Close acquaintance with an electromechanical punch card sorter (excursion into the beginning of the 20th century)

Having understood how to work with an electromechanical punch card sorter (from the point of view of a regular user), and starting to get to know him more closely (from an engineer’s point of view), you expect to see several sensors in it to read holes in punch cards and a dozen manipulators, each which takes the punch card in your pocket. However, the electrician of the sorter is much more elegant and simple: all its intelligence rests on one sensor and one electromagnet. How exactly, read below.

The principle of the sorter (for example, IBM Type 82 Sorter)

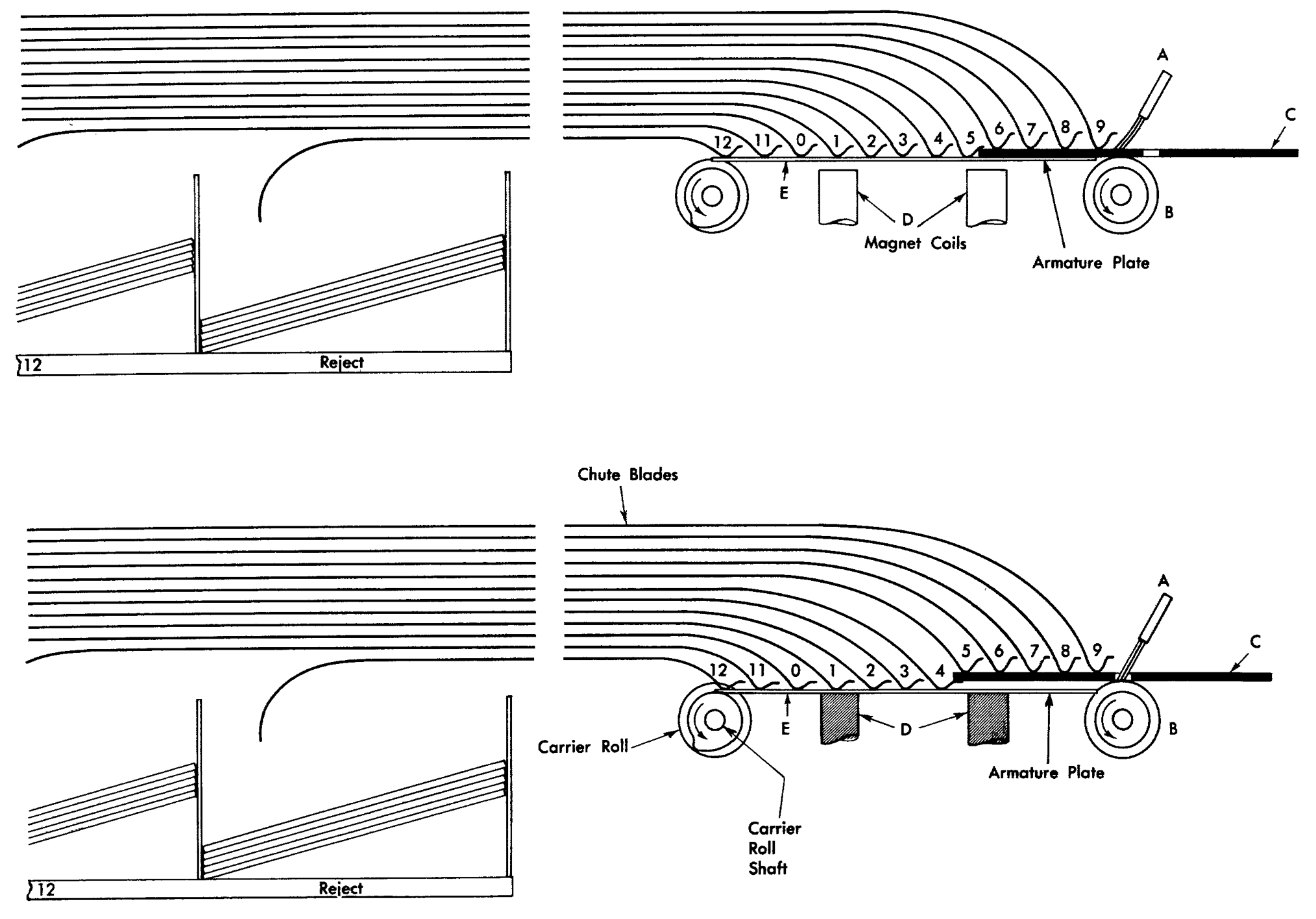

- Punch cards come into the sorter one by one (see the bold line on the diagram, marked with the letter "C"). Sideways, the lower edge forward (this edge is called the “edge of nines”, because there are nines along the bottom row).

- A small wire brush (marked with the letter “A”) slides along the surface of the punch card (one of its columns), trying to close the electrical circuit through contact with a metal shaft (marked with the letter “B”). Slides on a given operator column. From digit 0 to digit 9.

- If there are no punched digits in the current column, then the punch card does not allow the circuit to close. But if there is a hole in the punch card, the wire brush is in contact with the metal shaft, and so on. closes the circuit.

- When the wire brush closes with a metal shaft, an electromagnet is activated (marked with the letter “D”), which pulls the metal reinforcement (marked with the letter “E”). These fittings, in turn, carry along a stack of metal strip guides (these strips are marked on the diagram with the words “Chute Blades”), - those of them that the card has not yet passed.

- As a result, a “tunnel” is formed in front of the punch card to enter the correct pocket. The bottom line is that the edges of the metal strip guides are located at the same spacing as the lines on the punched card — so that the hole (if pierced) is detected just before the punched card reaches the corresponding strip.

- If there are no punched digits in the current column, the punch card falls into the pocket for discarded punched cards (for cards that are “out of the game”).

How quickly did sorters work

IBM Type 80 Sorter , the very first sorter, released by IBM in 1925, drove 450 punch cards per minute. He performed data processing exclusively electromechanical way. Without transistors, and even without tube electronics. The whole "intelligence" was built on an electromechanical relay and electromagnets. Despite its technological primitiveness, the Type 80 was classified as a high-precision equipment. Why? Because the speed with which he worked meant that the edges of the guiding metal belts would fall and rise more than seven times a second. Any overlap in time could lead either to an incorrect sorting, or to the fact that the edge of the metal guide tape will damage the punch card.

IBM Type 82 Sorter , the next model of the sorter from IBM, has already chased 650 punch cards per minute. For an electromechanical relay, this speed was too tough, and for the first time in its new model, IBM used lamp electronics to control the electromagnet.

IBM Type 83 Sorter , released in 1955, sorted punch cards at an even more fantastic speed: 1000 pieces per minute! In it, a more advanced punch card processing algorithm was implemented: this model read all the holes of the selected column from the punch card at once. Due to this, the Type 83 could perform new tasks, the solution of which on earlier models was fundamentally impossible. Among such tasks: rejection of erroneous punched cards, - in which several holes were punched in one column at once.

The IBM Type 84 Sorter , the most productive of the models that IBM has ever produced, was released in 1959. In the literal and figurative sense of the word ... In this sorter wire brush gave way to an optical (photoelectric) sensor. Plus, his intelligence was built on semiconductor technology. Moreover, in the new model of its sorter, IBM replaced the electromagnet with a vacuum suction cup. Thanks to such dramatic improvements, the Type 84 Sorter drove punch cards of 2,000 pieces per minute. So through it more than 30 punched cards flew every second.

PS Despite its technological primitiveness, electromechanical punch card sorters at one time revolutionized the processing of business data, and set the stage for the emergence of electronic “mini” business-class computers, such as IBM 1401. In addition, even after the advent of computers, sorters punched cards for a long time remained in demand. For example, the very first model of the sorter (IBM Type Sorter 80), released in 1925, was maintained until 1980.

Only registered users can participate in the survey. Sign in , please.