How to build a spacecraft without leaving the office

DX1 satellite, born to become the first private spacecraft in Russia, was late to this title, but for the development company it will forever remain the firstborn. About a year it was created, more than six months it was waiting for launch, and, finally, took its place in the Soyuz 2.1b rocket.

What do you need to create your own spacecraft? What difficulties will have to be solved? How much will it all cost? The answers to these questions had to be found until the moment the satellite was sent to Baikonur.

Many of Dauria Aerospace already had experience in creating spacecraft and were ready to work, but in order to form a coherent team, it was necessary to go through all the stages of creating a spacecraft together. Only having accumulated joint positive and negative experience, having gone through the whole process from concept to launch and operation, we can confidently talk about the company's readiness for further achievements. This was perhaps the main motive for creating the DX1. But more prosaic factors also played an important role: it was necessary to write and test the device software, ready for use on other company satellites; build up chains of suppliers and subcontractors; prepare the assembly site.

As a rule, satellites are created for specific tasks or orders. The company did not have such yet, so they decided to develop a universal platform based on the possibility of launching Meteor-M No. 2 with the Roskosmos satellite. Immediately laid the capabilities of this platform for the implementation of both company projects and custom-made. When choosing the platform concept, we proceeded from a number of parameters:

1) weight up to 100 kg, - the so-called. class of "microsatellites";

2) scalability - the ability to change the dimensions of the platform, without changing the basic elements and avionics, and, as a result - the general software;

3) a wide range of applications - equipping the platform with high-precision orientation means, which allows satellites, for example, to survey the earth's surface or carry out astrophysical tasks.

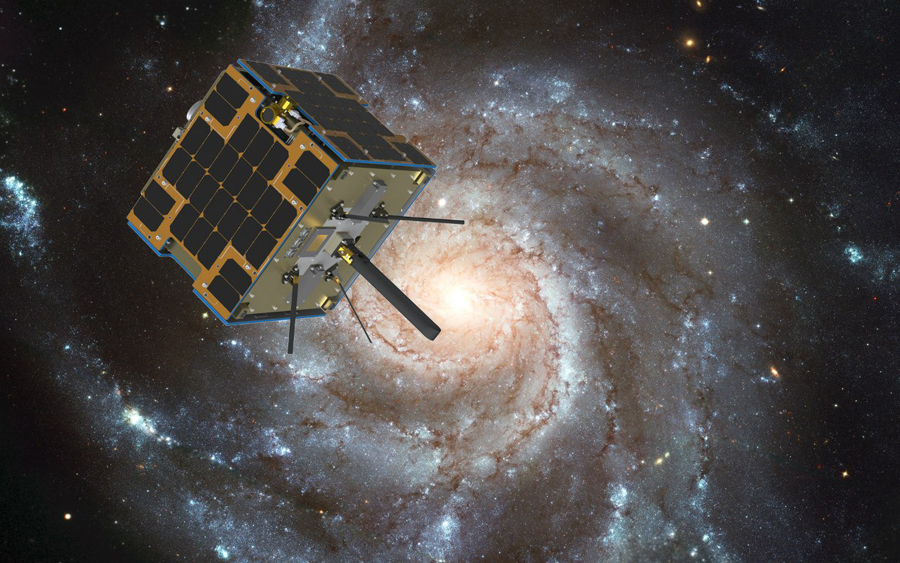

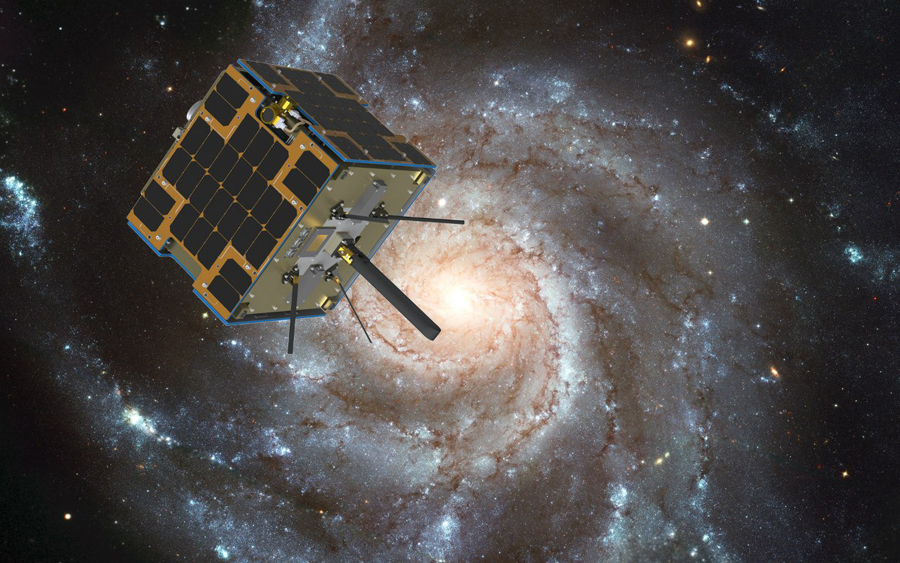

The result was the DX1 project - “Dauria Experimental First”. In order not to launch a simple technological demonstrator, the satellite was equipped with an AIS signal receiving unit - this is how it got commercial application and the possibility of partial or full payback. But this device must confirm abilities that exceed the needs of a given payload.

The power consumption of the AIS unit is not high, which made it possible to do without opening solar panels. This simplified the design, facilitated the work and management. But even so, the satellite is capable of producing three times more energy than it really needs.

The airborne radio complex operates in two bands: VHF and S. Obtaining permission to use them over the territory of Russia took almost as much as creating the device itself.

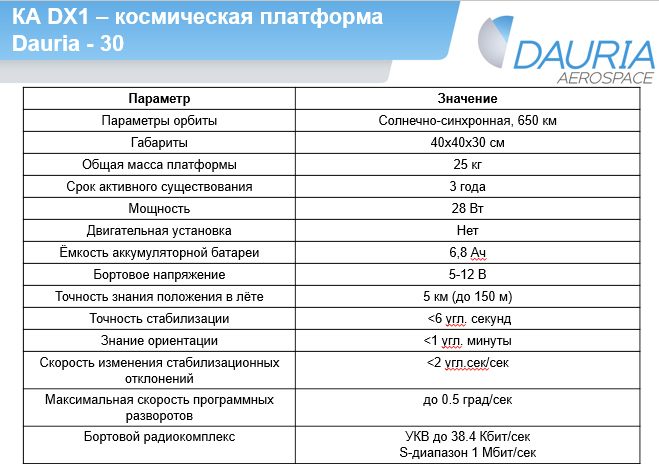

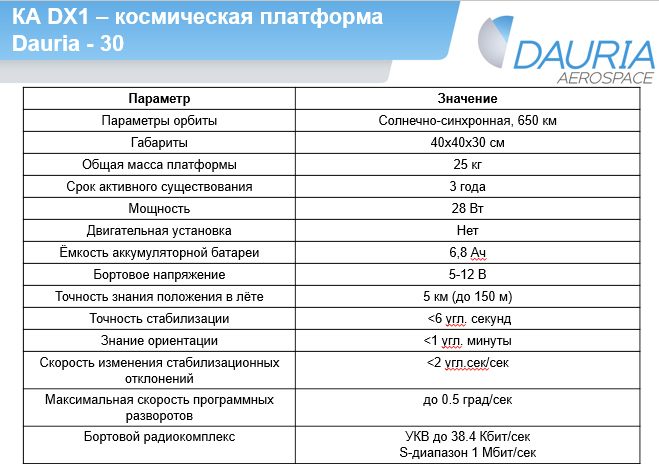

The main technical characteristics of DX1 are visible from the table:

Positioning in orbit up to hundreds of meters and pointing accuracy of up to 6 arc seconds - these are characteristics suitable for capturing the surface of the Earth or planetary astronomy. Such opportunities have been laid for the future, with the expectation of future tasks.

The birth of the apparatus began with an assessment of what modern world industry has to offer. Traveled a bunch of exhibitions and forums around the world. Searched for the components of the industrial class, i.e. suitable for industrial use on Earth. Space or military components are orders of magnitude more expensive, which contradicts the ideology of a conceived business. And with the advent of sanctions, difficulties would only increase.

But now industrial electronics is capable of performing space tasks. Actually, the state-owned companies of Roscosmos do not disdain its application. This did not work at Phobos-Grunt, but in near-Earth space, satellites have been operating on “non-space” components for up to ten years. Roscosmos uses such electronics because there is simply no other: its own microelectronics is often not ready to offer the necessary, and foreigners “space” and “military” simply do not sell.

“Dauria” consciously goes to “industrialization” by considering additional methods of protection in space: shielding with a thick layer of aluminum, duplication, hardware and software.

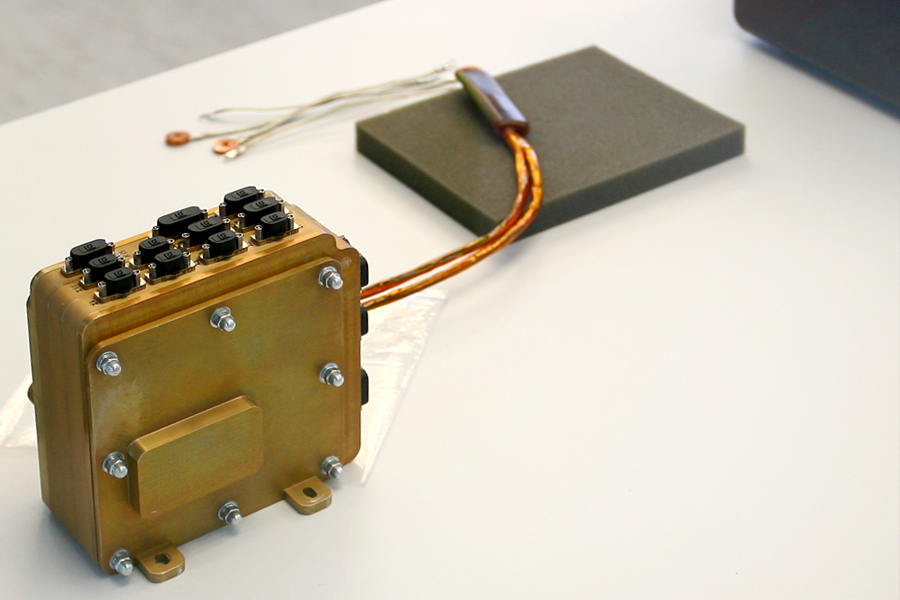

As a result, the DX1 airborne vehicle became similar to the part from the tank, but in general the satellite turned out to be quite light, for its dimensions - 22 kg. (A joke about positive buoyancy). The on-board computer filling already has flight practice on the NASA experimental satellite.

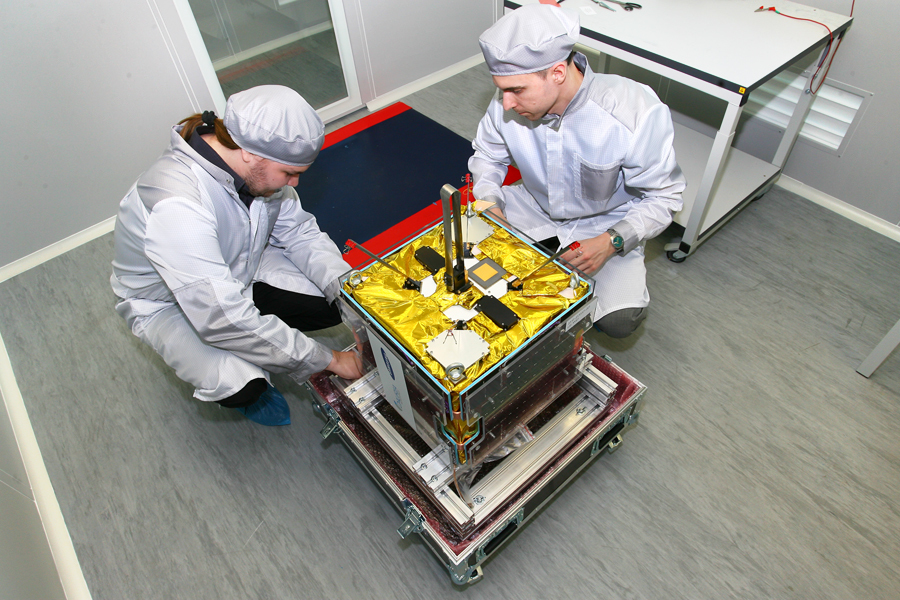

The satellite architecture is built on a supporting aluminum frame, and solar panels act as walls. Devices are mounted on the top and bottom panels and uprights. The frame was milled according to its own drawings. We thought about 3D printing, but so far there are concerns that metal printing will not give the required accuracy, and it will come out more expensive than a cutter, so we wait until the technology develops to the desired quality.

The unpleasant news was the fact that often supplied components do not meet the declared characteristics. Therefore, we checked everything before installing it on the device. Sometimes I had to be smart. For example, gyroscopes of an orientation system were tested on an astronomical mount. It was lucky that one of the engineers, in his free time from conquering near space, was engaged in contemplating the distant.

In the photo - the solar sensor is tested under the rays of an artificial "sun":

Another device that I have high hopes for is the star sensor. Russian, by the way, production. It can be seen on the opposite side of the apparatus antennas. It should be used for star orientation and satellite positioning. In fact, this is a black and white low-resolution camera, but it is the only camera on the satellite, so I hope to persuade our specialists to take the moon in the new moon. Similar shooting and transfer of the picture is theoretically possible, but you have to try. This will be the best proof of the health of the device.

Although the company did not report to anyone for the development of the DX1, the engineers decided to conduct a full range of tests that the Roskosmos spacecraft must withstand. To this end, they created a mass-dimensional layout for vibrodynamic tests. He had to confirm the reliability of the satellite design, its willingness to withstand overload during the launch of the launch vehicle. After successfully passing the tests, the model became the first exhibit of the future museum of private cosmonautics in Russia. He managed to light up in several TV plots and photo reports (this is a remark for the most attentive who could be surprised by a twisted pair on a spacecraft).

Another model - the antenna - was tested in an anechoic chamber, which allows one to evaluate the propagation of radio waves in conditions close to space. There, too, the characteristics laid down by the designers were confirmed.

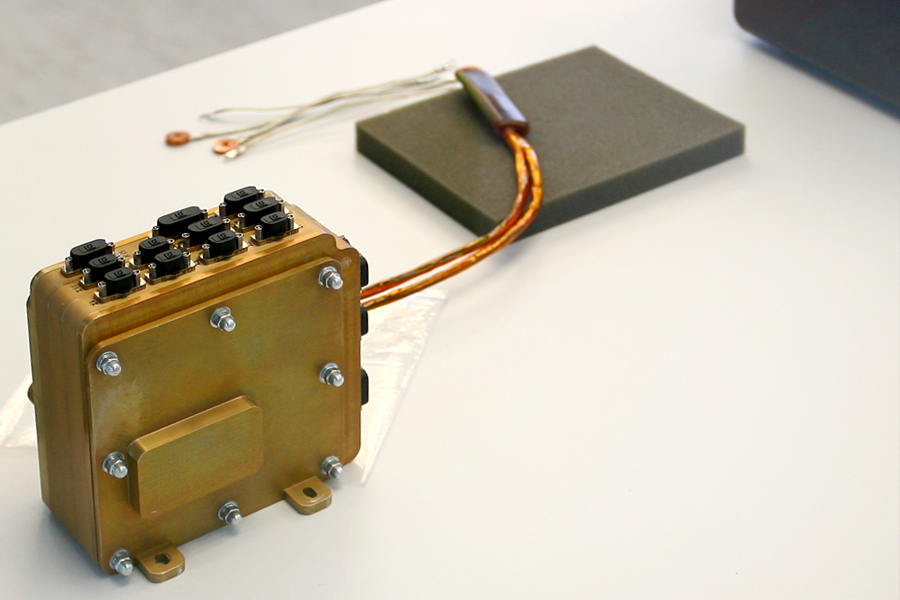

Finally, the fully assembled spacecraft was checked in a thermal vacuum chamber. This stage of testing allowed us to evaluate the readiness of the device to work in conditions of space cold and heat. Here a flaw was revealed: it turned out that, being stationary, the satellite was very overheated from the sunny side. In principle, this is not fatal - just start the device in the "kebab" mode, i.e. turn around regularly, exposing different facets to the sun. But such a regime would not allow a series of operations for future promising missions. Therefore, the problem was solved by a constructive method - they replaced the brackets of solar panels from aluminum to copper. The thermal conductivity of copper is higher, so excess heat should "leak" onto the body and dissipate on the shadow side.

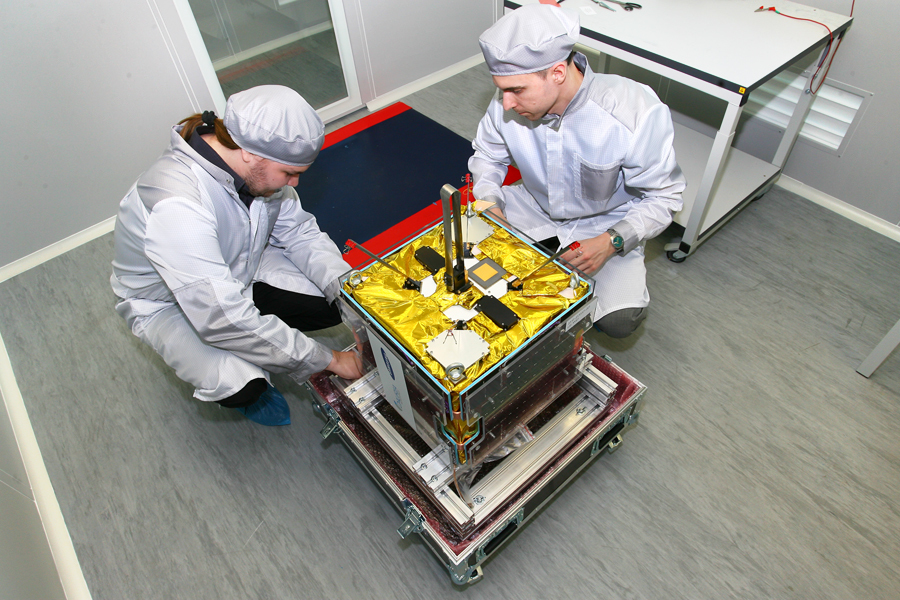

In general, maintaining the thermal regime on spacecraft is an art, I’ll tell you about it separately. All elements of the satellite, except antennas and solar panels, were wrapped in screen-vacuum thermal insulation - “gold foil” even before testing. Unlike electronics, there was found a high-quality domestic manufacturer - KAM Research Institute from Pereslavl. First, our specialist in thermal conditions mastered the skills of cutting and sewing and drew a natural pattern. They made a draft version of thermal insulation on it and came to our office for a natural fitting.

The suit did not sit down immediately, but as a result, our gentleman went to Baikonur during the parade.

Before the launch, we almost got ruined by the start - they screwed the satellite to the booster block so qualitatively that they transferred the cable through which the team should go to the compartment. As a result, the bare wire shorted to the case and discharged the battery ...

Before the start, it took less than three weeks, to Baikonur more than 2 thousand km, spare parts in Moscow. Roscosmos postponed the launch for more than a year, so no one would wait for us either. The score went to the clock: have time to fix it or not? The first flight to Baikonur on Saturday to our guys went to help with a spare cable. They also drove a mass model of the device - a metal blank, which would replace the satellite if it were removed. The missile flight program was written in advance, so any discrepancy in mass could ruin the entire launch.

They did not have time to physically replace anything other than the cable. The satellite was removed from the booster block, the cable was replaced, the battery was charged - they were packed in two days. Next, I had to check the operability of the devices - to make sure that the short circuit did not burn out any chip. Deviations from the norm were not identified and decided to fly.

Photos from the workshops of Baikonur can not be shown, so here is the Baikonur gopher :)

How will it fly and how DX1 will work we will soon find out. The specialists of Dauria are confident in their work. The Soyuz rocket is reliable. The Frigate booster also works like a clock. Now the main thing is that the components are not let down, and there will be space for us.

PS I think the text will cause questions for many. I’ll immediately warn you that I won’t be able to answer all the narrowly technical questions. I’ll ask the engineers to help, but now, on the eve of the launch, they have something to do, and no one has canceled the concept of trade secret. Therefore, if whose questions remain unanswered - understand and forgive.

What do you need to create your own spacecraft? What difficulties will have to be solved? How much will it all cost? The answers to these questions had to be found until the moment the satellite was sent to Baikonur.

Many of Dauria Aerospace already had experience in creating spacecraft and were ready to work, but in order to form a coherent team, it was necessary to go through all the stages of creating a spacecraft together. Only having accumulated joint positive and negative experience, having gone through the whole process from concept to launch and operation, we can confidently talk about the company's readiness for further achievements. This was perhaps the main motive for creating the DX1. But more prosaic factors also played an important role: it was necessary to write and test the device software, ready for use on other company satellites; build up chains of suppliers and subcontractors; prepare the assembly site.

As a rule, satellites are created for specific tasks or orders. The company did not have such yet, so they decided to develop a universal platform based on the possibility of launching Meteor-M No. 2 with the Roskosmos satellite. Immediately laid the capabilities of this platform for the implementation of both company projects and custom-made. When choosing the platform concept, we proceeded from a number of parameters:

1) weight up to 100 kg, - the so-called. class of "microsatellites";

2) scalability - the ability to change the dimensions of the platform, without changing the basic elements and avionics, and, as a result - the general software;

3) a wide range of applications - equipping the platform with high-precision orientation means, which allows satellites, for example, to survey the earth's surface or carry out astrophysical tasks.

The result was the DX1 project - “Dauria Experimental First”. In order not to launch a simple technological demonstrator, the satellite was equipped with an AIS signal receiving unit - this is how it got commercial application and the possibility of partial or full payback. But this device must confirm abilities that exceed the needs of a given payload.

The power consumption of the AIS unit is not high, which made it possible to do without opening solar panels. This simplified the design, facilitated the work and management. But even so, the satellite is capable of producing three times more energy than it really needs.

The airborne radio complex operates in two bands: VHF and S. Obtaining permission to use them over the territory of Russia took almost as much as creating the device itself.

The main technical characteristics of DX1 are visible from the table:

Positioning in orbit up to hundreds of meters and pointing accuracy of up to 6 arc seconds - these are characteristics suitable for capturing the surface of the Earth or planetary astronomy. Such opportunities have been laid for the future, with the expectation of future tasks.

The birth of the apparatus began with an assessment of what modern world industry has to offer. Traveled a bunch of exhibitions and forums around the world. Searched for the components of the industrial class, i.e. suitable for industrial use on Earth. Space or military components are orders of magnitude more expensive, which contradicts the ideology of a conceived business. And with the advent of sanctions, difficulties would only increase.

But now industrial electronics is capable of performing space tasks. Actually, the state-owned companies of Roscosmos do not disdain its application. This did not work at Phobos-Grunt, but in near-Earth space, satellites have been operating on “non-space” components for up to ten years. Roscosmos uses such electronics because there is simply no other: its own microelectronics is often not ready to offer the necessary, and foreigners “space” and “military” simply do not sell.

“Dauria” consciously goes to “industrialization” by considering additional methods of protection in space: shielding with a thick layer of aluminum, duplication, hardware and software.

As a result, the DX1 airborne vehicle became similar to the part from the tank, but in general the satellite turned out to be quite light, for its dimensions - 22 kg. (A joke about positive buoyancy). The on-board computer filling already has flight practice on the NASA experimental satellite.

The satellite architecture is built on a supporting aluminum frame, and solar panels act as walls. Devices are mounted on the top and bottom panels and uprights. The frame was milled according to its own drawings. We thought about 3D printing, but so far there are concerns that metal printing will not give the required accuracy, and it will come out more expensive than a cutter, so we wait until the technology develops to the desired quality.

The unpleasant news was the fact that often supplied components do not meet the declared characteristics. Therefore, we checked everything before installing it on the device. Sometimes I had to be smart. For example, gyroscopes of an orientation system were tested on an astronomical mount. It was lucky that one of the engineers, in his free time from conquering near space, was engaged in contemplating the distant.

In the photo - the solar sensor is tested under the rays of an artificial "sun":

Another device that I have high hopes for is the star sensor. Russian, by the way, production. It can be seen on the opposite side of the apparatus antennas. It should be used for star orientation and satellite positioning. In fact, this is a black and white low-resolution camera, but it is the only camera on the satellite, so I hope to persuade our specialists to take the moon in the new moon. Similar shooting and transfer of the picture is theoretically possible, but you have to try. This will be the best proof of the health of the device.

Although the company did not report to anyone for the development of the DX1, the engineers decided to conduct a full range of tests that the Roskosmos spacecraft must withstand. To this end, they created a mass-dimensional layout for vibrodynamic tests. He had to confirm the reliability of the satellite design, its willingness to withstand overload during the launch of the launch vehicle. After successfully passing the tests, the model became the first exhibit of the future museum of private cosmonautics in Russia. He managed to light up in several TV plots and photo reports (this is a remark for the most attentive who could be surprised by a twisted pair on a spacecraft).

Another model - the antenna - was tested in an anechoic chamber, which allows one to evaluate the propagation of radio waves in conditions close to space. There, too, the characteristics laid down by the designers were confirmed.

Finally, the fully assembled spacecraft was checked in a thermal vacuum chamber. This stage of testing allowed us to evaluate the readiness of the device to work in conditions of space cold and heat. Here a flaw was revealed: it turned out that, being stationary, the satellite was very overheated from the sunny side. In principle, this is not fatal - just start the device in the "kebab" mode, i.e. turn around regularly, exposing different facets to the sun. But such a regime would not allow a series of operations for future promising missions. Therefore, the problem was solved by a constructive method - they replaced the brackets of solar panels from aluminum to copper. The thermal conductivity of copper is higher, so excess heat should "leak" onto the body and dissipate on the shadow side.

In general, maintaining the thermal regime on spacecraft is an art, I’ll tell you about it separately. All elements of the satellite, except antennas and solar panels, were wrapped in screen-vacuum thermal insulation - “gold foil” even before testing. Unlike electronics, there was found a high-quality domestic manufacturer - KAM Research Institute from Pereslavl. First, our specialist in thermal conditions mastered the skills of cutting and sewing and drew a natural pattern. They made a draft version of thermal insulation on it and came to our office for a natural fitting.

The suit did not sit down immediately, but as a result, our gentleman went to Baikonur during the parade.

Before the launch, we almost got ruined by the start - they screwed the satellite to the booster block so qualitatively that they transferred the cable through which the team should go to the compartment. As a result, the bare wire shorted to the case and discharged the battery ...

Before the start, it took less than three weeks, to Baikonur more than 2 thousand km, spare parts in Moscow. Roscosmos postponed the launch for more than a year, so no one would wait for us either. The score went to the clock: have time to fix it or not? The first flight to Baikonur on Saturday to our guys went to help with a spare cable. They also drove a mass model of the device - a metal blank, which would replace the satellite if it were removed. The missile flight program was written in advance, so any discrepancy in mass could ruin the entire launch.

They did not have time to physically replace anything other than the cable. The satellite was removed from the booster block, the cable was replaced, the battery was charged - they were packed in two days. Next, I had to check the operability of the devices - to make sure that the short circuit did not burn out any chip. Deviations from the norm were not identified and decided to fly.

Photos from the workshops of Baikonur can not be shown, so here is the Baikonur gopher :)

How will it fly and how DX1 will work we will soon find out. The specialists of Dauria are confident in their work. The Soyuz rocket is reliable. The Frigate booster also works like a clock. Now the main thing is that the components are not let down, and there will be space for us.

As a bonus, a direct speech by the DX1 project manager, Alexander Malinin:

When we started designing the DX1, we certainly did not know what this could lead to. Of course, before that, each person in the team was engaged in one or another task of developing the spacecraft, but none of the engineers did this to make the spacecraft from the first sketch to the last bolt.

Design began according to the system used in the USA for most spacecraft. The stages of PDR and CDR have passed, the device was copied at first glance. At this stage, an important mistake was made, one of the systems, in particular the AFS, was poorly developed, which negatively affected the subsequent stages of design and production. Then I had to adjust this system to the existing dimensions and limitations, which it was too late to change.

The general view of the spacecraft design was chosen at an early stage of design, so we did not have big throws in this regard. But the production process of this very construction dragged on for months. Indeed, in order to make a small part from aluminum, it had to be drawn in detail in the drawings, restrictions on tolerances and roughnesses were introduced. These are the realities of domestic metalworking companies, few are ready to work on a 3D model, and their quality leaves much to be desired.

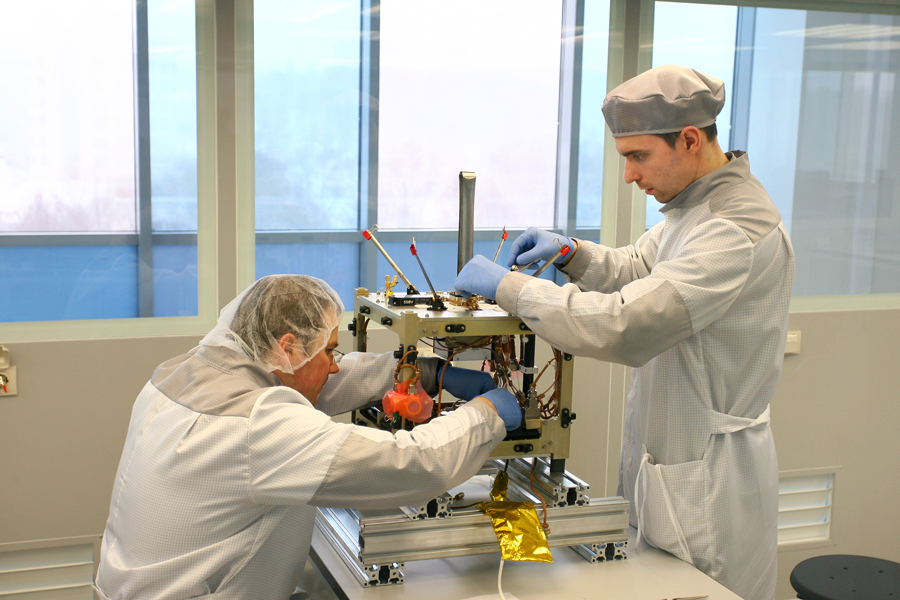

But now, the design of the spacecraft was completed, and the first copies of flight and technological models of instruments began to come to the office. The stage of autonomous, and then complex tests of the spacecraft instruments and systems began. With some devices there were less difficulties, with some much more. It turned out that not all devices work as stated in the documentation for it. We had to solve these problems along the way and refine the part that depended on us, be it cables or interface settings.

With flying cables for the spacecraft came a separate story. Everyone, at least once, had worked with them before and this was taken for granted. But now, we ourselves had to develop them. This was a completely new task for us, which no one had ever encountered before. But, we were able to cope with it and develop the required competencies, albeit at the cost of several months. We have fully purchased the necessary components: wires, screens, adhesives, fillings, connectors, covers, etc. And they independently made and tested them.

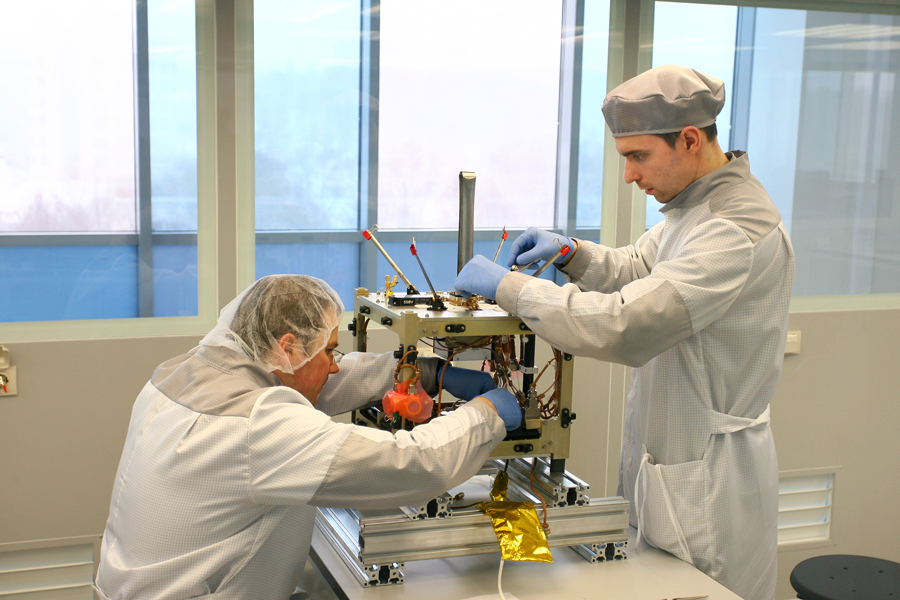

After going through a difficult stage of testing as part of an integrated test bench, our designers started assembling the spacecraft. Due to the fact that those who designed the spacecraft, the same people and collected it, the process went briskly. There was no need to issue unnecessary documentation between the services, because these services were from the same people.

Having assembled the spacecraft, we proceeded to complex tests of the spacecraft, and then to TVI. And at this stage I clearly realized: to test and debug the spacecraft nodes separately and to do the same thing on the spacecraft assembly, these are completely different things. At first, nothing works, both on software and on hardware levels. But, work is in progress, and now the spacecraft began to function as we wanted it to. Not fast, gradually, day after day. But started!

To say that the enthusiasm for creating your own spacecraft was great is to say nothing. We worked 12-14 hours a day, sometimes seven days a week. There were days when things went wrong, and deadlines are running out. These days, hands fall and faith in one's own strength and success is weakening. But tomorrow, a new day is coming, and you are again systematically approaching your brainchild to the logical ending.

Now, having completed all the stages of the development of the spacecraft, I can say that we have become much more experienced, self-confident and, importantly, much more ambitious professionally.

Now we have the most important thing left, to launch the spacecraft and receive the first signal from it. It would seem that such a trifle in comparison with what we have already done. But this trifle will be so long-awaited and earned labor that for the sake of this it is worth doing this business!

Design began according to the system used in the USA for most spacecraft. The stages of PDR and CDR have passed, the device was copied at first glance. At this stage, an important mistake was made, one of the systems, in particular the AFS, was poorly developed, which negatively affected the subsequent stages of design and production. Then I had to adjust this system to the existing dimensions and limitations, which it was too late to change.

The general view of the spacecraft design was chosen at an early stage of design, so we did not have big throws in this regard. But the production process of this very construction dragged on for months. Indeed, in order to make a small part from aluminum, it had to be drawn in detail in the drawings, restrictions on tolerances and roughnesses were introduced. These are the realities of domestic metalworking companies, few are ready to work on a 3D model, and their quality leaves much to be desired.

But now, the design of the spacecraft was completed, and the first copies of flight and technological models of instruments began to come to the office. The stage of autonomous, and then complex tests of the spacecraft instruments and systems began. With some devices there were less difficulties, with some much more. It turned out that not all devices work as stated in the documentation for it. We had to solve these problems along the way and refine the part that depended on us, be it cables or interface settings.

With flying cables for the spacecraft came a separate story. Everyone, at least once, had worked with them before and this was taken for granted. But now, we ourselves had to develop them. This was a completely new task for us, which no one had ever encountered before. But, we were able to cope with it and develop the required competencies, albeit at the cost of several months. We have fully purchased the necessary components: wires, screens, adhesives, fillings, connectors, covers, etc. And they independently made and tested them.

After going through a difficult stage of testing as part of an integrated test bench, our designers started assembling the spacecraft. Due to the fact that those who designed the spacecraft, the same people and collected it, the process went briskly. There was no need to issue unnecessary documentation between the services, because these services were from the same people.

Having assembled the spacecraft, we proceeded to complex tests of the spacecraft, and then to TVI. And at this stage I clearly realized: to test and debug the spacecraft nodes separately and to do the same thing on the spacecraft assembly, these are completely different things. At first, nothing works, both on software and on hardware levels. But, work is in progress, and now the spacecraft began to function as we wanted it to. Not fast, gradually, day after day. But started!

To say that the enthusiasm for creating your own spacecraft was great is to say nothing. We worked 12-14 hours a day, sometimes seven days a week. There were days when things went wrong, and deadlines are running out. These days, hands fall and faith in one's own strength and success is weakening. But tomorrow, a new day is coming, and you are again systematically approaching your brainchild to the logical ending.

Now, having completed all the stages of the development of the spacecraft, I can say that we have become much more experienced, self-confident and, importantly, much more ambitious professionally.

Now we have the most important thing left, to launch the spacecraft and receive the first signal from it. It would seem that such a trifle in comparison with what we have already done. But this trifle will be so long-awaited and earned labor that for the sake of this it is worth doing this business!

PS I think the text will cause questions for many. I’ll immediately warn you that I won’t be able to answer all the narrowly technical questions. I’ll ask the engineers to help, but now, on the eve of the launch, they have something to do, and no one has canceled the concept of trade secret. Therefore, if whose questions remain unanswered - understand and forgive.