = Convert.ToInt32(Math.Abs(readADC(3)));

Thread.Sleep(1000);

}

}

private void minControl()

{

double val = 0;

while (val < 0.4) // val < 300

{

this.radRadialGauge1.Value += 7;

serialPort1.Write("increase");

val = Convert.ToInt32(Math.Abs(readADC(3)));

Thread.Sleep(1000);

}

}

Data visualization

Displaying the measurement results in real time is a very important point, as it allows you to control the process and the correctness of the experiment. Having analyzed the article on Habr “ Graphing Tools for .NET,” I chose ZedGraph . Free, fast, simple and fairly functional library.

charting function

private void DrawGraph(int x, double n, double k)

{

GraphPane pane = zedGraphControl1.GraphPane;

PointPairList listN = new PointPairList();

PointPairList listK = new PointPairList();

LineItem myCurve;

listN.Add(x, n);

listK.Add(x, k);

myCurve = pane.AddCurve("", listN, Color.Blue, SymbolType.Default);

myCurve = pane.AddCurve("", listK, Color.Red, SymbolType.Default);

zedGraphControl1.AxisChange();

zedGraphControl1.Invalidate();

}

And finally, saving to a file:

the code

public static void ExportToExcelIntensity(ArrayList arrLamda, ArrayList arrI0, ArrayList arrI45, ArrayList arrI90)

{

try

{

Microsoft.Office.Interop.Excel.Application excelApp = new Microsoft.Office.Interop.Excel.Application();

excelApp.Visible = true;

excelApp.Workbooks.Add();

Microsoft.Office.Interop.Excel.Worksheet workSheet = excelApp.ActiveSheet;

workSheet.Cells[1, "A"] = "WaveLength";

workSheet.Cells[1, "B"] = "I0";

workSheet.Cells[1, "C"] = "I45";

workSheet.Cells[1, "D"] = "I90";

int row = 1;

for (int i = 0; i < arrLamda.Count; i++)

{

row++;

workSheet.Cells[row, "A"] = arrLamda[i];

workSheet.Cells[row, "B"] = arrI0[i];

workSheet.Cells[row, "C"] = arrI45[i];

workSheet.Cells[row, "D"] = arrI90[i];

}

workSheet.Range["A1"].AutoFormat(Microsoft.Office.Interop.Excel.XlRangeAutoFormat.xlRangeAutoFormatClassic2);

excelApp.DisplayAlerts = false;

workSheet.SaveAs(string.Format(@"{0}\OpticalIntensities.xlsx", Environment.CurrentDirectory));

excelApp.Quit();

}

catch (Exception ex)

{

MessageBox.Show("Error:\n" + ex.Message);

}

}

Total

A hardware-software complex designed to automate laboratory measurements based on WinForms has been developed. At the expense of the performance and relevance of choosing this particular PL for scientific computing, see the article .

PS This is part of the control hardware that I plan to write about in the next article:

The photo