Wearable "batteries": textile micro-supercondensers based on PEDOT-Cl

Wherever you look, one way or another you will stumble at a look at something that requires energy: from mobile phones, ending with much more important wearable medical devices. Dozens, if not more, of research groups around the world are brainstorming in search of new methods for obtaining and storing energy. Someone focuses on plastic, someone is on paper, and someone even suggests using bacteria that are in a “sleeping beauty” state until you need to recharge the phone. Our today's heroes decided to more literally approach the concept of “wearable energy carriers”. What do we wear almost always? Of course, clothes. To introduce into it some kind of “battery” is possible and not as difficult as it seems. But isn't it better to make fabric itself an energy carrier? Just imagine these dialogues from the future: “Dear, and where is my t-shirt charging? ”or“ I'll call you back, otherwise my jeans will soon be drained. ” Well, okay, from the flat jokes we go to the essence of the study. How did scientists create "energetic" clothes, how effective is their creation, and what are the prospects? Immersed in the report of the researchers for finding answers. Go.

The basis of the research

Scientists note that to create full-fledged, effective and practical compact, portable health monitoring devices (or other personal devices), non-standard batteries are an extremely important element. Excellent candidates for this position are MSC (micro-supercapacitors), which, unlike the classic supercapacitors * , can be extremely small in size, which is good news.

Supercapacitor * is an electrochemical charge storage device with an organic / inorganic electrolyte and a double electric layer between the electrode and the electrolyte.Of course, the most catchy minus of such batteries is their price, which bites quite strongly. However, scientists argue that it will decline with the development of technology and through the use of more economical materials and the expansion of mass production. At the moment, much attention is paid to the MSC on a paper or plastic basis. But textiles do not have such popularity among researchers. The main difficulty lies in the manufacture of electrochemical fiber electrodes that would be used to create the MSC. However, to stop due to the fact that the task is difficult, our today's heroes are not going to.

Researchers point out two important indicators that wearable supercapacitors should have: high energy density and mechanical stability. But what material to use? There are many options: graphene, conjugated polymers, MXene, carbon nanotubes, etc. The introduction of electrochemically active materials with high electrical conductivity in textiles is not an easy task. Nickel and reduced graphene oxide, which were introduced into previously prepared textiles for the implementation of MSC textile, have proven themselves well in this. But this option still does not have sufficient energy density for practical use.

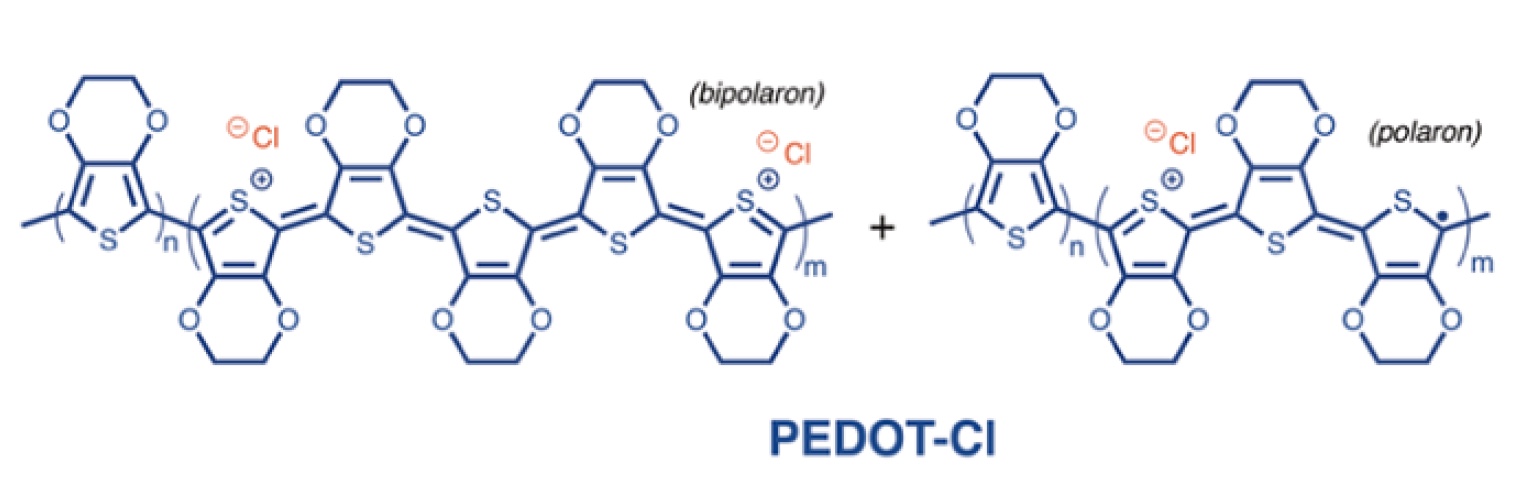

Chemical structure of PEDOT-Cl.

In this study, the scientists decided to use an even more “exotic” material - PEDOT-Cl. Another name (for lovers of articulation warm-up) is poly (3,4-ethylenedioxythiophene) p-type * .

A p-type semiconductor * is a semiconductor whose main charge carrier is holes. It is obtained by doping the semiconductors with acceptors.The coating of PEDOT-Cl, deposited on the base by the method of vacuum deposition, demonstrates a high degree of electrical conductivity on textiles and quite resistant electrochemical properties. Thus, scientists managed to create a textile micro-supercapacitor with a high energy density, which is based on an elastic textile substrate and conductive threads with PEDOT-Cl sputtering.

Now let's dig a little deeper in search of the details of this unique creation.

Preparation of the material base

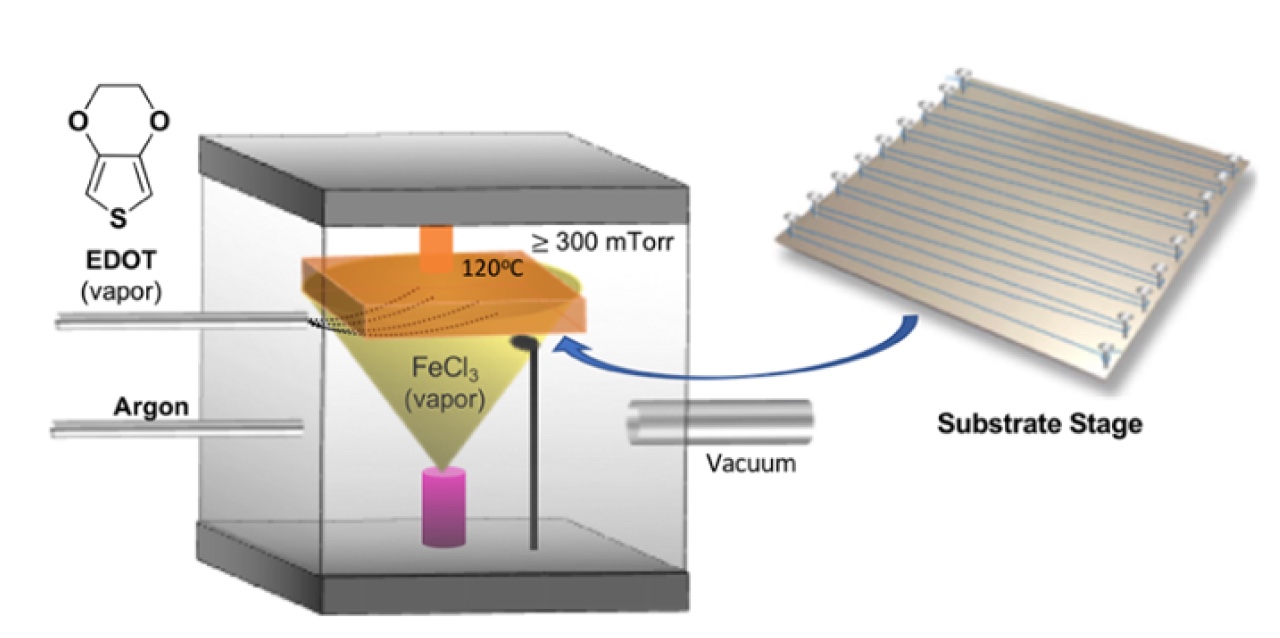

To begin with, it was necessary to apply p-type PEDOT-Cl films on a stainless steel base. The monomer was 3,4-ethylenedioxythiophene (EDOT), and the role of the oxidizing agent was played by FeCl 3- ferric chloride (III). After heating the EDOT to 90 ° C, the monomer was placed in an argon-containing chamber using a Swagelok SS-4JB needle valve, which was open a quarter of a turn.

Schematic illustration of the camera.

The pressure in the chamber was 300 ± 10 mTorr, and the temperature - 120 ° C. These parameters were maintained throughout the entire procedure of applying the film to the substrate. The thickness of the applied film and the deposition rate (2 mm / s) were controlled by the evaporation rate of the oxidizing agent FeCl3, which was measured by quartz microbalances located inside the chamber. Upon obtaining the desired film thickness, the application process stopped, but the chamber remained airtight until the temperature dropped to 60 degrees. To clean the film was placed in methanol for 15 minutes.

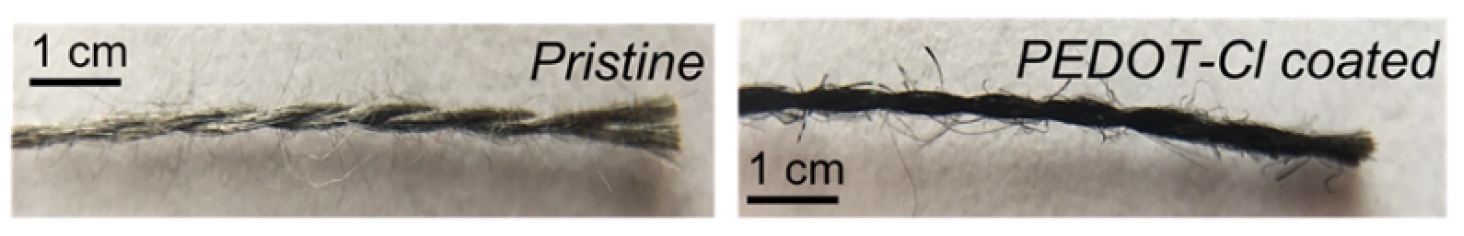

The appearance of the thread before and after applying it PEDOT-Cl.

To create a full-fledged solid-state MSC, a polymer gel electrolyte was used, made by slowly introducing 1 gram of polyvinyl alcohol into 10 grams of H 2 SO 4 solution . Next, the mixture was heated to 90 ° C and stirred for 2 hours. Next, the mixture was applied to the electrodes and dried.

The results of the study of

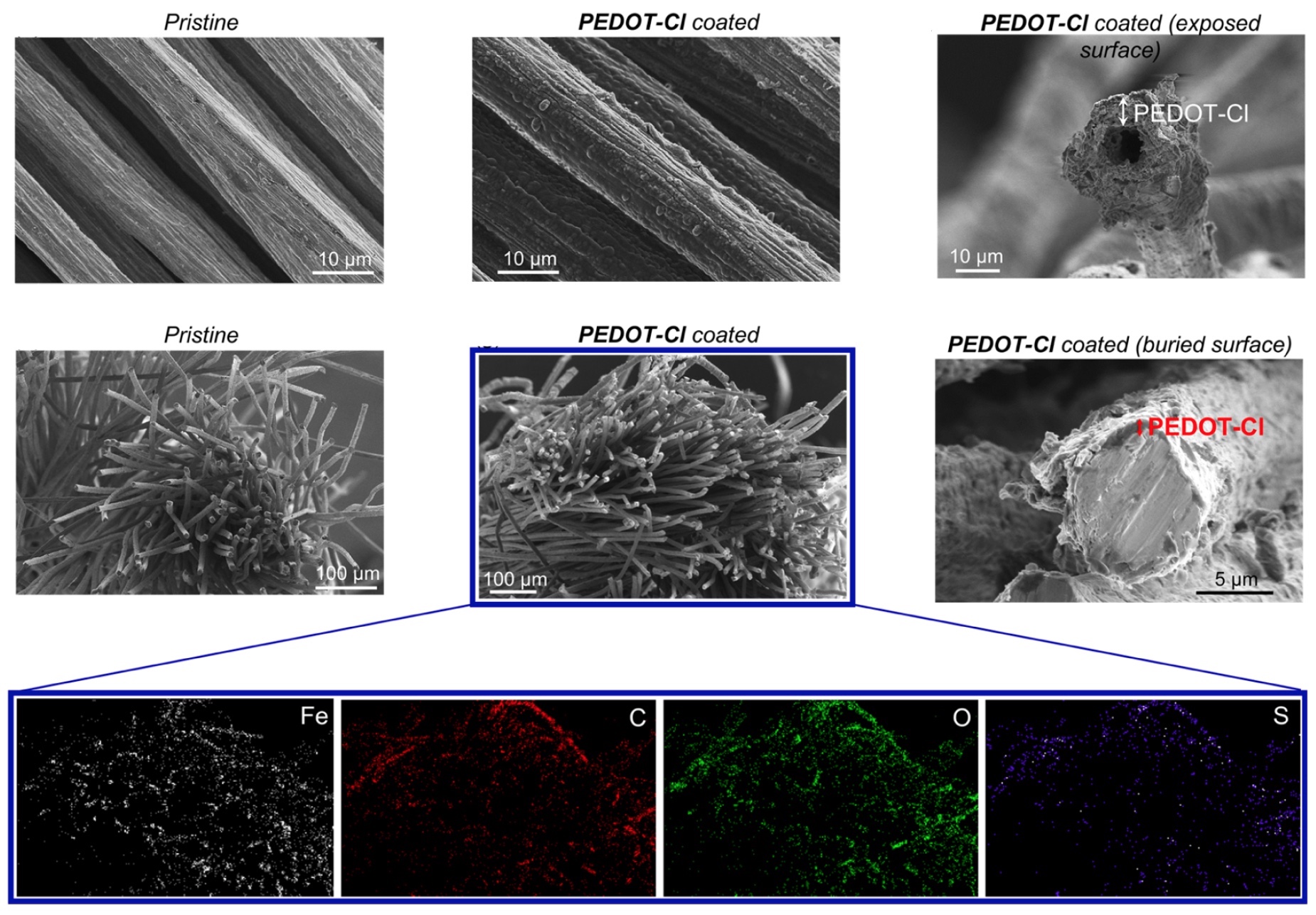

SEM images of the filaments before and after deposition of PEDOT-Cl and energy dispersive X-ray spectroscopy (bottom row).

In one, so to speak, approach can be made about 32 feet (9.7536 m) of threads. According to scientists, the main problem of obtaining so much of the required high energy density is poor adhesion (adhesion) of the electronic material or the non-optimized morphology of thick films, which makes the transfer of ions extremely difficult. In fact, the thicker the thread is, the better, but if you overdo it, it will only get worse.

In this study, the deposition method itself - vacuum deposition - helped to solve this problem. The use of stainless steel as a base was also a plus, since this material, due to its structure (take a look at the pictures above), has more area for adhesion with the PEDOT-Cl film.

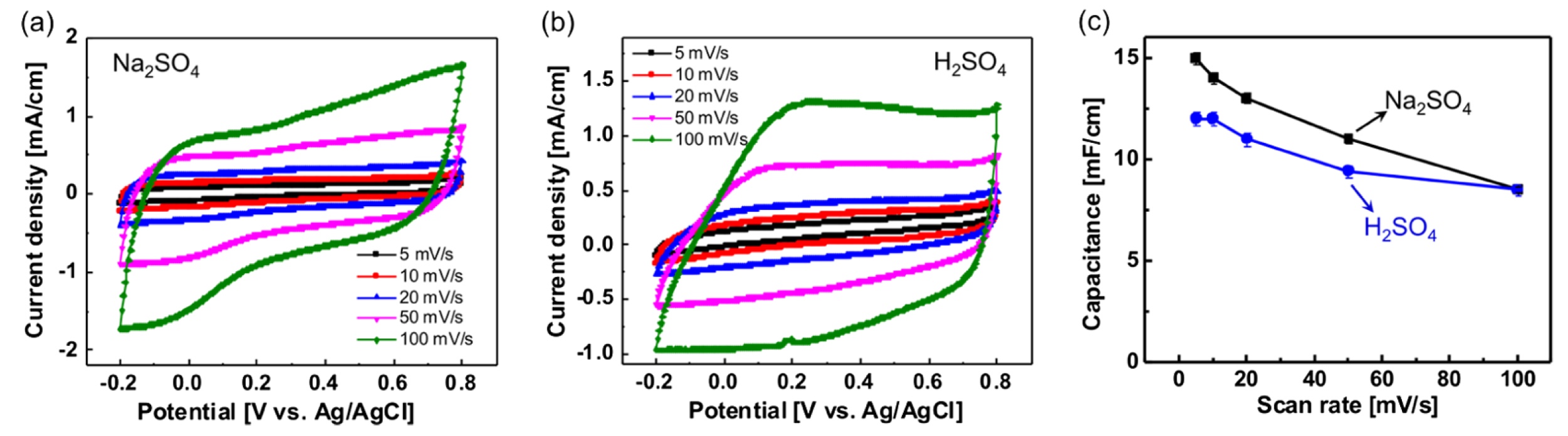

The images above show the results of cyclic voltammograms obtained by using a three-electrode electrolytic cell in 0.5 M Na 2 SO 4 or 0.5 MH 2 SO 4 . The working electrode was a PEDOT-Cl coating with a length of 1 cm. Auxiliary electrodes: platinum as an indicator electrode and silver chloride (Ag / AgCl) as a reference electrode.

When scanning (5 mV / s) in Na 2 SO 4 , an electrical capacitance of 15 mF / cm (millifarad per centimeter) is reached, and in H 2 SO 4- 12 mf / cm. Scientists consider the impact of scanning itself on indicators to be insignificant. So, at a scanning speed of 100 mV / s, the indicators fall in both electrolytes to the level of 8.5 mF / cm.

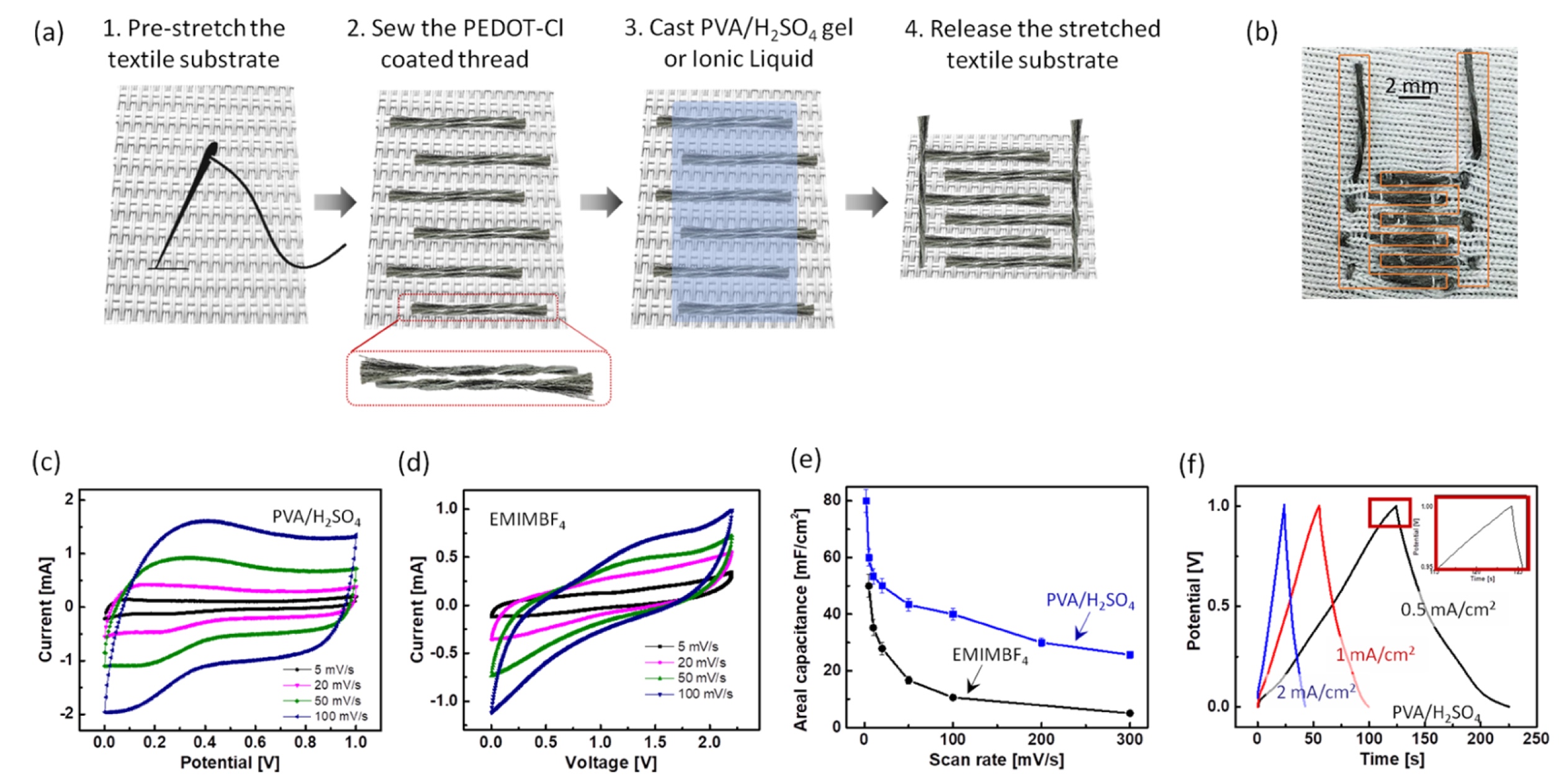

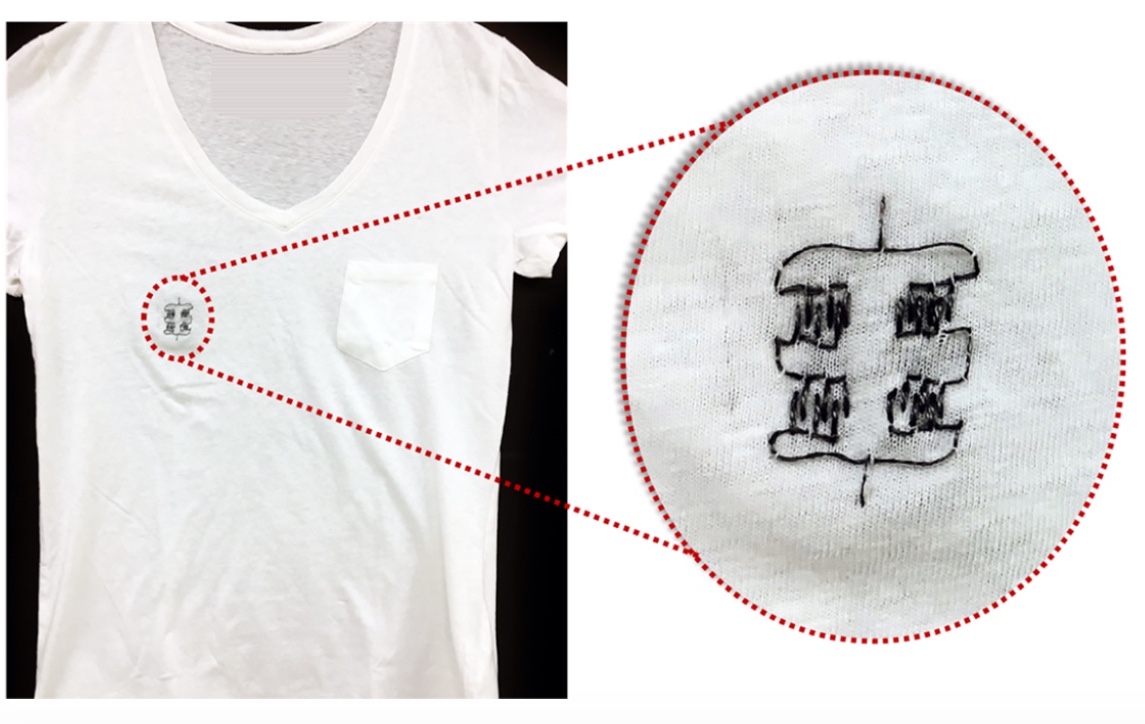

Here we see myself creating textile MSC process (the image above and). A very important point is to minimize the distance between the electrode pins (let's call them that, because in the study itself they are referred to as "electrode fingers"). This is necessary for use in the smallest devices, to reduce the length of the ionic conductivity and to increase the possible volume of stored charge. The problem to minimize this distance is that the fibers are quite "fluffy". That is, the stainless steel thread is not smooth. Small villi on the threads stick in different directions and come into contact with the neighboring ones, which causes short circuits. How to solve this problem is simple, but effective? Use elastic textiles, of course. First, the fabric is “squeezed” and sewn onto the MSC, after which the fasteners are removed, and the fabric passes into its natural state. Even the stitches of the material (fabric) have benefited by serving as a kind of “eye gauge.” The distance between the six electrodes is always the same - 2 stitches. Each of the electrodes is 2 strands coated with PEDOT-Cl and twisted to form one whole. The length of the electrodes is 5 mm, the width is 0.6 mm, and the height is 1.2 mm. Dimensions are also not accidental, because they have a great influence on the overall energy density indicator.

After the electrodes are sewn onto the compressed fabric, the gel electrolyte PVA / H 2 SO 4 is applied to them . Until it is frozen, the base fabric is leveled, thus providing another additional barrier between the electrodes so that no closures occur.

The graphs below the MSC images show voltammograms of textile MSC with gel electrolyte PVA / H 2 SO 4 ( s ) and electrolyte EMIMBF4 (full name: 1-ethyl-3-methyl-imidazolium tetrafluoroborate) ( d ).

With a scan rate of 2 mV / s, the capacity of MSC with PVA / H 2 SO 4 is 80 mF / cm 2. If the speed is increased to 5 mV / s - 60 mF / cm 2 . And with an incredible 300 mV / s, the capacity indicator drops to 26, but remains stable.

MSC with electrolyte EMIMBF4 when scanning at 5 mV / s showed a slightly lower result - 50 mF / cm 2 .

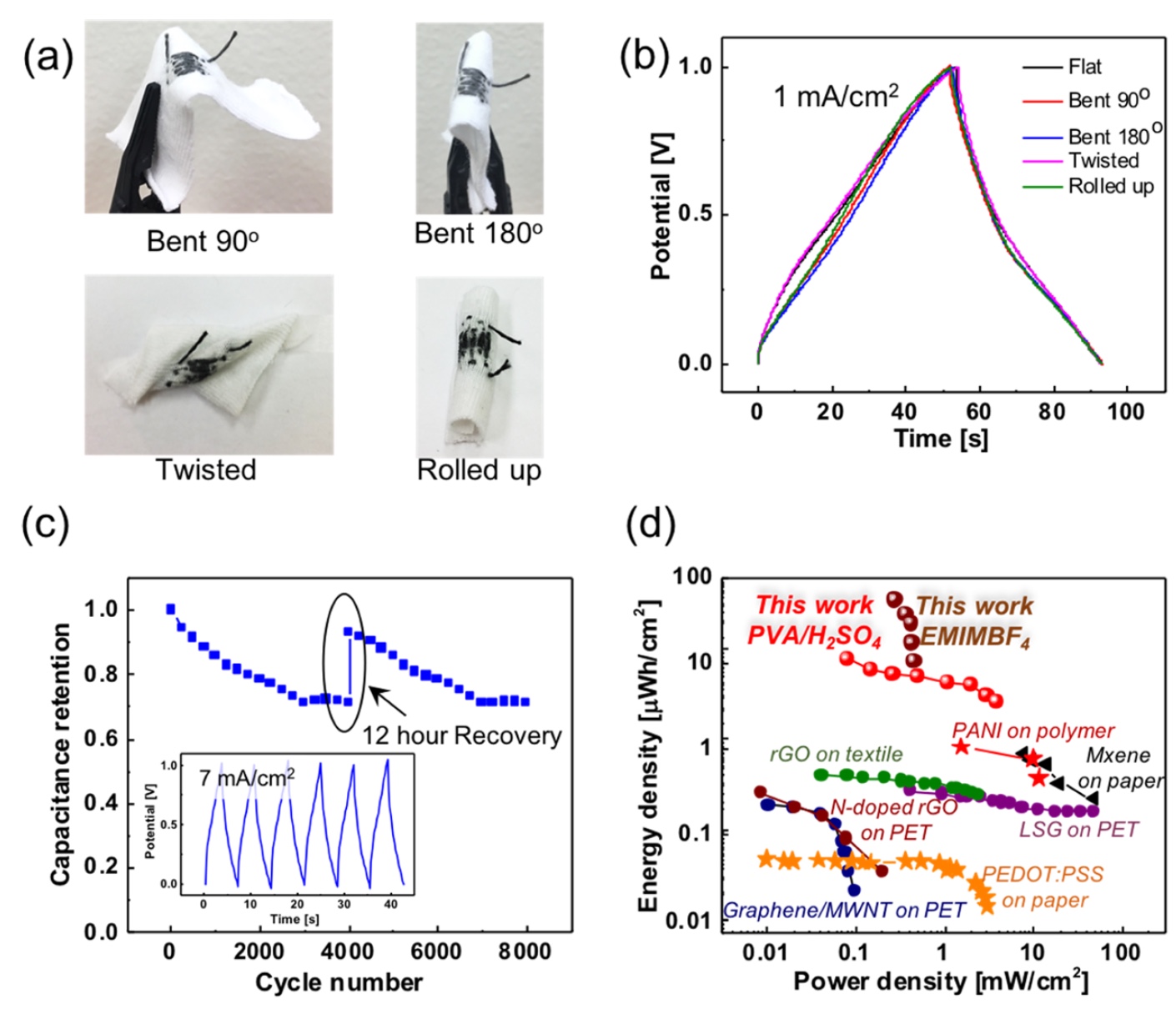

Checking the sample for resistance to mechanical stress ( a , b ). Electrochemical resistance ( s ). Comparison of the most advanced MSC currently available and the MSC experienced in this study ( d ).

Now we need to understand how hardy the MSC is, so to speak, and how scientists tested this parameter.

Galvanostatic measurements of charge / discharge were performed when the sample was bent at an angle of 90 ° or 180 °. The sample was also twisted and rolled into a roll. In other words, the scientists mocked him as best they could, and this is completely justified, because who needs, say, a T-shirt with these MSCs, which cannot be worn or put in a suitcase. Indicators of charge / discharge were absolutely the same as that of the sample in a quiet state (without mechanical impact on it).

Graph c shows the measurement results of the electrochemical stability of MSC with gel electrolyte PVA / H 2 SO 4. After 4000 cycles, the sample retained 71% of its original electrochemical state (capacity). After 12 hours at rest, the sample capacity indicator recovered to 93%. The scientists repeated the test with the same number of cycles, and the results were the same (71%, then after 12 hours - 93%). If you think that scientists have checked everything 1 time, then you are mistaken. This test was conducted on 12 different devices 3 times. And all the results were almost identical.

Scientists have compared the already developed MSC and their creation. Their variant of textile MSC has an energy density 10 times higher than that of flexible precursors made from paper or plastic. Textile MSC has a density of 0.1 mW · h / g.

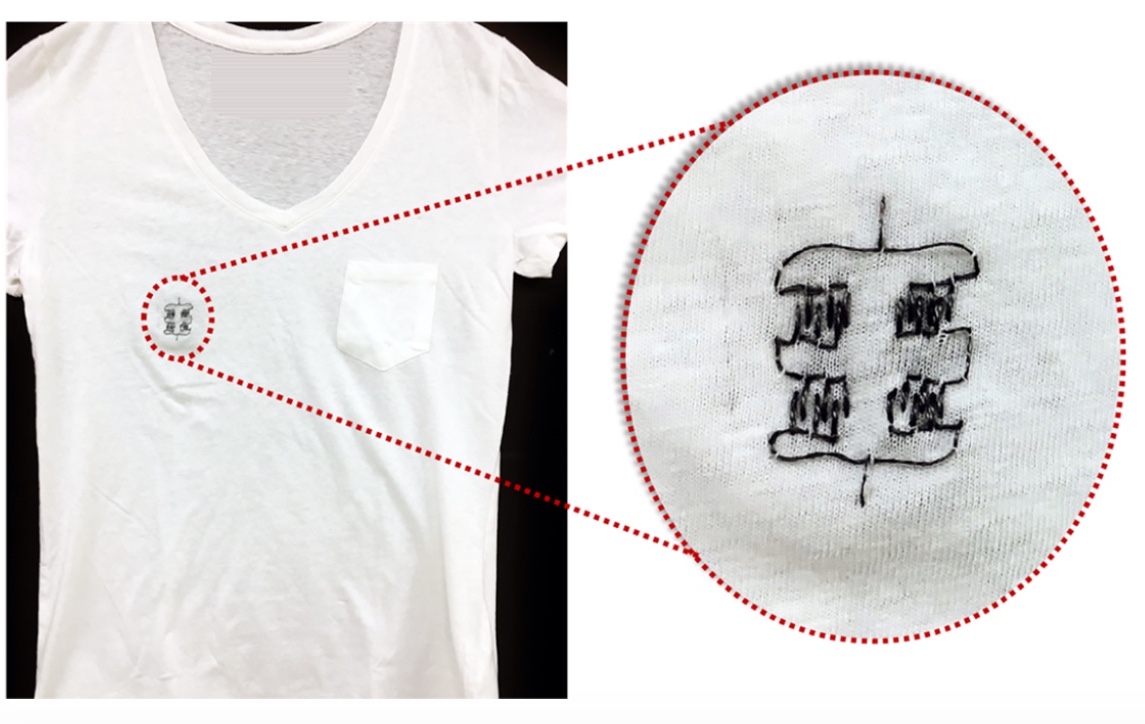

A plain T-shirt with an unusual MSC “logo”.

For a detailed acquaintance with the study I recommend to look here (report of the research group) .

Epilogue

Scientists note that their technology needs some work. Mostly due to compatibility issues with different device options. When working with micro-supercapacitors, the device architecture, the dimensions of the electrodes and the distance between them are of paramount importance. Accordingly, even the application of textile MSC on the base, that is, to sew one to the other, is a very painstaking process requiring incredible precision. Minor deviations in the "pattern" can lead to the inoperability of the entire device. But these are problems that always arise in one form or another in the process of creating something new and unique. They should not cause scientists to say: "Well, let's go, better go cross the praying mantis with the octopus." Textile technology MSC has great potential. And very nice that scientists themselves are focusing their attention not on smartphones and iPods (speaking exaggeratedly), but on much more important wearable devices - medical ones. Yes, now there are, for example, bracelets for monitoring heart rate. They are compact and convenient. But is it worth it to stop there? I do not think, otherwise we would still go with cell phones, which have an antenna larger than I have in the country for TV. There is no limit to perfection. And if scientists want to create something that will benefit people and their health, it is at least respected. than i have in the country for tv. There is no limit to perfection. And if scientists want to create something that will benefit people and their health, it is at least respected. than i have in the country for tv. There is no limit to perfection. And if scientists want to create something that will benefit people and their health, it is at least respected.

And, of course, Friday offtop:

Недавние исследования в области нейробиологии подтвердили, что объятия имеют крайне положительное влияние на восстановление нервной системы и психического равновесия человека после перенесенного стресса. Посему вот вам оффтоп по теме этого оффтопа (простите за каламбур).

Спасибо за внимание, оставайтесь любопытствующими, будьте здоровы и по-больше обнимайте любимых и родных. Хороших выходных, ребята.

Спасибо за внимание, оставайтесь любопытствующими, будьте здоровы и по-больше обнимайте любимых и родных. Хороших выходных, ребята.

Thank you for staying with us. Do you like our articles? Want to see more interesting materials? Support us by placing an order or recommending to friends, 30% discount for Habr users on a unique analogue of the entry-level servers that we invented for you: The Truth About VPS (KVM) E5-2650 v4 (6 Cores) 10GB DDR4 240GB SSD 1Gbps $ 20 or how to share the server? (Options are available with RAID1 and RAID10, up to 24 cores and up to 40GB DDR4).

VPS (KVM) E5-2650 v4 (6 Cores) 10GB DDR4 240GB SSD 1Gbps until December for free if you pay for a period of six months, you can order here .

Dell R730xd 2 times cheaper? Only we have 2 x Intel Dodeca-Core Xeon E5-2650v4 128GB DDR4 6x480GB SSD 1Gbps 100 TV from $ 249in the Netherlands and the USA! Read about How to build an infrastructure building. class c using servers Dell R730xd E5-2650 v4 worth 9000 euros for a penny?