LEGO NXT flex cable repair

The article describes one of the possible ways of making an artisanal repair of a graphite LCD cable for the LEGO Mindstorms NXT control unit . It is addressed to those who are no longer helped by putting rolled-up papers, rubber bands under a loop or a magic action with heating capacitors on the control buttons board (some kind of complicated magic, I could not understand what its sacred meaning is).

The article describes one of the possible ways of making an artisanal repair of a graphite LCD cable for the LEGO Mindstorms NXT control unit . It is addressed to those who are no longer helped by putting rolled-up papers, rubber bands under a loop or a magic action with heating capacitors on the control buttons board (some kind of complicated magic, I could not understand what its sacred meaning is).Also, the article may be useful to those who have stopped working on the screen of their favorite calculator, key fob car alarm, sewing machine and other devices, the repair of which in specialized workshops for some reason is impossible or impractical. Written by non-professionals for non-professionals, publicly available materials and tools will be used for repairs. Caution, in the text of the article there are many large photos of mediocre quality.

Required resources

- breadboard knife;

- scissors;

- tweezers;

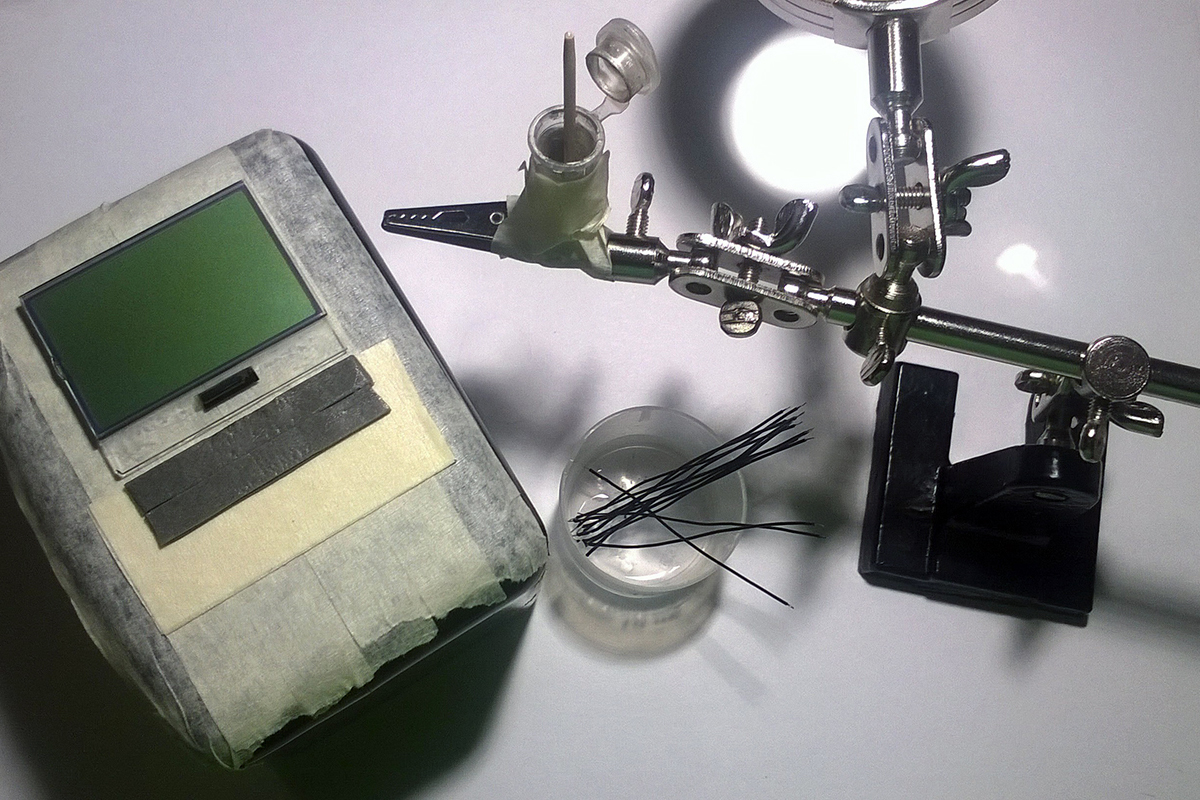

- tripod "third hand" with a lens;

- small soldering iron or soldering station;

- non-washing flux;

- conductive glue;

- epoxy adhesive;

- double sided tape;

- masking tape;

- thin mounting wire;

- wooden toothpicks;

- cotton buds;

- ethanol.

Prologue

The inborn problem of the control block of the LEGO Mindstorms NXT designers of the first releases was a graphite plume. Similar loops, judging by the number of articles devoted to their replacement or restoration of articles, helped pass the owners of some car models, sewing machines, calculators, synthesizers and other equipment with a soldering iron in their hands more than one evening. The failure of such a loop in the LEGO NXT control unit is a matter of time rather than intensity of use. At least, I once had to encounter such a problem with a designer who simply lay there, sealed for several years after the acquisition.

Outwardly, everything looks something like this: after turning on the unit, you hear the starting melody, pressing the control buttons also accompanied by sounds, when connected to a computer, the unit is normally detected by the system, through LEGO NXT software you can upload your programs to the unit or update the firmware. But the built-in LCD does not work.

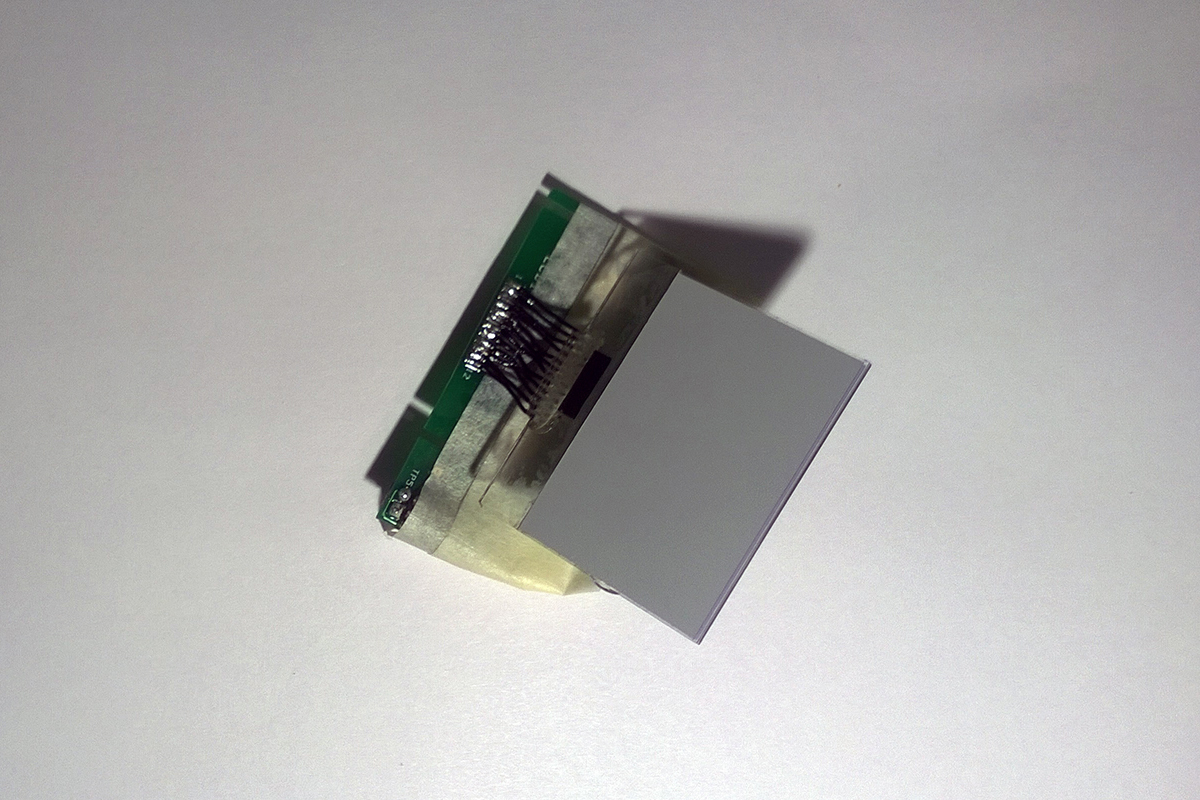

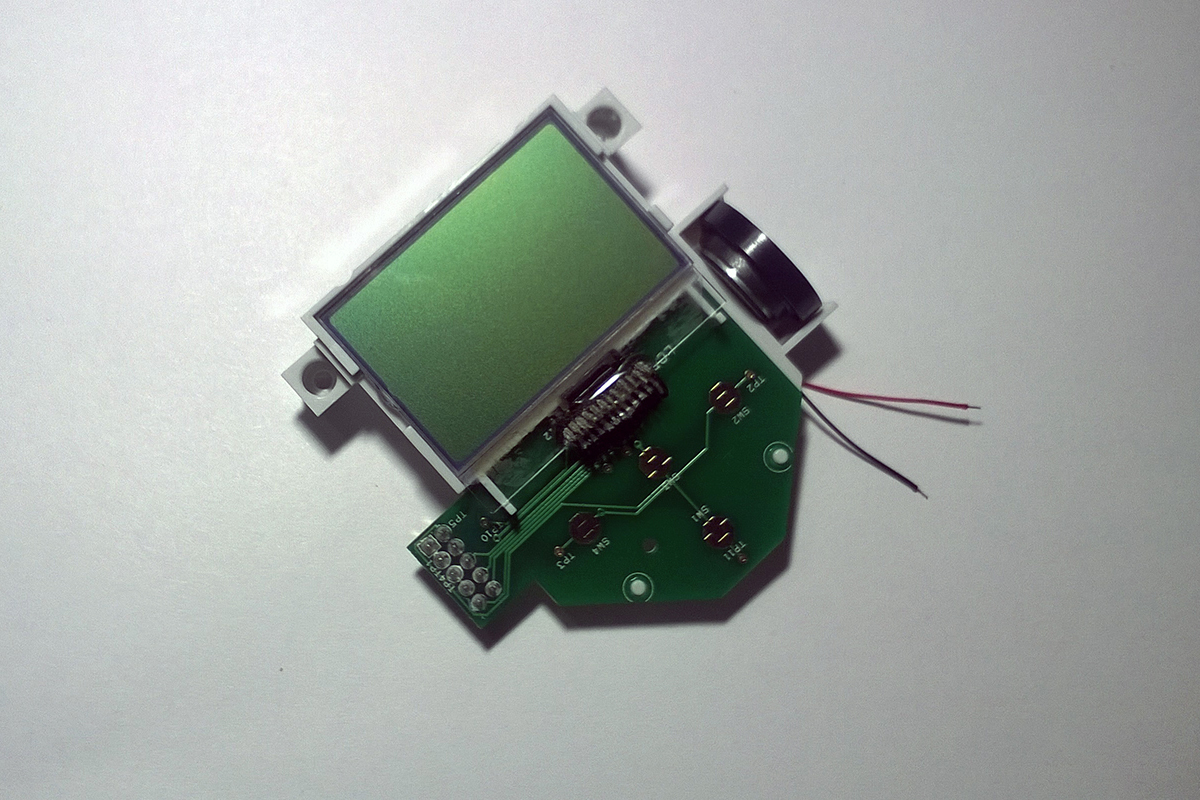

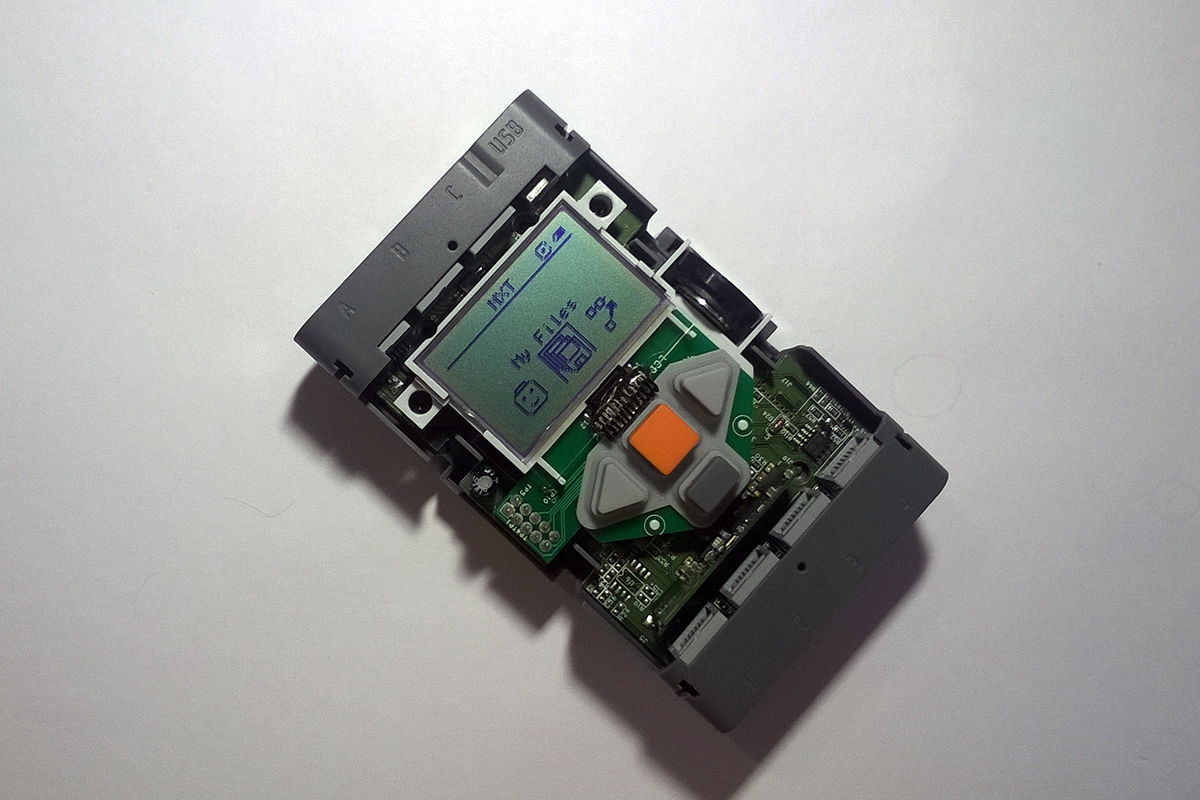

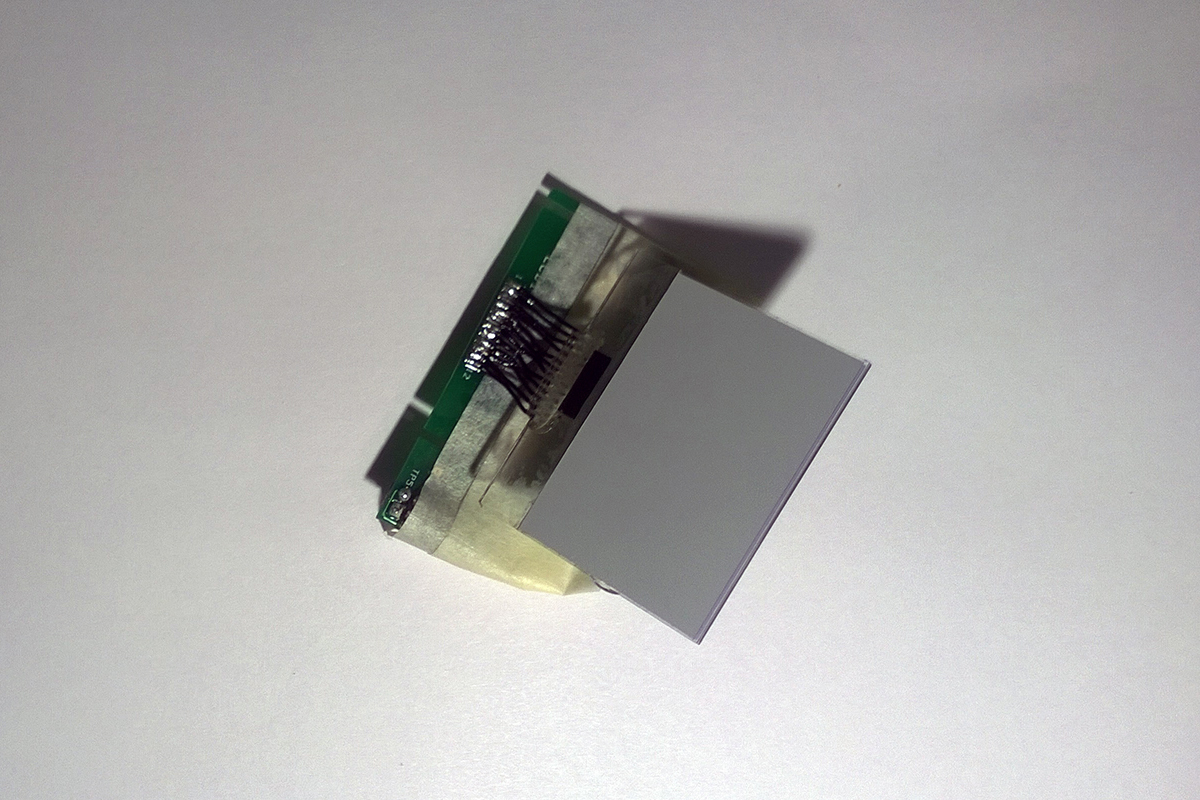

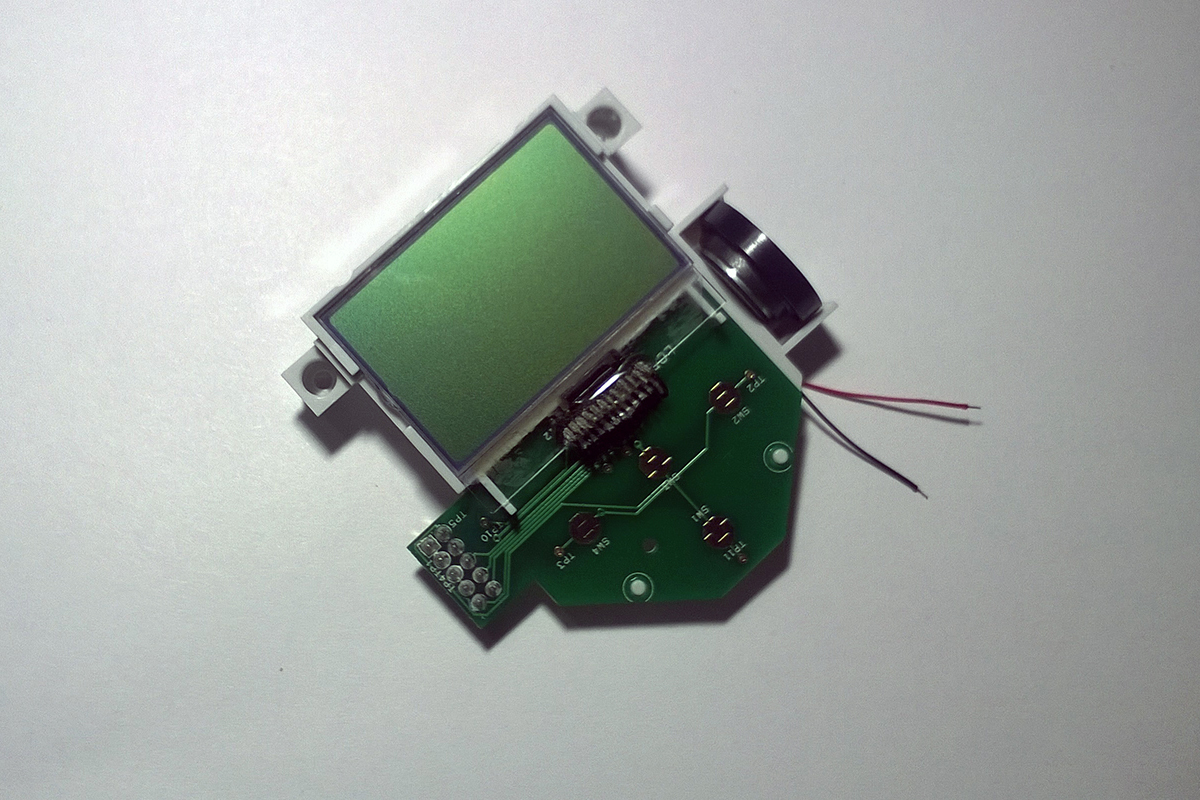

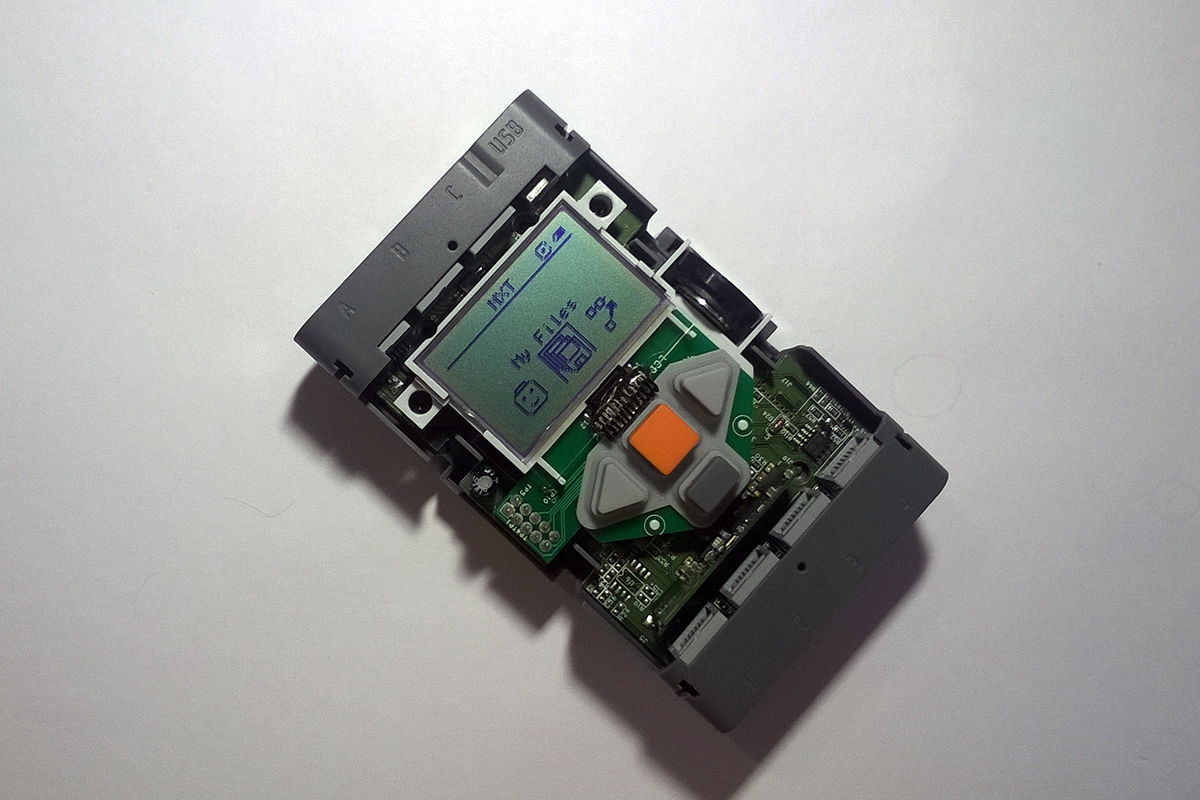

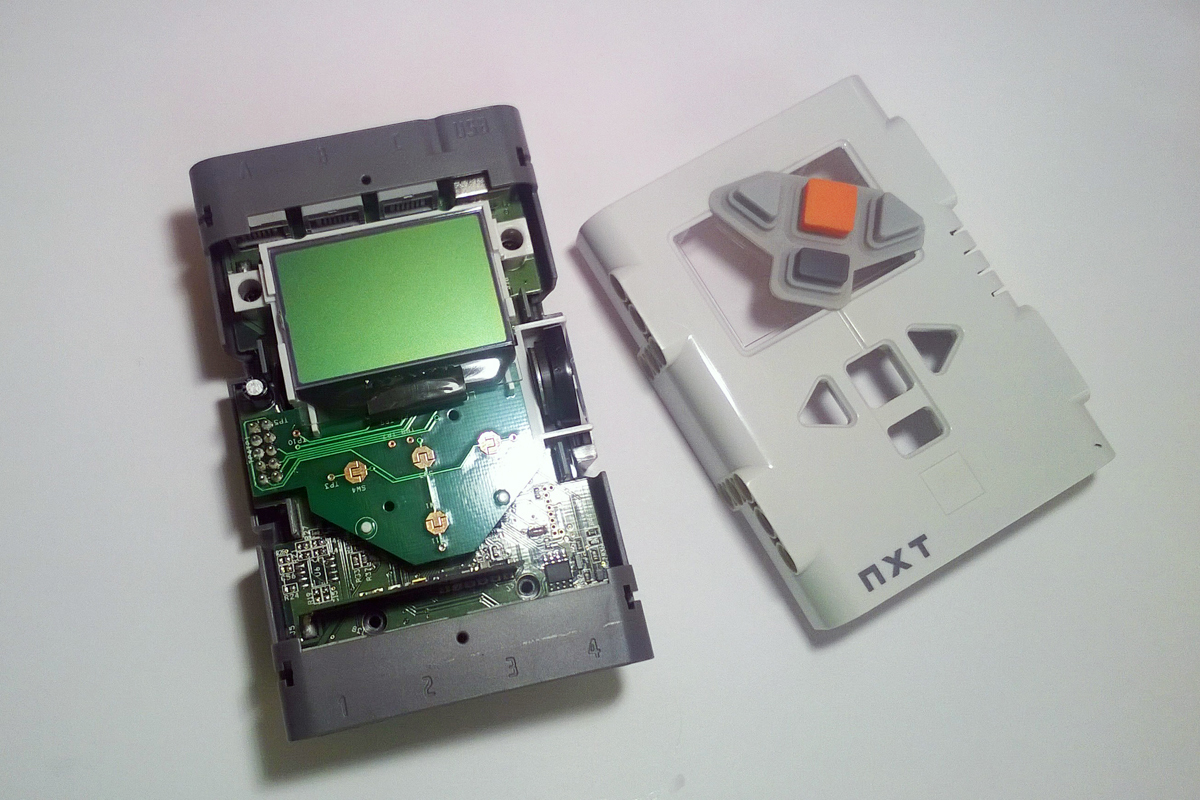

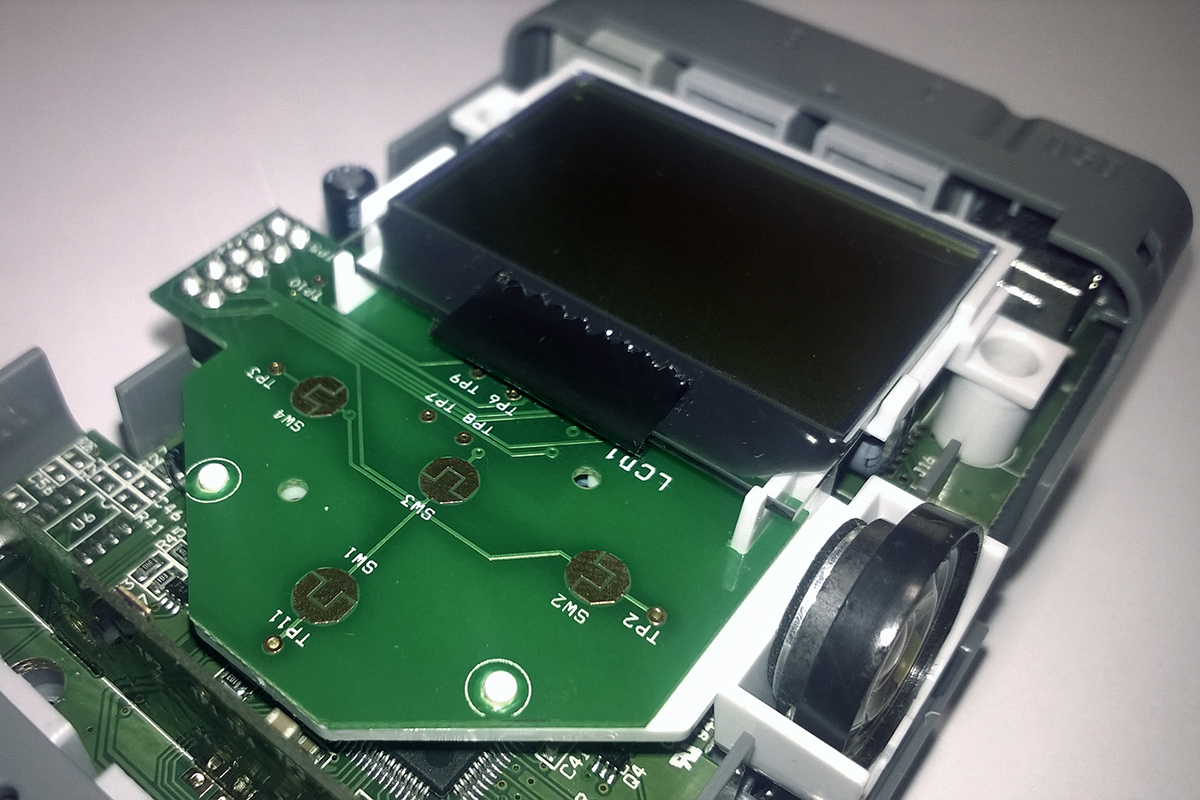

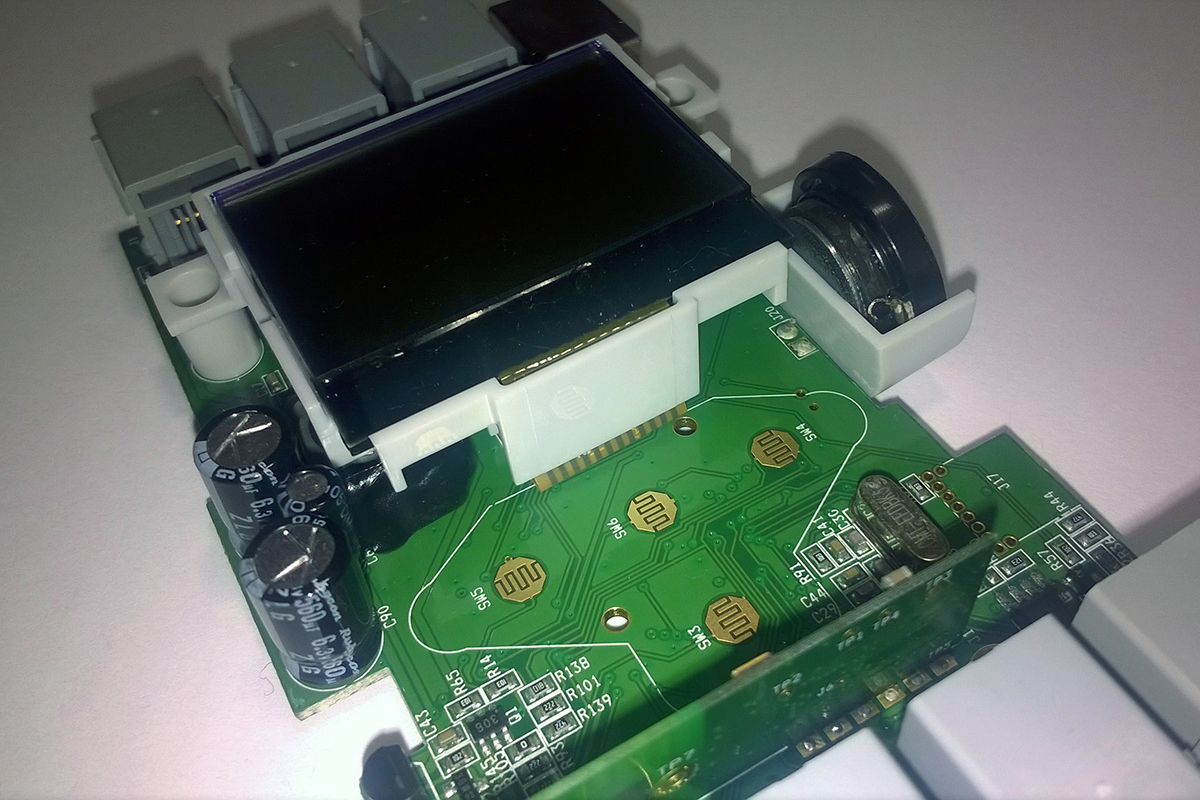

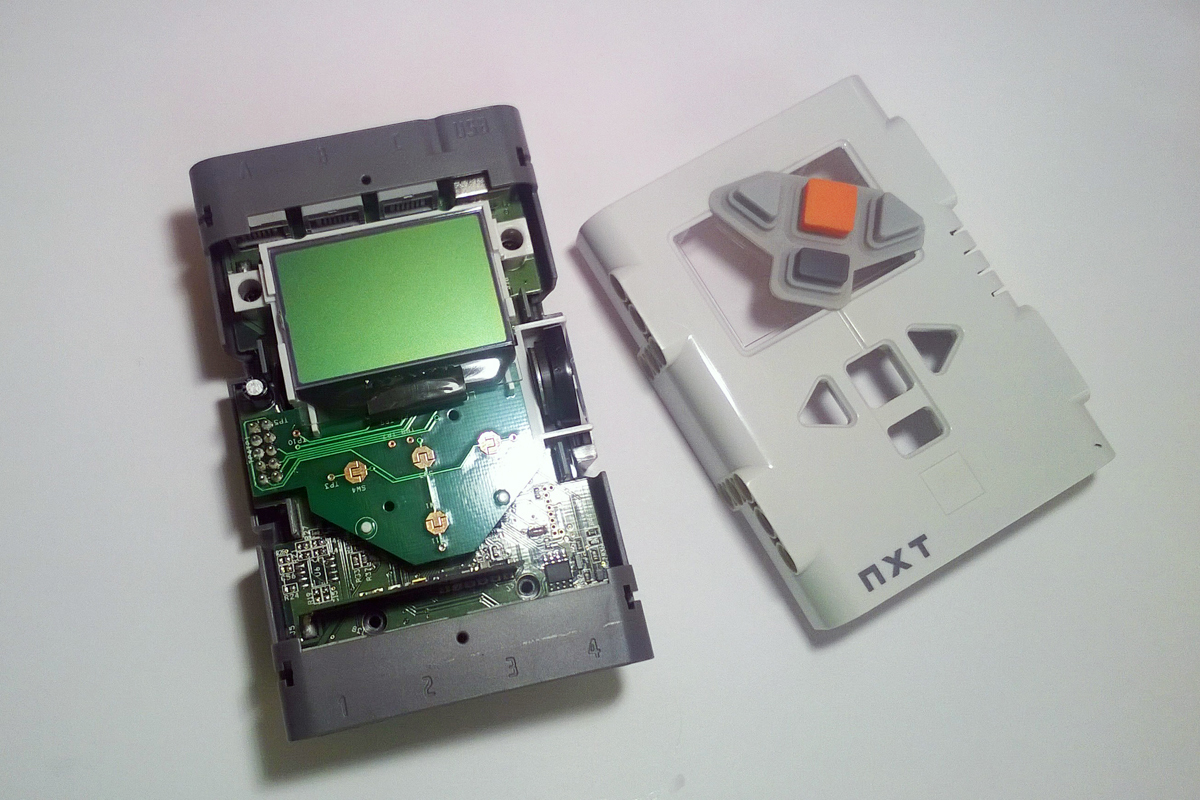

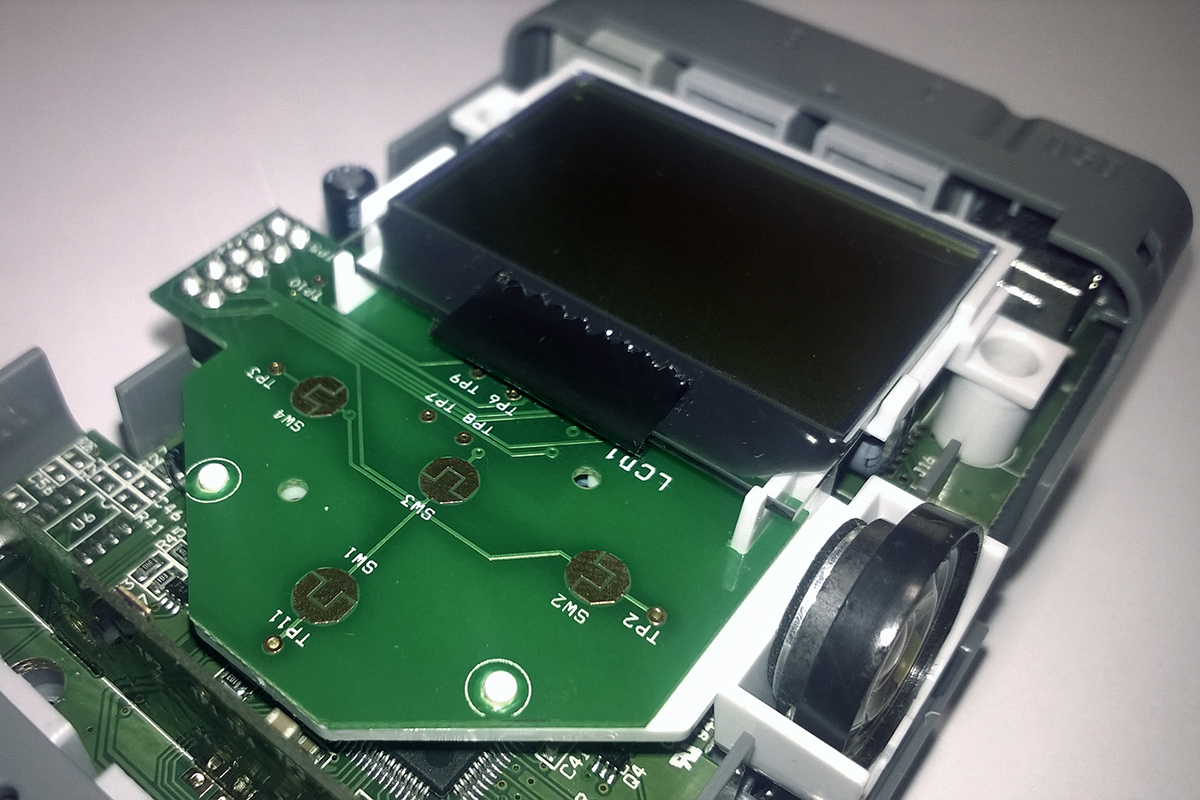

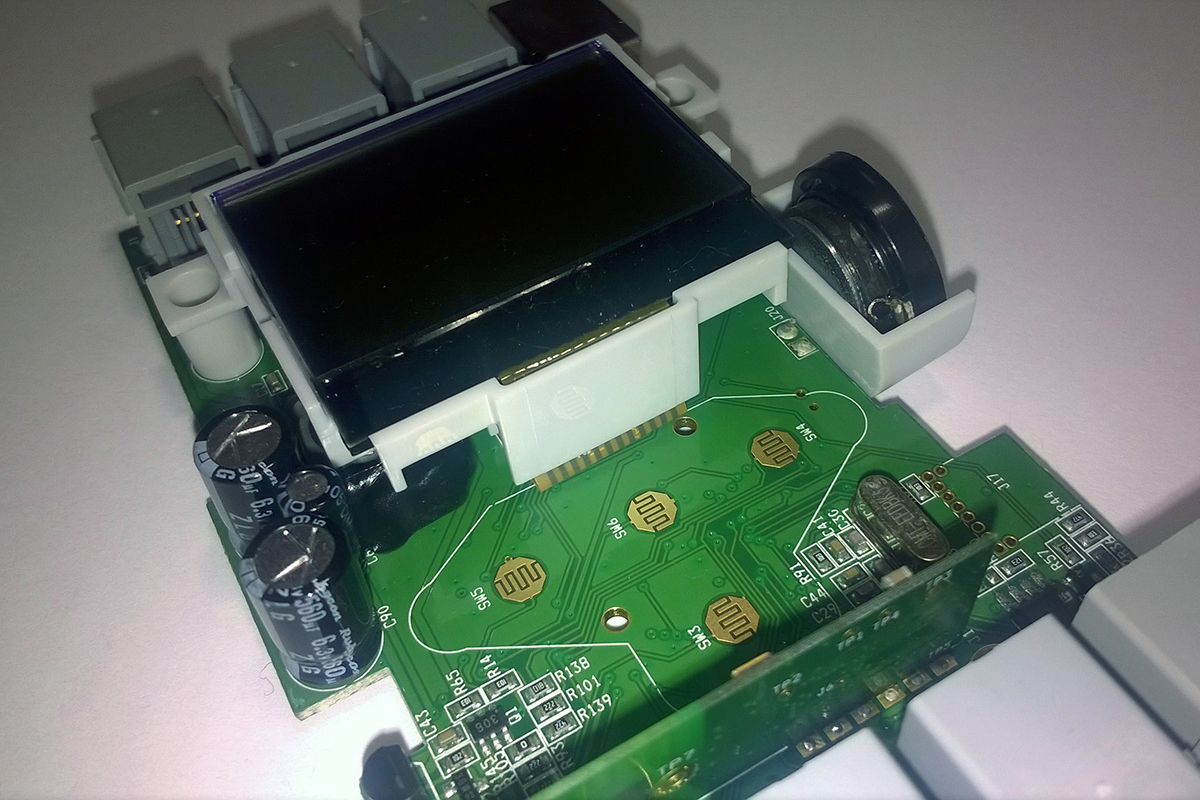

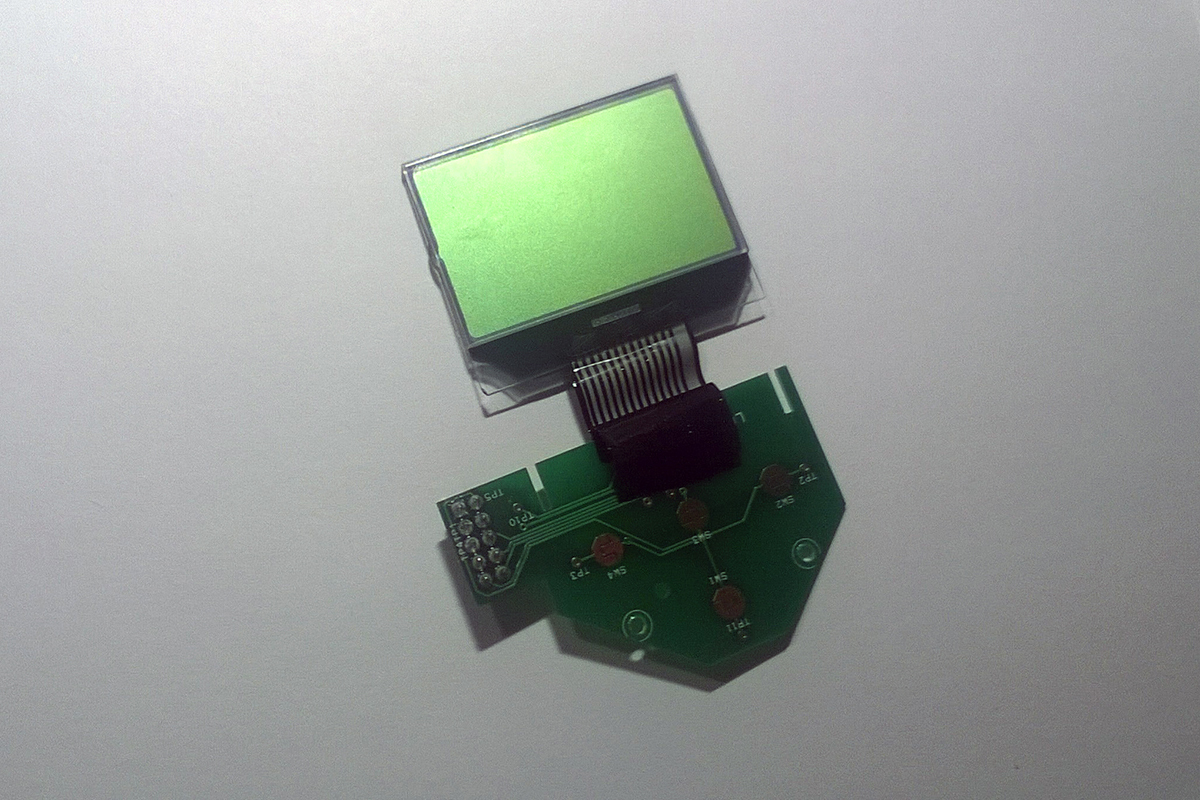

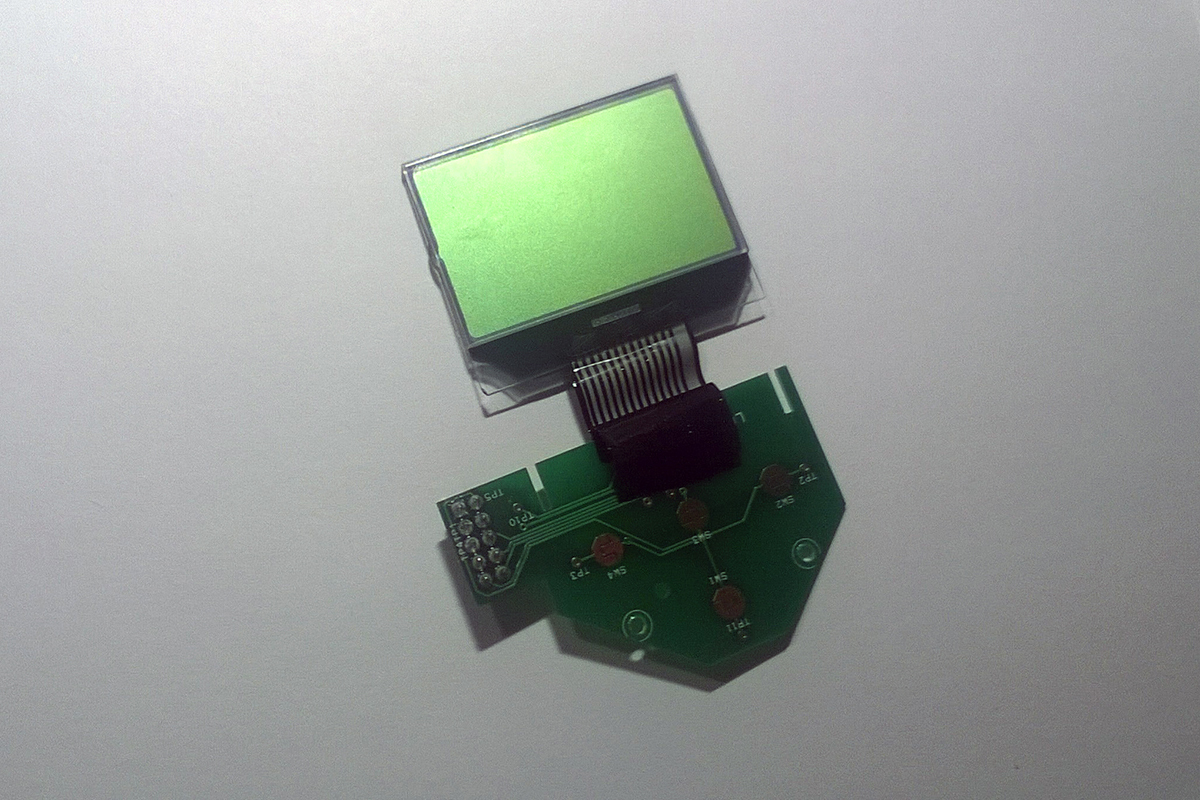

We must give credit to LEGO, after a couple of years they redesigned the control unit board, replacing the graphite cable with a copper one, at the same time transferring the contact pads of the control buttons to the main board. This made it possible to abandon the additional button board and simplified the design, adding reliability to it. Externally, the blocks are practically indistinguishable. Quickly find out who is in front of us by unscrewing four screws in the battery compartment and removing the cover from the unit. In the first and second photographs, a block with a graphite plume, in the third - its more “happy” brother with a copper one.

If your unit is with the same loop as in the first two photos, you can first try to iron it at the contact points with a heated soldering iron through a folded piece of paper double or triple. Be careful, the glass screen may burst. Such warming can help, sometimes for a long time. If it does not help, you have to repair the loop. For repair, you need to remove the LCD along with the control button board, speaker and plastic base. We twist two more screws, and the wiring to the speaker from the board can be unsoldered or just bite off. They are still short, for convenience, it is better to replace them with longer ones.

Outwardly, everything looks something like this: after turning on the unit, you hear the starting melody, pressing the control buttons also accompanied by sounds, when connected to a computer, the unit is normally detected by the system, through LEGO NXT software you can upload your programs to the unit or update the firmware. But the built-in LCD does not work.

We must give credit to LEGO, after a couple of years they redesigned the control unit board, replacing the graphite cable with a copper one, at the same time transferring the contact pads of the control buttons to the main board. This made it possible to abandon the additional button board and simplified the design, adding reliability to it. Externally, the blocks are practically indistinguishable. Quickly find out who is in front of us by unscrewing four screws in the battery compartment and removing the cover from the unit. In the first and second photographs, a block with a graphite plume, in the third - its more “happy” brother with a copper one.

View photos

If your unit is with the same loop as in the first two photos, you can first try to iron it at the contact points with a heated soldering iron through a folded piece of paper double or triple. Be careful, the glass screen may burst. Such warming can help, sometimes for a long time. If it does not help, you have to repair the loop. For repair, you need to remove the LCD along with the control button board, speaker and plastic base. We twist two more screws, and the wiring to the speaker from the board can be unsoldered or just bite off. They are still short, for convenience, it is better to replace them with longer ones.

Formulation of the problem

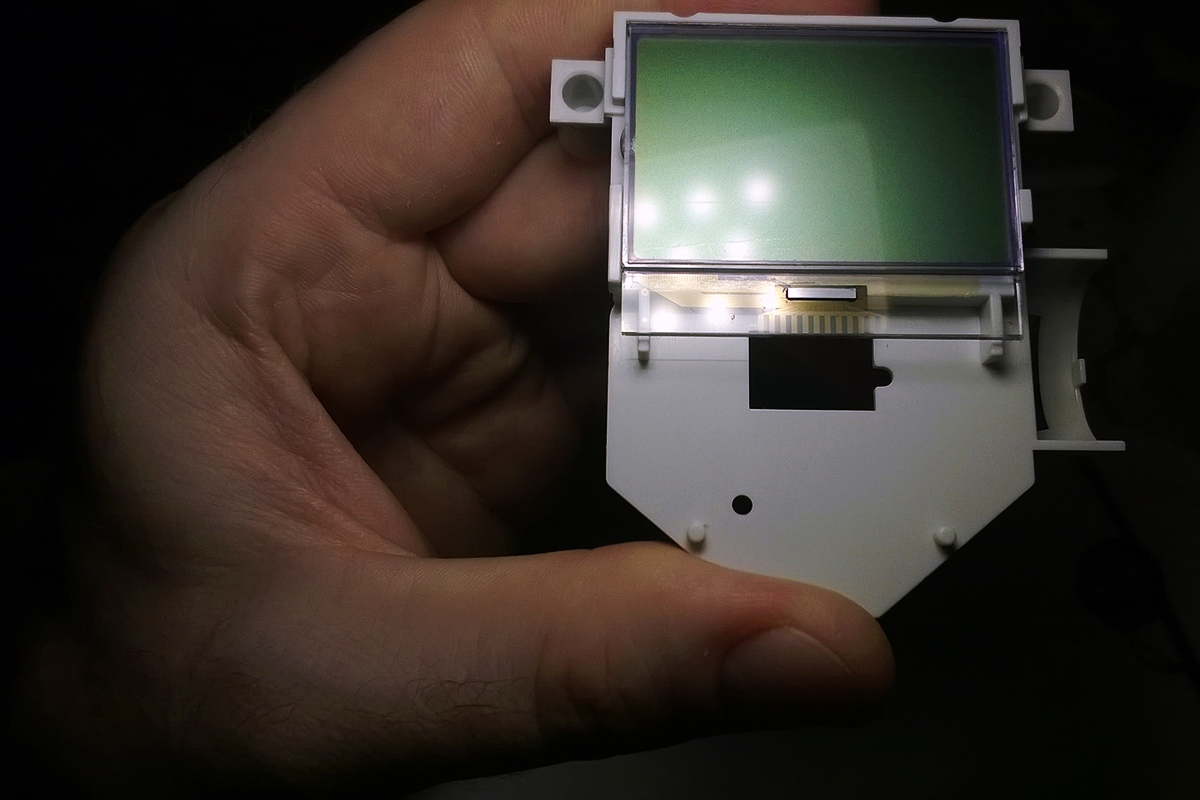

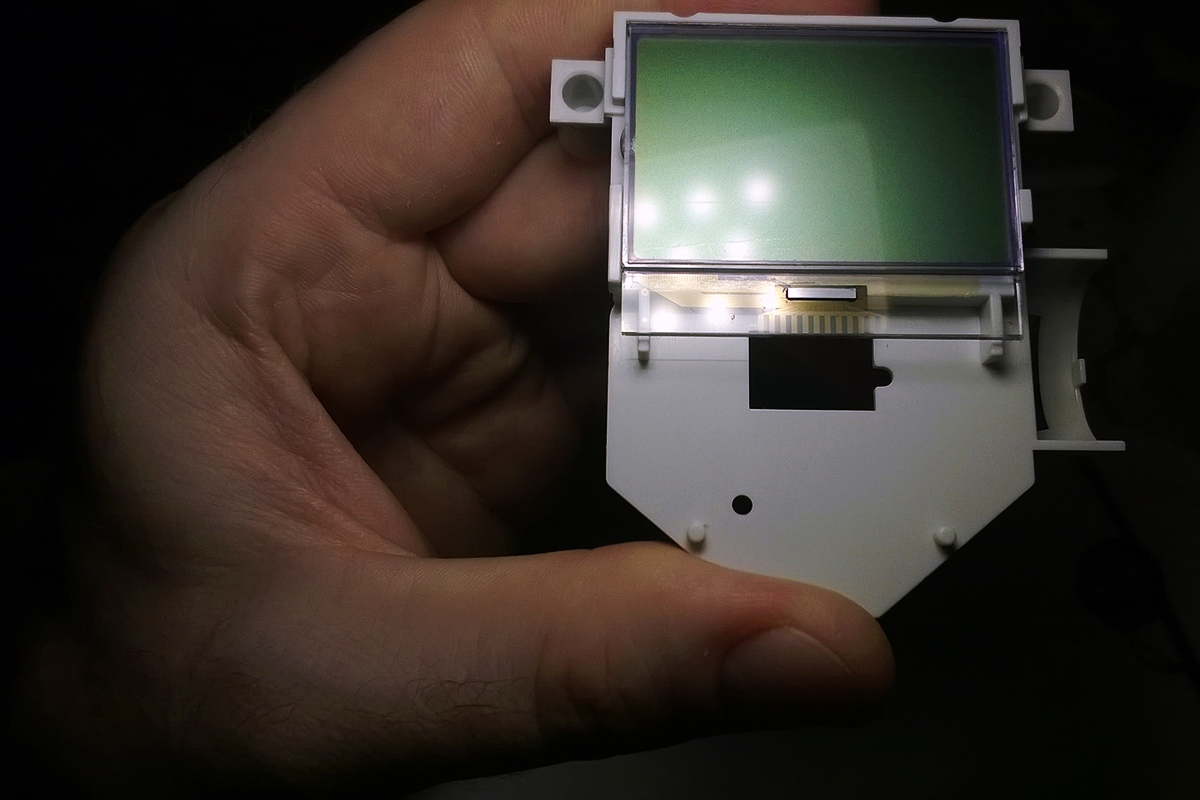

Our goal is to create a conductive connection between the contact pads on the LCD glass and the wiring, with which we will replace the failed cable. Contact pads on the glass can be seen by positioning the LCD at a certain angle to the light source. Just put it in your palm and try to swing slightly in different directions under the light of a table lamp.

View photos

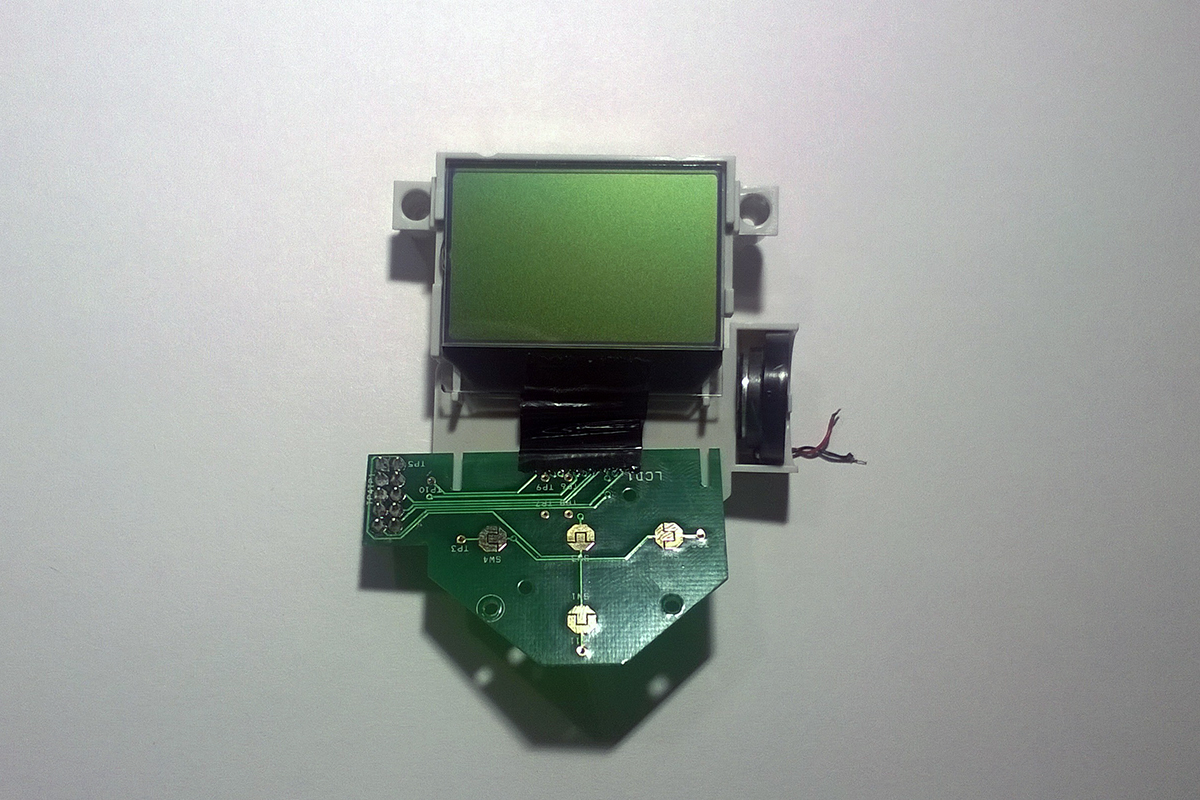

Bridgehead preparation

So, the hero of the occasion lies on the table in front of us. We poke a board of control buttons and remove it from the plastic base. The LCD is glued to the base with two strips of double-sided tape. Remembering that the screen is glass , we do not apply excessive force. We drip the inside of the LCD with five to six drops of alcohol, let it flow into the gap between the base and the LCD and spread over the adhesive tape and, slightly pulling the LCD off the base, carefully peel it off. Adhesive tape on the basis should not be changed, after the evaporation of alcohol, it will not lose its adhesive properties.

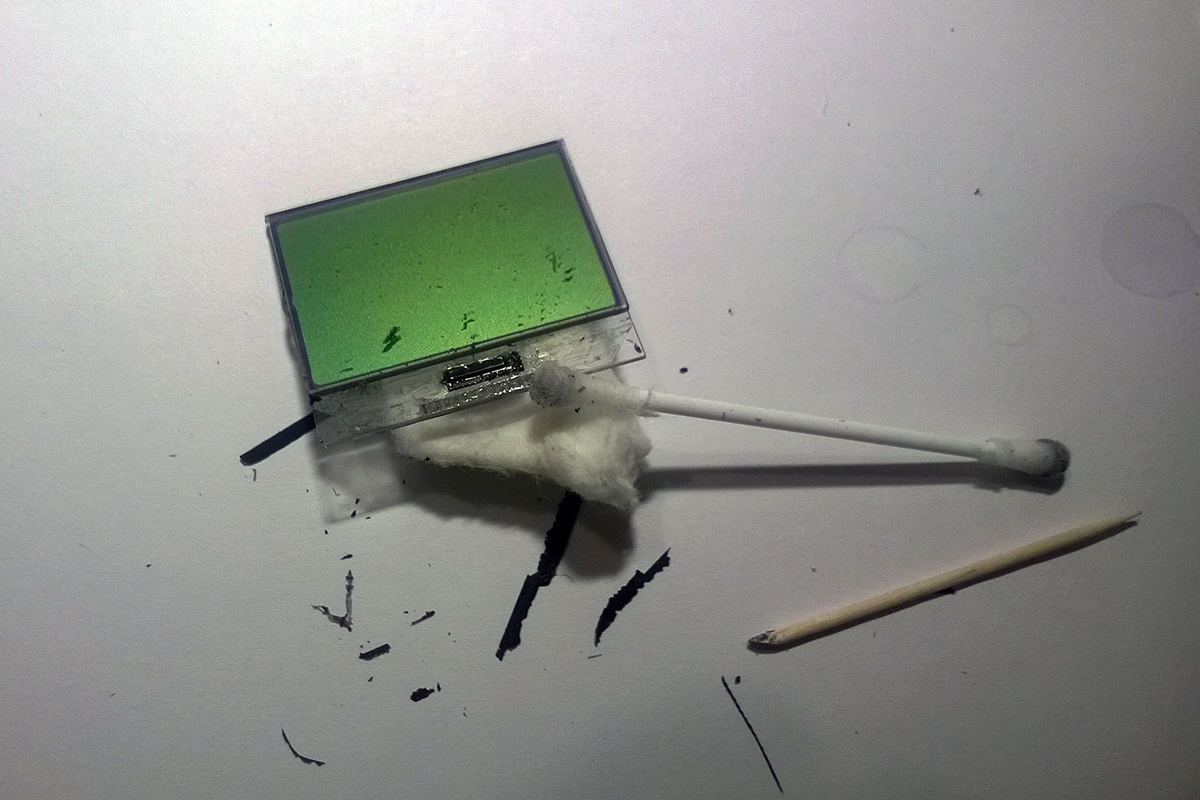

In the same way, we detach the speaker from the base so as not to burn it when replacing the wires. The speaker is glued to the base through the gasket, when peeling, we try to keep the gasket on the speaker, and adhesive tape on the base. We help them with a toothpick sharpened in the form of a scapula.

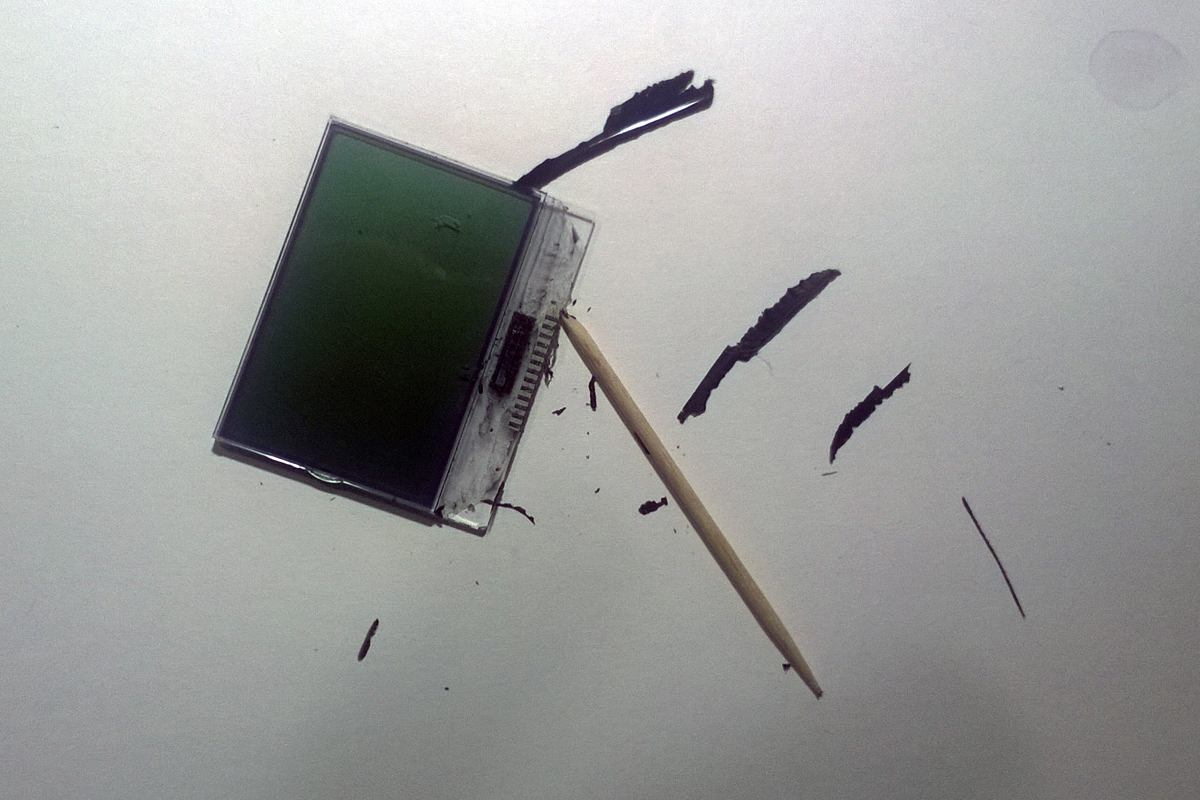

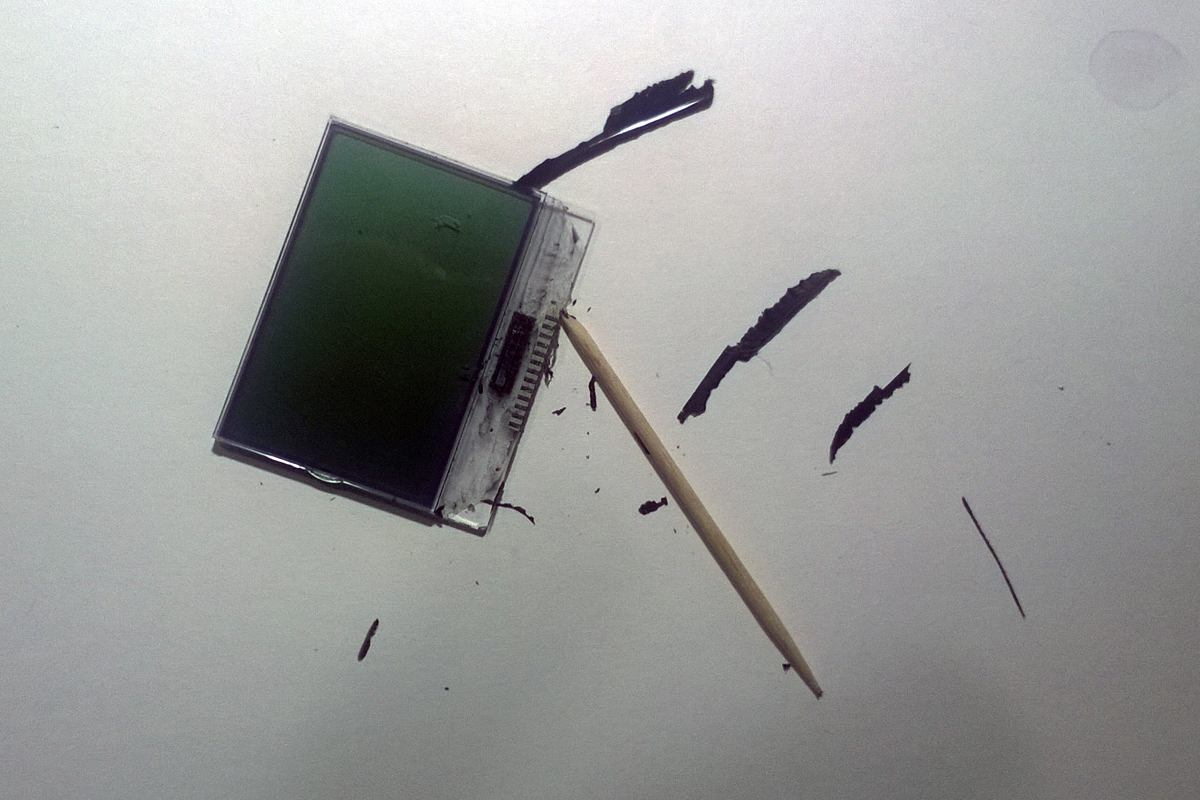

We use the same toothpick to pry the black protective tape and peel it off on both sides of the loop. After scotch tape we pry off and tear off the train. Since we decided to replace the cable with thin mounting wires, we can not stand on ceremony with it. If you still want to save it for history, you can try to remove protective tape from it, gradually soaking it with alcohol.

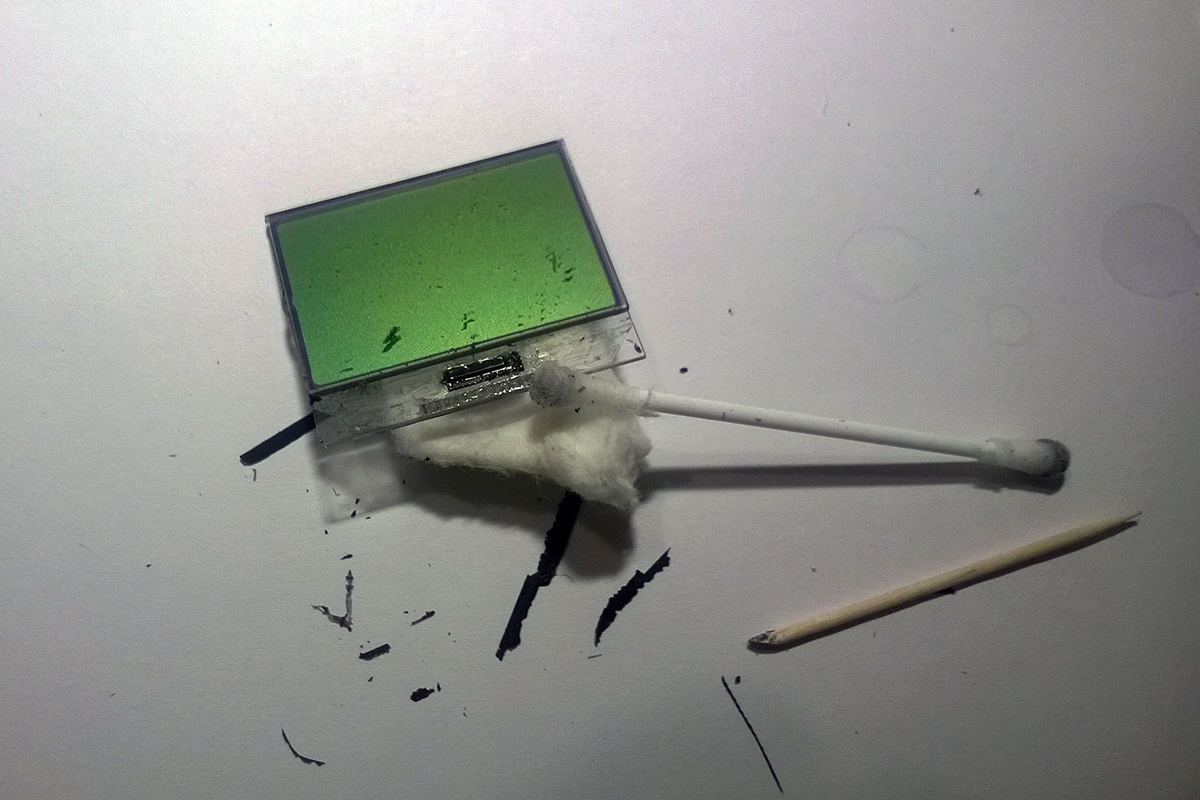

After removing the old loop with the help of toothpicks sharpened with a spatula, cotton swabs and alcohol, we clean the contact pads on the LCD and the board. Cleaning the glass will take some time and effort. Residues from the silicone compound around the pads are quite difficult to remove, and you need to clean them well. Caution, do not use metal objects or liquids that are more aggressive than alcohol for cleaning . The pads on the glass are very thin, and the surface of the screen is covered with a layer of plastic.

After cleaning, you can fix the LCD with double-sided tape on some basis for the convenience of further work.

View photos

Climax

Mindful of how they treat advertising articles on the hub, I still have to note that I was able to more or less tolerably stick the wires only with concrete glue of a particular manufacturer. What kind of glue can be seen in the first photo of this section. At the end of the article I will try to explain what motivated me to write it and justify the choice of glue.

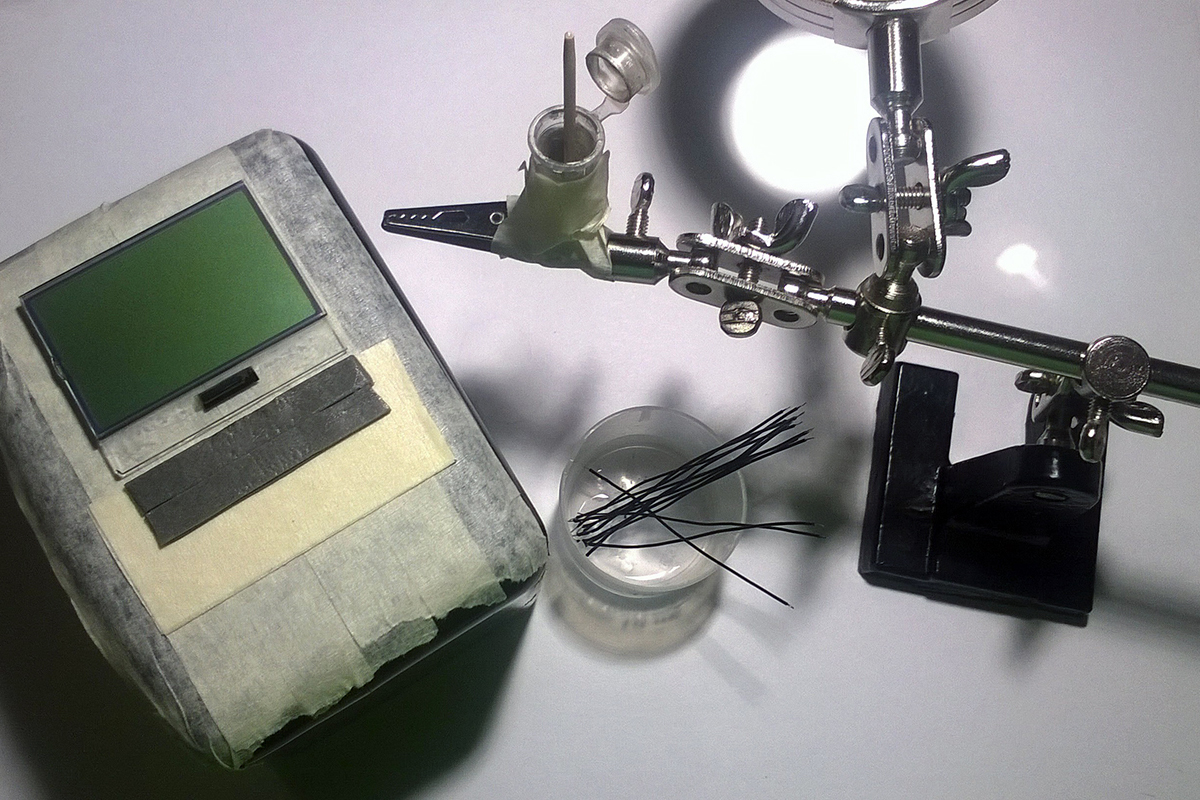

So, our test subject is fixed with double-sided tape on a suitable base, approximately two millimeters from it glued strips of double-sided tape for temporary fastening of wiring. The wiring itself is neatly peeled and tinned from two sides, and then placed in a suitable container with alcohol.

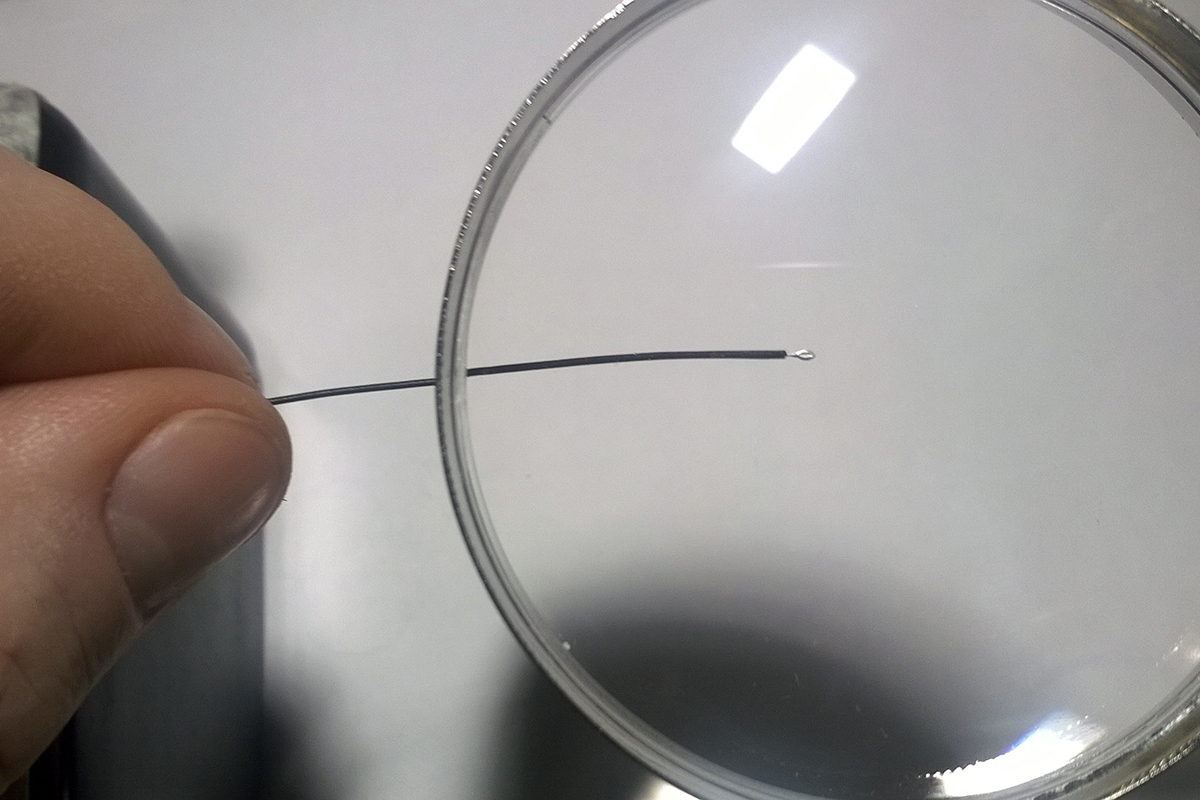

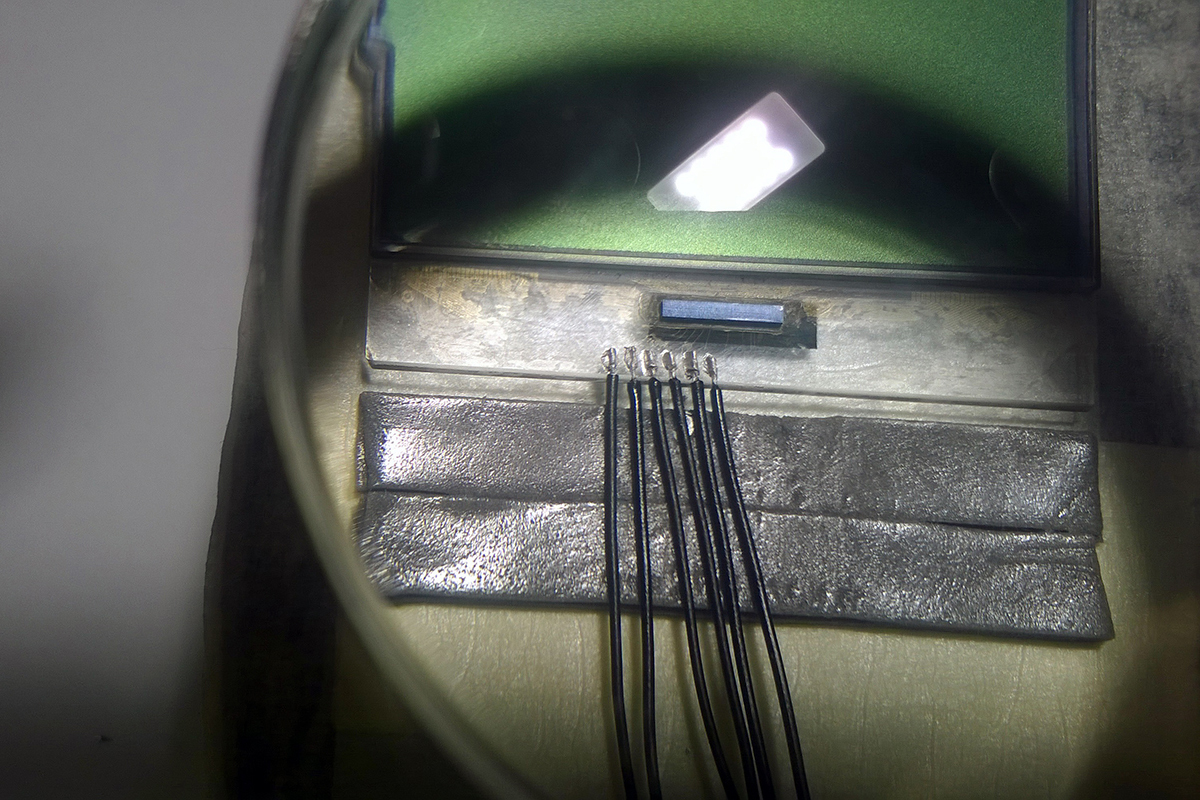

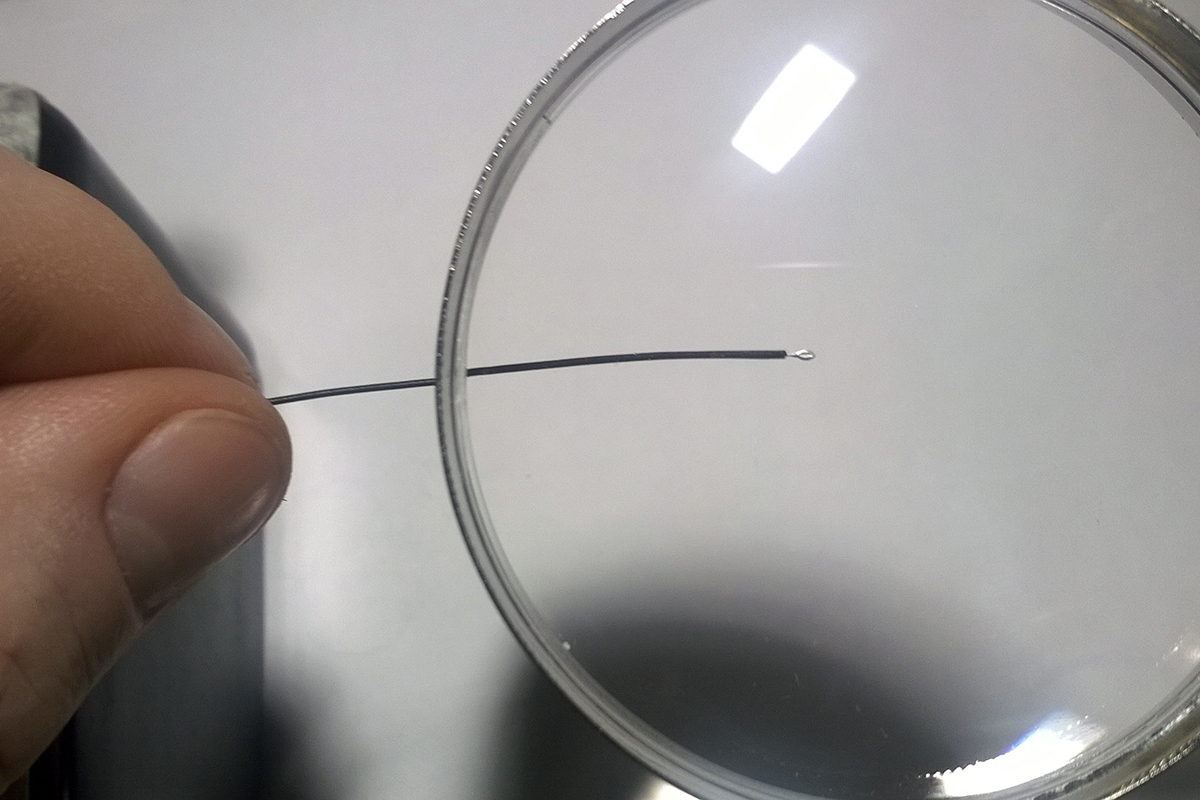

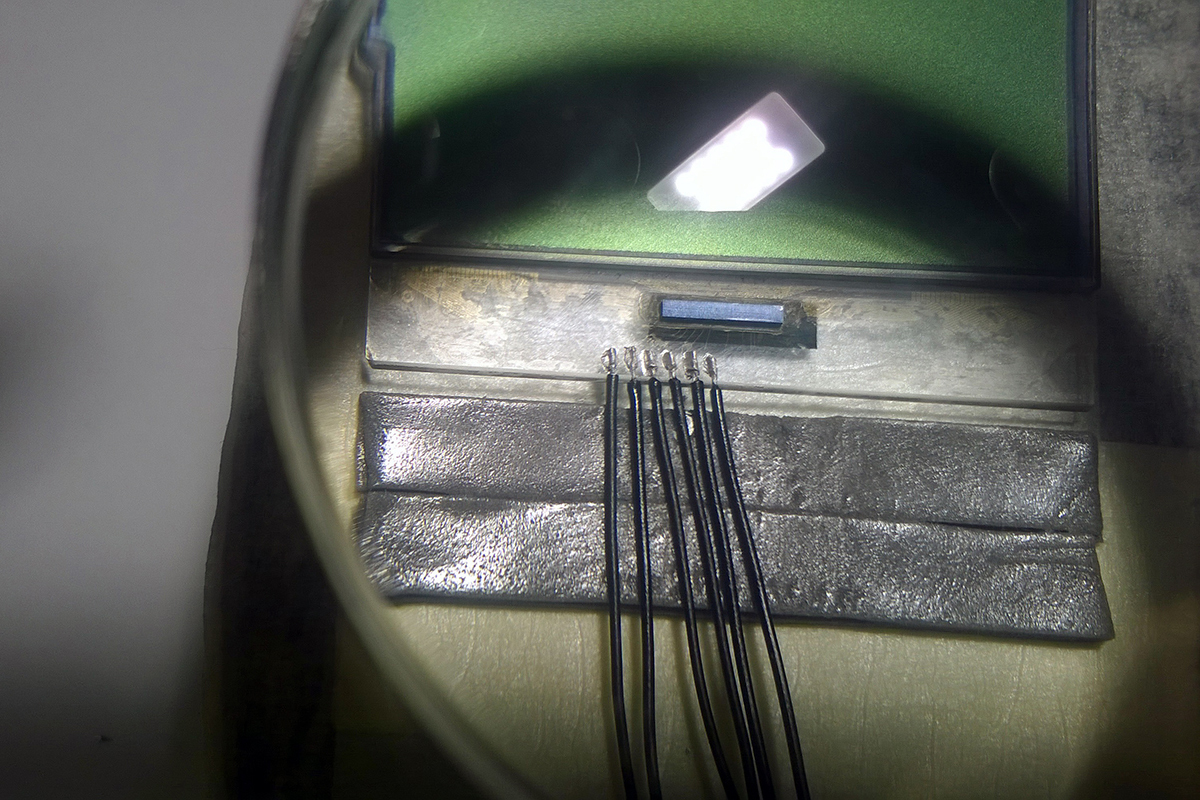

The main idea is to collect one or two drops of thoroughly mixed conductive glue on a toothpick and, holding it vertically above the bubble with glue, substitute tinned and cut to the desired length tip of a piece of thin mounting wire under the glue that flows from the toothpick. Gently turning the wire, it is necessary to achieve the formation of droplets of glue on it. Similar to the one that can be viewed in the third photo of this section. It is necessary to act quickly, because the glue thickens quickly enough . Therefore, as soon as possible after applying the glue, the wires must be clipped to the contact area on the glass. Approximately as shown in the fourth photograph of the section.

If you do everything fast enough, the glue on the tip of the wire does not have time to thicken very much and moistens the contact area well. For proper glue distribution, it is useful to make one or two movements with the tip of the wiring along the contact pad. After a successful docking, the wiring and the contact pad for the complete success of the wiring is fixed on a double-sided tape pasted next to the LCD. And if it didn’t work out, it doesn’t matter - the posting is returned with the end of the glue stained with glue to the alcohol container, the glue from the glass is cleaned with a toothpick, after which the operation is repeated as many times as necessary.

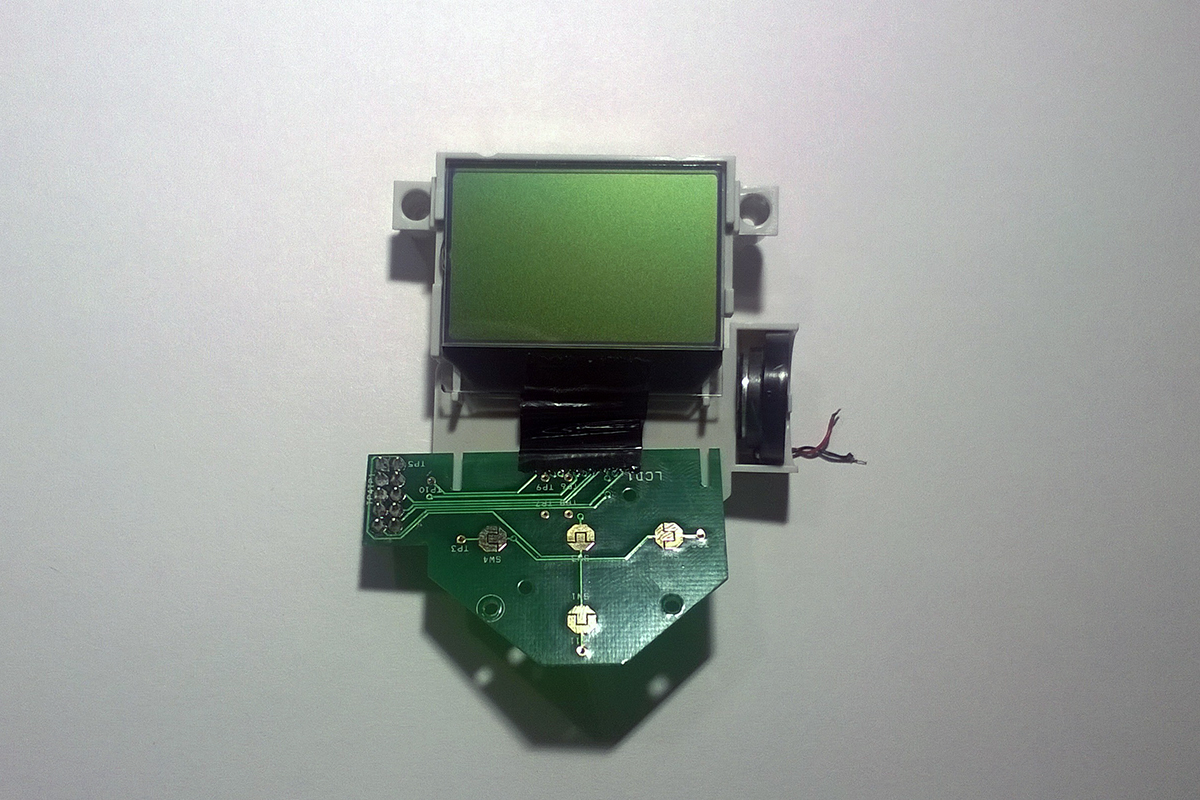

After the last posting is triumphantly slap on its contact pad and secured to the adhesive tape, we wait half an hour to glue the glue. Now you can gently install an additional clamp for the wires, I used as this a piece of plastic broken when unpacking the syringe with epoxy resin.

Well, then comes the moment of truth. We serve the contact pads on the control buttons board and, acting as accurately as possible, solder the free ends of the wires to them. We connect everything to the main board, after inserting five batteries into the battery compartment. We insert the sixth battery, watching the LCD. We try not to cut the wires for joy, if everything works. Remember that the bond strength of conductive glue is almost none.

We secure success by applying a layer of epoxy to the glued wires. During this procedure, we try not to touch either the wires or the glass. You can wait until a small drop of the epoxy collected on it drains from the toothpick, touch this drop of the first wire to begin to stretch it, trying to reach the twelfth. If there was not enough epoxy, we recruit a new portion and continue from the gap. We are waiting for the full setting of epoxy.

All the most difficult behind. If necessary, align the wiring, add another layer of epoxy on the front side, wait for it to set, unfasten and flip the LCD, epoxy glue the back side.

View photos

Final stage

Carefully measure everything, align and cut to the required length glued to the LCD wiring. Carefully strip and tin the ends of the wires and, having folded the LCD and the board of buttons for controlling the front sides, solder the wires to the previously tinned contact pads of the board. When soldering, use non-wash flux.

Having washed off the excess flux with alcohol, we install the reunited circuit board and LCD on the base. It is more convenient to first install the board, and then, gently bending the wires, stick to the base of the LCD. Do not forget to replace the wiring, we return the speaker and buttons to the place.

Soldering the wires from the speaker into place, we install the repaired assembly on the main board. We twist two screws, fill the battery compartment with batteries. Hearing the starting melody, we are convinced of the performance of the LCD.

View photos