Production of the case for the robot with a limited budget. Vacuum forming

How to show investors a beautiful robot? Develop a beautiful body. How to do it while there is no investment? I tried to briefly describe my path. We are developing a robot for collecting golf balls in the driving range . Without a beautiful body is very difficult to explain how the robot will look. In this article I will tell you how for 24,000 rubles. get a case of 1000mm x 800mm x 250mm, as well as what kind of rake we collected along the way. Perhaps this will help you avoid our mistakes.

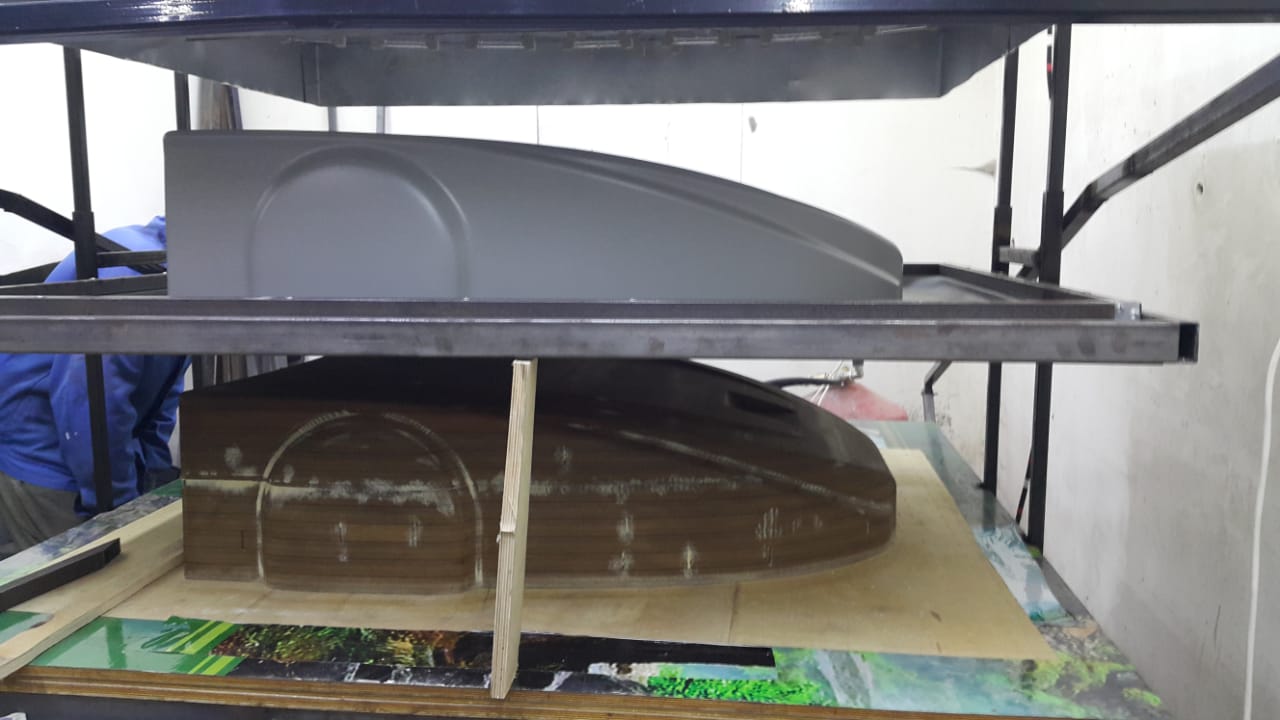

The first version of the case we made of glass mat and epoxy resin, this made it possible to assess the overall dimensions and appearance in nature. After making changes to the model, we began to search for possible low-cost body fabrication technologies.

The body can be made by injection molding , but the cost of making molds is a huge barrier to a startup. Therefore, for the manufacture of the upper part, it was decided to use a thermal vacuum molding.

Vacuum forming products is possible on inexpensive equipment and requires a small initial investment.

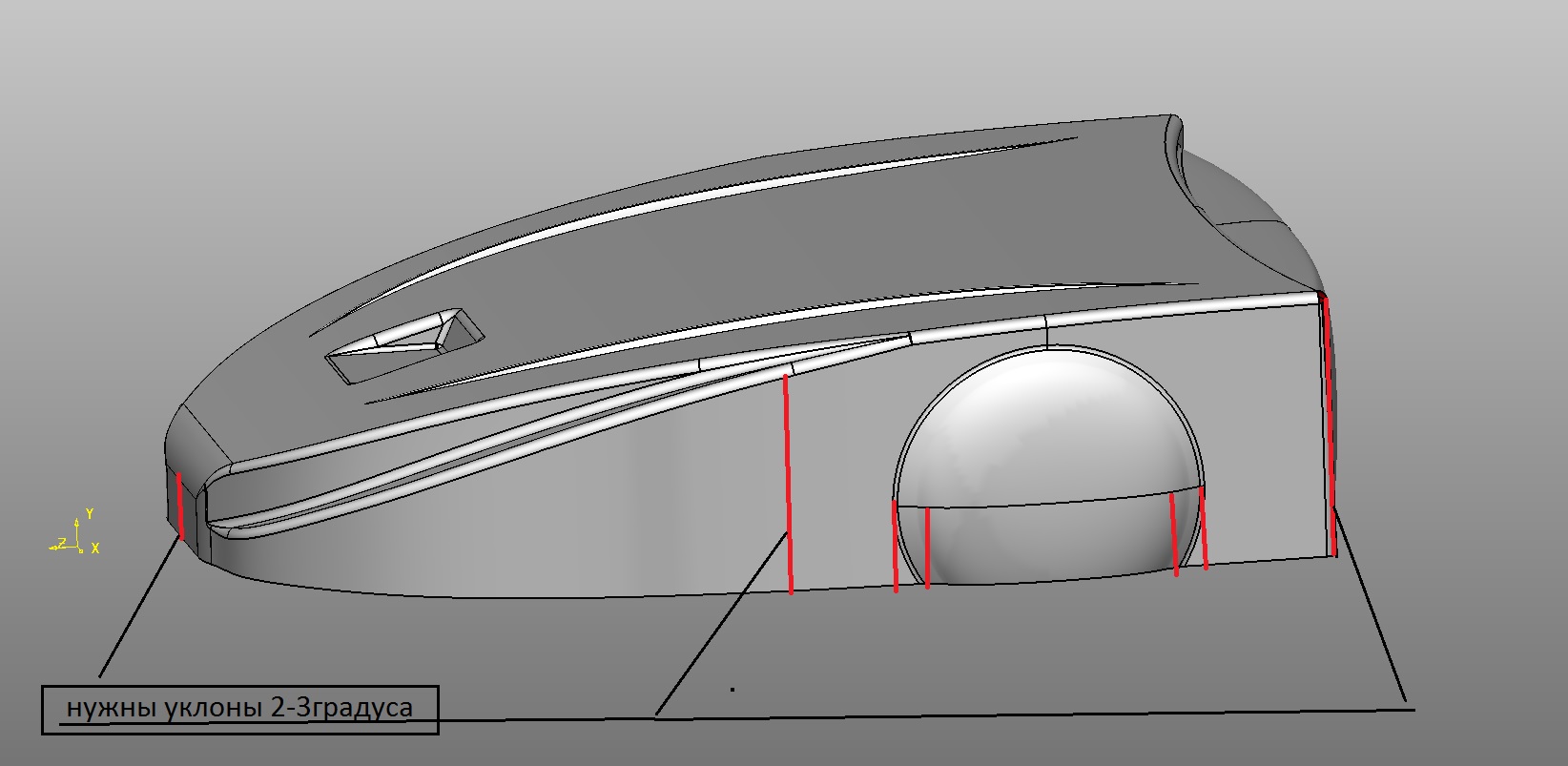

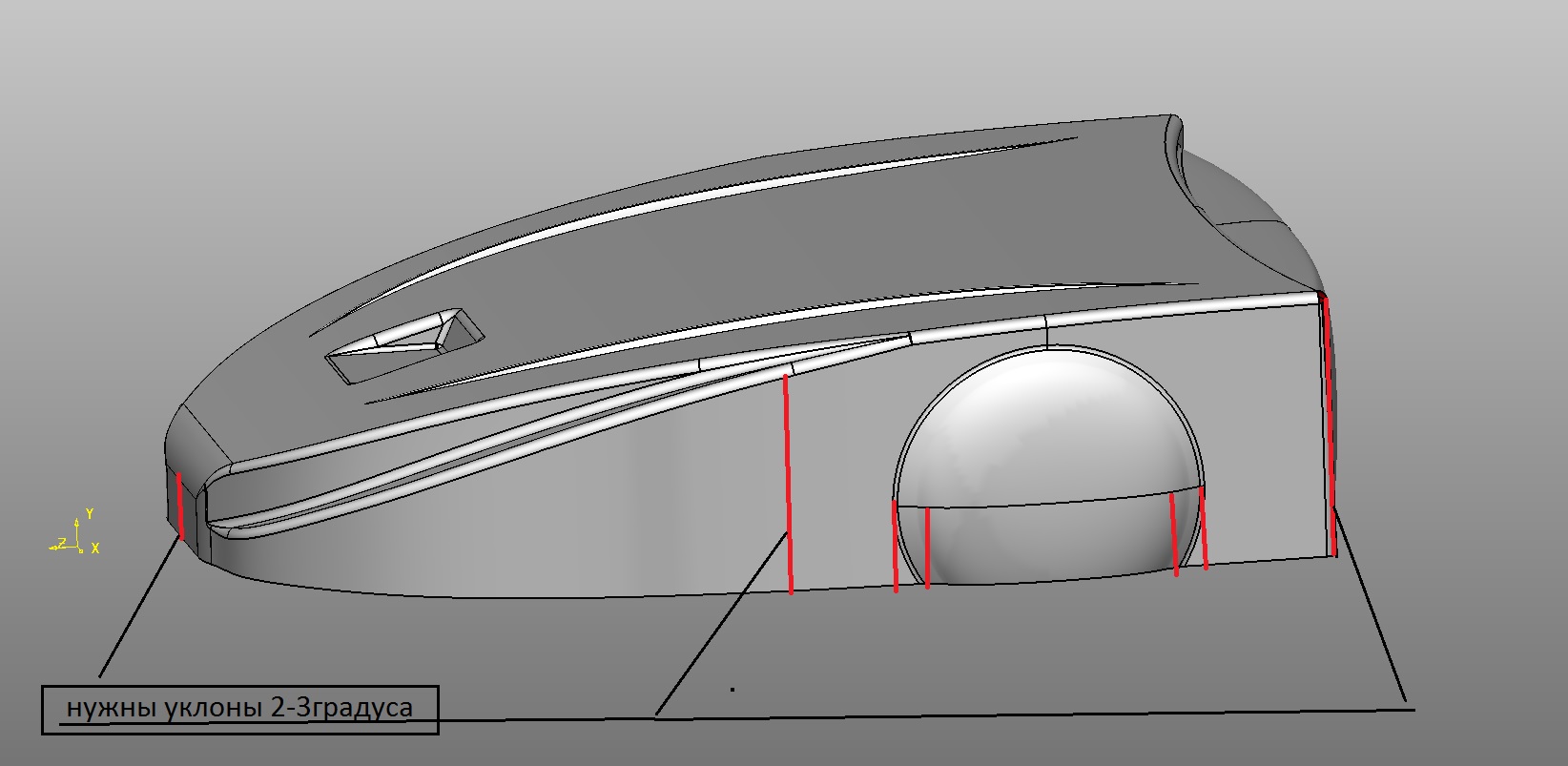

The model should have no negative angles, i.e. all bevels and ends should have angles greater than 90 degrees. The side surfaces should have at least a minimum slope of 2-3 degrees so that the model can be easily removed from the matrix. The matrix must be done higher, because In the corners of the junction to the table, the air cannot be completely removed, this will give a smooth bend to the table. The lower part is better to cut. How much more to do depends on the thickness of the sheet, the power of the equipment and how much you will heat the polymer material.

First of all, when you have a model you need to prepare a matrix. I read about the use of chipboard on the forums, but in practice they use MDF most often. Forms that require greater accuracy and are designed to produce more copies are made from aluminum.

Our second mistake was choosing a contractor for milling the model. Since our model is 1000mm x 800mm x 250mm., It was necessary to immediately look for a contractor with the appropriate working field of the CNC machine. We believed that you can easily assemble a matrix of 12 parts.

Having lost time and money, we found another contractor who made a two-part matrix.

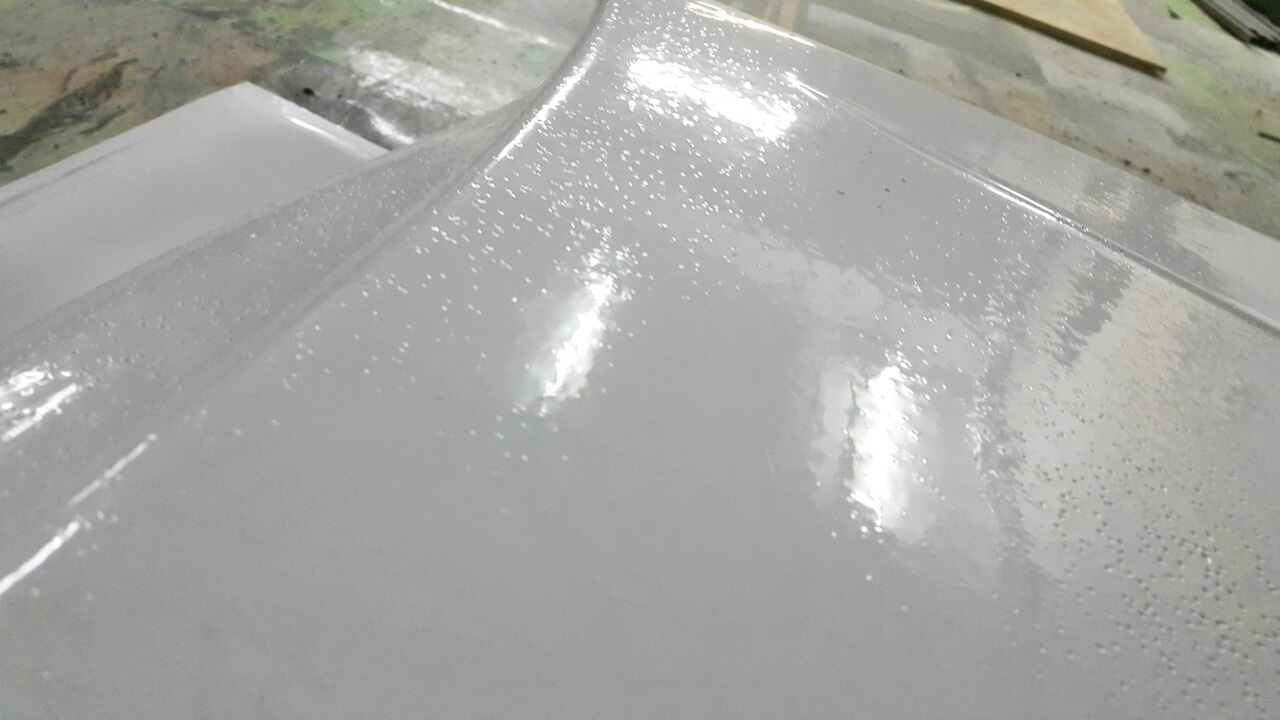

After milling MDF, the obtained parts must be glued together, otshkurit and covered with a layer of epoxy resin to create a protective layer.

When you have the matrix ready, you can begin the process of forming. We decided to make a molding table ourselves. It would seem that nothing complicated: a table of the required size with technological holes for air discharge, a vacuum pump, infrared lamps. Under the dimensions of the model a frame was made in advance.

Photos of our "machine" did not, but it looked like this. Affected by the lack of experience. Quality product did not work.

Our fourth mistake was that we bought ABS plastic sheets too early. While we were waiting for the model, the plastic absorbed moisture from the air. Because of this, when forming artifacts appeared in the form of bubbles, I had to buy new sheets of ABS.

And as sometimes happens, at the end of our torment, we found acquaintances who provide a full cycle of services for model preparation and thermal vacuum molding. They are located in Nizhny Novgorod, but offered to help for very adequate money. As a result, the molding process was completely outsourced.

The main molding process:

We chose a sheet of ABS 4mm thick because of the availability, it gives when pulling the side walls of 2mm, which is quite suitable for us. In general, there is a huge amount of materials.

Information from Wikipedia

Thermo-vacuum molding is a great way to make a case for prototypes, MVP and small series. After testing the new building, we will most likely try to make the necessary changes to the existing matrix and use it to make a small series.

Thanks for attention!

PS: 6 people from Habr are participating in the project. We are developing three versions of the software (including on the Ardupilot and are starting the version on ROS), have made a Schild board for raspberries, two versions of the case, we have three prototypes and ambitious plans. This robot would not exist if it were not for Habr .

Introduction

The first version of the case we made of glass mat and epoxy resin, this made it possible to assess the overall dimensions and appearance in nature. After making changes to the model, we began to search for possible low-cost body fabrication technologies.

The body can be made by injection molding , but the cost of making molds is a huge barrier to a startup. Therefore, for the manufacture of the upper part, it was decided to use a thermal vacuum molding.

Vacuum forming products is possible on inexpensive equipment and requires a small initial investment.

Preparing the model. First mistake

The model should have no negative angles, i.e. all bevels and ends should have angles greater than 90 degrees. The side surfaces should have at least a minimum slope of 2-3 degrees so that the model can be easily removed from the matrix. The matrix must be done higher, because In the corners of the junction to the table, the air cannot be completely removed, this will give a smooth bend to the table. The lower part is better to cut. How much more to do depends on the thickness of the sheet, the power of the equipment and how much you will heat the polymer material.

Milling the matrix. Second mistake

First of all, when you have a model you need to prepare a matrix. I read about the use of chipboard on the forums, but in practice they use MDF most often. Forms that require greater accuracy and are designed to produce more copies are made from aluminum.

Our second mistake was choosing a contractor for milling the model. Since our model is 1000mm x 800mm x 250mm., It was necessary to immediately look for a contractor with the appropriate working field of the CNC machine. We believed that you can easily assemble a matrix of 12 parts.

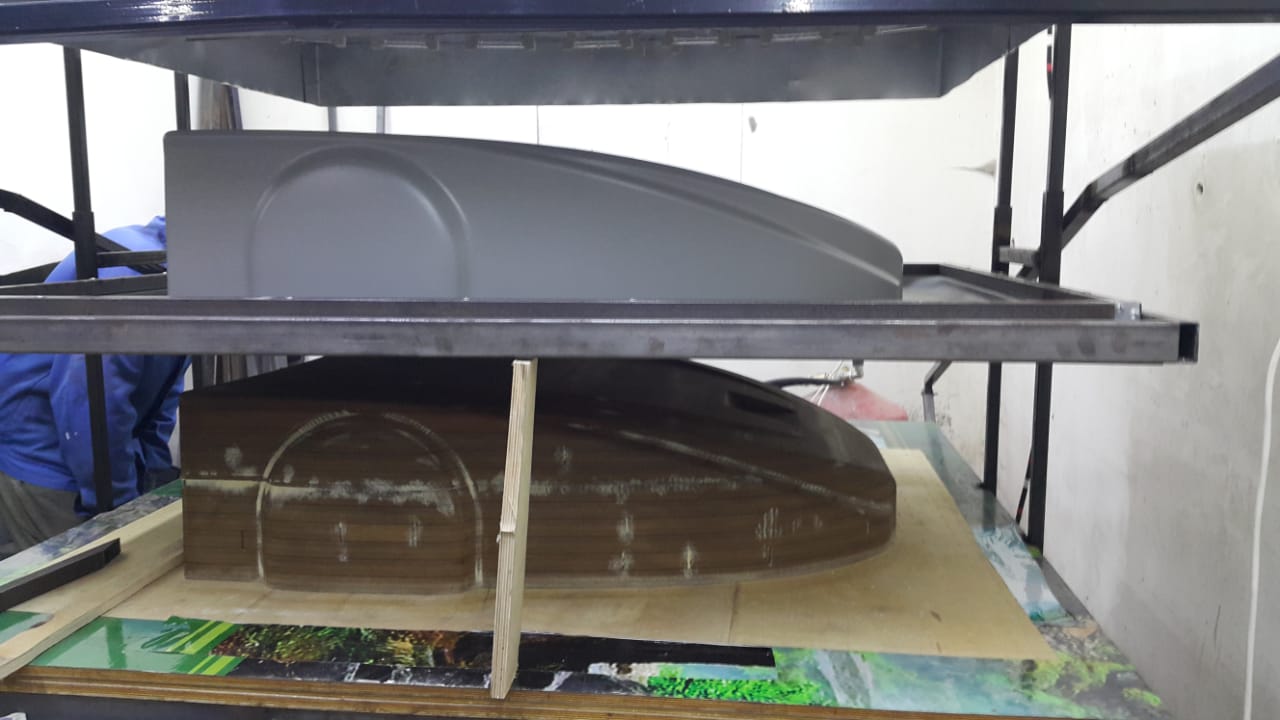

Having lost time and money, we found another contractor who made a two-part matrix.

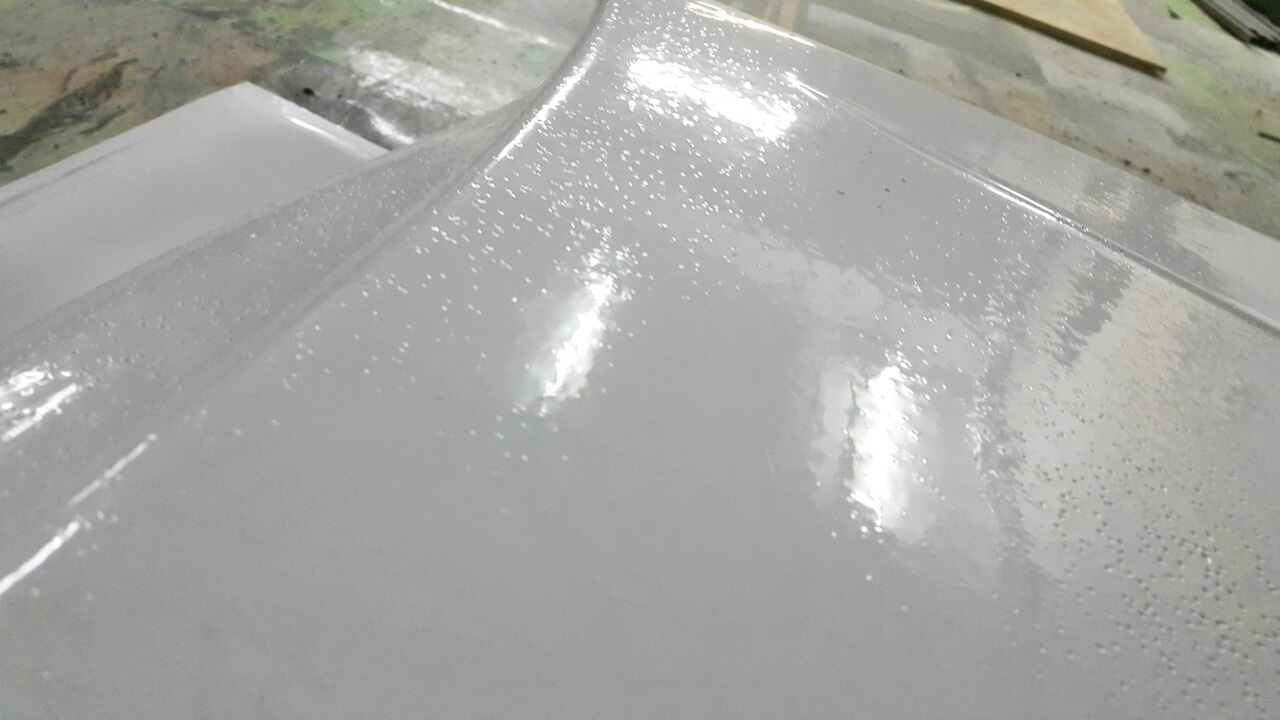

After milling MDF, the obtained parts must be glued together, otshkurit and covered with a layer of epoxy resin to create a protective layer.

Vacuum forming. Third, fourth error

When you have the matrix ready, you can begin the process of forming. We decided to make a molding table ourselves. It would seem that nothing complicated: a table of the required size with technological holes for air discharge, a vacuum pump, infrared lamps. Under the dimensions of the model a frame was made in advance.

Photos of our "machine" did not, but it looked like this. Affected by the lack of experience. Quality product did not work.

Our fourth mistake was that we bought ABS plastic sheets too early. While we were waiting for the model, the plastic absorbed moisture from the air. Because of this, when forming artifacts appeared in the form of bubbles, I had to buy new sheets of ABS.

And as sometimes happens, at the end of our torment, we found acquaintances who provide a full cycle of services for model preparation and thermal vacuum molding. They are located in Nizhny Novgorod, but offered to help for very adequate money. As a result, the molding process was completely outsourced.

The main molding process:

- Fixing the matrix on the vacuum table;

- Fixing a sheet of material in the frame. The fixation of the sheet along the perimeter is important to avoid deformation during heating;

- Heating polymer material. Even heating of the whole sheet is important; infrared emitters or quartz lamps are usually used;

- Pre-stretching sheet. Either under its own weight or air;

- Pressing sheet on the matrix;

- Air exhaust between the sheet and the workpiece;

- Material cooling; A very important step to avoid product deformation.

- Extract matrix;

- Completion of the product.

Process video

Result

Main formed materials

We chose a sheet of ABS 4mm thick because of the availability, it gives when pulling the side walls of 2mm, which is quite suitable for us. In general, there is a huge amount of materials.

Information from Wikipedia

| Polymeric material | ISO designation |

|---|---|

| Standard polystyrene | PS |

| High impact polystyrene | SB, HIPS |

| Styrene-butadiene-styrene block copolymer | Sbs |

| Oriented polystyrene sheet | OPS, BOPS |

| Polystyrene Foam Sheet | EPS, XPS |

| Acrylonitrile styrene copolymer | SAN |

| Copolymer of acrylonitrile, polybutadiene and styrene (ABS plastic) | ABS |

| Copolymer of acrylic ether, styrene and acrylonitrile | ASA |

| Unplasticized polyvinyl chloride | PVC-U |

| Plasticized polyvinyl chloride | PVC-P |

| Polyvinyl Chloride Sheet | EPVC |

| High density polyethylene | HDPE |

| Low density polyethylene | LDPE |

| Polyethylene sheet | EPE |

| Polypropylene | PP |

| Polypropylene sheet | EPP |

| Polymethyl methacrylate | PMMA |

| Polyoxymethylene, polyacetal | POM |

| Polycarbonate | PC |

| Polycarbonate Sheet | EPC |

| Polyether carbonate | Pec |

| Polyphenylene ether | PPE |

| Polyamide | PA |

| Polyethylene terephthalate | PET |

| PET, almost non-crystalline | |

| PET amorphous | |

| PET, partially crystalline (with nucleation) sheet of oriented polyethylene terephthalate | (OPET) |

| Polyethylene Terephthalate Sheet | EPET |

| Polysulfone | PSU |

| Polyethersulfone | PES |

| Polyphenylene sulfide | Pps |

| Acrylonitrile / Methacrylate / Butadiene Copolymer | A / MMA / B |

| Cellulose Acetate | CA |

| Cellulose Acetobutyrate | CAB |

| Cellulose Diacetate | (CdA) |

| Polyetherimide | PEI |

| Thermoplastic elastomers (thermoplastic elastomers) | TPE |

| Thermoplastic Polyolefin Elastomer | TPO |

Video, which is clearly not enough for the presentation of the project. Need MVP with real body

Conclusion

Thermo-vacuum molding is a great way to make a case for prototypes, MVP and small series. After testing the new building, we will most likely try to make the necessary changes to the existing matrix and use it to make a small series.

Thanks for attention!

PS: 6 people from Habr are participating in the project. We are developing three versions of the software (including on the Ardupilot and are starting the version on ROS), have made a Schild board for raspberries, two versions of the case, we have three prototypes and ambitious plans. This robot would not exist if it were not for Habr .