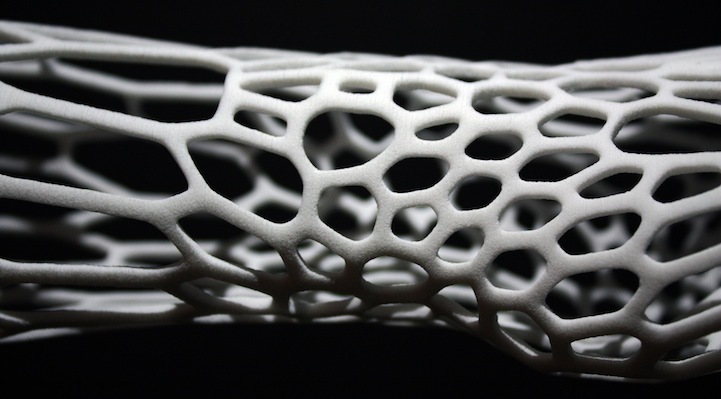

Gypsum on a 3D printer

Thanks to this innovative idea of exoskeleton gypsum, printed by a 3D printer and having an original design, you no longer have to suffer, not knowing how to scratch a hand that itches under gypsum, or balance while standing on one foot in the shower so as not to wet the gypsum other. A graduate of the Department of Architecture and Design, University of Wellington, Victoria Jake Evill developed this unique plaster called Cortex.

According to Evill, exoskeletal gypsum provides complete fixation and protection of broken bones, is well ventilated, easy to process, friendly to water and in addition it is also lightweight. “After many centuries of tires and bulky gypsum, which was the itchy and stinking scourge of millions of children and adults around the world, we finally raised the fracture fixators to the 21st century,” comments Evil to his brainchild.

To create a gypsum, the patient is scanned with an X-ray, a fracture is found, then the fracture zone is 3D-scanned and the data is downloaded to a computer that simulates the gypsum, which, in turn, is then printed by a 3D printer. The final product has one opening side, which is subsequently fixed by strong fasteners.

A source

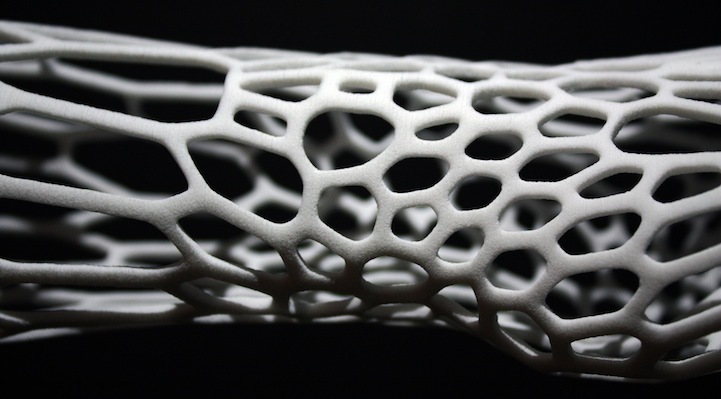

According to Evill, exoskeletal gypsum provides complete fixation and protection of broken bones, is well ventilated, easy to process, friendly to water and in addition it is also lightweight. “After many centuries of tires and bulky gypsum, which was the itchy and stinking scourge of millions of children and adults around the world, we finally raised the fracture fixators to the 21st century,” comments Evil to his brainchild.

To create a gypsum, the patient is scanned with an X-ray, a fracture is found, then the fracture zone is 3D-scanned and the data is downloaded to a computer that simulates the gypsum, which, in turn, is then printed by a 3D printer. The final product has one opening side, which is subsequently fixed by strong fasteners.

A source