This is an electric bus: what do we know about transport with a battery

After the appearance of the first electric transport in the 19th century and the second surge in popularity in the 70s of the 20th century, electric buses again took to the streets of cities. The fact that influenced their development and how technologies have changed: from creating capacious batteries to developing charging infrastructure - can be found in our new article.

The first electric transport: greetings from the XIX century

Electric cars appeared long before cars with an internal combustion engine. Gottlieb Daimler and Karl Benz patented the first self-propelled carts with a gasoline engine in 1886, while the first electric vehicle for transporting people was introduced in 1837. Due to the high cost and low efficiency of the first electric vehicles could not be with machines with a steam engine. The cost of servicing a car with a zinc battery was 40 times higher than the price of servicing a steam engine on coal.

After the appearance of the available lead-acid batteries, the electric cars managed to enter the fashion for a while. In 1890, American William Morrison built the first electric bus - a car with a capacity of 6 people, which can reach speeds of up to 19 km / h and travels on a single charge of up to 160 km. 24 batteries, weighing almost 350 kg, delivered a current of 112 A with a voltage of 58 V and required 10 hours to fully recharge.

Electric bus of William Morrison. Source: american-automobiles.ru

At the very beginning of the 20th century, 20 electric buses successfully operated on city transport routes in London, which at that time were more efficient and economical than their gasoline counterparts. A single battery charge was enough for 60 km of the way, so at the end stations the empty batteries were replaced with new ones - the process took only three minutes.

London electric bus with a removable battery - a prototype of the future Tesla with quick-release batteries. Source: London Transport Museum

By 1900, 38% of cars in the US were powered by electricity, but improving internal combustion engines and lowering fuel prices dramatically slowed down the development of the autonomous electric transport industry — by the 30s of the 20th century, electric buses had almost disappeared. Unlike gasoline cars, electric transport was not cheaper, and the state of the environment has not yet aroused any concerns. The cross on investments in buses with batteries was set by the appearance of cheap trolleybuses in the 1920s.

The process of replacing the battery in the electric bus is fully automatic, as in the 21st century.

Source: British Library

But due to low fuel prices in the middle of the 20th century, the ICE industry took the path of increasing the volume, which directly affected the consumption of gasoline. Even cars were supplied with uneconomic six-liter engines, servicing of which in the 70s became literally “golden”. The current situation has caused a new surge in popularity of electric vehicles. So in English in Manchester in 1974, electric buses Seddon Pennine 4-236 with chloride batteries came out on city routes.

A rare shot of the Seddon Pennine 4-236 electric bus in 1975.

Source: Alan Snatt

The only universal commercial vehicle left to remember about that time is the Mercedes-Benz LE 306 minivan, whose quick-release battery provided about 76 horsepower, but was exhausted after 50 kilometers. The car lived until 1983, after testing by the postal service of the German city of Bonn, it was declared unprofitable.

Mercedes-Benz LE 306 electric minivan - a reminder of the era of fuel crisis. Source: Mercedes-Benz

Only in the twentieth century, when society began to think about environmental threats and to realize the environmental damage caused by automobile exhaust, began to seriously talk about mass production and the use of electric transport. Against the background of discussing environmental issues, the idea of converting diesel buses to electricity became quite popular, and the appearance of lithium-ion batteries capable of storing energy and providing autonomous movement of electric buses for a long time played a significant role in this. The invention of such batteries also solved the economic problem, making the production and maintenance of electric transport more economical and opening the way for it to the mass market.

Nutrition issues

In modern electric buses, batteries or supercapacitors are used for power supply. The latter method of energy storage is interesting in its own way, although it severely limits the possibilities of electric transport.

Supercapacitors can store as little as 5% of energy compared to lithium-ion batteries of a similar volume. It is obvious that on a single charge of a capacitor the bus will travel only a few kilometers, which means that there is no need to speak of any autonomy. But the positive property of capacitors is the charging speed. It takes seconds to recover a charge.

Chinese Supercapacitor Ultracap Bus at a bus stop with a charging station - looks like a section with trolleybus wires. Source: Shanghai Aowei Technology

So in the Chinese city of Ningbo there is a capacitor electric bus, which needs only 10 seconds for recharging - thanks to the developed infrastructure of charging stations, the bus receives energy at each stop during disembarking and disembarking passengers, which usually lasts a little longer. In addition, up to 80% of the braking energy is converted into electricity and returned back to the capacitors, which saves up to 50%.

Supercapacitors are constantly being improved, but the introduction of electric buses on such batteries requires a very expensive infrastructure in the form of high-power charging stations at each stop. In addition, emergency situations in the form of unexpected traffic jams can leave a bus with discharged capacitors on the road and create additional problems for traffic.

A lithium-ion battery is not a specific type of battery with a single approved composition, but a whole family of energy elements. The development of lithium-ion batteries is a complex process of finding the right balance between power, capacity, compactness and price. The ideal does not exist yet. Each type of lithium-ion battery is good for a particular application. Not all of them are used in electric transport, many find their place in electronics with low power consumption.

Lithium cobalt oxide batteries (LiCoO 2), - the most affordable and popular today, - have excellent capacity per unit volume, low cost and 3.6V voltage per cell. You will find this kind of battery in mobile devices and portable consumer electronics. The disadvantages of such batteries are also known: low discharge current, a maximum of 1000 charge / discharge cycles before the beginning of a serious degradation of capacity, long charging and the inability to work at negative temperatures. An electric bus on LiCoO 2 will be cheaper than on other types of batteries, but it can work only in warm countries on short routes with minimal load, such as transfers within campuses.

Li-manganese battery (LiMn 2 O 4) thanks to the three-dimensional structure, it was able to provide a high discharge current - up to 30 times its capacity. This made it possible to use LiMn 2 O 4 in devices with short-term high power consumption, for example, in electric cars Nissan Leaf and BMW i3. But lithium-manganese batteries showed their disadvantages: even smaller than lithium-cobalt batteries, a vital resource and intolerance to cold. Therefore, lithium-manganese batteries are combined with another type of battery - NMC.

The Nissan Leaf NMC battery costs half the price of a Tesla NCA battery, but also loses its capacity about twice as fast (70% after 100 thousand km). Source: Benjamin Nelson

Lithium-nickel-manganese-cobalt-oxide batteries, or simply NMC, got a good specific energy intensity and service life (up to 2000 discharge cycles), but the return current from them turned out to be small. That is why NMC is combined with LiMn 2 O 4 for use in electric vehicles - during normal driving, NMC cells are mainly used, and during acceleration, LiMn 2 O 4 cells give a high current .

Lithium-nickel-cobalt-aluminum-oxide batteries (LiNiCoAlO 2 , or NCA) have a high specific capacity and an acceptable cost. Charging rate and discharge current for NCA-batteries are average, they can not be written into advantages or disadvantages. It was the NCA that became the energy source for Tesla cars and Powerwall storage systems.

The Tesla Model S 85 kW 540 kg NCA battery, when replaced due to wear, is sent to Tesla Powerwall energy storage systems. Source: wk057

But one feature of the NCA batteries cast a shadow on Tesla even before the owners could face potential problems - the batteries have a service life of 500 cycles comparable to lithium-cobalt cells. And then the replacement and disposal of worn items. Real experience has shown that even after 200 thousand kilometers of battery, Tesla electric vehicles remain working, losing a third of their capacity. But, despite this positive experience, for urban electric vehicles, NCA batteries are not the best choice, because the mileage of buses is many times and even orders of magnitude greater than the mileage of private cars.

Lithium titanate response

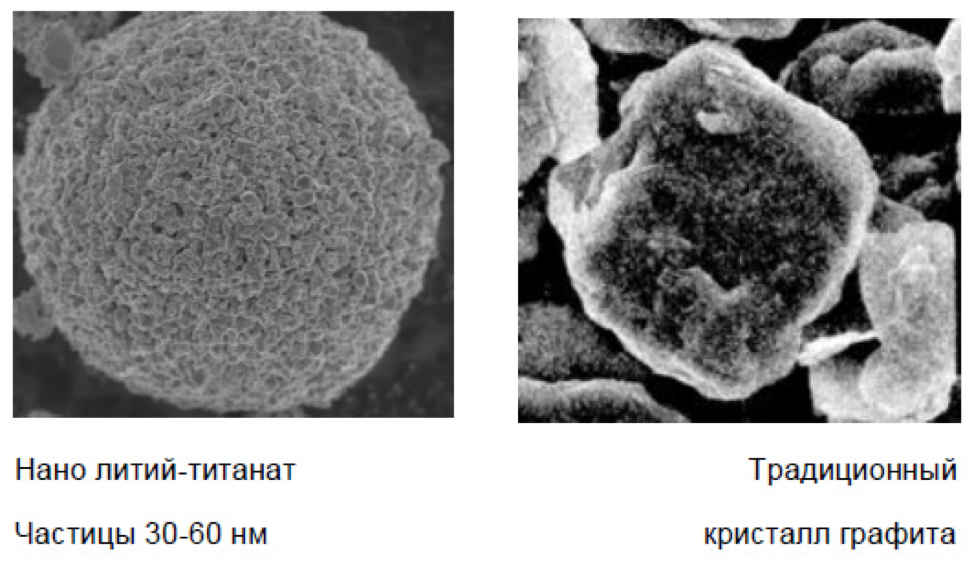

Lithium-titanate batteries (Li 4 Ti 5 O 12 , LTO) have been known since the 1980s. Toshiba actively develops and manufactures this type of battery called SCiB (Super Charge Ion Battery). For the manufacture of the anode they use lithium titanate instead of graphite. In this case, the cathode can be borrowed from NMC-batteries. Replacing graphite made it possible to increase the effective anode area from 3 m 2 / g to 100 m 2 / g, which affects the cell charge rate and discharge current for the better. So in 2017, Toshiba demonstrated a SCiB-battery, capable of recovering up to 90% of its capacity in just 5 minutes.

The porous structure of lithium titanate oxide provides 30 times more area than graphite, and many times longer service life. Source: KB "Energy"

Lithium-titanate batteries stably deliver a current ten times higher than their capacity, and thirty times with pulsed loads. Early samples withstand up to 7,000 discharge cycles, while modern batteries provide 15,000–20000 cycles — no other type of lithium-ion battery can match these indicators. In addition, LTO-batteries are fireproof, during depressurization, they heat up to 70 degrees and cool down, they are also not afraid of overheating. In the cold, the element almost does not lose efficiency - at a temperature of –30 degrees, the capacity of the lithium titanate cell decreases to 80% of the nominal value.

Toshiba lithium titanate battery used in Proterra buses. Source: Proterra

Incredible vitality, instant charging, resistance to cold. Sounds like the perfect battery for your phone. But there are LTO-batteries and their shortcomings, which still limit their use. First of all, this is a low specific capacity of 50-80 W / kg, whereas in traditional lithium-cobalt elements it is 150-200 W / kg - that is, to obtain an equal capacity, the lithium-titanate cell must be twice or three times larger. Secondly, the nominal cell voltage is only 2.4 V versus 3.6 V in lithium-cobalt. Thirdly, while lithium-titanate batteries have a high price, three times higher than that of NCA batteries. That is why it is not yet possible to integrate a lithium-titanate battery into a smartphone - you get an expensive element with low capacity and insufficient voltage to operate the device.

But in electric buses, where there is no shortage of space, and also requires a high battery life, lithium-titanate batteries are the place.

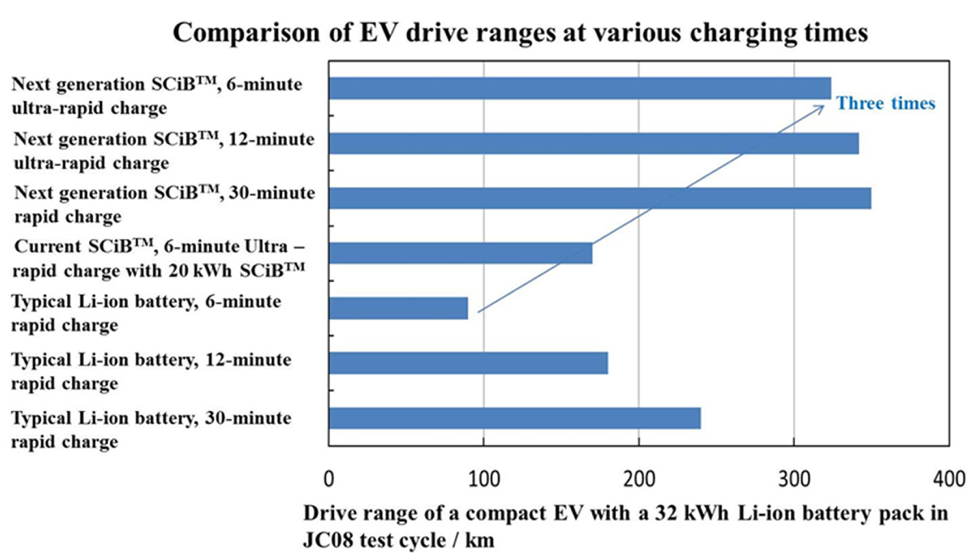

The graph shows the mileage of the test machine on SCiB and lithium-cobalt-oxide batteries. The advantage of SCiB is more than obvious. Source: Toshiba

Recharge question

Without a developed infrastructure, the electric bus turns into a problem. The electric bus can be charged in three different ways: long nightly charging, fast charging at end stations and express charging at stops.

Charging stations at public transport stops are required, for example, for electric buses on supercapacitors: a contact platform or wires, which the bus touches the pantograph, are installed above the pavilion. If supercapacitors have enough power for a few seconds, then at least a minute is needed to recharge the battery. Considering that modern Toshiba lithium titanate batteries restore most of the charge in five minutes, it’s enough to install only a few charging stations on the electric bus route network that can keep the bus batteries charged.

Long nightly charging in public transport is only used in conjunction with one of the two other methods. It is impossible to charge the bus only once a day and send it to the route for the whole day for objective reasons. Firstly, to work for at least half a day, very capacious batteries are needed, which will take up a lot of space in the cabin - this circumstance increases the cost of each bus dramatically. Secondly, it is necessary to bring very powerful power supply lines to the bus depot in order to simultaneously feed dozens and even hundreds of buses.

The serial KamAZ electric bus is charging at the terminus of the Moscow route No. 73.

Source: alisa

What's next?

City electric transport has always been considered a dubious exotic, and now there are hundreds of thousands of electric buses in the world. The champion in the adaptation of new technologies is China, where almost 99% of the electric buses existing in the world are located. According to Bloomberg New Energy Finance, by 2025, 47% of buses in the world will be electric.

Russia is also not lagging behind global trends. Every year, many Russian cities purchase electric transport and take it to regular routes, create a special infrastructure and offer solutions in the field of energy supply. It is possible that the transition to electric transport will be delayed for decades and, perhaps, we will find the time when personal electric cars will no longer be a luxury item and will compete with diesel analogues.