Plastic, steel and two Teflon nozzles. New 3d 打印机 from China

War loves victory and does not like duration. (故 兵 貴 勝 , 不 貴 久)

Sun Tzu, The Art of War. (孫子兵 法)

In 2002, he read Computerru with the theme of the issue "Real Chinese Quality . " Now I saw what real Chinese agility is.

The keys did not have time to cool down after the article about Ultimaker 2 , as the Chinese announced the "analog" of the ultimaker - Mankati Fullscale XT , but with two extruders at once (and there is a place for the third in the menu items).

I hope they guessed that 3d 打印机 is a 3d printer in Chinese (although who knows, 3d-printer can be an English translation of 3d 打印机).

Over the past two months, when preparing posts on Habré, the third time I got to Chinese Wikipedia (the first time was when I wrote about Svetlyachka, the second time that Chinese hackers hacked Tesla S).

As once I learned English from

Under the cat are some photos and a description, a comparison of Mankati vs Ultimaker and a survey, what is the first advantage of the two extruders.

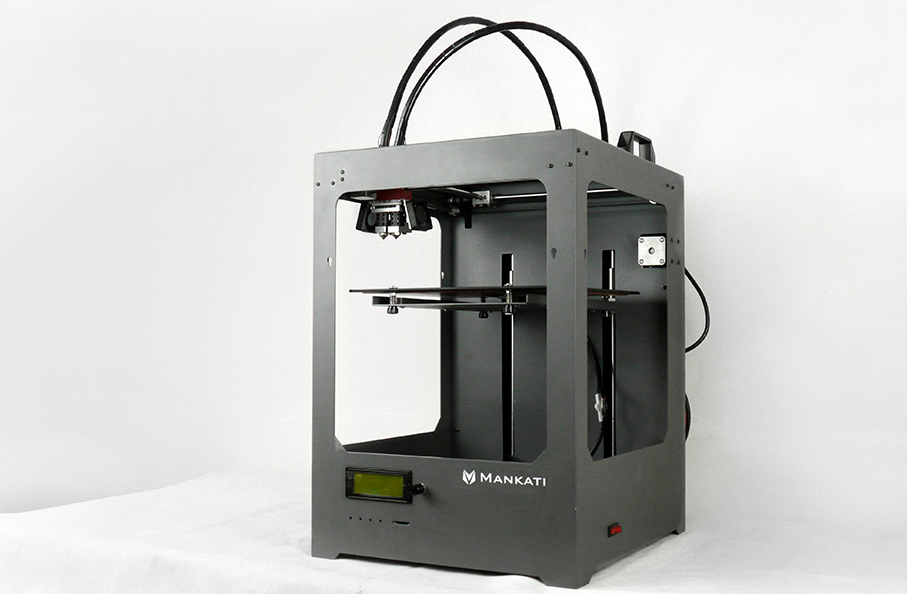

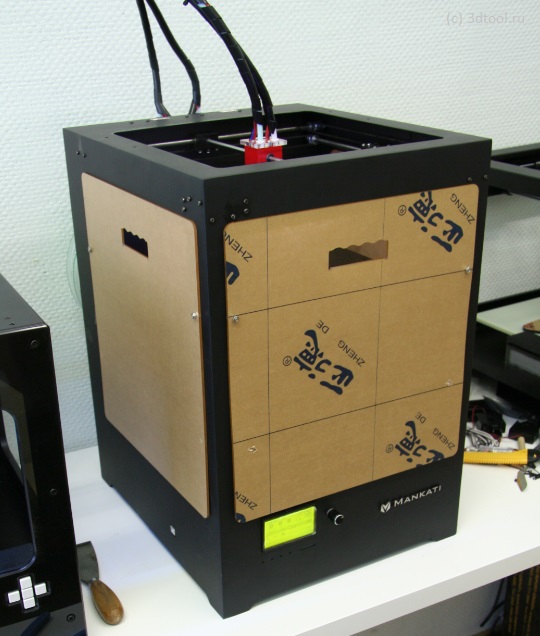

It’s quite large (380 x 420 x 530 mm) and heavy (25 kg). There are special carry handles on top

TTX

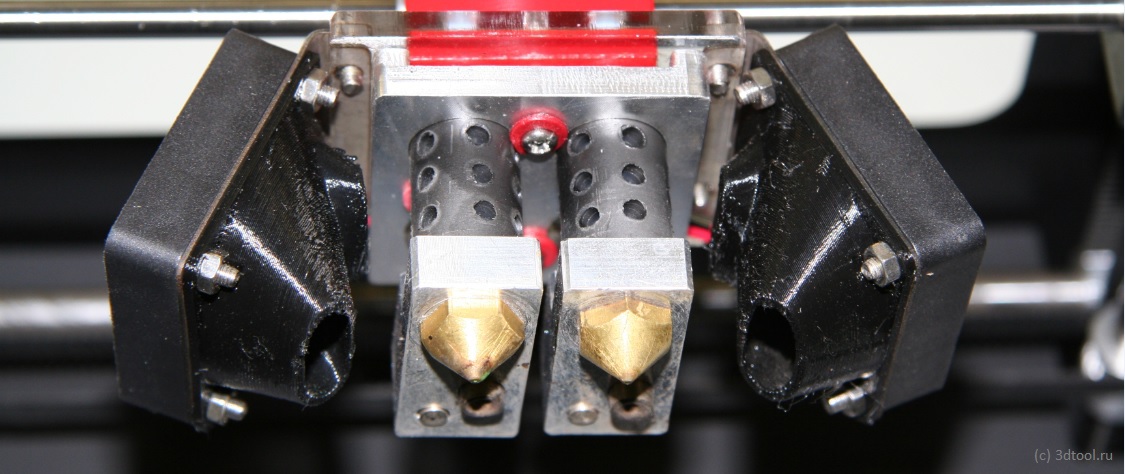

Double extruder for printing in two colors at the same time

Large print area: 250 * 250 * 300 mm

Accuracy: X-axis, Y0.01 mm, Z-axis 0.015 mm

Layer resolution: 0.04 mm -0.4 mm

Nozzle diameter: 0.4 mm

Speed: maximum movement speed: 250 mm / sec .; maximum print speed: 180 mm / sec .; maximum speed of the extruder: 100 mm / sec.

Device size: 380 * 420 * 530 mm

Weight: 25 kg

Controller: Arduino AT mega 2560 R3 Micro Controller

Motherboard: Mankati Stable Main Board V3.x

Stepper motor of the axes X, Y 42 * 48, 1.3 A; Z axis 42 * 63, 1.5 A

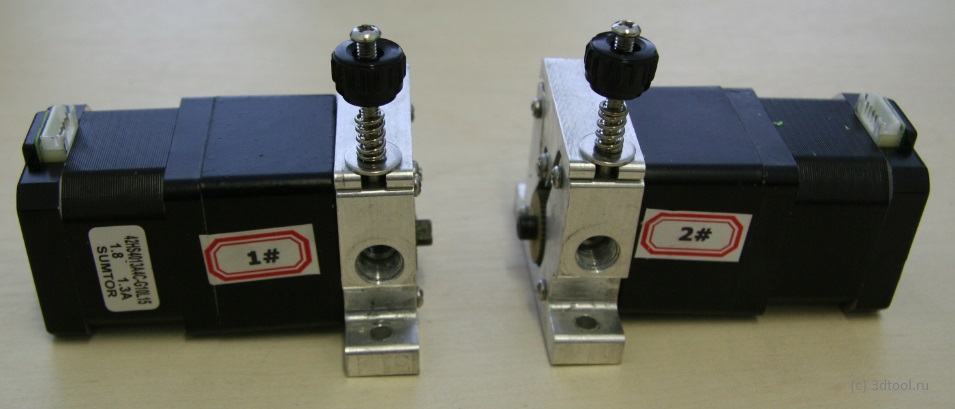

Gear motor E42 * 42, coefficient 1:10

Large print area: 250 * 250 * 300 mm

Accuracy: X-axis, Y0.01 mm, Z-axis 0.015 mm

Layer resolution: 0.04 mm -0.4 mm

Nozzle diameter: 0.4 mm

Speed: maximum movement speed: 250 mm / sec .; maximum print speed: 180 mm / sec .; maximum speed of the extruder: 100 mm / sec.

Device size: 380 * 420 * 530 mm

Weight: 25 kg

Controller: Arduino AT mega 2560 R3 Micro Controller

Motherboard: Mankati Stable Main Board V3.x

Stepper motor of the axes X, Y 42 * 48, 1.3 A; Z axis 42 * 63, 1.5 A

Gear motor E42 * 42, coefficient 1:10

Control Panel. Shows the temperature of the platform, the temperature of the first nozzle, the temperature of the second nozzle and ... the temperature of the third nozzle.

Size of the printing area 250x250x300 mm

Heated platform bottom view. Calibrated with 4 screws.

Structurally very similar to ultimaker 2.

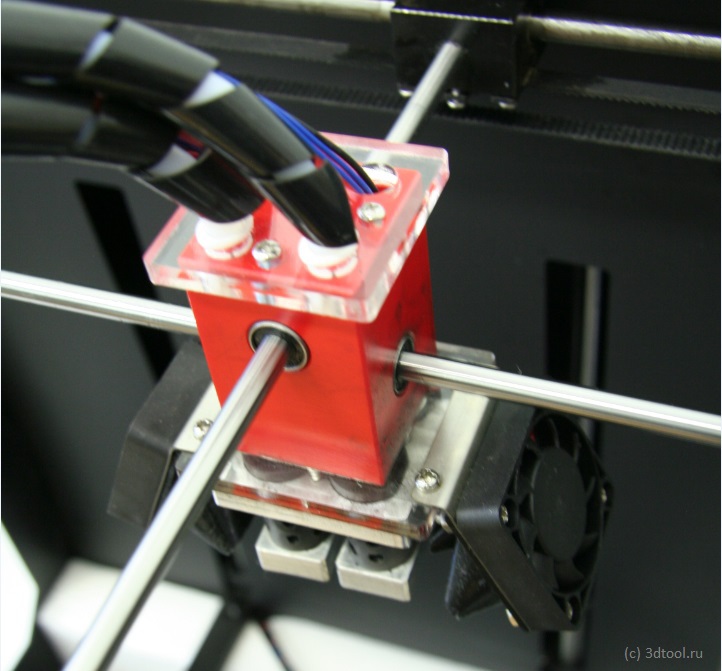

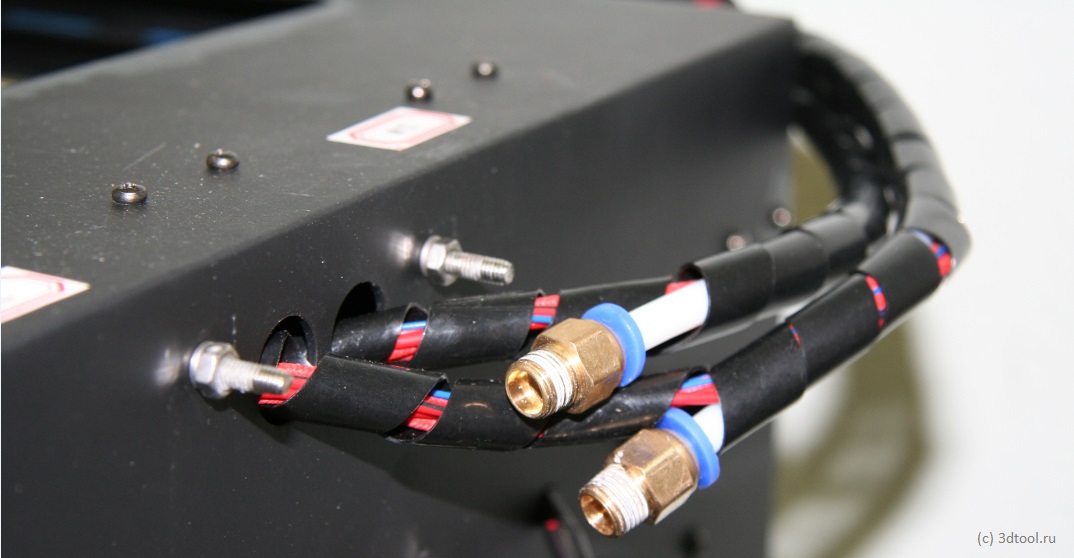

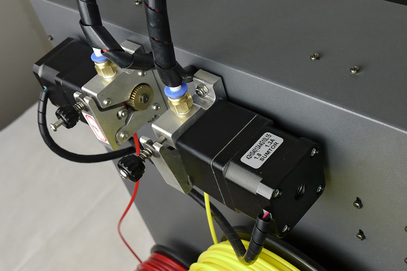

Two powerful motors to push

through plastic. Tubes through which the “force” is transmitted to the extruders.

There are no motors on the extruders themselves, which makes the print head easier.

The motors are located on the rear panel.

Rear panel.

Powered by 3mm plastic printer.

Shutters made of transparent plastic. In the photo they are with a transport “protective film”.

Video of the printing process from the official channel

at 1:38 - print "over the air", without supports

Mankati vs Ultimaker 2

With equal performance and accuracy parameters, Mankati is inferior to Ultimaker in external design and noiseless, but it wins in price (83 thousand for Mankati versus 120 thousand for Ultimaker 2) and the ease of replacing parts (plastic feed motors are outside, it is easy to change the nozzle and extruder, etc.)

Mankati has a print area of 250x250x300mm, and Ultimaker 2 has 226x226x206mm. When communicating

with manufacturers and suppliers, I always wonder who buys their printers and why, and ask you to tell me the most interesting cases.

This time, the Russian distributor told me about the most remarkable cases of the acquisition of Mankati Fullscale XT. One client was from the film industry (making props for filming), the other from the puppet theater. We bought a printer to prototype bottles for drinks, to create parts for aircraft modeling, as well as to open our business in 3d printing.

And as always there was a conversation about why 2 extruders are needed.

The first option (design) is to create two-tone beautiful things that a single-color printer is not capable of making.

The second option (engineering) is to make support with water-soluble plastic, which allows you to create unusual design solutions (and amenities too).

Only registered users can participate in the survey. Please come in.

Two extruders first of all need to

- 33.2% print in two colors 183

- 66.7% print support water soluble material 367