A quick look at DesignSpark PCB

Traditionally, in the design of printed circuit boards for electronics of varying degrees of DIY-nosti, most use almost the same set of software: Proteus, EagleCAD, SprintLayout, etc. Until recently, all my needs were met by the Proteus + SprintLayout bundle, however, Proteus was a success, and I didn’t have a good relationship with other CAD programs of electronic orientation (of which I’m “hearing”) and draw diagrams only on paper or on the window did not want to.

Traditionally, in the design of printed circuit boards for electronics of varying degrees of DIY-nosti, most use almost the same set of software: Proteus, EagleCAD, SprintLayout, etc. Until recently, all my needs were met by the Proteus + SprintLayout bundle, however, Proteus was a success, and I didn’t have a good relationship with other CAD programs of electronic orientation (of which I’m “hearing”) and draw diagrams only on paper or on the window did not want to. The search for alternatives led me to the website of the bourgeois program DesignSpark PCB, and further use prompted me to write this short review.

From my purely subjective point of view, the usability of such CAD-programs is 80% of two points:

- The convenience of creating your own electronic components

- Convenience of tracing boards

These two points will be discussed later.

Disclaimer

All drawings described in this article are created exclusively for this article. They do not claim to be optimality, sophistication, compliance with any norms and standards. They were never and will not be created by the author, so even the performance of the boards is not confirmed by anything. Any estimates, comparisons, comparisons and conclusions are 100% subjective.

A few words about the program itself

The first and probably most pleasant impression is the shareware program. And in this case, the concept of conditional gratuity is revealed in a profitable way and is noticeably different from the concept of temporary gratuitousness or free of charge with limited functionality. After installation, an activation code is requested, an activation code is issued on the site after registration - everything is simple. After specifying the profession “engineer” in my profile, I was issued a license for 6 computers. Another useful side of registration is the presence on the site of an open database for downloading electronic components. The base is huge, but filled very fragmented.

Second, the program belongs to the class of “full-cycle programs,” as I call it, i.e. on the basis of the circuit diagram (one or several), a board is created and bred, along with all the checks, and you can immediately muddle the 3D model of the future shawl.

DS1307

The easiest way to describe the process of creating a component for a user library is by the example of some microcircuit, in this case the DS1307 in the DIP-8 package will become a test subject.

The process itself is similar to that in the Eagle CAD environment:

- Draw a sketch

- Draw a body (one or more)

- Blind together the circuitry and the housing by comparing the sketchy conclusions with the real ones.

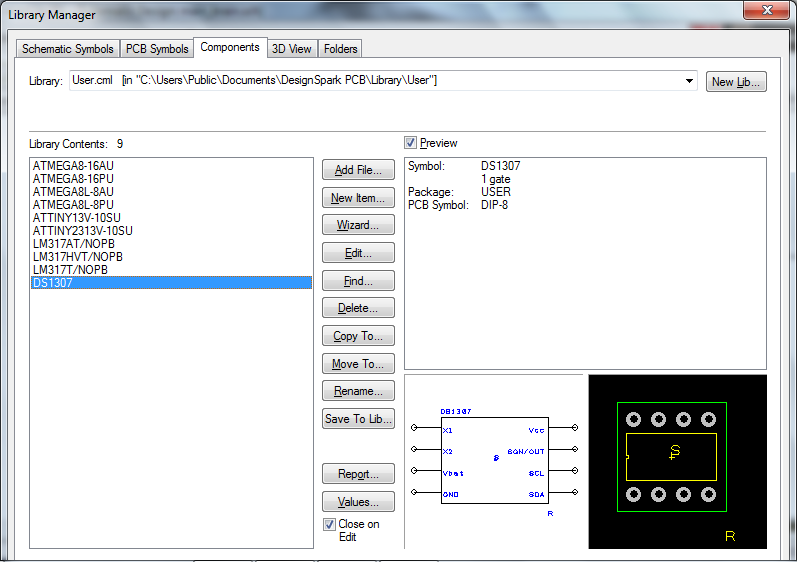

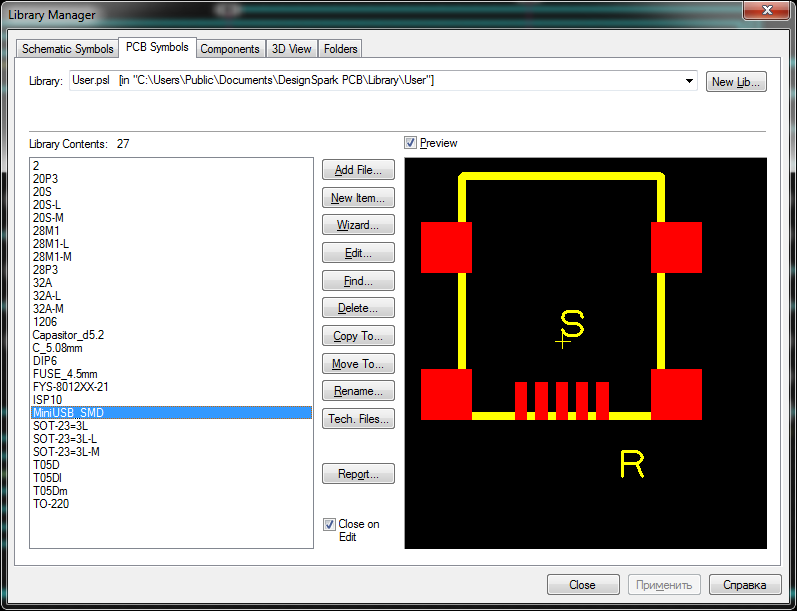

Take a look at the structure of the library catalog:

Library catalog. The schematic is separate, the enclosures are separate, the components created from them are also separate.

In the screenshot above, what I got as a result.

The designer is responsible for the process of rendering electronic components - a separate designer for each stage of the design of our future detail: Symbol Wizard, Footprint Wizard, Component Wizard. Now about each in more detail.

Symbol wizard

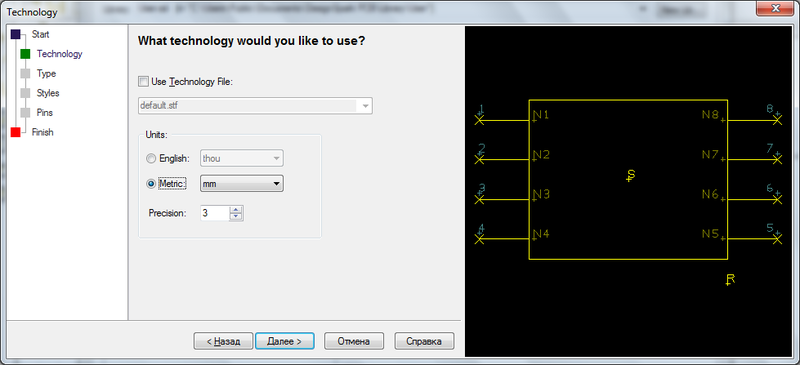

We launch the Symbol Wizard, which offers to draw a schematic.

The left describes the main stages of rendering the component.

Technology can be left "by default." We choose a metric measurement system for the sake of convenience and follow.

We select the type / type of the symbol of the future detail and the positioning of the inscriptions relative to the scheme.

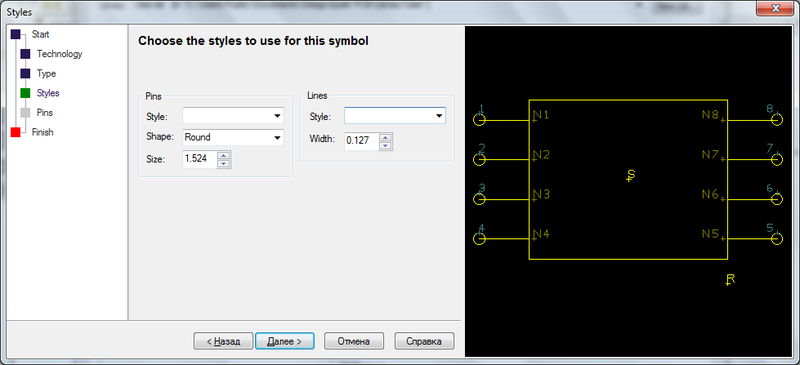

We set the display styles of the pins and their sizes.

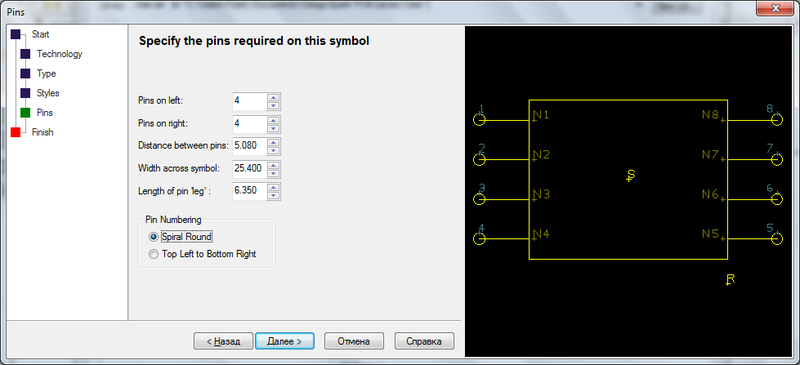

Finally, we specify the number of pins on the left and on the right, the distance between them, their length and numbering order.

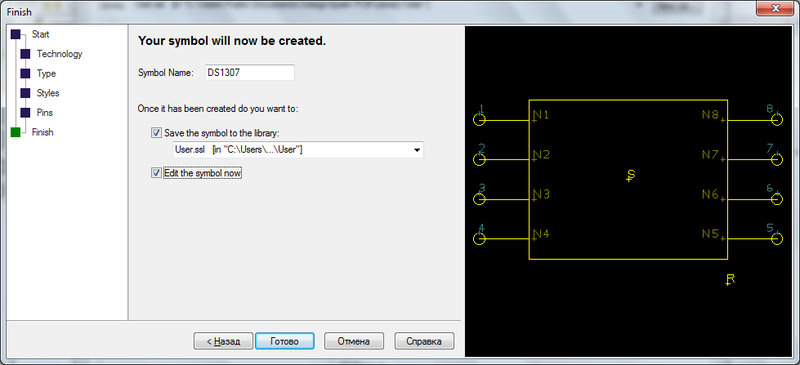

We assign a name to the created symbol and save it to the user symbol library. By the way, in this case I used the name of the created microcircuit, although it would be more reasonable to name the component as “PIN-8”, since once created the circuitry can subsequently be used for any other component with a suitable number of legs.

Here's what happened in the end. The inscriptions N1-N9 at the stage of creating the component based on this schematic will be replaced with their corresponding names. In this screenshot, for clarity, I signed their resulting values.

Footprint wizard

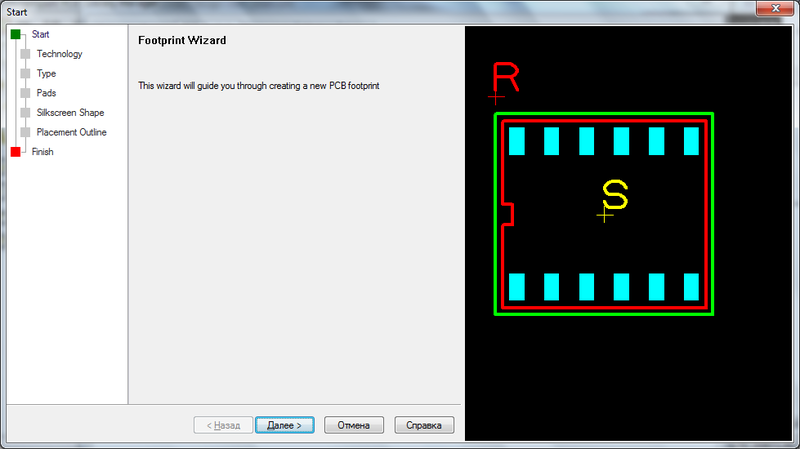

The Footprint Wizard responsible for creating PCB models of electronic components is exactly like the Symbol Wizard. The same constructor, just create the case now.

The process is almost completely identical and kills with its simplicity in comparison with the same Eagle CAD.

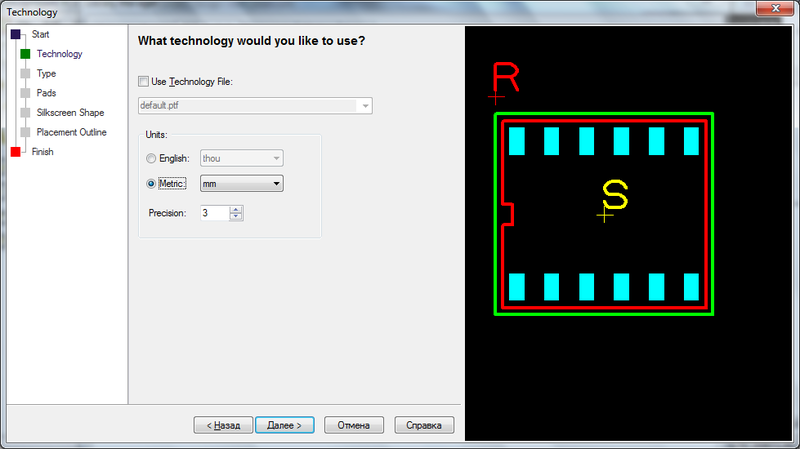

We leave the technology “by default”, expose the metric system.

We choose the type of case and the positioning of the inscriptions (this is already for silk-screen printing).

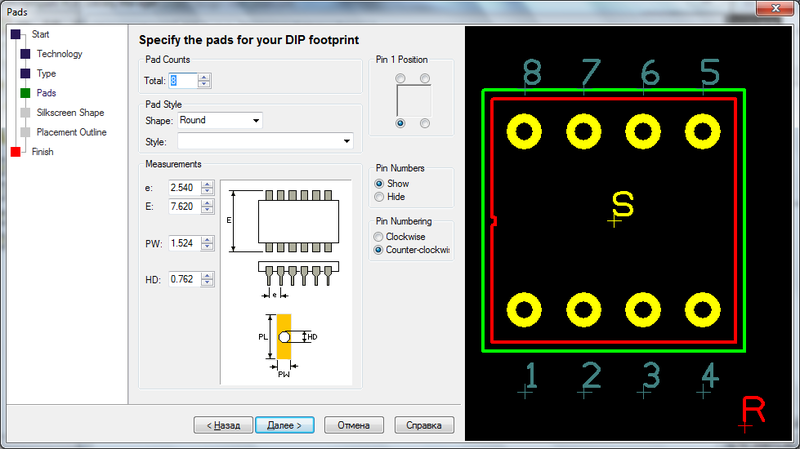

We set the parameters of the pads under the legs: their number, size, style, the distance between the legs and the numbering order.

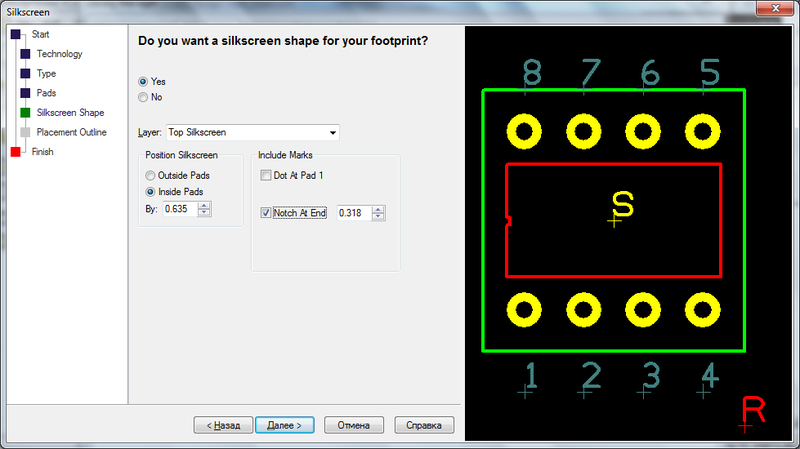

We set a model for silk-screen printing. I have a rectangle set inside the pads, although it is usually found on the contrary - outside, but I like it more.

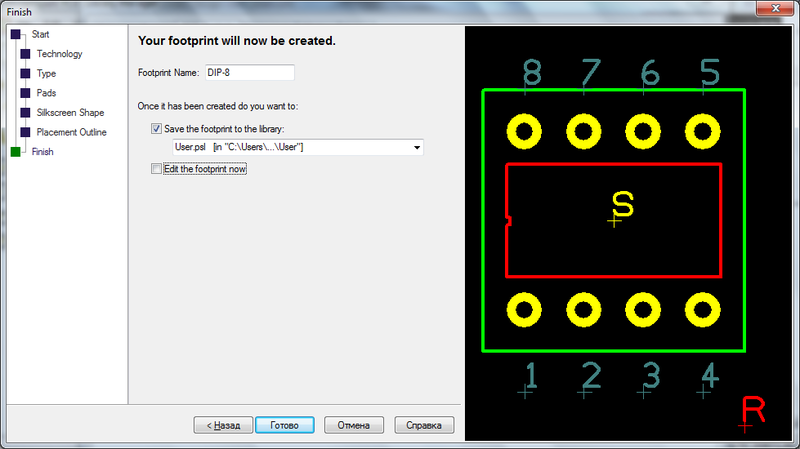

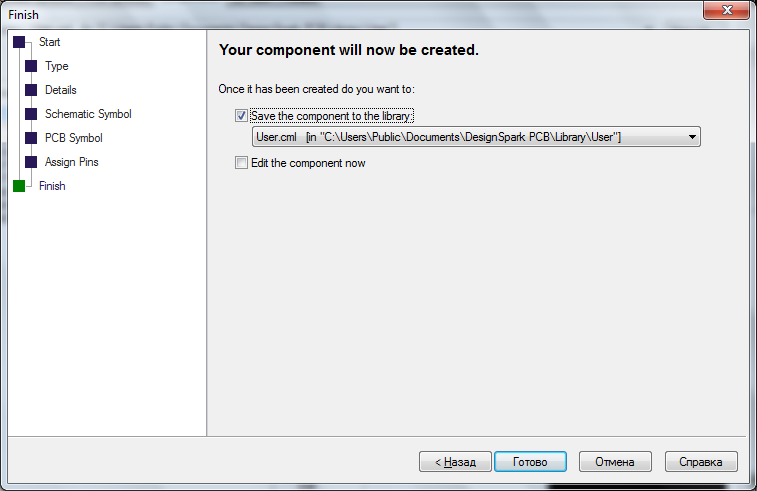

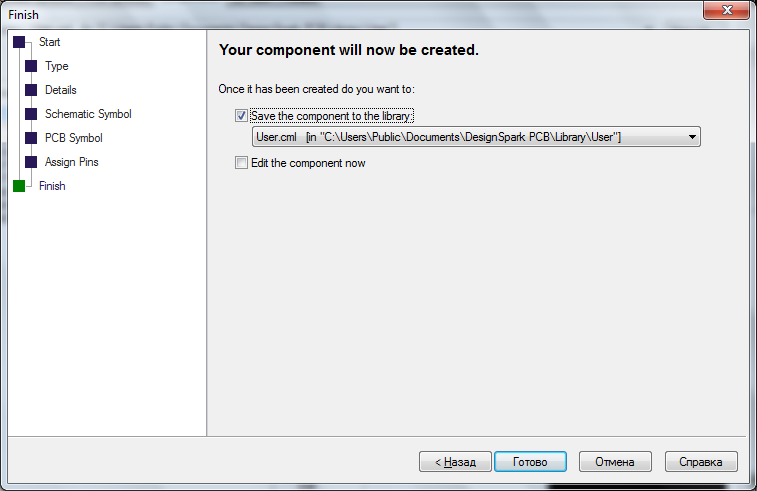

The penultimate step is to choose whether or not the external borders indicated for the component are indicated, after which you can either simply save the resulting PCB model or immediately go to manual editing of the result, which depends on the state of the “Edit the footprint now” checkbox at the time the “Finish” button is clicked.

In the manual editing mode, you can delete anything or add anything to the model created in the constructor. For example, from half of the contacts from the SOIC-10 case and four square pads, a mini-USB model for SMD-mounting is obtained.

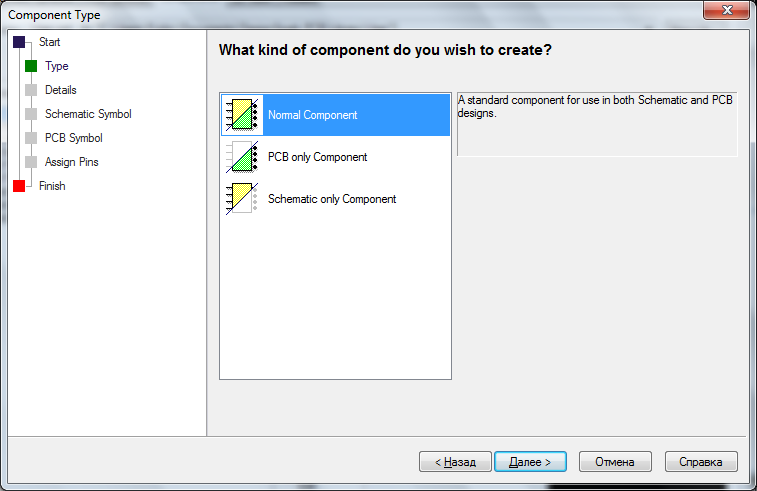

Creating an electronic component from the schematic and PCB models is, in fact, a simple comparison of the schematic pins with the pads of the PCB model. There is also a constructor for this, but since it is identical to the ones presented above, I will hide it.

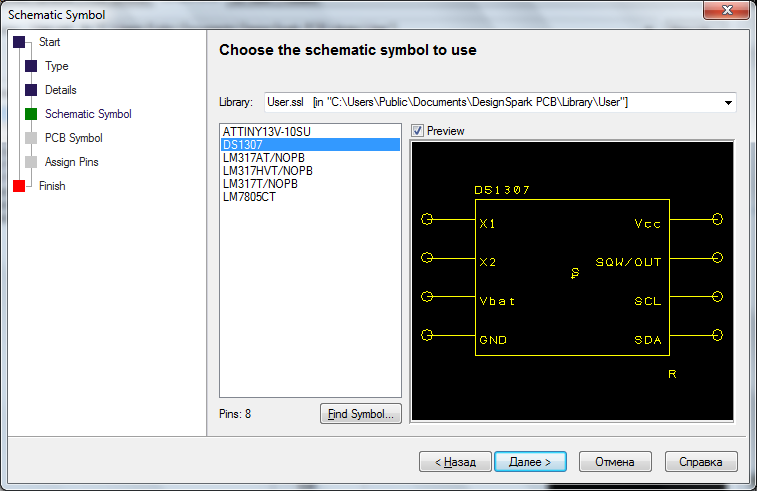

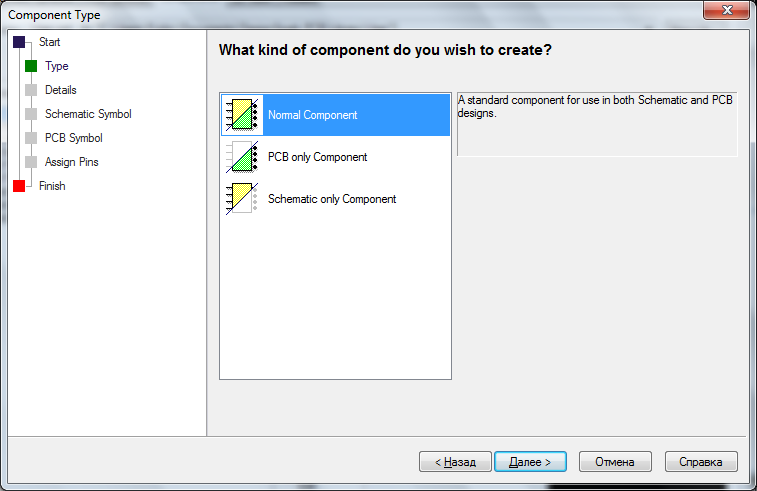

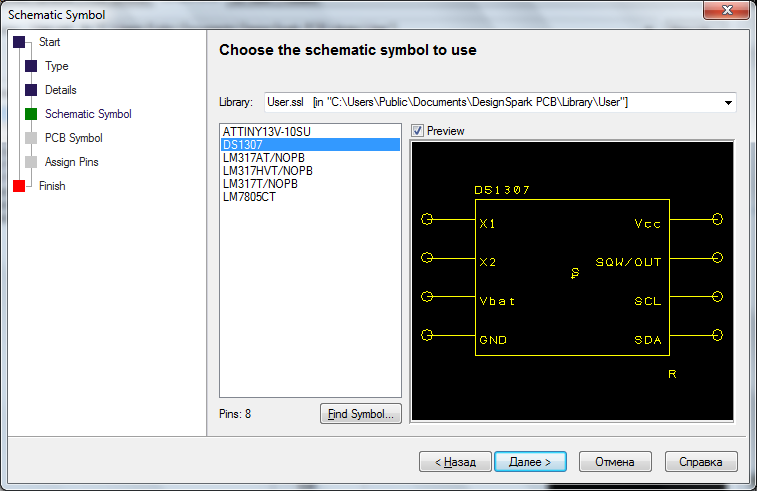

Screenshots Component Wizard

Board trace

... starts in 2 clicks. :)

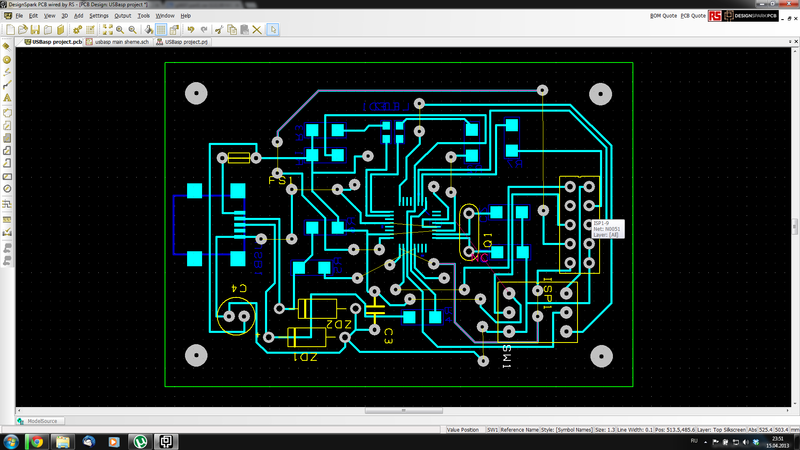

The scheme for tracing looks like this:

Slightly modified USBasp programmer

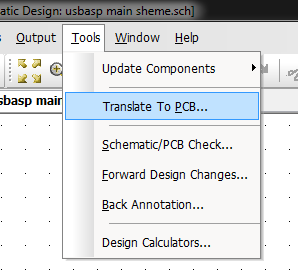

Without departing from the traditions of this program, 2 clicks on Tools - Translate to PCB ... will launch another designer - the designer of the future board.

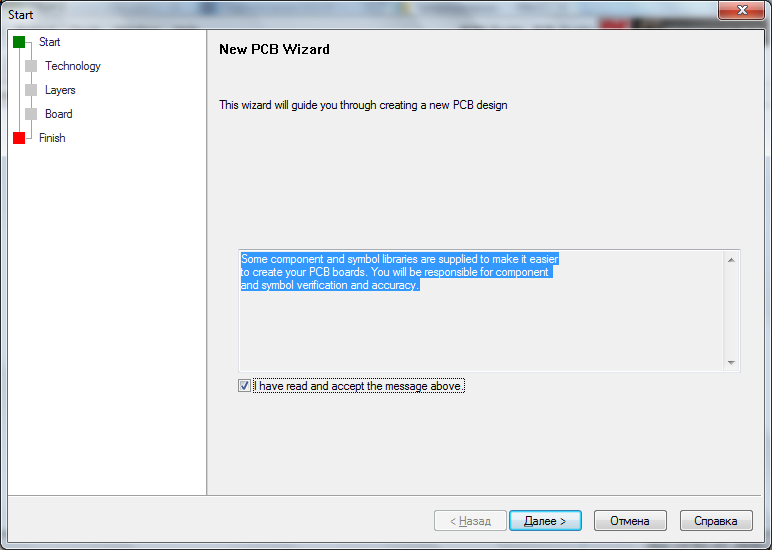

We read (or do not read) the message, agree or refuse to create a board - at your discretion.

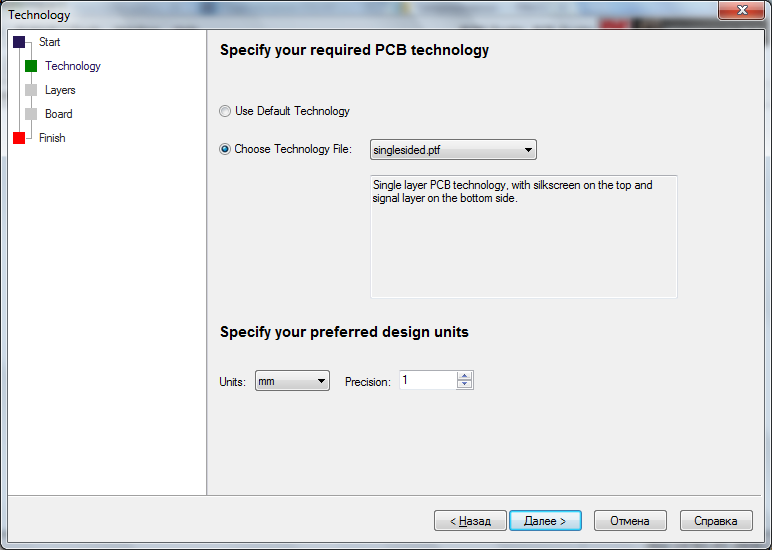

I’ll talk about the notorious technology files later in the text, now you can leave the default technology and mm as units (or thou, if it’s more convenient for someone).

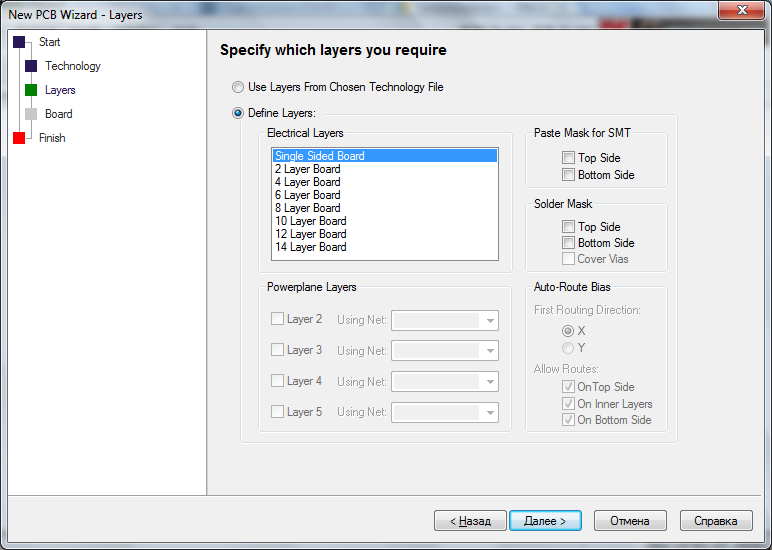

This screenshot clearly shows why the technology in the previous paragraph can be left default. Choose the number of layers (from 1 to 14) and indicate on which layers to place the solder mask.

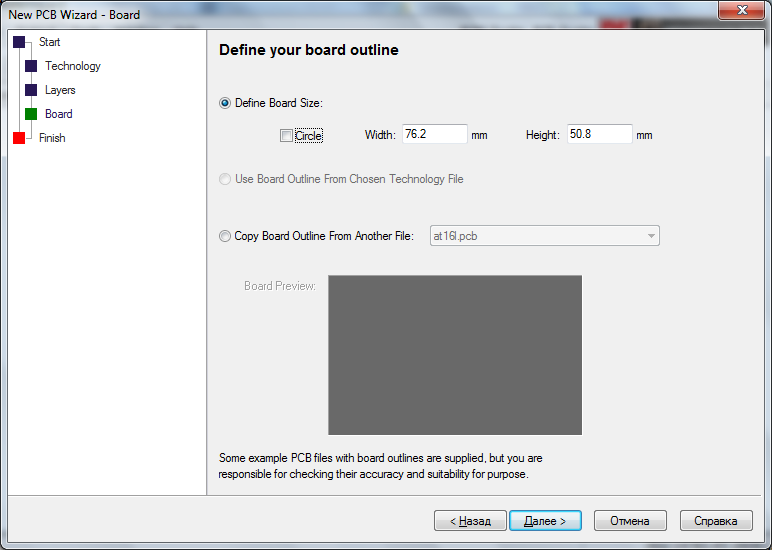

We indicate the starting dimensions of the board or the diameter if the board is round. The "starting" sizes only because then all the same, all these parameters are easily changed.

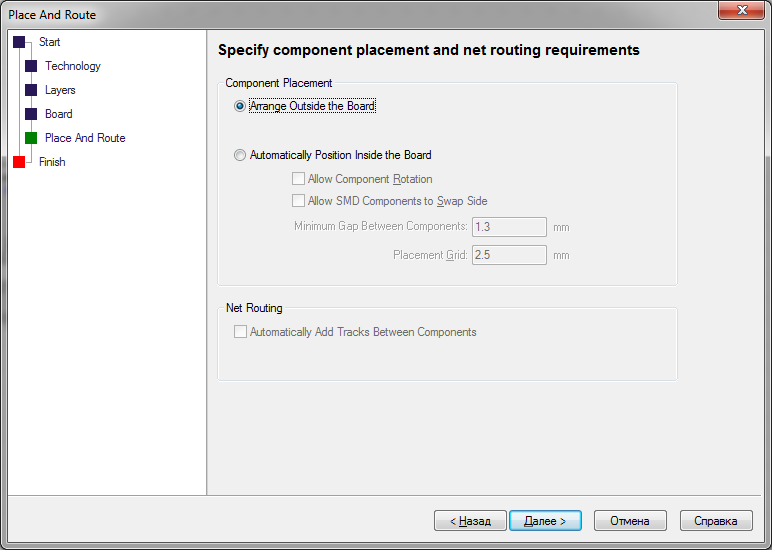

"Placement and tracing." There is no point in automatically placing components on the board and tracing the tracks between them - you get a bunch of small ones with a long list of undiluted tracks. There is an autorouter, but it breeds poorly.

The result of all these actions will be a picture similar to the one below: The

silhouette of the board, components, communications. Just like in the Eagle CAD.

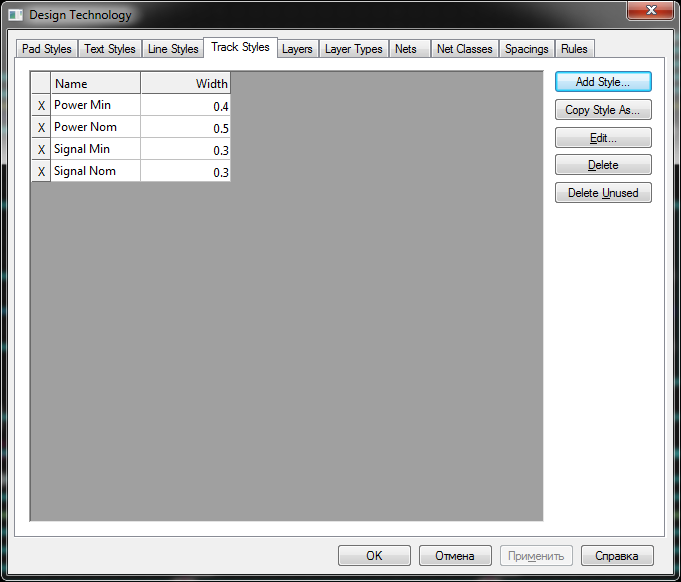

However, before you place the components on the board and breed the tracks, you need to say a few words about the very technological file that was left default in the designer. It is this file that controls the technological norms used in wiring: the width of the power and signal tracks, the distance between them, between tracks and components, etc. And right now, before starting the trace, it is best to take care of it. Its settings are found in Settings - Design Technology, outwardly they look like a table into which the required values are entered.

Further, you can already place the components, and track the tracks, run the tests, correct errors, etc.

There are several checks, I will only mention the main one - Design Rule Check. It verifies compliance with all the rules described in the technology files: distances, connections, gaps, intersections, etc.

The audit report in * .txt format will appear in the project folder.

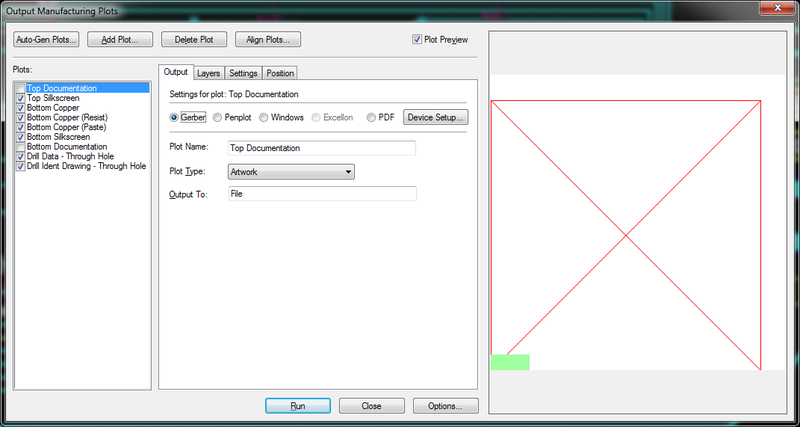

In conclusion, a few words about export opportunities.

In addition to the most popular Gerber format, it is possible to export to DXF, which, in fact, is a universal exchange format for drawings. Hence the corresponding opportunities for subsequent import into AutoCAD or any other program that supports DXF, of which there are quite a lot now.

You can download the program from the official site .