Automatic 3D packaging size scanner

Recently they have set a very specific task for us, from the warehouse of one of the Russian distributors of electronic components, from which we send our products to our customer, among many other parcels. Oh well! Let's try ... Moreover, some time ago, an ultrasonic sensor for measuring distances appeared in our samples . In price, it was noticeably different from the widespread ones, but the manufacturer promised better measurement accuracy. And just at that time we made our own version of the microcontroller compatible with Arduino Leonardo in terms of functions, providing the board with screw connectors, LCD sockets and a number of other lotions designed to expand the module's capabilities in the future.

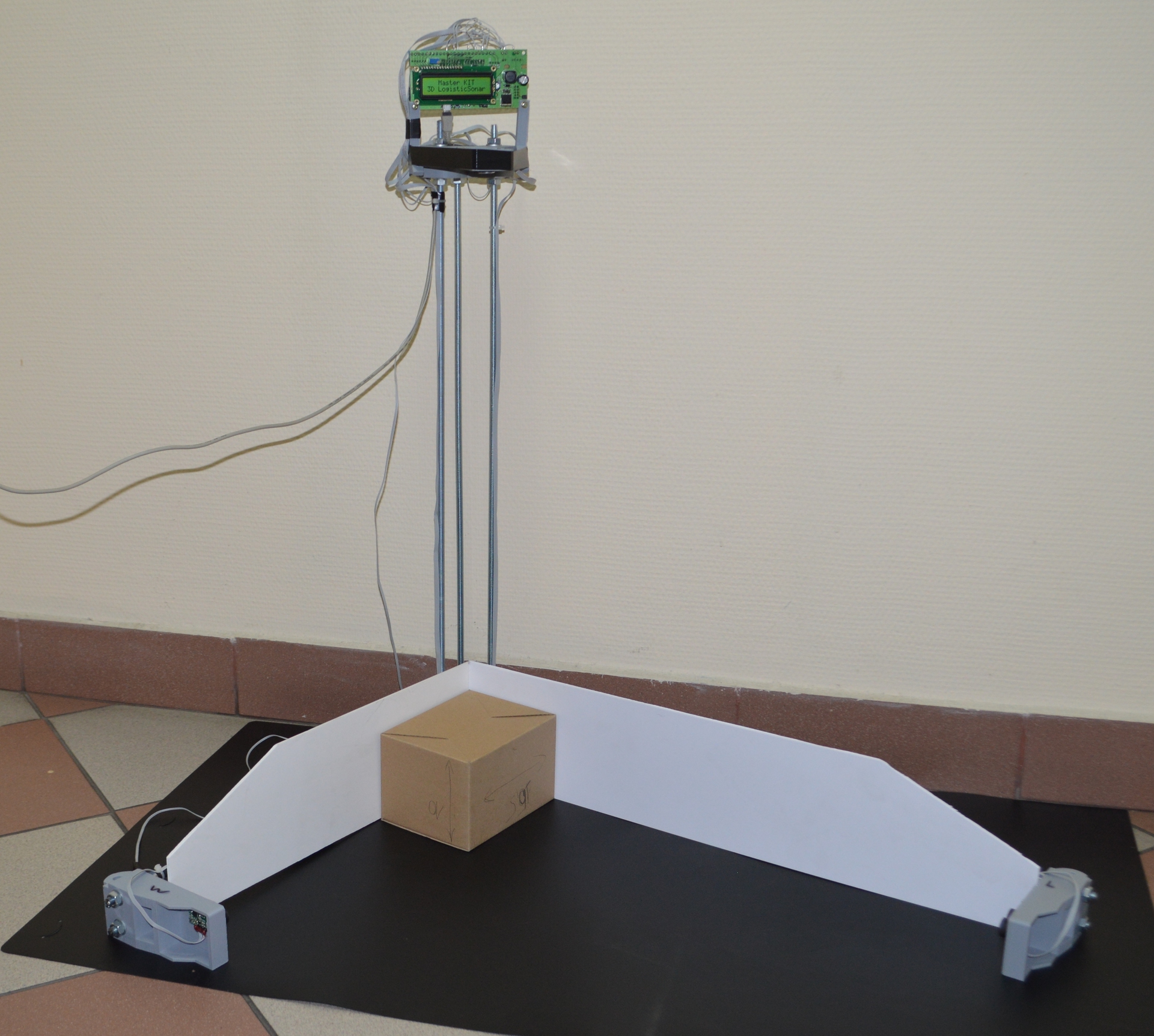

This is how the packer’s workplace looks, where he weighs and measures the packaging:

Let's try to improve and automate it.

The silver surface is the scales, they are connected to the computer through their own COM port and automatically transfer the weight to the accounting system. But to measure the size of the box, local innovators placed next to the scales of the line, from improvised means. This significantly increased labor productivity, but the data had to be entered into the system by hand using the keyboard.

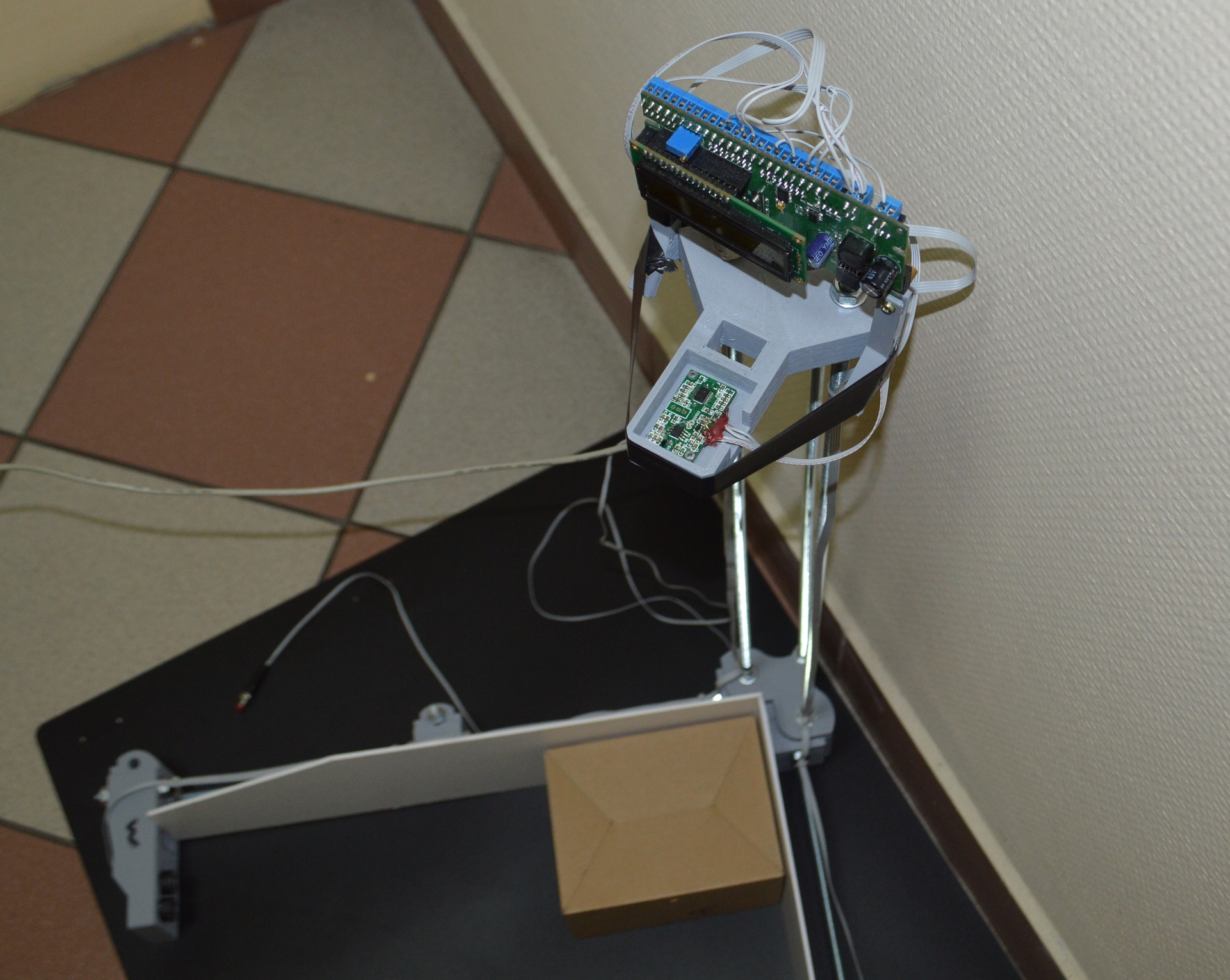

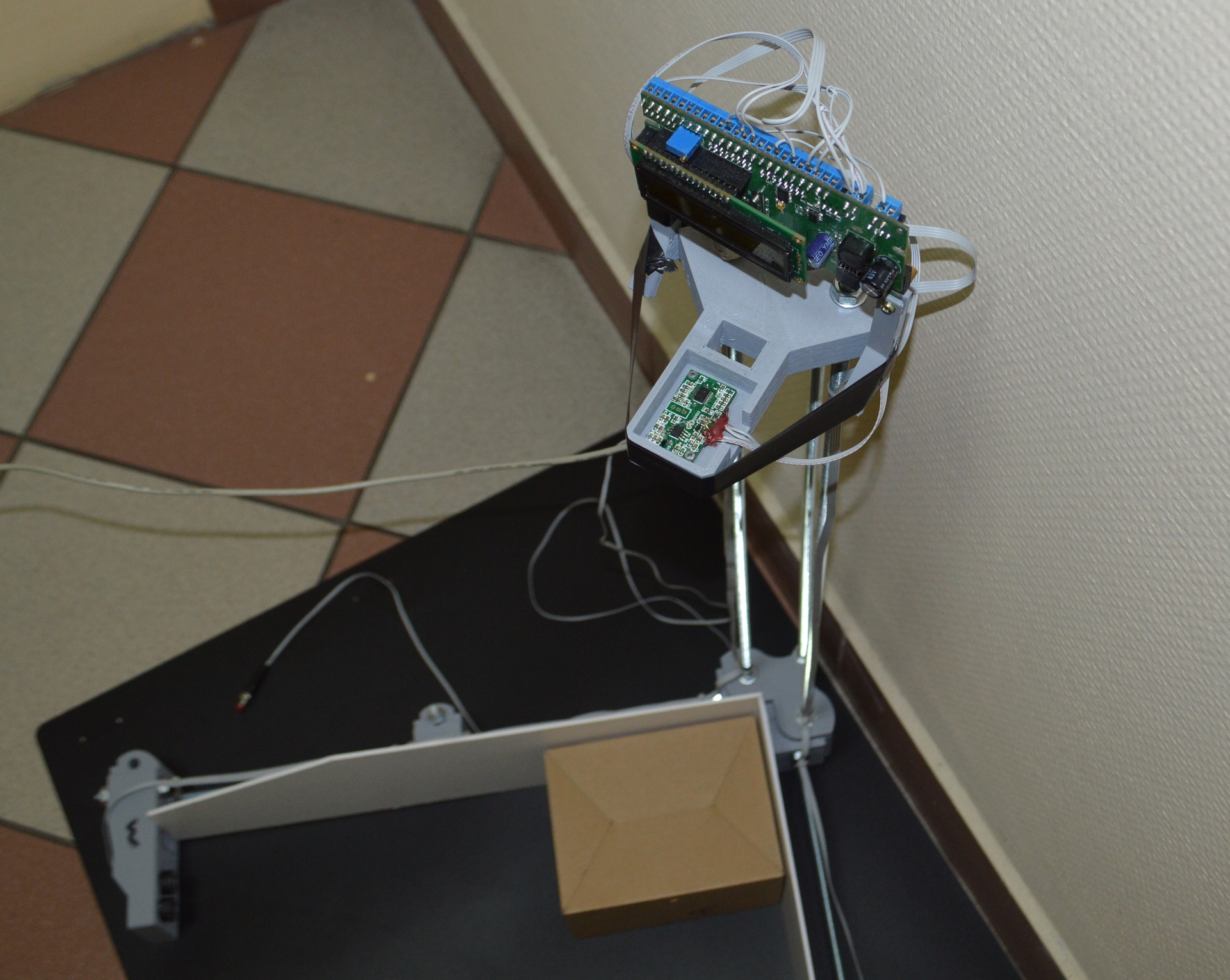

So, for the prototype we take the workplace as a basis and add sensors to the Wood-Cartesian coordinate system, rotate them in the axes, connect them to the microcontroller, write a sketch in the ARDUINO IDE using the sensor library and Leonardo built-in capabilities. Namely, that the Atmega 32u4 microcontroller used is connected to a computer via the built-in USB interface using the technology of HID devices. This is how keyboards, mice, and trade barcode scanners work. This is exactly what we need - to transfer data to the keyboard buffer, simulating manual data entry.

Look at the video, what happened in the "draft"

We wrote a simple sketch. Having implemented only the basic functions, but nothing prevents to supplement it with various services such as manual calibration, changing the unit of measurement, setting the transmitted characters depending on the accounting system used, etc. The controller memory is large enough and will allow this in the future if necessary.

In the meantime, the sketch works according to the following logic:

• After turning on, each of the three sensors measures the distance from itself to the opposite wall and remembers this distance as the base

• Goes into operation mode and cyclically measures the current distance

• If the current distance is noticeably different from the base - the device considers that a box is placed in the measurement zone. The measurement takes place in three axes according to the formula:

Side size = Base - current distance

• The size along three axes is recorded in the corresponding variables.

• Transfer to the computer is carried out by pressing the button by the operator. This is done to eliminate false positives.

• After data transfer, the button is pressed until the box is removed. The system will feel this by measuring the current distance - it will again become equal to the base.

• The cycle repeats - the system waits for a new box.

So, we made, installed, tuned the sensors for the experiment at fixed base distances ... and left them for trial operation. What did she show? We didn’t get the accuracy of measurements, but the accuracy is quite suitable for the logistic task.

Besides:

• Increased productivity - Yes.

• Convenience for the packer - Yes.

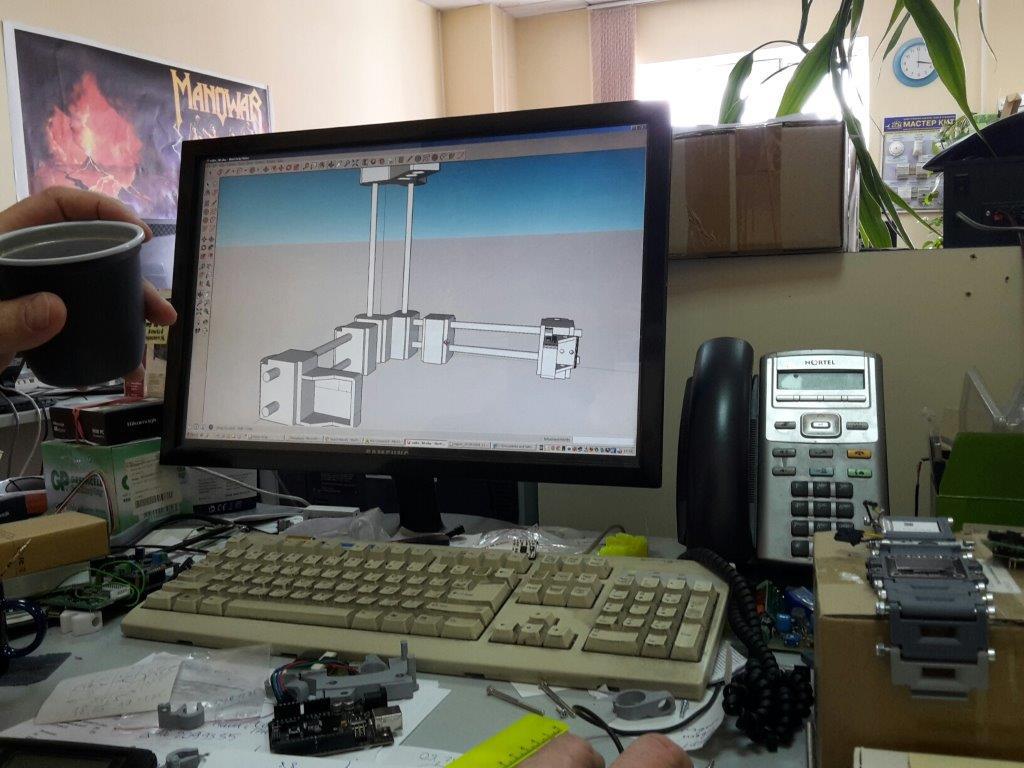

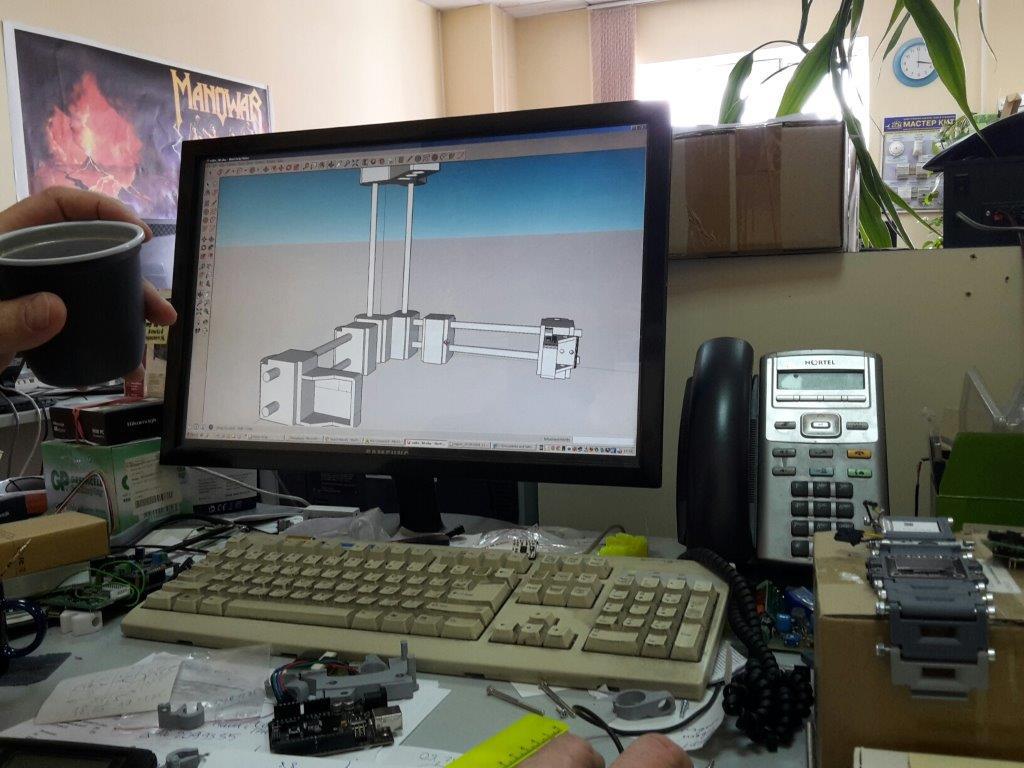

The second stage of our development has begun - bringing to the presentation. The designer took up the matter and with the help of SketchUp and several cups of coffee he developed a design that was somewhat similar to the well-known RepRap 3D printer.

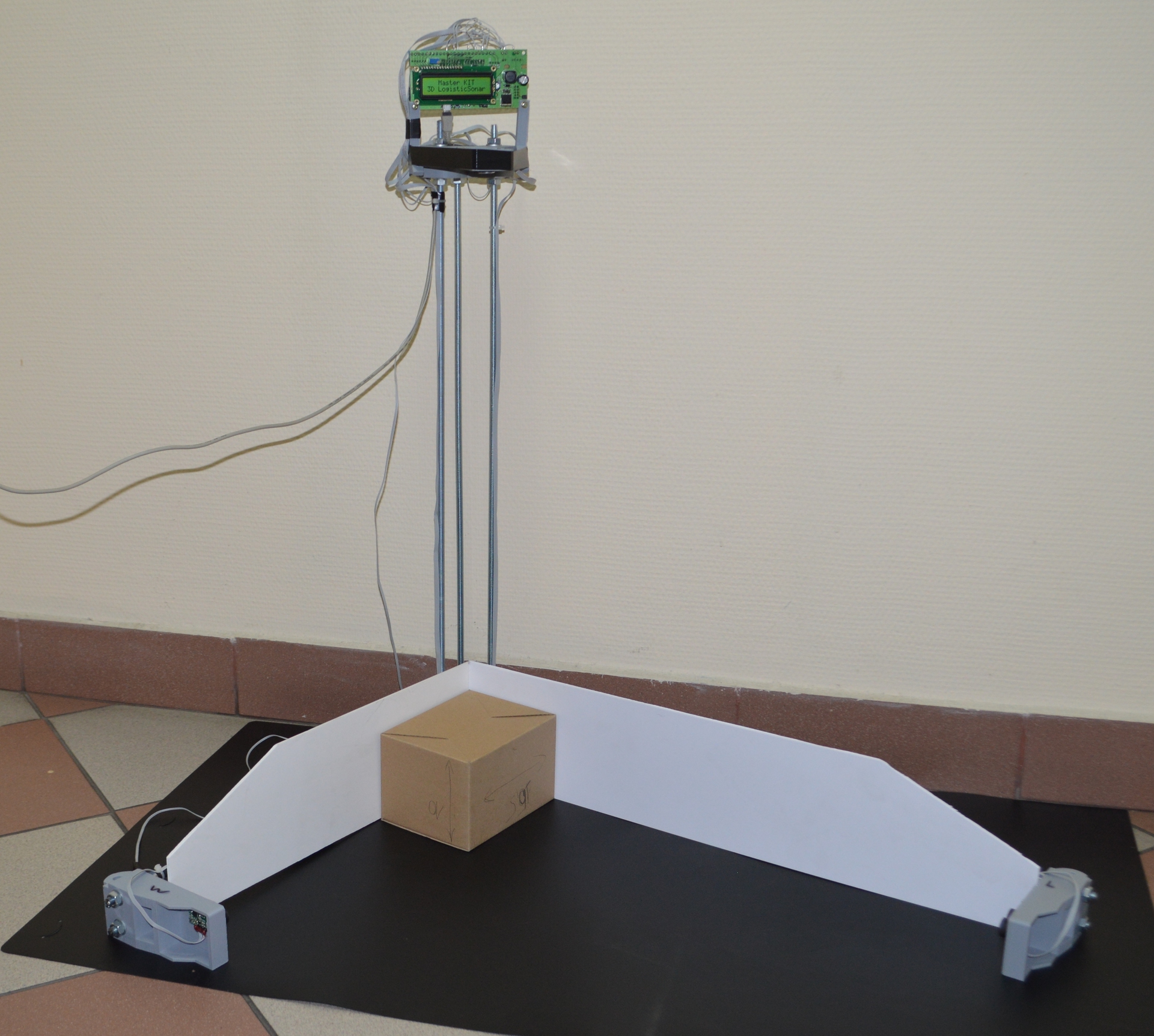

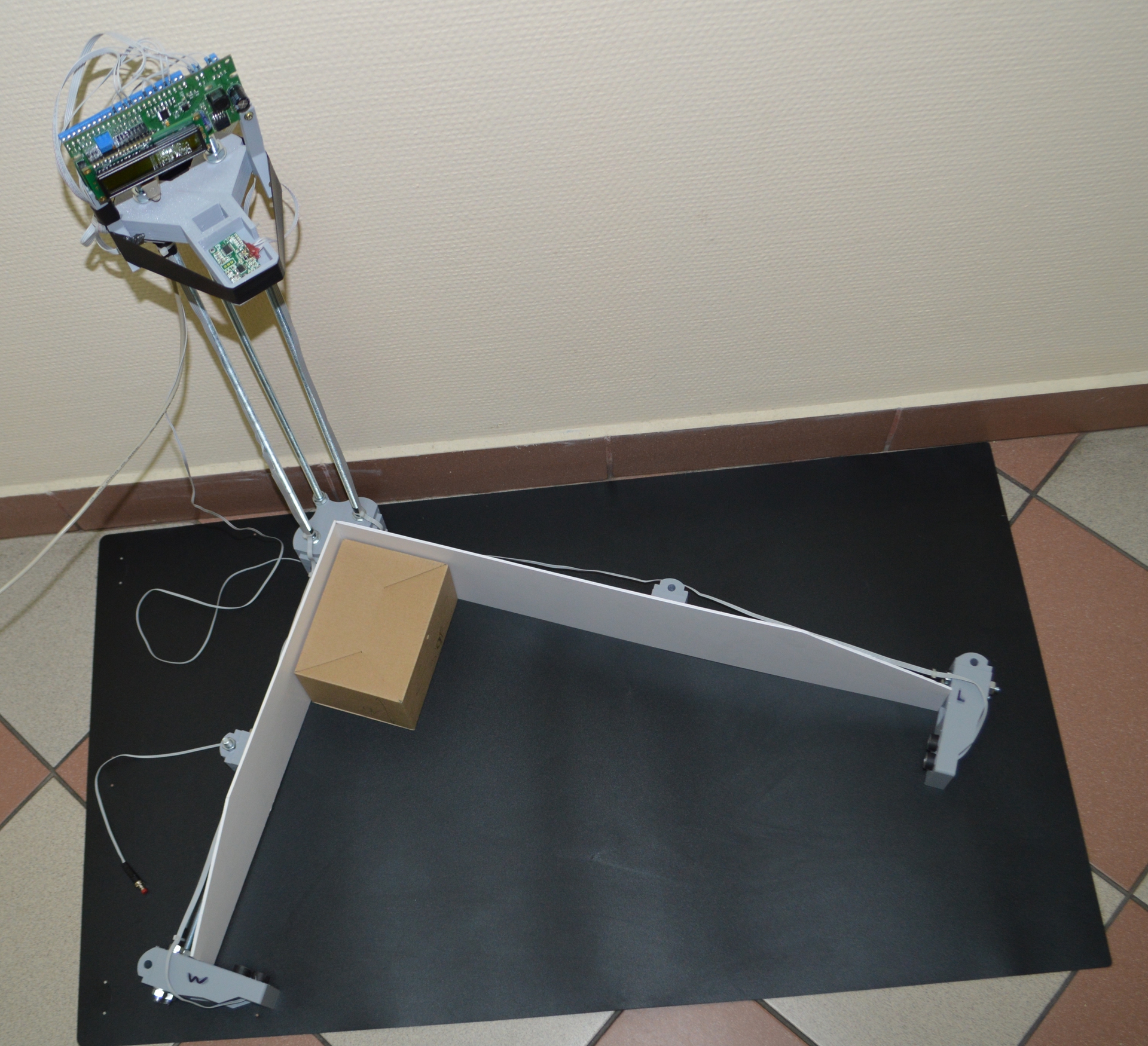

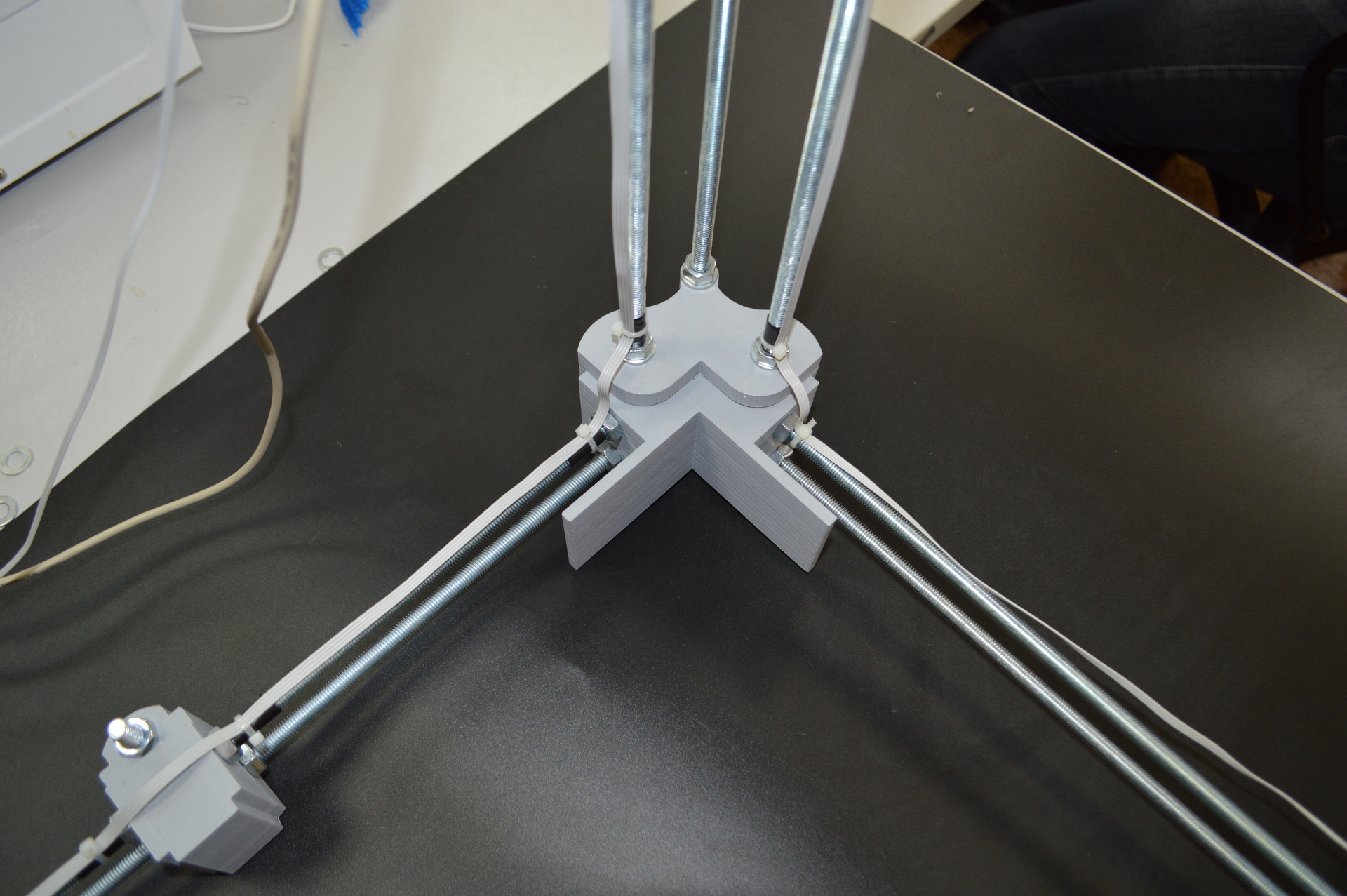

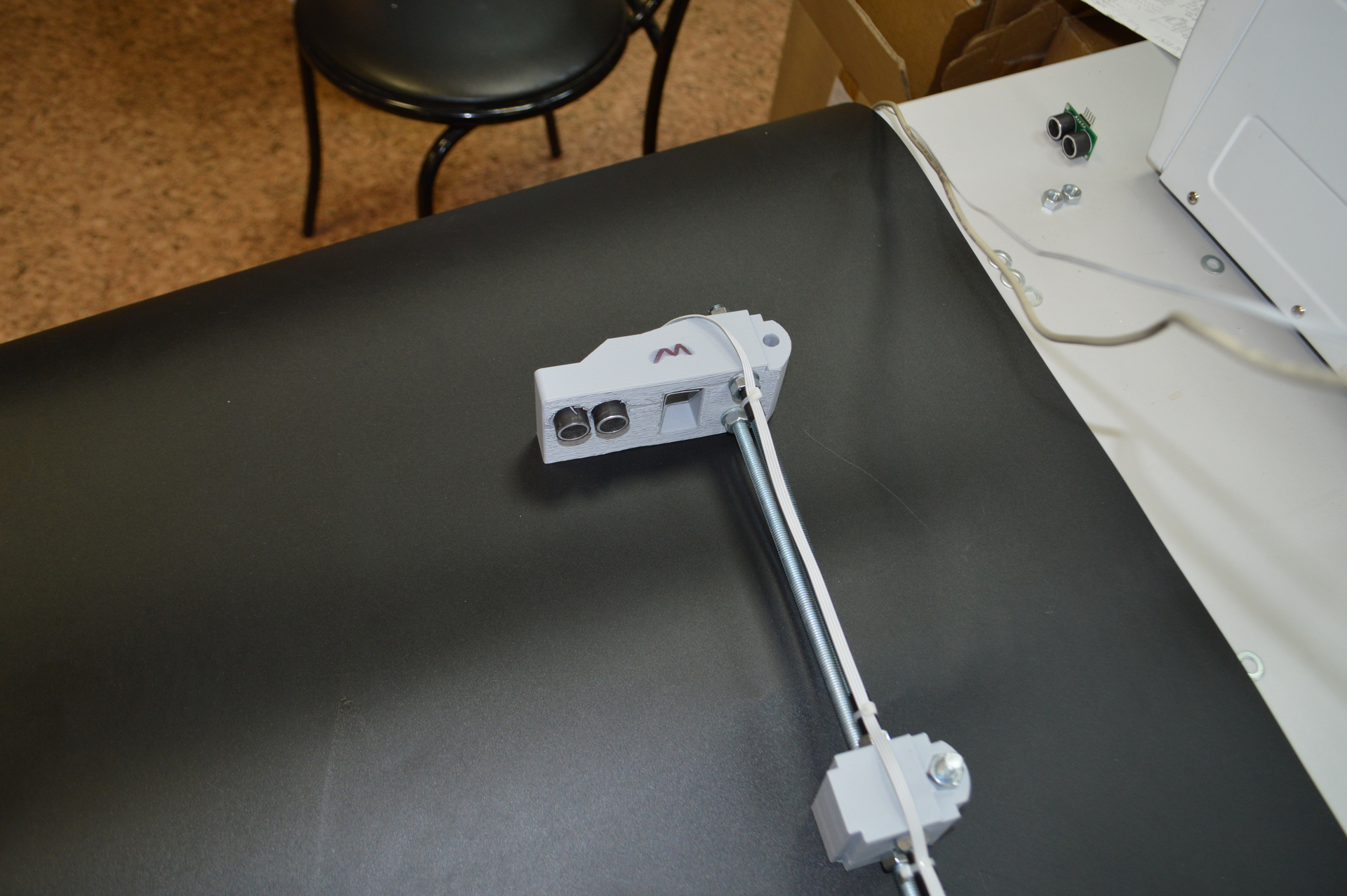

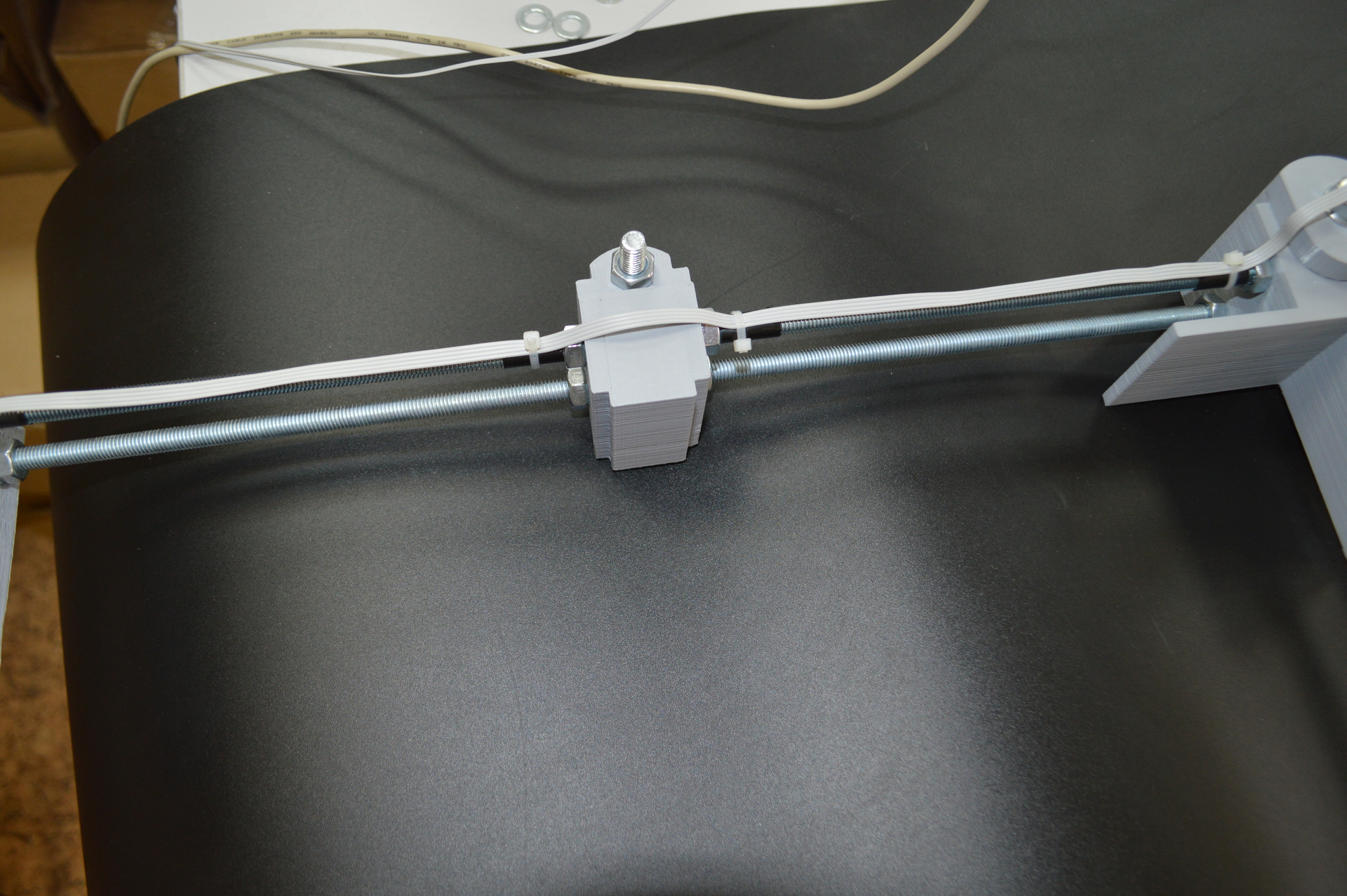

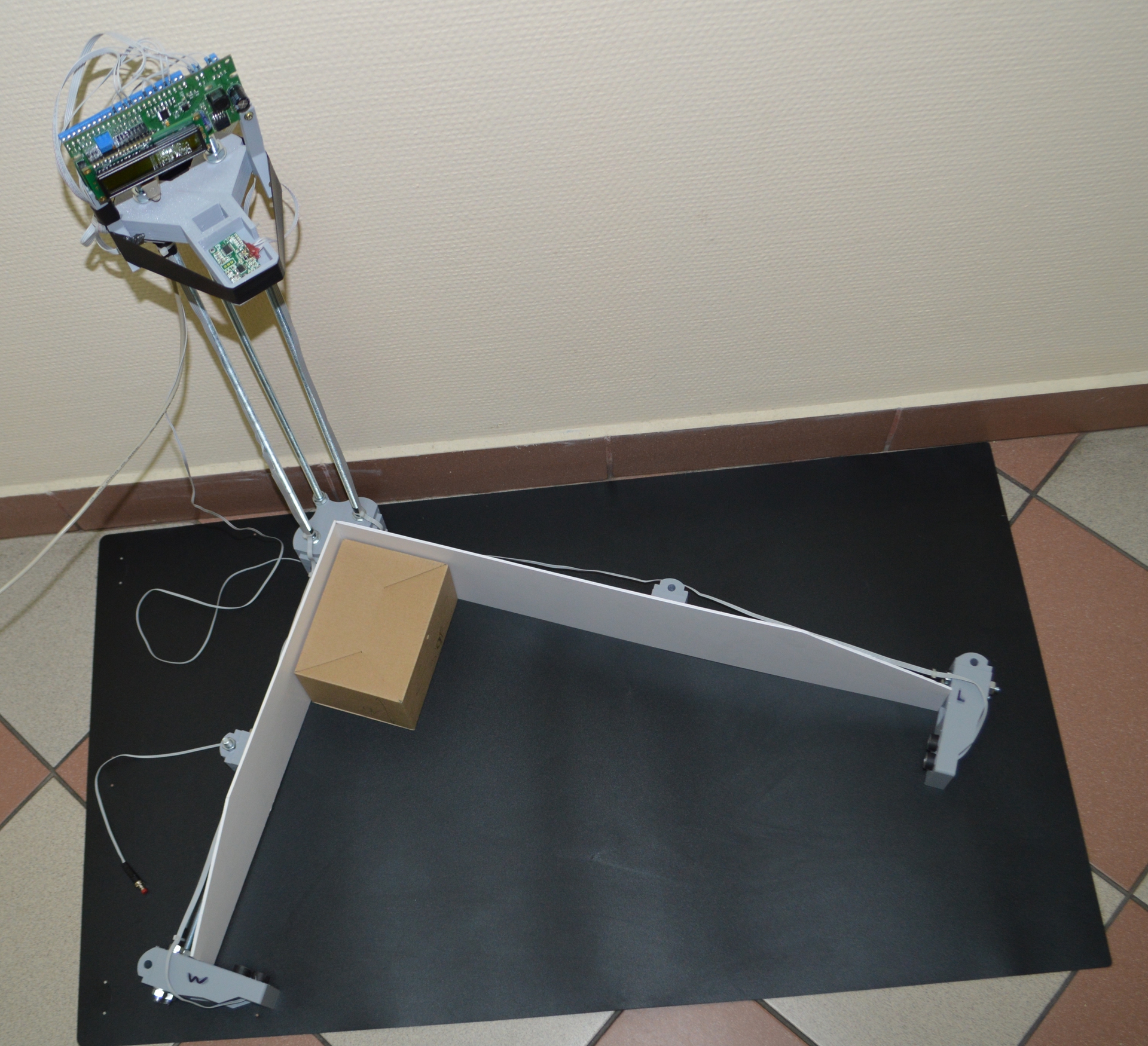

Actually speaking on a 3D printer, we were going to print the details necessary for the designer. Here is the result:

Here you can download STL files .

Having fun with our ears and crazy wristwatches , we found commercial use for our 3D printer.

Summary:

Now we will finish our scanner and send it to the warehouse for continuous operation, which we will write about and shoot a new video.

This is how the packer’s workplace looks, where he weighs and measures the packaging:

Let's try to improve and automate it.

The silver surface is the scales, they are connected to the computer through their own COM port and automatically transfer the weight to the accounting system. But to measure the size of the box, local innovators placed next to the scales of the line, from improvised means. This significantly increased labor productivity, but the data had to be entered into the system by hand using the keyboard.

So, for the prototype we take the workplace as a basis and add sensors to the Wood-Cartesian coordinate system, rotate them in the axes, connect them to the microcontroller, write a sketch in the ARDUINO IDE using the sensor library and Leonardo built-in capabilities. Namely, that the Atmega 32u4 microcontroller used is connected to a computer via the built-in USB interface using the technology of HID devices. This is how keyboards, mice, and trade barcode scanners work. This is exactly what we need - to transfer data to the keyboard buffer, simulating manual data entry.

Look at the video, what happened in the "draft"

We wrote a simple sketch. Having implemented only the basic functions, but nothing prevents to supplement it with various services such as manual calibration, changing the unit of measurement, setting the transmitted characters depending on the accounting system used, etc. The controller memory is large enough and will allow this in the future if necessary.

In the meantime, the sketch works according to the following logic:

• After turning on, each of the three sensors measures the distance from itself to the opposite wall and remembers this distance as the base

• Goes into operation mode and cyclically measures the current distance

• If the current distance is noticeably different from the base - the device considers that a box is placed in the measurement zone. The measurement takes place in three axes according to the formula:

Side size = Base - current distance

• The size along three axes is recorded in the corresponding variables.

• Transfer to the computer is carried out by pressing the button by the operator. This is done to eliminate false positives.

• After data transfer, the button is pressed until the box is removed. The system will feel this by measuring the current distance - it will again become equal to the base.

• The cycle repeats - the system waits for a new box.

So, we made, installed, tuned the sensors for the experiment at fixed base distances ... and left them for trial operation. What did she show? We didn’t get the accuracy of measurements, but the accuracy is quite suitable for the logistic task.

Besides:

• Increased productivity - Yes.

• Convenience for the packer - Yes.

The second stage of our development has begun - bringing to the presentation. The designer took up the matter and with the help of SketchUp and several cups of coffee he developed a design that was somewhat similar to the well-known RepRap 3D printer.

Actually speaking on a 3D printer, we were going to print the details necessary for the designer. Here is the result:

Here you can download STL files .

Having fun with our ears and crazy wristwatches , we found commercial use for our 3D printer.

Summary:

Now we will finish our scanner and send it to the warehouse for continuous operation, which we will write about and shoot a new video.