Chips with sub-threshold operating supply voltages - a revolutionary approach to reducing current consumption

Recently, in my work I constantly face challenges to reduce the consumption of developed microcircuits. The most popular solutions at the moment are dynamic control of clocking and supply voltage. Those. if for solving the current problem this or that block of the microcircuit is not required, then clocking is turned off for it, the supply voltage is reduced or completely turned off. Such giants as Texas Instruments and Renesas are still being measured

The energy consumed by the chip is due to two reasons:

- static leakage current in transistors even if they are not switched.

- dynamic current required to recharge circuit capacitance when switching occurs.

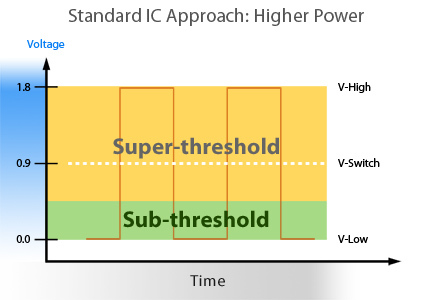

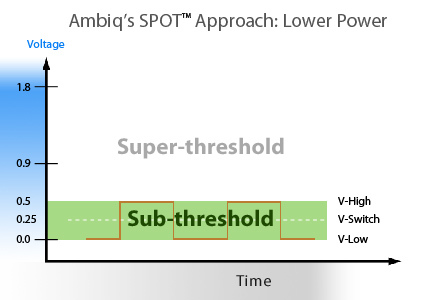

For conventional circuits, dynamic current prevails during operation, especially for the high levels of supply voltage that are currently in use. The dependence of the consumption currents on the supply voltage is shown in the following figure.

Since the dynamic current of consumption is proportional to the square of the supply voltage, it is the decrease in the supply voltage that is the main key to reducing the total consumption of the microcircuit (in this case, we have the opposite, but not as dramatic effect of the increase in the static current of consumption). For example, if you compare a conventional circuit with 1.8V power and a circuit operating in the vicinity of the threshold region by 0.5V, then the dynamic consumption is reduced by 13 times. And for a circuit operating at a threshold voltage of 0.3 V, consumption can be reduced by 36 times.

The traditional design of digital circuits involves two transistor states - “open” and “closed” - and this is the basis of the concept of implementing digital logic. Analog developers can operate with transistors in gain mode, i.e. on the threshold of damage. The use of sub-threshold voltages means that the transistor will never be “open”. And thus, the “logical unit” will correspond to the state of the transistor that is practically indistinguishable from the “closed” one. And this means that for the implementation of microcircuits according to this scheme, new approaches and solutions are required.

Subthreshold solutions have been known for several decades.

The development of circuits with sub-threshold supply voltages is not something supernova. Back in the 70s, Swiss watchmakers noticed the potential for using transistors in a subthreshold mode. This idea is used for pacemakers and RFID tags, but so far it has not been actively used anywhere else. After a lull that lasted several decades, this topic regained academic interest in the late 90s and early 2000s. By this time, the importance of current consumption in commercial electronics became apparent, and research began on various methods in the field of reducing current consumption. Ambiq's founders were part of academic research data when they worked at the University of Michigan. The main focus of their research was the commercialization of this technology.

The question arises, why if the ability to work with subthreshold supply voltages has been known since the 70s, then it still does not apply. It is possible that the disadvantages of this approach do not allow its application in ordinary conditions. Simply put: "If it is so simple, then why does not everyone do it?" The answer is simple: "Because it is very difficult." There are no fatal flaws in this technology, but the transition to methods of working with subthreshold supply voltages is not trivial. You can also ask what has changed since the 70s, when the first subliminal commercial devices appeared. First of all, the scale has changed. Old designs used a maximum of several tens of transistors operating in a subthreshold mode and such a circuit could be calculated and optimized manually. Chips now contain millions of transistors. It is impossible to calculate such a scheme manually and for their development it is necessary to use standard software tools that are primarily focused on working with standard above-threshold logic. And the adaptation of standard tools and approaches for working with subthreshold supply voltages allowed Ambiq to commercialize this technology.

Subthreshold Issues

Adaptation of standard subthreshold approaches for developing circuits with subthreshold supply voltages has several key problems.

Bad transistor models

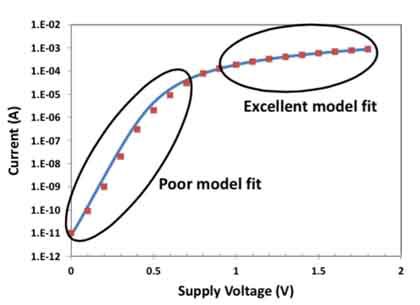

The transistor model is the basis of everything in the development of modern microelectronics. All simulators, all abstractions and automation of the entire development process are tied to the accuracy of the transistor model.

Most modern transistor models focus on its operation at high supply voltages, i.e. they accurately describe his behavior when eating well above the threshold. But when powered from 0V to the threshold, these models do not work at all or produce inadequate data.

Logic switching and noise

In the subthreshold mode, to detect a change in the current through the transistor during the transition from the "open" to the "closed" state and vice versa, a greater sensitivity is required. And although the currents change exponentially from a change in voltage, but they still remain extremely small. In the subthreshold mode, the current through the "open" transistor is only 1000 times greater than the current of the "closed" transistor, while in normal mode this ratio exceeds several million. Thus, it is much easier for external noise to distort the operation of the circuit.

Sensitivity to operating conditions

The subthreshold mode of operation of the transistor is also much more sensitive to deviations of the manufacturing process and environmental conditions. For example, when the manufacturing process of crystals is deviated to the slow side, the current through the transistor will be 10-100 times less than with a typical process. Given the fact that the ratio of the currents of “open” and “closed” is already about a thousand, such a change cannot be ignored.

Temperature changes also have a huge effect on the currents of transistors. Moreover, changes in currents in the subthreshold mode are orders of magnitude superior to changes in currents in normal mode. Thus, when developing a circuit using sub-threshold supply voltages, developers require additional efforts to make the circuit operational in various operating conditions.

Infrastructure problems

The current process for the production of microcircuits is based on the use of suprathreshold supply voltages, and cease to work when applied under threshold technology. This is associated with various problems, for example, test installations and measuring instruments with which the manufacturing processes are controlled do not have the sufficient accuracy required to work with threshold supply voltages. These measuring instruments allow you to measure microamps, and you need nano- and even picoamper ranges.

Even the set of characteristics of circuits at a subthreshold supply voltage should be rethought in relation to traditional circuits. A typical set of properties cannot be sufficient to prove that a circuit with a sub-threshold supply voltage will work completely correctly in all operating modes.

Ambiq Solution

The technology developed by Ambiq SPOT allows you to better understand the behavior of the transistor in these conditions. Ambiq characterized a selected set of transistors from conventional fabrication technology for operation in a subthreshold mode. With this characterization, a large number of transistors of the same type were measured to obtain high-quality statistical data on the scatter of parameters, this is necessary in order to detect and understand the various effects caused by the deviation of the manufacturing process, the influence of the environment.

After the high-quality models of transistors were obtained on their basis, a library of standard digital cells was developed that can operate in a subthreshold mode. This library is also thoroughly researched and characterized. When developing the library of standard cells, two mutually exclusive problems had to be solved - we had to make circuits with extremely high sensitivity, and at the same time minimize our own cell consumption.

The development of analog circuits requires additional effort. While the development of digital cells for the subthreshold mode was largely built on the processing of existing solutions, the development of analog blocks requires other circuitry solutions that are fundamentally different for those that are usually used. When developing circuits with subthreshold power levels, there are no general approaches suitable for all cases. In some cases, it was not possible to implement the circuit on a subthreshold mode of the transistors, and it was necessary to use transistors in the normal mode with the usual power supply, and the use of such circuits in small quantities does not significantly affect the overall consumption. A good example of this is non-volatile memory, which stores settings and calibration factors while the device is turned off. When the power is turned on, the circuit starts to operate in a mode with power above the threshold. After the setup is completed and the calibration coefficients are transferred to the setup registers, the power is reduced to a sub-threshold level, and non-volatile memory is no longer used. In cases where increased performance is required and the subthreshold voltage is no longer enough to provide the required speed, the voltage can be raised to a threshold level or even higher. Obviously, in this case, consumption is growing. Also, for the stable operation of the circuit, it is necessary to dynamically monitor external factors, for example, such as temperature, and, depending on them, restructure the operating modes of subthreshold circuits to ensure their high-quality operation. After the setup is completed and the calibration coefficients are transferred to the setup registers, the power is reduced to a sub-threshold level, and non-volatile memory is no longer used. In cases where increased performance is required and the subthreshold voltage is no longer enough to provide the required speed, the voltage can be raised to a threshold level or even higher. Obviously, in this case, consumption is growing. Also, for the stable operation of the circuit, it is necessary to dynamically monitor external factors, for example, such as temperature, and, depending on them, restructure the operating modes of subthreshold circuits to ensure their high-quality operation. After the setup is completed and the calibration coefficients are transferred to the setup registers, the power is reduced to a sub-threshold level, and non-volatile memory is no longer used. In cases where increased performance is required and the subthreshold voltage is no longer enough to provide the required speed, the voltage can be raised to a threshold level or even higher. Obviously, in this case, consumption is growing. Also, for the stable operation of the circuit, it is necessary to dynamically monitor external factors, for example, such as temperature, and, depending on them, restructure the operating modes of subthreshold circuits to ensure their high-quality operation. In cases where increased performance is required and the subthreshold voltage is no longer enough to provide the required speed, the voltage can be raised to a threshold level or even higher. Obviously, in this case, consumption is growing. Also, for the stable operation of the circuit, it is necessary to dynamically monitor external factors, for example, such as temperature, and, depending on them, restructure the operating modes of subthreshold circuits to ensure their high-quality operation. In cases where increased performance is required and the subthreshold voltage is no longer enough to provide the required speed, the voltage can be raised to a threshold level or even higher. Obviously, in this case, consumption is growing. Also, for the stable operation of the circuit, it is necessary to dynamically monitor external factors, for example, such as temperature, and, depending on them, restructure the operating modes of subthreshold circuits to ensure their high-quality operation.

A lot of effort was spent on the fact that the technology of work in subthreshold modes would ensure operability in the framework of standard processes for the manufacture of crystals. Special processes for making crystals could make life easier, but they significantly increased the cost of manufacturing. Ambiq technology works in those processes that are already well known and tested and are widely used.

The development process is based on a special library characterized for special working conditions in subthreshold modes. This process largely repeats the tasks that arise when developing a circuit for a 28-nm process. Ambiq just did the same for simpler and more affordable technologies, which significantly reduced consumption.

A lot of attention was paid to the problems of testing circuits. Since conventional measuring equipment cannot accurately measure microcircuit consumption. Screening testing of microcircuits also requires more thoroughness than is usual for conventional microcircuits, since it is necessary to measure the microcircuit in more combinations of environmental conditions.

In general, all stages of the development of microcircuits were rethought and changed to ensure the operation of the circuit in a subthreshold mode and reduce the current consumption. The development of schemes for new technology requires that they be verified that they work for a long time. For hardware developers, the reliability of microcircuits is an equally important parameter along with consumption. Therefore, Ambiq's microcircuits were subjected to a series of reliability tests, including under extreme environmental conditions. In addition, other standard tests were carried out, for example, resistance to static electricity. All tests have proved that microcircuits have the necessary reliability.

Conclusion

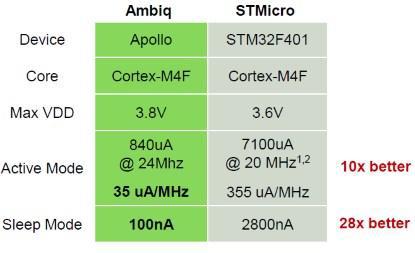

Currently, Ambiq has already released a series of real-time clock chips with a consumption of no more than 55 nA. And he plans to start production of Apollo series microcontrollers with an extremely low level of consumption of 30 μA / MHz.

Key features of Apollo microcontrollers:

- Extremely low active consumption 30 μA / MHz

- Ultra-low power consumption in sleep mode 100 nA (RTC on)

- High Performance ARM Cortex-M4F Core

- Clock frequency up to 24 MHz

- Program memory up to 512 KB Flash

- Data memory up to 64 Kbytes

- ADC 10 bits, 13 channels at speeds up to 1 MSa / s

- Standard peripheral kit I2C, SPI, UART

- Supply voltage from 1.8V to 3.8V

- Compact 64-pin BGA and 42-pin CSP enclosures

Comparison of the Apollo microcontroller with other microcontrollers: The

comparison was carried out on the Coremark test.

According to the materials: