How to produce PLA for 3d printers. Report from the workshop

A pistol shot served as a signal to create a business.

In order to dispel the myths that coils with plastic for 3D printersgrow on trees you can only buy and resell, as well as the fact that it is enough to buy an all-in-one extruder and start your own business, I went to explore Moscow manufacturers of ABS and PLA (and HIPS). Indeed, I ended up in a professional workshop with industrial equipment, with measuring and control instruments of high accuracy, high standards for cleanliness (for the production process is very responsible) and sociable founders (ready to share knowledge with an inquisitive and thoughtful audience), who have a bunch of techno-creative ideas and plans to capture the world market. (+5 to level of national pride)

As the co-founder of the company told me: “First, we saw a printed fruit knife, and peeled orange, then the shock was a video with a gun of Cody Wilson and it started ...”

While I wrote the first 2 articles about Habré 3D printers (spring 2013), these guys have already started building a plastic business. It is interesting that I and they came up with a similar idea, how to supplement the saying, they say, a person can endlessly look at fire, water, how another person works and how a 3D printer prints.

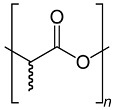

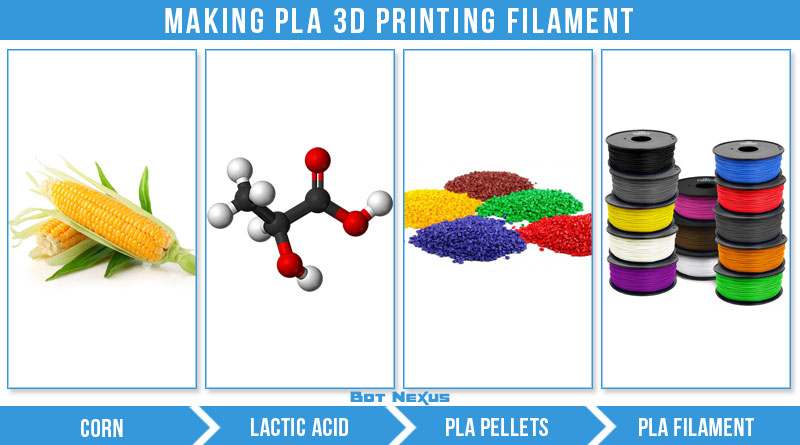

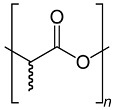

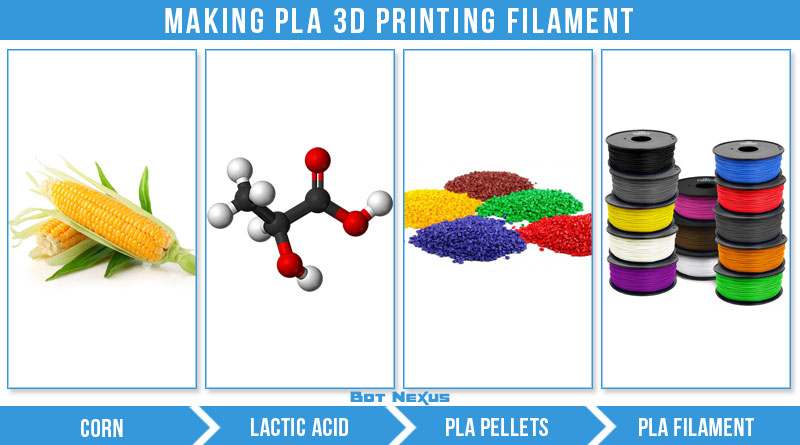

Polylactide (PLA) is a biodegradable, biocompatible, thermoplastic, aliphatic polyester, the monomer of which is lactic acid. Annually renewable resources such as corn and sugarcane serve as raw materials for production. It is used for the production of products with a short service life (food packaging, disposable tableware, bags, various containers), as well as in medicine, for the production of surgical sutures and pins.

Under cat - the main stages of converting raw materials into reels with PLA for 3d printers

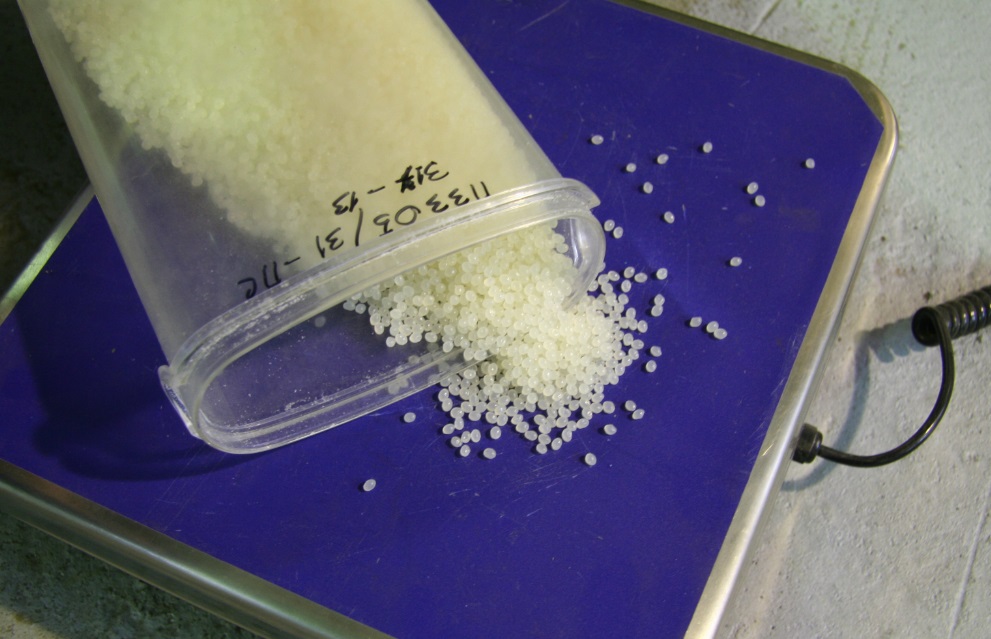

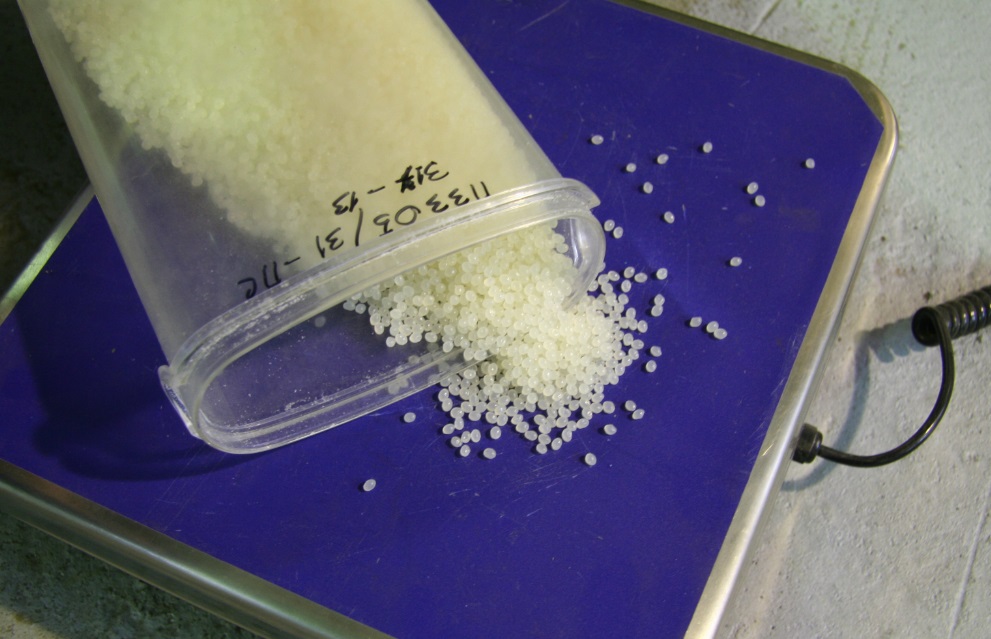

There was corn, then it is processed into such balls and put into such boxes. A

ton of raw material produces about 900 kg of plastic.

Since it is a natural product, it is afraid of light and moisture, therefore it is protected with such a bag and a piece of silica gel.

And this is a “vacuum cleaner”, with which 100 kg of “corn balls” are scooped up and sent to a container.

Here the raw material is dried, and the smell is like in a confectionery.

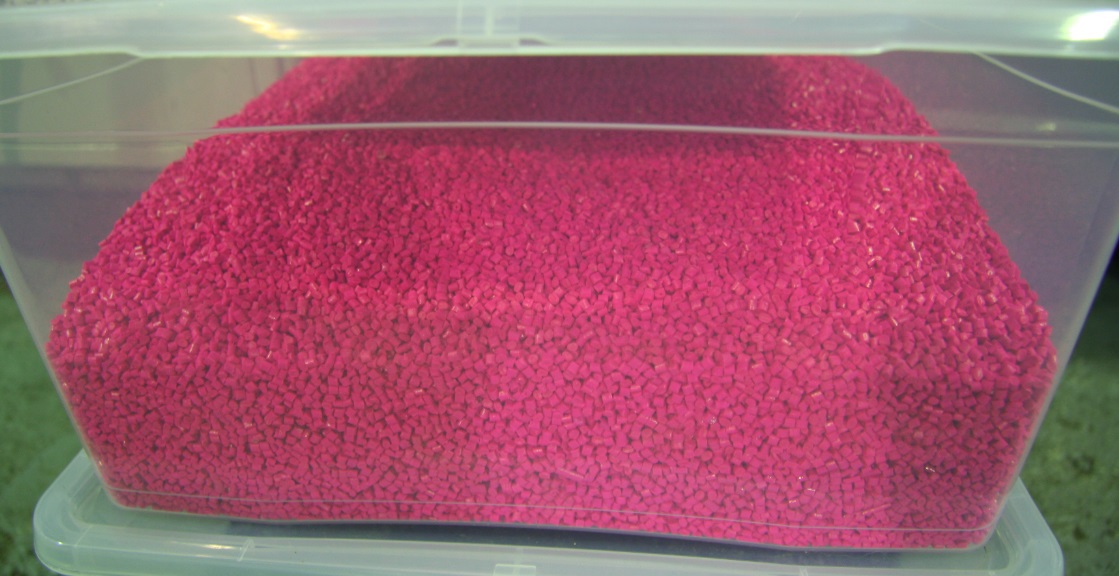

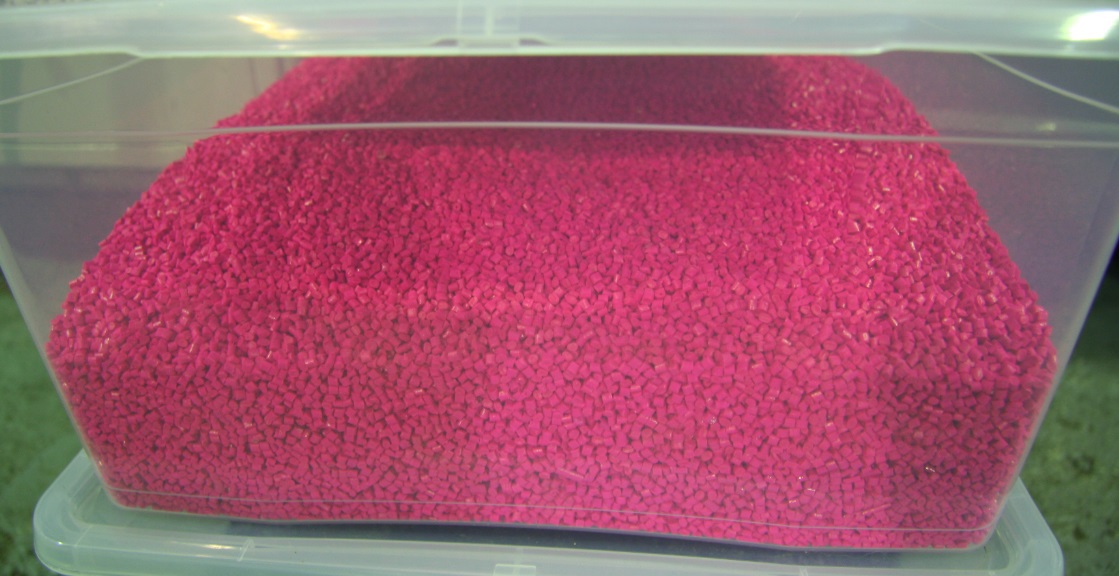

Add a pinch of dye (also completely natural, Austrian quality).

Here the raw material is heated and turns into a viscous mass.

Under the pressure of the shaft we pass through the heating elements.

The diameter of the “firebox” outlet is about 3 mm, the plastic acquires the desired diameter (1.75 mm) due to the fact that it is pulled right there, and the draft is very precisely tuned

for cooling bath. For ABS and PLA, different temperatures.

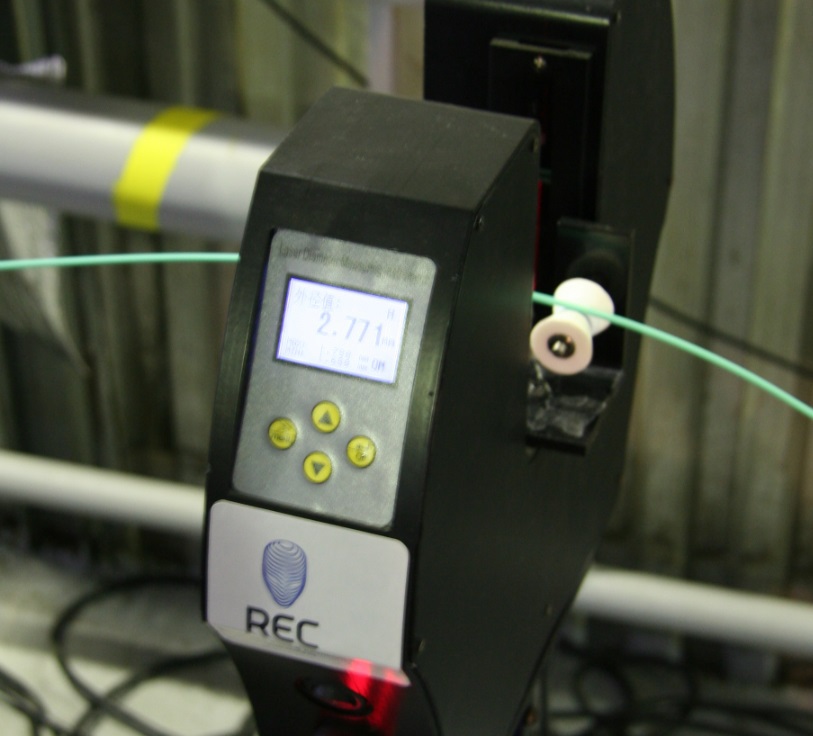

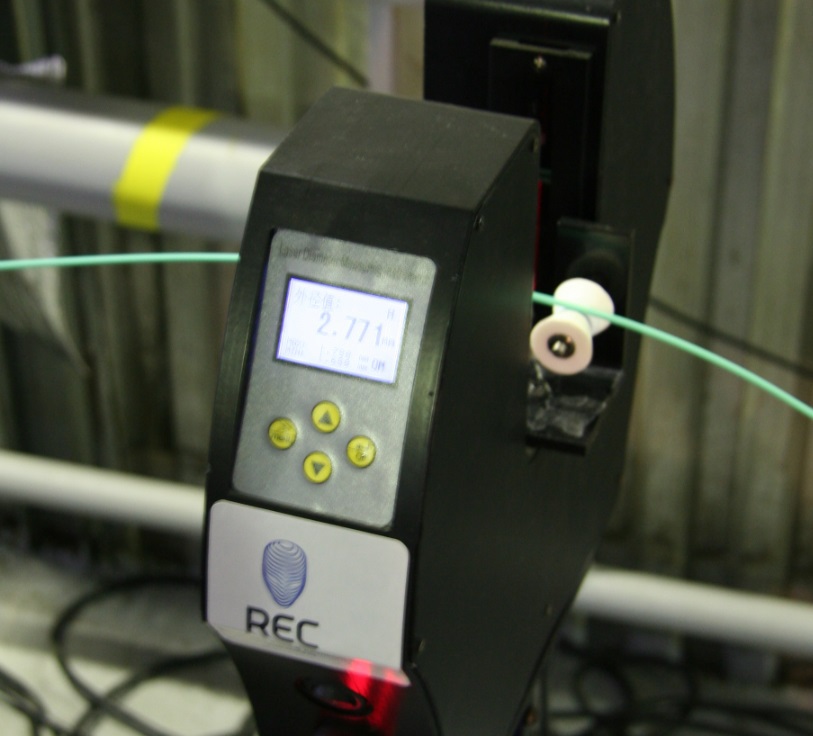

The diameter of the cooled plastic is measured with a laser device. The permissible error of the diameter of the thread is ± 0.03 mm.

Remote monitoring of the diameter of the plastic. The

speed of the thread through the laser is 55 meters per minute

Traction control. That traction creates the desired diameter. Using this unit, you can very accurately select the thrust of the motors and thereby adjust the diameter of the plastic.

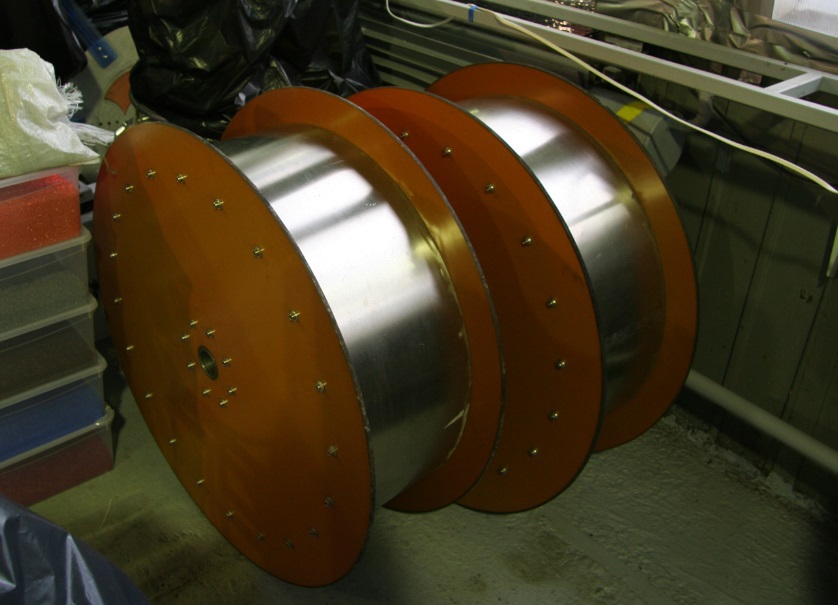

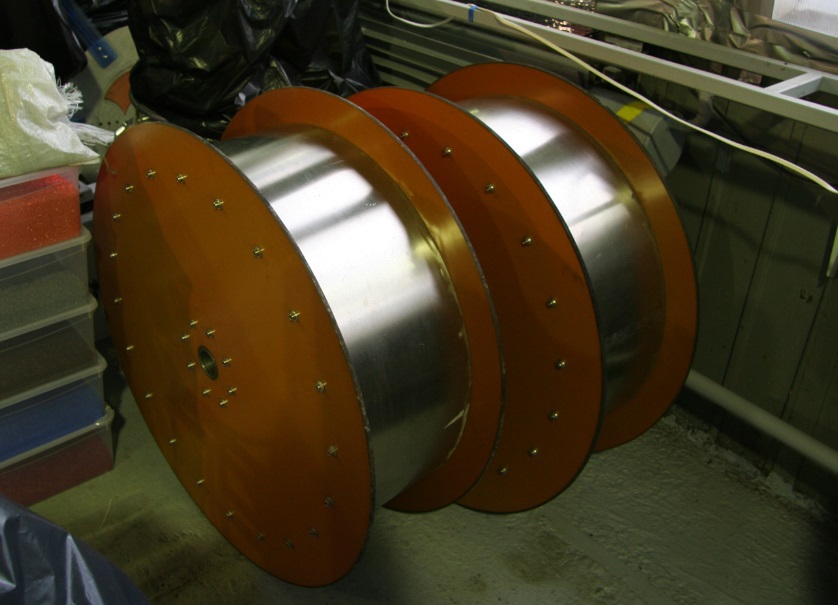

"Spindle" - controls the speed of winding on the reel. No to the COIL.

Here it is - COIL.

Without plastic.

It is important to note the evenness of filling the spool.

After the large spool is full, it is removed and the thread is rewound onto small (common to all) spools.

Conventional coils fall into the caring hands of the girl who completes the box.

Dust - proof bag, silica gelMoisture-proof, dense box that protects from direct sunlight and stickers. The labels indicate the recommended melting point (they are different for ABS and PLA), thread diameter, weight and material.

From here they will travel throughout Moscow and the CIS countries.

What I drew attention to is that the workshop is very clean, all measures have been taken to keep dust as low as possible: windows are sealed with tape, cleaning is often done, antistatic liquid is used, especially important places are covered with polyethylene.

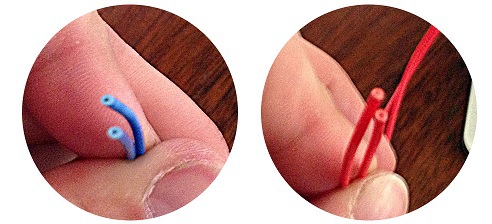

A couple of tips on how to choose a good plastic.

PLA is very sensitive to storage conditions (in the dark, dry and dust free). The twig should be clean without inclusions, smooth, without peeling, on the surface - a light shine.

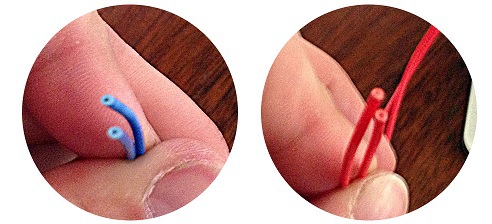

The presence of foreign bodies is checked at the rupture site. If you pull yourself up and tear a piece of plastic (and breaks where it is “thin”), then the gap should be uniform - this is a sign of good quality.

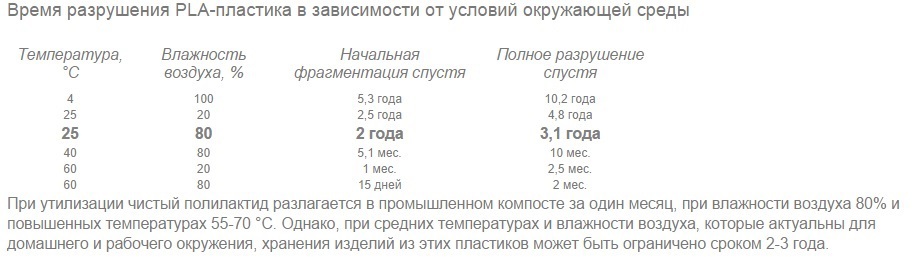

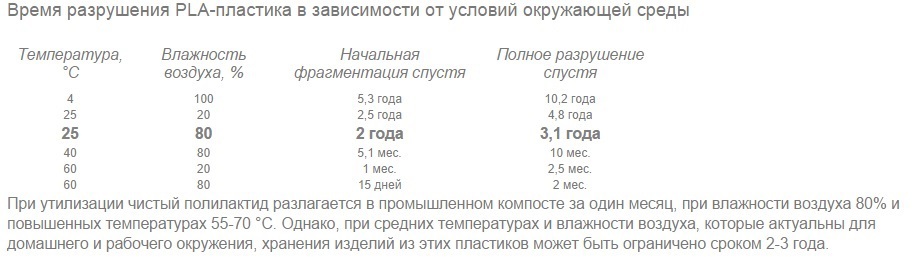

(picture for environmental investors)

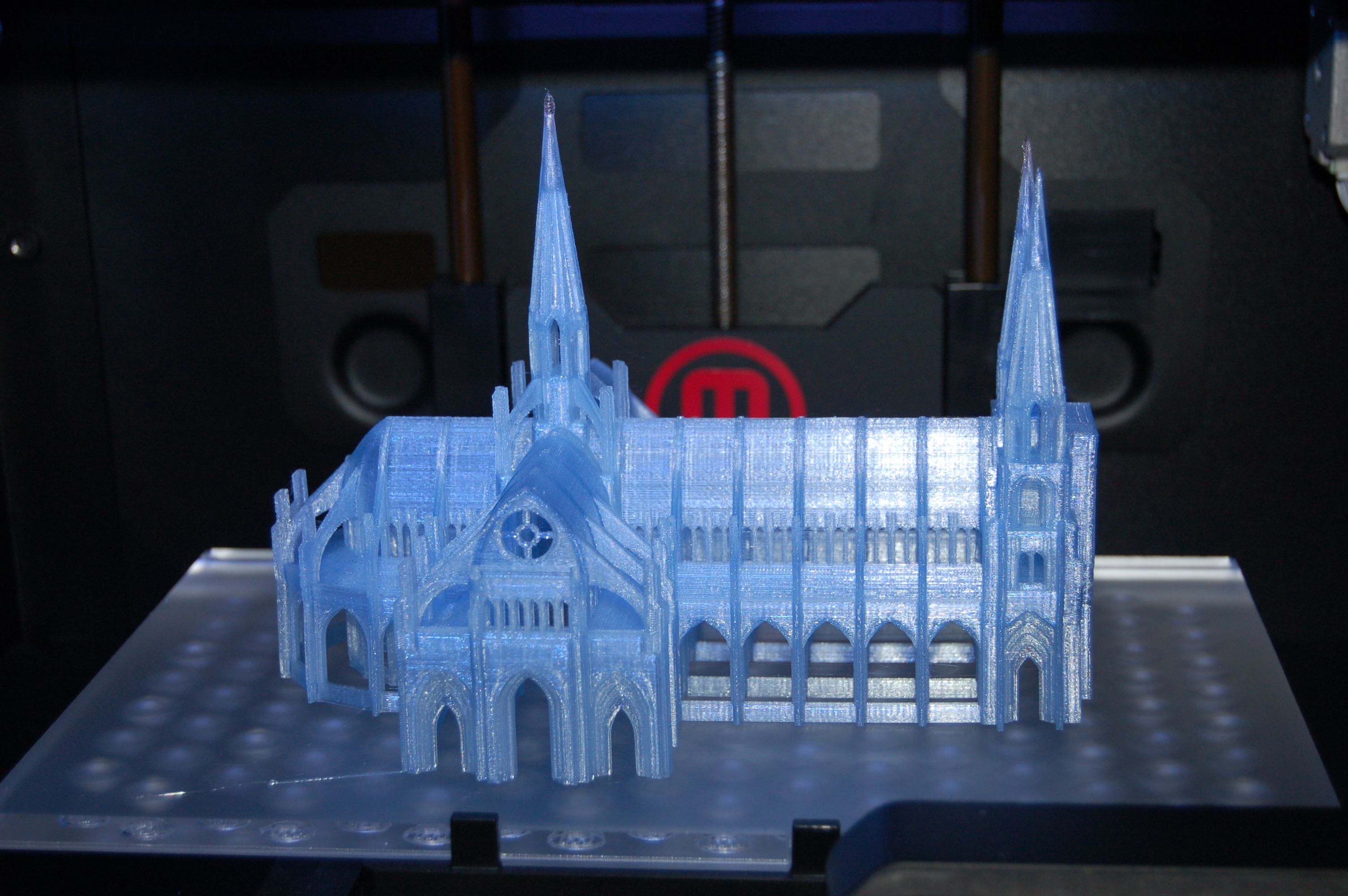

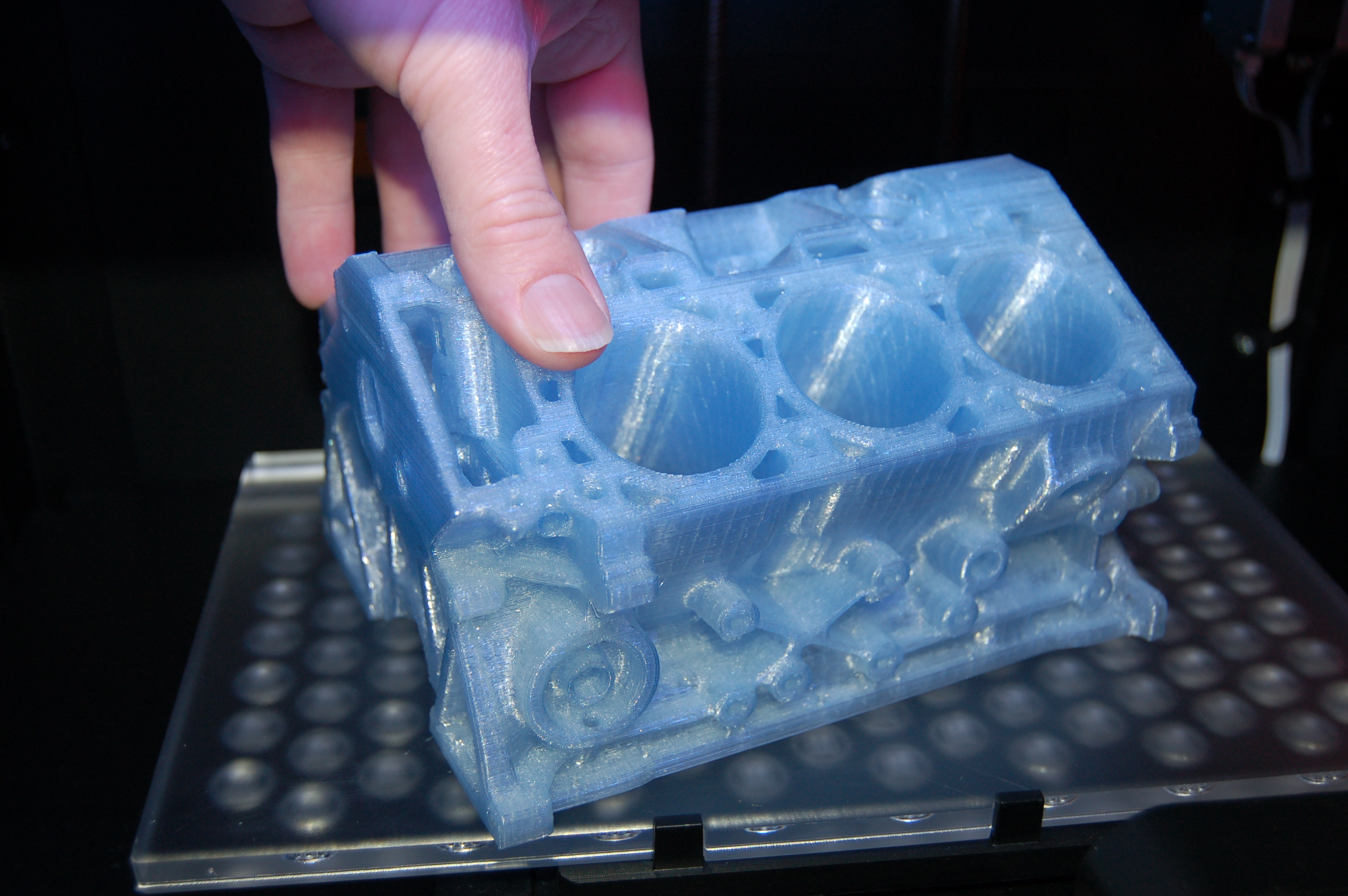

but here are some similar to the truth

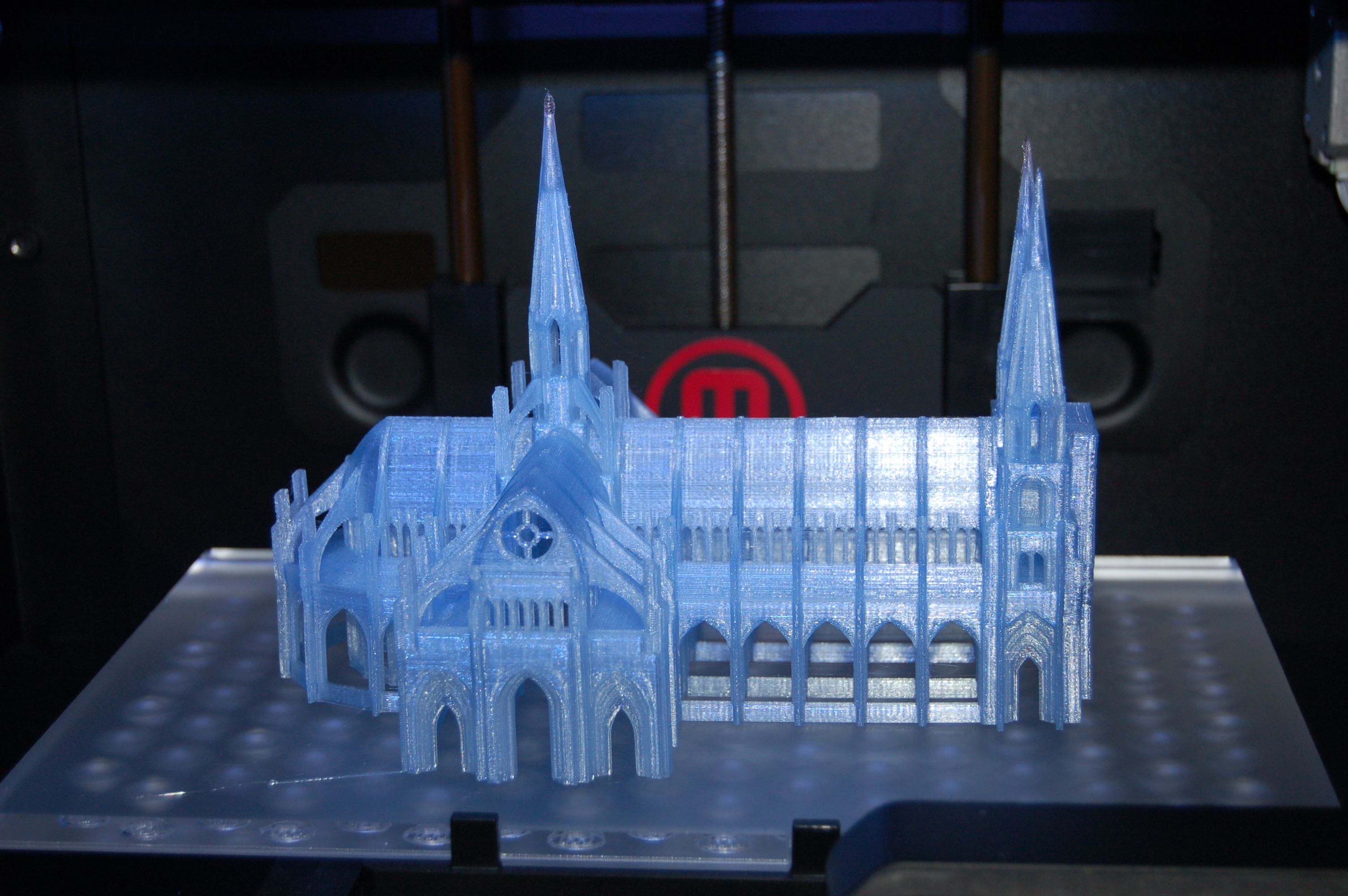

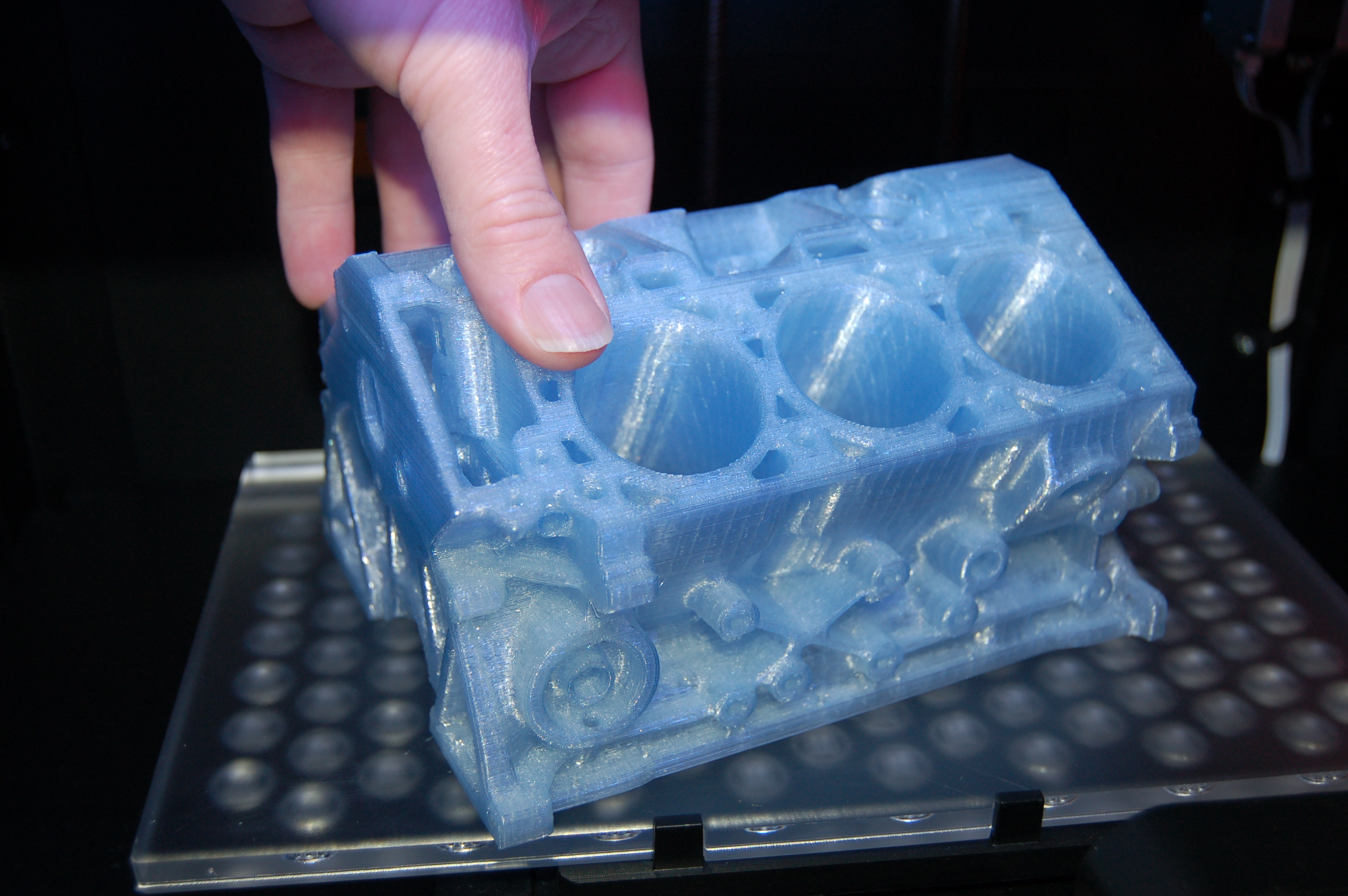

examples from the PLA

In order to dispel the myths that coils with plastic for 3D printers

As the co-founder of the company told me: “First, we saw a printed fruit knife, and peeled orange, then the shock was a video with a gun of Cody Wilson and it started ...”

While I wrote the first 2 articles about Habré 3D printers (spring 2013), these guys have already started building a plastic business. It is interesting that I and they came up with a similar idea, how to supplement the saying, they say, a person can endlessly look at fire, water, how another person works and how a 3D printer prints.

Polylactide (PLA) is a biodegradable, biocompatible, thermoplastic, aliphatic polyester, the monomer of which is lactic acid. Annually renewable resources such as corn and sugarcane serve as raw materials for production. It is used for the production of products with a short service life (food packaging, disposable tableware, bags, various containers), as well as in medicine, for the production of surgical sutures and pins.

Under cat - the main stages of converting raw materials into reels with PLA for 3d printers

Workshop panorama

From right to left

There was corn, then it is processed into such balls and put into such boxes. A

ton of raw material produces about 900 kg of plastic.

Since it is a natural product, it is afraid of light and moisture, therefore it is protected with such a bag and a piece of silica gel.

And this is a “vacuum cleaner”, with which 100 kg of “corn balls” are scooped up and sent to a container.

Here the raw material is dried, and the smell is like in a confectionery.

Add a pinch of dye (also completely natural, Austrian quality).

Here the raw material is heated and turns into a viscous mass.

Under the pressure of the shaft we pass through the heating elements.

The diameter of the “firebox” outlet is about 3 mm, the plastic acquires the desired diameter (1.75 mm) due to the fact that it is pulled right there, and the draft is very precisely tuned

for cooling bath. For ABS and PLA, different temperatures.

The diameter of the cooled plastic is measured with a laser device. The permissible error of the diameter of the thread is ± 0.03 mm.

Remote monitoring of the diameter of the plastic. The

speed of the thread through the laser is 55 meters per minute

Traction control. That traction creates the desired diameter. Using this unit, you can very accurately select the thrust of the motors and thereby adjust the diameter of the plastic.

"Spindle" - controls the speed of winding on the reel. No to the COIL.

Here it is - COIL.

Without plastic.

It is important to note the evenness of filling the spool.

After the large spool is full, it is removed and the thread is rewound onto small (common to all) spools.

Conventional coils fall into the caring hands of the girl who completes the box.

Dust - proof bag, silica gelMoisture-proof, dense box that protects from direct sunlight and stickers. The labels indicate the recommended melting point (they are different for ABS and PLA), thread diameter, weight and material.

From here they will travel throughout Moscow and the CIS countries.

Purity

What I drew attention to is that the workshop is very clean, all measures have been taken to keep dust as low as possible: windows are sealed with tape, cleaning is often done, antistatic liquid is used, especially important places are covered with polyethylene.

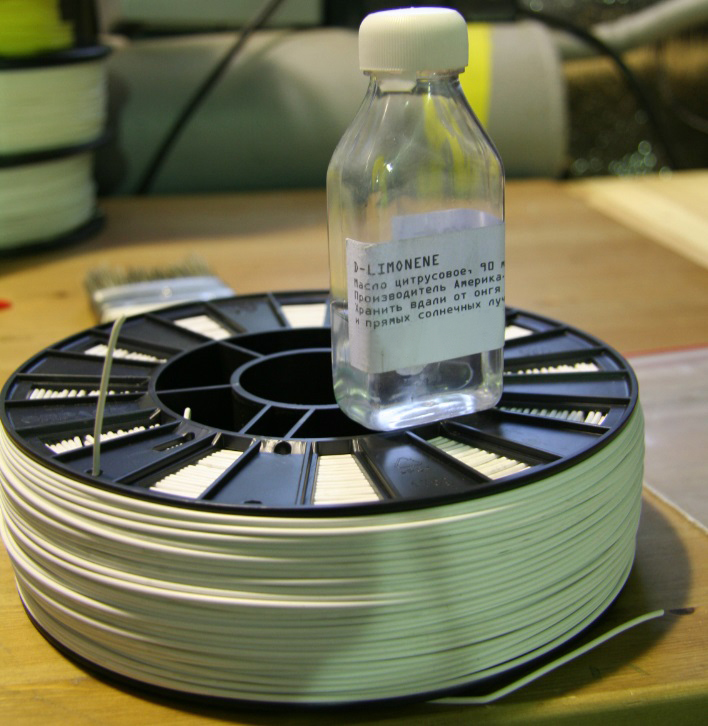

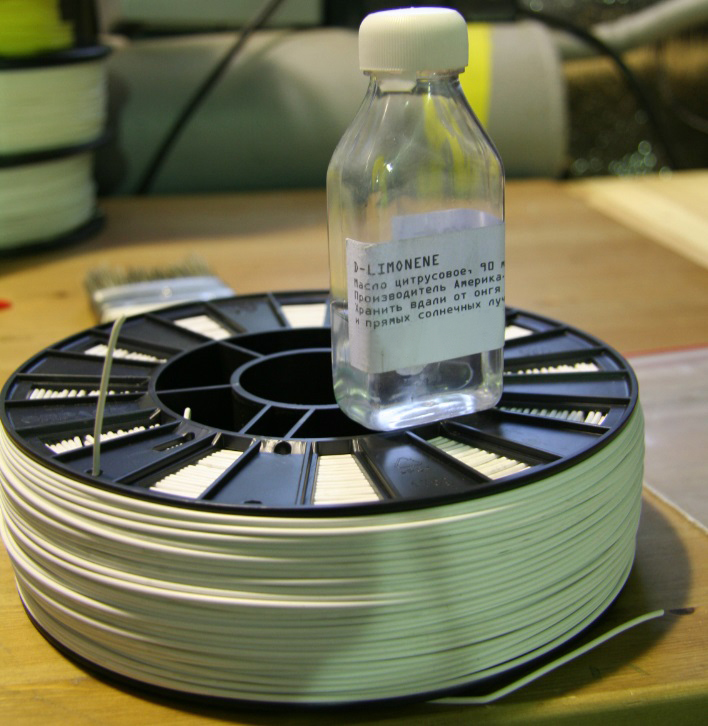

soluble plastic

high-strength polystyrene (HIPS), which in its characteristics is very similar to ordinary ABS (for which Rep 2X is “optimized”). HIPS is soluble in limonene, a citrus-based substance. Complex objects can be printed with standard ABS or PLA, and HIPS can be used as support material. The final product is immersed in a limonene bath, where HIPS dissolves in a few hours. In addition, HIPS has a close operating temperature, glues well to ABS and the platform. The consumption of limonene is small, since most of the support is usually removed by hand. A limon bath is a slightly more complicated procedure than if it was ordinary water, but it has its own plus: after bathing, the part smells like lemon.

high-strength polystyrene (HIPS), which in its characteristics is very similar to ordinary ABS (for which Rep 2X is “optimized”). HIPS is soluble in limonene, a citrus-based substance. Complex objects can be printed with standard ABS or PLA, and HIPS can be used as support material. The final product is immersed in a limonene bath, where HIPS dissolves in a few hours. In addition, HIPS has a close operating temperature, glues well to ABS and the platform. The consumption of limonene is small, since most of the support is usually removed by hand. A limon bath is a slightly more complicated procedure than if it was ordinary water, but it has its own plus: after bathing, the part smells like lemon.

A couple of tips on how to choose a good plastic.

PLA is very sensitive to storage conditions (in the dark, dry and dust free). The twig should be clean without inclusions, smooth, without peeling, on the surface - a light shine.

The presence of foreign bodies is checked at the rupture site. If you pull yourself up and tear a piece of plastic (and breaks where it is “thin”), then the gap should be uniform - this is a sign of good quality.

Durability / Biodegradability

(picture for environmental investors)

but here are some similar to the truth

examples from the PLA