Factory Digitalization: A Look at the Front

How close are Russian and global enterprises to industry standards 4.0? How is the digitalization process going and at what stage are we now? This was told to us by the representative of the company " Digital " Vasily Churanov . Their dispatcher system is already used by 120 Russian plants.

Under the cut - the most interesting and important excerpts from our conversation.

Vasily Churanov will participate in the discussion “Industrial Internet of Things: Industry 4.0” at the conference on September 25 .

What should be a factory in industry 4.0

Ideally, production should work without human intervention. Only then is maximum efficiency achieved: when people are not involved, the equipment operates in three shifts 24 hours a day. There are such plants, and they have workshops that operate in complete darkness. For example, the production of Philips razors in the Netherlands is located in a dark room with 128 robots.

Another important point for industry 4.0 is the construction of mass production for individual orders. Instead of stamping a huge amount of the same product - a large number of products for individual customers. Harley-Davidson has such a plant; they assemble motorcycles. The plant reduced the average production time of custom-made motorcycles from 28 days to 16 hours.

The transition to such technologies took about 10 years. Now, if you build production from scratch, you can do everything quite quickly, in a few years: there is already equipment, there are technologies and an understanding of how to do it.

But neither the United States nor Europe has fully switched to industry principles 4.0. You can’t even talk about a significant transition. In many cases, there is no autonomous production and it cannot be said that it is much more efficient than in Russia. Although yes, there are separate factories and separate sites that are built ultramodern.

MDC system as a first step to the industrial Internet of things

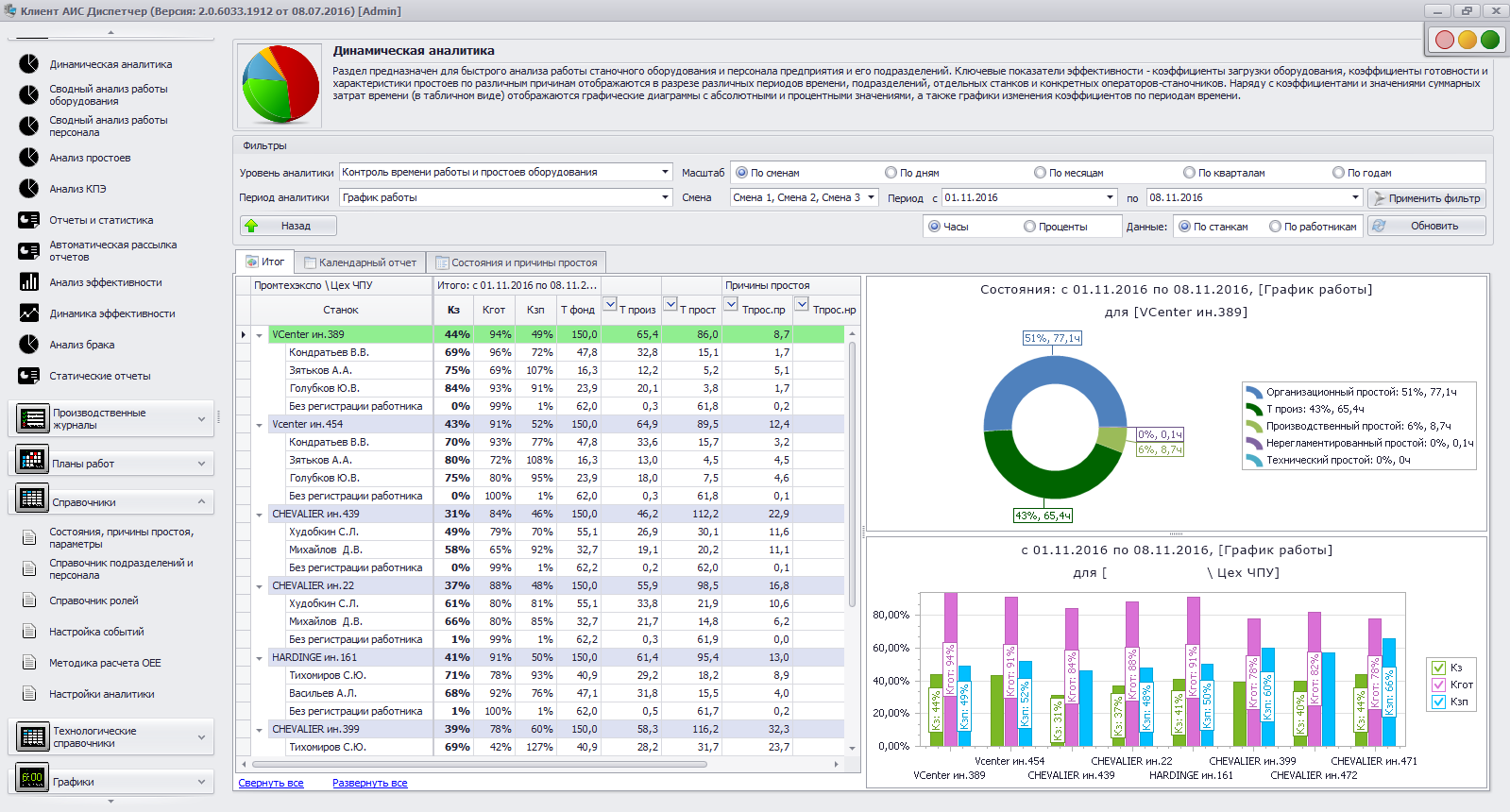

Our system, AIS "Dispatcher", is a system of class MDC (machine data collection). This is the lowest level when information about its operation and condition is collected from the equipment: how many machines worked, how many were idle, reasons for downtime, additional information - current, power, power consumption, vibration. Based on these "big data", production analytics is formed and various management decisions can be made.

Solving the problem of production control, enterprises take the first step into industry 4.0, where the main component is the industrial Internet of things. By introducing a monitoring system, enterprises form an environment where machines begin to understand their surroundings and communicate with each other via the Internet protocol, bypassing operators, independently solving issues of increasing efficiency or preventing emergency situations.

According to our estimates, in Russia about 400 thousand machines, and 6-7% of this equipment use MDC systems. The volume of unconnected equipment is still very large and there is still a lot of work. Clickable

70% of machine tools in factories are old

Each Russian plant has a large fleet of old equipment. Speaking in percentage terms, approximately 70% of the machine tool fleet in Russia is old machines, which are already several decades old. The uniqueness of our system is that we can connect both new CNC equipment and old machines. For this, we produce special terminals that are placed in the electrical cabinet of the machine. We connect the terminal to electric automation and all kinds of sensors, and already we collect the necessary data from them.

Old equipment in factories can be both universal and highly specialized. Presses, furnaces, turning and milling machines - it can be anything. Each plant has its own legacy of the Soviet era, and everyone uses this equipment as he can. If these machines are specialized and rare, they are often the “bottleneck” in production. They need to be controlled in the first place, to see how efficiently they work, how busy they are - because the speed of production is equal to the speed of the "narrowest link" on it.

About the device MDC-system on the example of the "Dispatcher"

The basic component is the monitoring module, MDC module. It allows you to collect information from equipment in production. There is a dispatching unit in the same module; it is responsible for responding to various events within the system.

On top of this there are modules that help organize the production itself more efficiently. The module "Production Control" allows you to write shift tasks, control the technological and organizational parameters of operators. The “Downtime Management” module (in fact, it is the TOIR module, maintenance and repair) allows you to organize repairs according to their condition, operating hours and according to schedule. Another module is program management for CNC machines. The new module is Vibrodiagnostics. Based on the vibration monitoring data of the machines, the system says when and which of the critical components of the machine can fail, provides information on the technical condition of the bearings on the machines.

The customer, depending on his tasks, selects the necessary modules. The system can be integrated with higher-level systems - production systems, ERP (enterprise resource management systems).

120 enterprises are now connected to our system. We received our first order about 6 years ago from the Smolensk Aviation Plant. There are now connected more than 70 pieces of equipment. In general, there are a lot more machine tools, but these numbers are classified information.

A source

Enterprise Implementation

The implementation takes place in several stages. First, a pilot project is done, then a workshop is equipped. When an enterprise understands that it can increase efficiency using this system, it makes a decision on implementation throughout the plant. The next stage is equipment at the holding level, so that management from the management company can see the load across enterprises.

To equip a site of 10 machines, you need 2-3 business days. It takes about a month to equip an enterprise with 100-150 machines.

Modern CNC machines, which can be connected via a local network, are equipped in 10-20 minutes. Complex (old) machines - in a couple of hours.

A source

Workers Resist

Unfortunately, resistance was initially observed in almost all factories. People do not really want to change the usual way. If earlier they just needed to sit to work and submit some reports at the end of the shift, now they are asked to additionally enter information, press buttons on the terminals.

The second reason is that the shop workers begin to understand that everything is under control and every minute of unreasonable downtime falls on their shoulders. Often this causes a boycott on the part of staff and the introduction of incorrect information into the system. But after about a month, everything falls into place, because the “black box” becomes a “transparent aquarium”, and any action by the operator who is trying to unbalance the system is controlled and subsequently disassembled into gliders. These planning meetings are organized regularly during the break-in phase of the system.

After six months or a year, the psychology of workers changes: they begin to understand that everything is controlled, it is more profitable to work honestly, according to the rules, and receive all privileges from managers.

At traditional plants in Russia, the level of machine utilization does not exceed 30-50%

We judge this by the fact that more than 5 thousand machines are already included in the system. Some customers provide us with access to help sort out the situation, and we see great potential for increased efficiency. The optimal load is considered to be 70%.

Some of the enterprises where we operate achieve 60 percent utilization, including through the use of our system. For example, the Russian Helicopters holding has seriously taken on increasing the efficiency of existing resources. And so, we have clients from most large corporations: UAC, Rosatom, KTRV, etc.

Private customers are few

There are few inquiries from private factories, mostly inquiries come from state-owned enterprises. I attribute this to the fact that in large enterprises with a large amount of equipment, the economic effect, even if you increase the efficiency of equipment loading by 5-10%, is very significant. It is much larger than in an enterprise with 10-15 machines. But everything is changing. When people begin to struggle for efficiency improvement not by tens, but by a couple of percent, then small production will come to the point that it is necessary to count every minute of the machine. The program of the event and tickets are on the official website .