3D pen: prototype or not?

As you remember from my previous posts, we are smoothly moving towards the ability to collect interesting things on our own. For training, we have already assembled a robot from the DIY constructor, excitingly soldered a couple of schemes , and in front of me there are a couple more interesting posts planned for the same very, very beginners. And today, let's take a little rest and see if there are enough 3D pens to prototype our ideas?

Of course, the first thing you are likely to say is: do not complicate. Buy a 3D printer and prototype as much as you want. In principle, I am for it, but I would like to start by trying the technology itself without the need to master software and 3D modeling. In addition, for a beginner, the option with a handle is much more affordable. Well, in principle, this is a spectacular gadget with its own capabilities.

Oddly enough, 3D pens are really used for prototyping. Since the parts drawn with ABS plastic using the lines are very light, they are primarily used in aircraft modeling. On this channel on YouTube, you can follow the desperate attempts of a representative of foggy albion to make such a model of a plane fly. And this is his blog about the same.

Although the model looks pretty pretty, unfortunately, none of the launches have so far really taken place, they all look something like this:

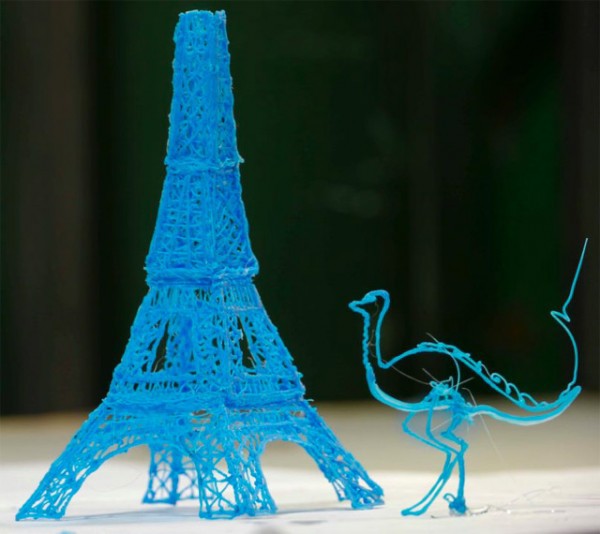

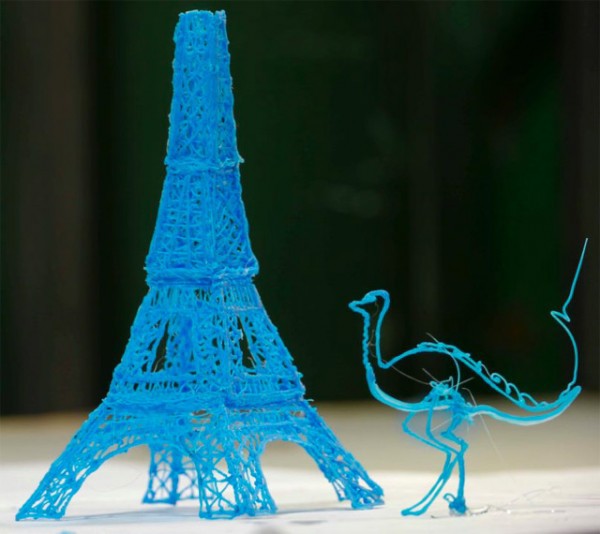

The craftsmen also created a drone from the heading of the post using a 3d pen. See the description of this project here .

It’s especially nice to watch the video of creating and launching another quadrocopter after the previous video - it just took it and flew:

Note to the hostess - the author of the project uses a rather interesting technique of working with a 3D pen and ABS plastic to create such a difficult, in fact, to manually draw parts like a propeller:

The second area in which 3D pens have already found application for creating technology is lighting. You can draw a lot of things with a pen where you can put a light bulb, if you know what I mean : A

lamp by Brooklyn artist Rachel Goldsmith , who was written about in PCmag .

Super-painstaking work of Korean artist Gina Sim - made on the basis of papier-mâché, then cut to remove from the base and again glued with a pen. Her other works are no less impressive.

Our choice fell on the 3Dali pen . In this post, among others, the Myriwell pen is mentioned, a Russified copy of which is Dali. Compared to the Doodler , the handle is smaller in size — it’s more convenient to hold it in your hand — and doesn’t make noise with a cooler like a clipper, as the first version of the handle did.

The only thing that is heard during the work is a slight crackling of the plastic sometimes. In my childhood, such crackles, as well as a characteristic smell, were when we burned the wires. Wires, Carl. How much has changed since then.

In addition to the smaller dimensions, the handle is very light. In addition, she goes into standby after five minutes of inactivity - well done.

TTX

Model: RP-100A

Power supply: 12V DC

Printing material: ABS plastic 1.75 mm

Feed rate: adjustable

Heating temperature: adjustable from 160 to 250 C

Heating power: 12V 3A

Nozzle diameter: 0.4 - 0.7 mm (indicated on the package)

Warranty period: 12 months

Options: adapter, Russified manual, ABS plastic 3 colors

Made in china

Pros:

Separately, a REC plastic kit of 12 colors was used:

Diameter: 1.75 mm

Heating temperature: 210 - 245 C

Weight: 300 g

Nowhere is simpler: like ordinary felt-tip pens, only much more fun. As usual, I was pleased with the simplest instruction on a small sheet, with images - a minimum of reading, a maximum of action!

Key parameters are heating rate and flow temperature. Their correct combination plus a little dexterity allows you to freely use the device.

To get started, fill your hand - here you can take pictures of snowflakes on a sheet of paper. You can download them here .

It is with these stencils that a rainbow girl starts working , devoting her channel to the possibilities of 3D drawing. Here's what she does:

Important! All videos with 3D handles are accelerated to one degree or another. In fact, the 3D modeling process is more painstaking and unhurried work with plastic.

Safety precautions:

Here is the DIY project site with a pen where you can find descriptions of projects and stencils in the public domain. Pinterest dedicated to wire sculpture and products made using a 3D pen.

The Brooklyn Bridge project, stencils for which are publicly available at the link above.

The wire sculpture , which according to Wikipedia information appeared in Ancient Egypt and received a second wind in the 20th century, is very similar to what can be created with a pen. We found the most interesting works from Frank Plant , an American sculptor living in Barcelona: The

man on the box and headphones, the works of Frank Plant.

Many of the works that can be found on the Internet, done with 3d pens, look depressingly clumsy. Firstly, in the first 3Doodler, there were difficulties with the speed and temperature of the feed. Secondly, there were no specific techniques for working with a pen.

In this article, the expert shares some of the best practices. We checked what works and what doesn’t:

Plastic film

How: Hold the pen perpendicularly and press it to the paper. Drive in a circular motion or straight, fast enough. The resulting plastic film is quite flexible.

In fact: ... and quite fragile. The method is not very .

Shaping

Like:ABS freezes in the air, and PLA freezes a little slower, so there are 5-8 seconds to correct it with your fingers. The main thing is not to get burned. The finished product from ABS can be slightly warmed up and bent, correcting irregularities.

In fact: it is torture if the plastic does not harden immediately. It is better to adjust the temperature and feed rate so that this does not happen. If something doesn’t work out, it’s easier just to cut it off with scissors and do it again. We never burned fingers on plastic.

Hold the product with your second hand.

How: With your second hand. The fact is that the first work everyone tried to draw right in the air. But the more part of the product is ready, the more convenient it is to take it in your free hand and twirl it while continuing to draw.

In fact:Works. That is how we made our “lamp” which you will see below.

Polishing the finished product

How: the article gives three options.

In fact: Probably the best thing for this purpose is a soldering iron. Sanding with ABS plastic will not give a result, but you can try using a file - although there are chances that the part will break in the process.

Any basis

How: You can create a product on almost any basis, not just on paper or on a table. You can sink glass, small mirrors, fridge magnets, printed circuit boards, etc. into plastic. For example, this project of marine fish was created on a wooden disc. And these are fridge magnets:

Actually: Works great. Need a frame on which you can "pull" the plastic further. Therefore, it is better to either "draw" it right away and then pick it up, or use at least a ball of paper as a basis.

"String theory"

How: The sloppy appearance of many products was due to the frozen “tails” or “strings” that appeared if the handle was not taken off at the right time. If you need to create a "string" of plastic (for example, you create a "lawn"), stretching from the product - stop pressing the plastic feed button and quickly remove the handle. If you want to avoid creating such a string, stop feeding plastic and hold the knob in place for several seconds.

Actually: Partly true, but on a finished product such a string can simply be cut off with scissors. And it's easier than fooling around like that.

Nothing very strong at first :

Then we tried using a pen to finish the device that was soldered the last time . You probably remember the unlit row of red diodes? Everything is in order, it still does not burn, but on the other hand:

It turned out exactly the prototype - everything we wanted. Here you also need to think over the base case and complete the installation. As in the examples above, the combination of light and a plastic product made with a pen gives a nice effect.

I will experiment more, but I liked the process itself. Plastic can be replaced quickly and work with different colors conveniently. There were no problems with the pen. In addition, the "lampshade" for the device, created "from the air" pleased with this fact alone. Of course, unlike the prototype projects above, this is so far the wildest DIY, but we will continue to explore the capabilities of the device.

Verdict: you can quickly sketch a prototype by hand or painstakingly draw a finished model using a 3D pen. She will remain in my DIY arsenal, especially since plastic is used economically enough. The main advantage here is the fascination of the process itself.

Software and 3D modeling are not needed - this is a plus, just draw a stencil and circle it with a pen. The products are light and transmit light well - this can also be used.

Of the minuses - the products are quite fragile and brittle; they look more like rainbow crafts, rather than technological devices.

Although the latter can just be used for DIY - my "lampshade" suited me perfectly. In this form, he will go to the contest from Masterkit . If I’m lucky, next time I’ll write about prototyping using a 3D printer (although, in my case, of course, this can only happen if there are no more works at the competition =).

At the end of this post, I would like to personally thank everyone who helped me with electronics in the comments on the last post:

ploop , Anisotropic , eta4ever , Zuy , Ako_Ito , Zzzuhell , xReaper , hardex , Deranged , Iv38 , vladikas , argz , apple01 , mickvav , AlNinyo , edejin , alecv , nikitosk , Hoshi , Phmphx , tdhster , timothyz , AlexeyStn , NeoSasha , Ku6ep , Impuls , LAVBoy , klirichek , @Arlakz, as well as Alexei Korotich , Dmitry Gordeev , Rinat Ibragimov .

Thanks a lot for patient answers to the questions and the books sent. Your support inspires you to move on and not be afraid of the new!

Of course, the first thing you are likely to say is: do not complicate. Buy a 3D printer and prototype as much as you want. In principle, I am for it, but I would like to start by trying the technology itself without the need to master software and 3D modeling. In addition, for a beginner, the option with a handle is much more affordable. Well, in principle, this is a spectacular gadget with its own capabilities.

What are others doing?

Oddly enough, 3D pens are really used for prototyping. Since the parts drawn with ABS plastic using the lines are very light, they are primarily used in aircraft modeling. On this channel on YouTube, you can follow the desperate attempts of a representative of foggy albion to make such a model of a plane fly. And this is his blog about the same.

Although the model looks pretty pretty, unfortunately, none of the launches have so far really taken place, they all look something like this:

The craftsmen also created a drone from the heading of the post using a 3d pen. See the description of this project here .

It’s especially nice to watch the video of creating and launching another quadrocopter after the previous video - it just took it and flew:

Note to the hostess - the author of the project uses a rather interesting technique of working with a 3D pen and ABS plastic to create such a difficult, in fact, to manually draw parts like a propeller:

The second area in which 3D pens have already found application for creating technology is lighting. You can draw a lot of things with a pen where you can put a light bulb, if you know what I mean : A

lamp by Brooklyn artist Rachel Goldsmith , who was written about in PCmag .

Super-painstaking work of Korean artist Gina Sim - made on the basis of papier-mâché, then cut to remove from the base and again glued with a pen. Her other works are no less impressive.

3Dali pen 3Dali: test drive

Our choice fell on the 3Dali pen . In this post, among others, the Myriwell pen is mentioned, a Russified copy of which is Dali. Compared to the Doodler , the handle is smaller in size — it’s more convenient to hold it in your hand — and doesn’t make noise with a cooler like a clipper, as the first version of the handle did.

The only thing that is heard during the work is a slight crackling of the plastic sometimes. In my childhood, such crackles, as well as a characteristic smell, were when we burned the wires. Wires, Carl. How much has changed since then.

In addition to the smaller dimensions, the handle is very light. In addition, she goes into standby after five minutes of inactivity - well done.

TTX

Model: RP-100A

Power supply: 12V DC

Printing material: ABS plastic 1.75 mm

Feed rate: adjustable

Heating temperature: adjustable from 160 to 250 C

Heating power: 12V 3A

Nozzle diameter: 0.4 - 0.7 mm (indicated on the package)

Warranty period: 12 months

Options: adapter, Russified manual, ABS plastic 3 colors

Made in china

Pros:

- Simplicity

- Dimensions

- Temperature and feed rate controls

- In the event of a device malfunction, a free exchange is provided.

Separately, a REC plastic kit of 12 colors was used:

Diameter: 1.75 mm

Heating temperature: 210 - 245 C

Weight: 300 g

How to draw?

Nowhere is simpler: like ordinary felt-tip pens, only much more fun. As usual, I was pleased with the simplest instruction on a small sheet, with images - a minimum of reading, a maximum of action!

Key parameters are heating rate and flow temperature. Their correct combination plus a little dexterity allows you to freely use the device.

To get started, fill your hand - here you can take pictures of snowflakes on a sheet of paper. You can download them here .

It is with these stencils that a rainbow girl starts working , devoting her channel to the possibilities of 3D drawing. Here's what she does:

Important! All videos with 3D handles are accelerated to one degree or another. In fact, the 3D modeling process is more painstaking and unhurried work with plastic.

Safety precautions:

- Do not touch the tip - up to 230 degrees according to the instructions and up to 250 according to TTX.

- Do not give children under 8 years of age (terrible injustice: of course, give, but under supervision).

- Ventilate the room

- Don't turn on

- What horrible handle does not melt.

What to draw?

Here is the DIY project site with a pen where you can find descriptions of projects and stencils in the public domain. Pinterest dedicated to wire sculpture and products made using a 3D pen.

The Brooklyn Bridge project, stencils for which are publicly available at the link above.

The wire sculpture , which according to Wikipedia information appeared in Ancient Egypt and received a second wind in the 20th century, is very similar to what can be created with a pen. We found the most interesting works from Frank Plant , an American sculptor living in Barcelona: The

man on the box and headphones, the works of Frank Plant.

Equipment

Many of the works that can be found on the Internet, done with 3d pens, look depressingly clumsy. Firstly, in the first 3Doodler, there were difficulties with the speed and temperature of the feed. Secondly, there were no specific techniques for working with a pen.

In this article, the expert shares some of the best practices. We checked what works and what doesn’t:

Plastic film

How: Hold the pen perpendicularly and press it to the paper. Drive in a circular motion or straight, fast enough. The resulting plastic film is quite flexible.

In fact: ... and quite fragile. The method is not very .

Shaping

Like:ABS freezes in the air, and PLA freezes a little slower, so there are 5-8 seconds to correct it with your fingers. The main thing is not to get burned. The finished product from ABS can be slightly warmed up and bent, correcting irregularities.

In fact: it is torture if the plastic does not harden immediately. It is better to adjust the temperature and feed rate so that this does not happen. If something doesn’t work out, it’s easier just to cut it off with scissors and do it again. We never burned fingers on plastic.

Hold the product with your second hand.

How: With your second hand. The fact is that the first work everyone tried to draw right in the air. But the more part of the product is ready, the more convenient it is to take it in your free hand and twirl it while continuing to draw.

In fact:Works. That is how we made our “lamp” which you will see below.

Polishing the finished product

How: the article gives three options.

- Bonsai technique: cutting off excess works.

- Soften with a hairdryer - does not work. It would be strange if the hair dryer (for the head!) Heated to 230C.

- Soften the handle with a nose - does not work. Or it works, but somehow it’s not very effective.

In fact: Probably the best thing for this purpose is a soldering iron. Sanding with ABS plastic will not give a result, but you can try using a file - although there are chances that the part will break in the process.

Any basis

How: You can create a product on almost any basis, not just on paper or on a table. You can sink glass, small mirrors, fridge magnets, printed circuit boards, etc. into plastic. For example, this project of marine fish was created on a wooden disc. And these are fridge magnets:

Actually: Works great. Need a frame on which you can "pull" the plastic further. Therefore, it is better to either "draw" it right away and then pick it up, or use at least a ball of paper as a basis.

"String theory"

How: The sloppy appearance of many products was due to the frozen “tails” or “strings” that appeared if the handle was not taken off at the right time. If you need to create a "string" of plastic (for example, you create a "lawn"), stretching from the product - stop pressing the plastic feed button and quickly remove the handle. If you want to avoid creating such a string, stop feeding plastic and hold the knob in place for several seconds.

Actually: Partly true, but on a finished product such a string can simply be cut off with scissors. And it's easier than fooling around like that.

What did we end up with?

Nothing very strong at first :

Then we tried using a pen to finish the device that was soldered the last time . You probably remember the unlit row of red diodes? Everything is in order, it still does not burn, but on the other hand:

It turned out exactly the prototype - everything we wanted. Here you also need to think over the base case and complete the installation. As in the examples above, the combination of light and a plastic product made with a pen gives a nice effect.

I will experiment more, but I liked the process itself. Plastic can be replaced quickly and work with different colors conveniently. There were no problems with the pen. In addition, the "lampshade" for the device, created "from the air" pleased with this fact alone. Of course, unlike the prototype projects above, this is so far the wildest DIY, but we will continue to explore the capabilities of the device.

Verdict: you can quickly sketch a prototype by hand or painstakingly draw a finished model using a 3D pen. She will remain in my DIY arsenal, especially since plastic is used economically enough. The main advantage here is the fascination of the process itself.

Software and 3D modeling are not needed - this is a plus, just draw a stencil and circle it with a pen. The products are light and transmit light well - this can also be used.

Of the minuses - the products are quite fragile and brittle; they look more like rainbow crafts, rather than technological devices.

Although the latter can just be used for DIY - my "lampshade" suited me perfectly. In this form, he will go to the contest from Masterkit . If I’m lucky, next time I’ll write about prototyping using a 3D printer (although, in my case, of course, this can only happen if there are no more works at the competition =).

At the end of this post, I would like to personally thank everyone who helped me with electronics in the comments on the last post:

ploop , Anisotropic , eta4ever , Zuy , Ako_Ito , Zzzuhell , xReaper , hardex , Deranged , Iv38 , vladikas , argz , apple01 , mickvav , AlNinyo , edejin , alecv , nikitosk , Hoshi , Phmphx , tdhster , timothyz , AlexeyStn , NeoSasha , Ku6ep , Impuls , LAVBoy , klirichek , @Arlakz, as well as Alexei Korotich , Dmitry Gordeev , Rinat Ibragimov .

Thanks a lot for patient answers to the questions and the books sent. Your support inspires you to move on and not be afraid of the new!