DIY mini drill

Hello, Habr!

From time to time it becomes necessary to make a printed circuit board. And it seems like nothing complicated, laser-ironing technology allows you to do everything neatly and aesthetically, however, drilling holes for elements has always been a problem. I used to borrow a drill, but now I have the time and desire to finally get my own. Going over the shops, prices were somewhat upset, from 1000r. and higher. It seems to be not much, but the student period is not particularly spending. Well, it's time to rummage through the bins and see what there is for the implementation of our little drill!

In the picture, a plastic box from under the CD drilled by the drill assembled.

Obviously, for the implementation there you need an electric motor and a drill chuck. The first was found almost immediately, this is an old 9-volt engine from, apparently, a cassette recorder. Cartridge unfortunately was not found, I had to buy. Price 290 p. For this amount we get such a cartridge with seven interchangeable collets.

Case ... An empty bottle (or what to call it?) From a ball deodorant caught my eye. Looking ahead, I will say that its size was ideal, and the engine entered a millimeter into a millimeter, I did not even have to mount it.

Well now there are source materials.

The next step is to make a hole in the cover for the chuck and drill.

And here is the ideal engine entry into the future drill body.

We could stop at this, connect the engine to the power supply unit and plug it into a power outlet, starting the drilling process, but I wanted to make everything more cultured, namely: a socket for connecting power; Of course, the switch is right on the drill; Well, as an additional decoration a small LED.

I used RCA as a power socket . However, I do not advise, the cord turned out to be too quirky, although perhaps I came across this. The first used plug came off during assembly and testing. Therefore, the second immediately strengthened with improvised means.

The switch was found in such a Chinese adapter.

A little carried away by the process, I did not take photos of the process of cutting holes for the switch, LED, and power, but I think savvy habravchane already know how to wield a stationery knife.

Well, here is the final result: The

first hit the pen.

The assembled mini-drill without problems drills plastic, wood, and of course textolite, for which it was actually going to.

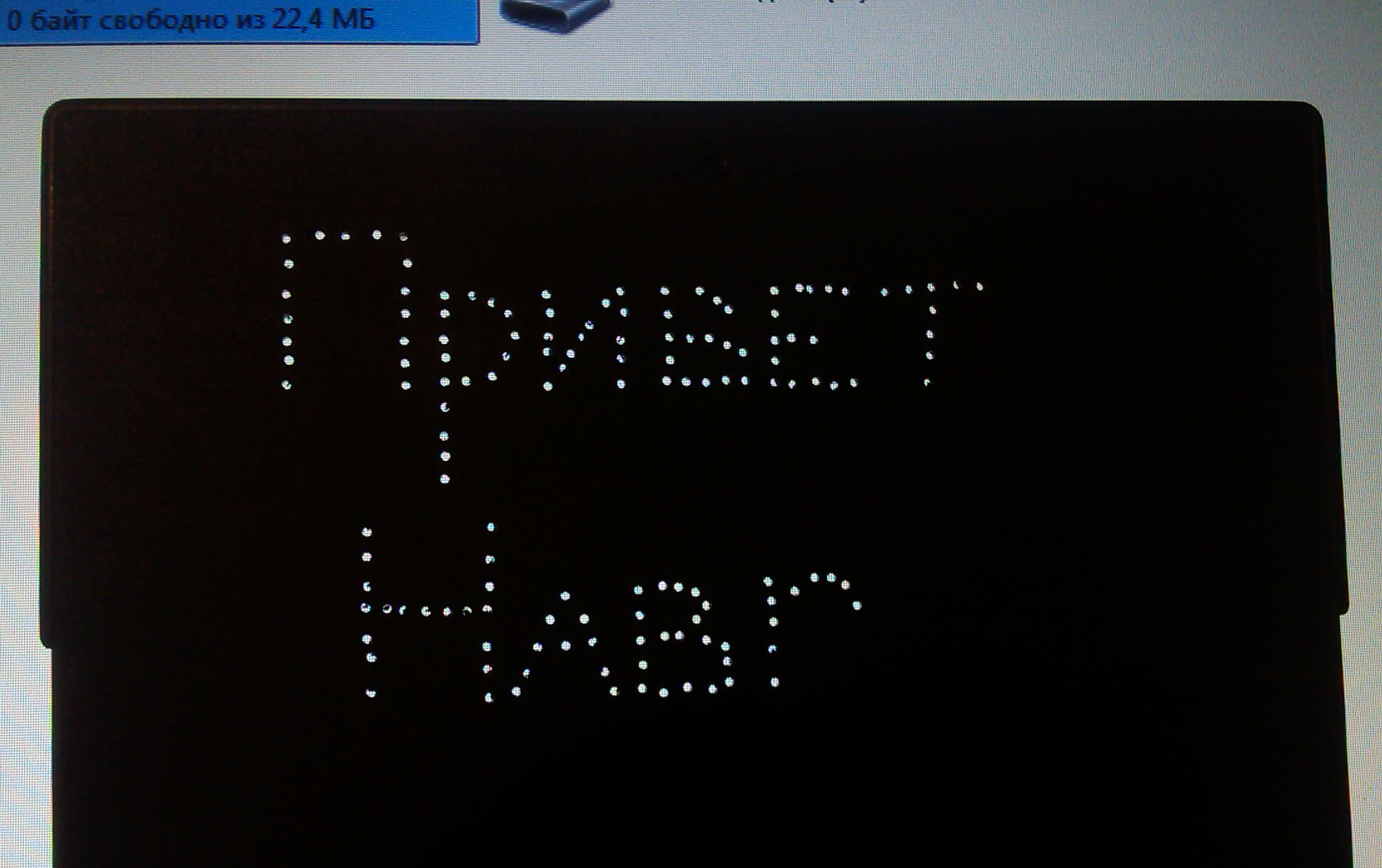

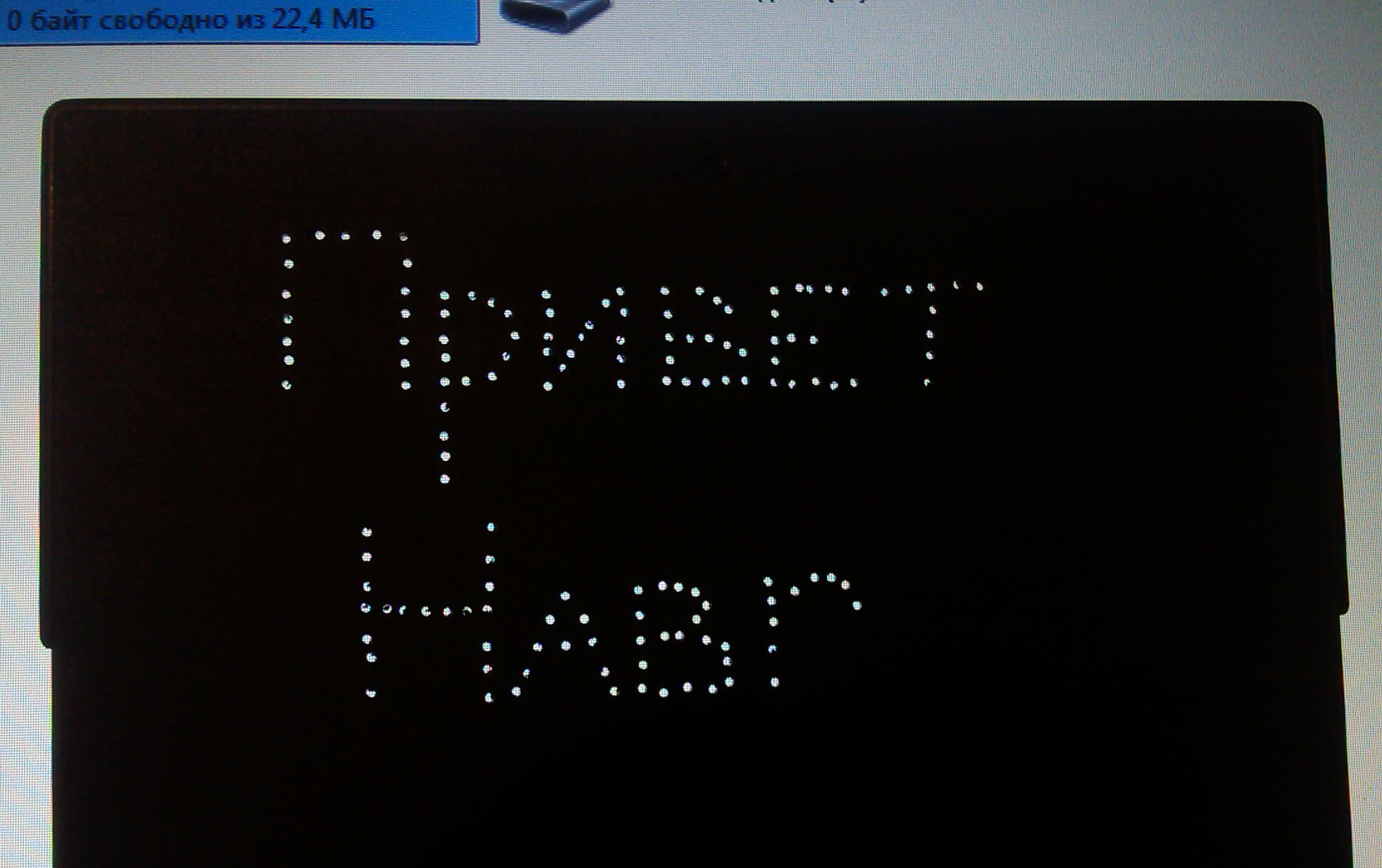

So, after sitting in the evening ~ 700-1000 rubles were saved. Well, the feelings from working with the instrument itself ... mmm! It is impossible to buy! And finally, one more hello for Habr.

From time to time it becomes necessary to make a printed circuit board. And it seems like nothing complicated, laser-ironing technology allows you to do everything neatly and aesthetically, however, drilling holes for elements has always been a problem. I used to borrow a drill, but now I have the time and desire to finally get my own. Going over the shops, prices were somewhat upset, from 1000r. and higher. It seems to be not much, but the student period is not particularly spending. Well, it's time to rummage through the bins and see what there is for the implementation of our little drill!

In the picture, a plastic box from under the CD drilled by the drill assembled.

Obviously, for the implementation there you need an electric motor and a drill chuck. The first was found almost immediately, this is an old 9-volt engine from, apparently, a cassette recorder. Cartridge unfortunately was not found, I had to buy. Price 290 p. For this amount we get such a cartridge with seven interchangeable collets.

Case ... An empty bottle (or what to call it?) From a ball deodorant caught my eye. Looking ahead, I will say that its size was ideal, and the engine entered a millimeter into a millimeter, I did not even have to mount it.

Well now there are source materials.

The next step is to make a hole in the cover for the chuck and drill.

And here is the ideal engine entry into the future drill body.

We could stop at this, connect the engine to the power supply unit and plug it into a power outlet, starting the drilling process, but I wanted to make everything more cultured, namely: a socket for connecting power; Of course, the switch is right on the drill; Well, as an additional decoration a small LED.

I used RCA as a power socket . However, I do not advise, the cord turned out to be too quirky, although perhaps I came across this. The first used plug came off during assembly and testing. Therefore, the second immediately strengthened with improvised means.

The switch was found in such a Chinese adapter.

A little carried away by the process, I did not take photos of the process of cutting holes for the switch, LED, and power, but I think savvy habravchane already know how to wield a stationery knife.

Well, here is the final result: The

first hit the pen.

The assembled mini-drill without problems drills plastic, wood, and of course textolite, for which it was actually going to.

So, after sitting in the evening ~ 700-1000 rubles were saved. Well, the feelings from working with the instrument itself ... mmm! It is impossible to buy! And finally, one more hello for Habr.