Lead-acid batteries: pulse charge alphabet

The topic of the pulsed charge of lead-acid batteries (SA) and the acid batteries (batteries) consisting of them is gaining relevance in recent years. Innovative chargers are on sale, articles are published, and active research is ongoing in specialized forums with heated debates over hundreds of pages.

What are we arguing about?

The most important battery performance characteristics are capacity, current efficiency, service life, and reliability. New charge methods and devices implementing them are intended to serve the purpose of increasing these characteristics. What is the essence of such methods, and why they are being updated right now, we will consider.

What is the difficulty?

CA is a complex physicochemical system in which at least dozens of well-known processes occur, experiencing the mutual influence and influence of external factors, primarily electrical effects and temperature. Of particular complexity is the fact that kinetics, that is, the dynamics of the rate of development and propagation, is different for the processes.

For decades, researchers have studied these processes and developed ways to interact with them using the equipment at their disposal. Oscillograms, graphs of recorders, tables of measurement results were recorded, experimental setups were developed and tested, and the conclusion was most often the same: SA is a difficult subject to understand and operate, many theoretical and practical questions remain open.

Why didn't you come up with this before?

But technology and technical culture do not stand still. Electronic computers (COMPUTERS) appeared and became available, moreover, in the form of not only personal computers, but also compact, inexpensive, economical microcontrollers (MCs), which are microcomputers with developed peripherals made on a single silicon crystal smaller than a tetrad cell, and with capable of performing millions of operations per second. Analog microelectronics also did not lag behind in development, providing all comers with components with unprecedented characteristics of accuracy, stability, and range of applications.

So, today is the time to return to the good old invention of Gaston Plante, who for many decades has been faithfully serving in many sectors of household and professional life - a lead battery - for the search for more adequate methods of its operation with their implementation on a modern elemental basis.

Theory of Double Sulfation

The battery, it is also a secondary chemical current source (CIT), accumulates electrical energy by reversibly converting the chemical composition of the electrodes (plates), for further useful use. In the simplest rough approximation, called the theory of double sulfation, the processes of charge and discharge of SA can be expressed by the following formula.

PbO 2 + Pb + 2H 2 SO 4 = PbSO 4 + PbSO 4 + H 2 O

The discharge reaction occurs from left to right, charge - from right to left. The active mass (AM) of the charged positive (positive) plate, - PAM, - is formed by lead oxide, minus (negative), - OAM, - spongy lead. As we see, both PAM and OAM during the discharge are converted to lead sulfate, during the formation of which sulfuric acid is consumed and water is formed.

The concentration of sulfuric acid, and, accordingly, the density of the electrolyte, decreases during discharge and increases during charging. This is the alphabet of lead batteries. But later on we will see that alphabet letters alone are not enough, they still need to be connected into words, sentences and a text suitable as a guide to action.

Simplified chemical formulas are statistical in nature and do not take into account the multitude of sequential and parallel transient processes, as well as modifications of the substances involved in them, therefore they should be considered only as input data, and in no case as exhaustive and closing answers to the question.

Structures and Functions

In contrast to the school exam and the competition of scholars, in practice, existing and repetitive methods (functions) and structures (devices) are necessary for their implementation. This means the need to decide (and adjust as the topic develops), with priorities: what, in this application, we take into account first of all, and what, again in this application, can be neglected. Otherwise, you get a presentation or an encyclopedia, but not an applied structure that implements a function. Presentations and encyclopedias are also needed, but these are structures for other functions.

This scary sulfation

From the consideration of the most simplified, elementary formula, we already see that sulfation, and even double it, is by no means a side effect, but the very basis of the SA discharge process, whether it is self-discharge or a useful discharge, for which the battery is built. How sulfation becomes pathological and ruins the battery, and how to avoid it, is our current question.

Polarizing effect and charging current

Lead sulfate is a poorly soluble dielectric. To dissolve it, or rather, convert it into the active mass of the plates, it is necessary to apply a polarizing effect, that is, a potential difference, it is an electric voltage, as well as spend an electric charge for its assimilation in chemical form, i.e. skip charging current for some time. Thus, the electric energy will be stored in chemical form, and the charge of SA will take place.

Simplistically, voltage (volts) times current (amperes) gives power (volt * amperes, watts), current for a time is a charge (pendants or amperes * hours, 3600 pendant each), power for a time or charge for voltage energy (joules or watts * hours, also equal to 3.6 kilojoules, because in an hour 60 minutes for 60 seconds).

What is a charger?

The polarizing effect and the charging current form a charging effect on the battery, the function of which is carried out by a structure called a charging device (charger), or an integrated charge controller, or an operational controller (driver).

It would seem simpler: apply voltage and create current. Any power source can do this. But we work on SA - a complex structure, and to maintain its useful functions, we must interact adequately with feedback. Otherwise, the impact will destroy the structure, and its functions will degrade, and this will not be good.

Conductivity-Structure-Strength

The capacity, current output, service life, reliability with which we started our conversation are functions of the battery. The structure is called upon to perform functions. Current conductivity requires high conductivity of the active mass and current-carrying parts of the structure, and this conductivity must be balanced for an even distribution of currents and powers, as well as the AM contact with the electrolyte, which allows to give maximum useful capacity at a given current. Therefore, the active mass needs a developed surface, achieved by different designs of electrodes. Of course, this developed structure must be mechanically strong and durable during operation, that is, the reception, storage and delivery of energy by the battery.

Molding

Formation is the process and result (state) of preparing the electrodes for receiving the charging and discharge of the discharge current, respectively, with the accumulation and return of useful energy. Since the accumulation and release of energy is associated with the physicochemical transformations of the active mass, the obvious conclusion suggests itself that the molding of the secondary chemical element, unlike the primary, does not occur simultaneously during its production and commissioning, but with each charge.

Lead sulphates

As already simplified, lead sulfate is a dielectric, that is, it has a high resistivity and low electrical conductivity. During self-discharge and useful discharge, it is formed on the surface of the active mass, isolating its sections both electrically and mechanically, preventing the access of electrolyte to it. Thus, it harms the aforementioned criteria of conductivity and structure of SA, reducing both the useful capacity (energy) and the ability to receive and give current (power).

It is possible to find a common language with the sworn friend of the battery, sulfate in two well-known ways. Firstly, it is possible to remove it from the active mass by overvoltage, or even electrical breakdown. The latter are engaged in extreme desulfation enthusiasts, and this topic, as well as dubious, according to many colleagues, methods of gross destruction of the sulfate crust by overcurrents, as well as chemical washing, are beyond the scope of our conversation.

Charging voltage: higher - better?

For now, we simply note that it is very useful to develop increased voltage between the SA plates during charging (servicing) for the destruction of sulfate, and moreover, (if you avoid undesirable side effects, see below), it does not precipitate (sludge), but returns its roughly speaking, the sulfate ion is in the sulfuric acid of the electrolyte, and lead, in the form of a metal or oxide, to the plates, that is, a useful charge is made.

Charging current: more is better ??

Secondly, lead oxides on a positive plate can form when the batteries are charged in various modifications, of which two, called alpha and beta, are known and important to us. Alpha oxide has a lower specific surface area, as well as a crystal lattice isomorphic with sulfate, which, when discharged, leads to the formation of a dense sulfate layer. All of these are disadvantages for structure and conductivity compared to beta oxide. True, the alpha modification is mechanically more robust, but practice shows this is immaterial.

So, it is desirable to charge the SA in such a way as to promote the predominant formation of beta-lead oxide, with a more developed surface and the absence of a tendency to overgrow with a dense layer of sulfate. And contributes to this higher charge current density.

Note: chargers that significantly reduce current at the end of the charge (and most of them), and even more so “chargers” that compensate for self-discharge by low currents, form alpha oxide, reducing the battery’s performance.

Electrolyte and electrolysis

But so far we have begun to deal only with the plates, mentioning the most important component of SA, the electrolyte, only in passing. The lead battery electrolyte is a solution of sulfuric acid in distilled water, both acid and water, as we saw in the double sulfation equation, are consumed and formed upon charge and discharge. Agree, this simple balanced system is admirable. But only while it is balanced.

If the potential difference between the plates reaches the so-called hydrogen overvoltage in the bank, i.e. cell battery, the process of electrolysis of water, its decomposition into oxygen and hydrogen, will begin. This simple and almost environmentally friendly process for CA, to put it mildly, is extremely harmful and multifaceted. Consider why.

Firstly, this is the loss of water, which has to be added to serviced bulk batteries, while to the so-called maintenance free (MF), especially gel (with thickened electrolyte) and AGM (with absorbent fiberglass separators), this is somewhat problematic.

CA developers are making a lot of efforts to recombine oxygen and hydrogen back into water and return it to the electrolyte. This function is assigned to structures in the form of valves in sealed, more precisely, sealed by VRLA valves, thickening of the electrolyte with silica gel in GEL batteries, absorbing AGM glass mat, as well as special recuperation plugs typical for stationary solutions. The ability to return water for all of these solutions, except perhaps cumbersome and expensive special plugs, is very limited, and the excess pressure of the gases, if it is formed, is simply released into the atmosphere.

Secondly, what are these gases? Oxygen, in the presence of sulfuric acid, is corrosive and lead to the release of heat, and not only negative plates, but also supporting and current-carrying structural elements, and hydrogen, which is environmentally friendly but extremely explosive with air oxygen. And with the loss of water, atmospheric oxygen also opens up to the plates.

If gas evolution from the battery is in full swing (“boiling” of the electrolyte), this process can no longer be called environmentally friendly, since drops of sulfuric acid are sprayed and sprayed, not pure, but with dust particles of sludge containing, as you might guess, lead compounds, antimony and other materials used as additives in the production of SA.

How grandfathers boiled batteries

"Boiling" mixes the electrolyte and destroys, in particular, the sulfate layer on the surface of the electrodes. Therefore, in the old wild days, it was the norm of battery operation. The worn-out top layer of the active mass was torn off by gas bubbles and settled in the sludge, for which a place was provided at the bottom of the cans, fresh layers were exposed for work.

At the same time, the criteria of durability, economy and environmental friendliness suffered, but the batteries worked out the characteristics normalized for them at that time, being charged and maintained by simple means. A transformer with diodes, well, if there is an ammeter and a rheostat or a switch of windings, a hydrometer with a pear, a tube-level meter, a funnel and two bottles, with an acid solution and distilled water, that’s all grandfather’s tools. A voltmeter, load plug is already a luxury. And in the battery workshops, the batteries were disassembled, blocks were welded from serviceable plates, and reassembled.

Electrolyte density: the higher the better ???

Since the hydrometer, or densimeter, was mentioned (one or several calibrated floats, the simplest of them is the indicator eye in some batteries), it's time to talk about the density of the electrolyte, which, we do not forget, consists of battery acid and water. Sulfuric acid is heavier than water, because the density of their mixture is higher, the higher its concentration.

According to the simplified Gladstone and Tribe equation, which we already know, in terms of acid concentration, i.e. electrolyte density, you can judge the degree of charge of the battery. But this is not an exhaustive criterion, because losses and additions of water and acid affect density in the same way as charge-discharge processes.

There is a formula that connects open circuit voltage (NRC), it is also electromotive force (EMF) without load, with the ratio of the amount of acid and water in the electrolyte, as well as temperature. This formula is also simplified, since it does not take into account other properties of SA, parts of which we will touch on below. And we will not bring it here, it is in the books, and our conversation will only overload.

The higher the concentration of acid, and therefore EMF, the more useful work each pendant and watt-hour can be produced by the battery, that is, the energy consumption increases. Also, an excess of acid in the electrolyte increases its resistance to freezing, because in cars for the winter it is customary to set increased electrolyte density and charge voltage.

With decreasing temperature, the useful capacity of the battery decreases, with increasing it increases. This is taken into account during winter starts of the engine and seriously limits the operation of vehicles with lead traction batteries in the cold season, because in a car with an internal combustion engine, as soon as it is started, the generator starts to work, compensating for the discharge, and the traction battery will have to give current throughout the journey.

Traction and buffer modes

Kohl spoke, continue. Battery operating modes are divided into traction, or cyclic (cycle use), when a significant part of the capacity is discharged with an average current (relative to the last) in magnitude, followed by a charge, and standby, when discharges are relatively rare, (uninterruptible power backup batteries ), and self-discharge is compensated in one way or another.

The starter mode can also be referred to the buffer mode, when a short-term shallow discharge with a high current is followed by a charge during the entire trip of a car or motorcycle. Close to the starter mode, a 15-minute discharge of backup batteries of compact uninterruptible power supplies, used to safely complete work with saving data, unlike the traction mode of the battery in high-power flashlights and UPSs to maintain automation, communications, medical equipment, etc. for several hours .

A characteristic distinguishing feature of batteries specially designed for a 15-minute discharge is the designation of power in watts given by one can in this mode, markings on the case, and even in the battery article. For example, HR12-34W means that a small “7-ampere” form factor battery is capable of delivering 6 * 34 = 204 watts for a quarter hour! At first glance, this is “only” 4.25 amperes * hours, but those who know the discharge curves of the SA and their nature will appreciate this characteristic thoroughly, and very much.

Energy storage devices in wind, and especially solar energy, work in traction, cyclic mode. When energy arrives, it is necessary to absorb it to the maximum, then to give it away, until the solar panels and wind generators give current. The dimensions and mass of stationary drives, unlike transport ones, are not critical, therefore they try to ensure their maximum capacity and shallow cycles as much as possible. After all, the deeper the discharge, the higher the battery wear.

Damage to overcharging and increased acid concentration

If at elevated temperatures, EMFs and acid concentrations, the battery produces more energy and power, why should it be protected (at least) from overheating, and when the heat comes on, the generator voltage and electrolyte density are manually or automatically corrected downward?

The fact is that the increased chemical activity of the acid in excessive concentration acts on the active mass, the bearing and current-carrying parts of SA are destructive. Contributes to this and high temperature. Self-discharge, sulfation, and corrosion, which can occur with the release of heat and gases, increase.

The same effect occurs with excess voltage, current, power, energy, charging effect. All those extra pendants, kilowatt hours and rubles to pay for the latter, which are not absorbed by the active mass, go to the electrolysis of water, heating and destruction of the battery, and in any case, albeit at a different speed.

A small “recharger” current will undermine your battery stealthily, you will not even notice heating and gas evolution, so weak that regular recombination will probably cope with it. But the molding of the active mass from lead current leads and supporting structures will occur. And as a result, no, the useful capacity will not increase, but the internal structure will crumble.

Have you ever removed covers and valve caps from a failed computer UPS battery? Did you see what the current-carrying tires turned into? This is it.

A bit of safety

Sulfuric acid is corrosive, hydrogen is explosive. This must be borne in mind when operating the SA. But the greatest danger is the active mass, both “real” and “parasitic”, accumulated by corrosion of holders and current leads. AM has a developed surface and is rightly called active. Even a small particle of it is a systemic poison and neurotoxin that can cause injury (lead paralysis), therefore it is strictly forbidden to touch the inside of the battery with bare hands, to avoid contact with the skin, mucous membranes, and inside. In case of contact, rinse immediately with plenty of water.

Now we know everything about batteries?

So, too low and too high voltages, currents, electrolyte concentrations, temperatures for the battery are harmful. This means that for cyclic, buffer, starter, etc. modes of operation, you can determine the optimal voltage, currents, formalized laws of thermal compensation, implement them in the charger, relay controller, charge controller, and we thereby increase the capacity, current transfer, service life?

Yes, it does. But again simplified. Manufacturers place data on thermally compensated charge parameters in the data sheets and on the battery cases. Their observance in operational controllers significantly improves the practice of CA application, but is not ideal. It is possible and necessary to improve further.

Take a look at the whole picture

To summarize what has been studied. CA is two blocks of plates with an active mass having a developed surface. The plates are surrounded by an electrolyte, an aqueous solution of sulfuric acid, by immersion in a liquid solution, separating the glass fiber impregnated with the last separators, or by placing it in a gel-like electrolyte thickened with silica gel.

Charged PAM is formed by lead oxide, OAM - by lead. When discharged, they both turn into dielectric and sparingly soluble lead sulfate with the consumption of sulfuric acid and the formation of water, when charged, on the contrary, with the consumption of water and the formation of acid. The lead of the electrodes, its oxide and sulfate do not pass into the solution (according to the simplified theory; in fact, they form ions that should immediately be deposited in AM), but they are taken from the solution and the ions are returned to it, namely the hydrosulfate ion and proton ( nucleus of a hydrogen atom).

And here the fun begins. Ions for current-forming reactions must come from the electrolyte into the active mass, the activity of which, as we recall, is provided by a structure with a developed surface, i.e. sponge. The AGM separator is another absorbent sponge that serves many purposes, in particular, increasing the recombination of water, and the gel is a viscous substance in which the movement of the substance is difficult.

So, we have wetting and capillary effect in at least two AM sponges, to which the effect of a separator and gel can be added. As a result, the movements of the substance in the battery bank are slowed down, and it takes time, moreover, to take charge and discharge, especially in the deep layers of the AM, depending on the current state of the active mass and electrolyte.

And this state is by no means exhausted by the NRC, density and temperature! During SA operation, the electrolyte is stratified, various ions move in an electric field at different speeds (electroosmosis), encounter structural obstacles, and sulfuric acid is also heavier than water, due to which it tends to fall down under the action of gravity, displacing water up !!! In the case of gel and AGM, this is hindered by the structure, but bulk batteries suffer from the gravitational gradient of electrolyte density in full.

Where are the plus and minus in the outlet?

So, is there a current or voltage value that, calculated on the basis of the NRC, the electrolyte density (density where ?! is it uneven!), The temperature, and applied to the CA terminals, will provide a full charge, self-discharge compensation and desulfation, while avoiding the slowly murderous sulfating undercharging, and electrolysis of water, and corrosion of the structure ?!

No, NRC, (even with a table of measurements of EMF under different loads), temperature, (which can also be very uneven in a massive inhomogeneous battery), and the density of the electrolyte, at least “average in the hospital”, even measured at the top of the can or at the bottom, or both at once, in a static aggregate, they do not provide comprehensive data on the kinetics, dynamics of chemical reactions in the SA bank and the entire battery.

They will be useful for assessing the state of the battery and making a decision on its future maintenance, but they will not give the optimal values of current and voltage to set on the regulators of the charger. Because these values change in the course of interacting processes occurring at different speeds!

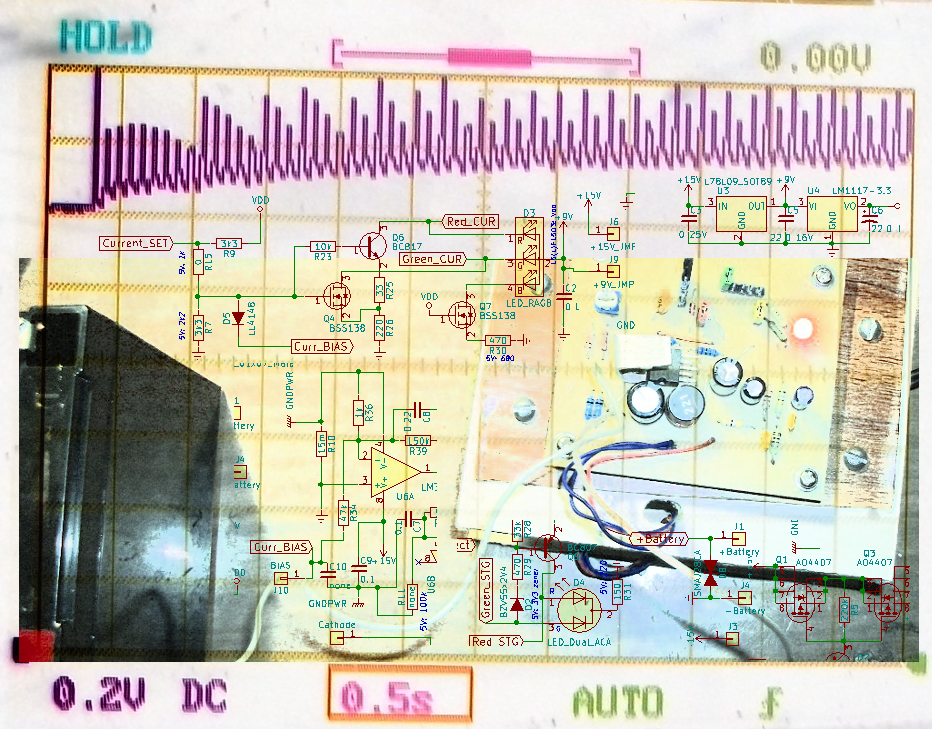

But the dynamics of changes in current and voltage can tell everything about the course of current-forming reactions. More precisely, everything needed to control the charging current and polarizing effect. Unless, of course, be able to process this data in real time (that is, with normalized delays). For this, microelectronics will be needed, and most likely, even a computer. Fortunately, it happens, as we recall, the size of a notebook cell.

The question of exactly what electrical effect is the battery need at the moment is akin to the question of where the plus and minus are in the outlet. A person cannot answer him: while he speaks, plus and minus will replace each other 50 times per second. But for an electronic device, such a performance is a couple of trifles. And we can accurately determine the phases of voltage and current, with the necessary reference to time. Of course, in SA we will see something more complicated than sinusoids shifted relative to each other. And see soon.

Repetition is the mother of learning. This is a simplified formulation of the third law of dialectics, a partial return to the old at a new level, and we will use it again.

We have two sponges of active masses, between which there is a liquid, gel or another sponge. We need the necessary ions for the current-forming reactions to reach each layer of the sponges, and these layers are partially clogged with sulfates, which require overvoltage for dissociation, and without this overvoltage we will lose both capacity and current efficiency and durability due to chronic undercharging leading to progressive sulfation.

However, overvoltage is fraught with overcharging with electrolysis and corrosion. As a charge commonly used in gray antiquity by “boiling” with thermal dispersal and useful, but too expensive, mixing of the electrolyte, as well as by changing its current decrease at the end of the charge, mitigating but not excluding harmful side effects, and in addition leading to the PAM coating with orthorhombic lead oxide , cannot be considered fully adequate solutions.

How does the battery charge?

And finally, after the first acquaintance with the chemistry and physics of SA, it is time to look at its electrical characteristics, namely, the response of the HIT to the charging effect. Only at first we will repeat the characteristics of this effect itself: voltage, current, time, charge, power, energy.

Since HIT has an electromotive force, that is, it creates (sets itself) a potential difference, it is natural to assume that the charging effect is carried out by a current. Indeed, when the current is applied from the charging source to the CA terminals, the voltage on the latter begins to increase (we assume that the source is able to develop the desired EMF, and then it is charging), which is the criterion for evaluating the charge course.

At the beginning of the passage of current, the potential difference of the terminals jumps sharply by the magnitude of the drop of this current on the internal resistance of the CA or battery. By the height of the resulting step, knowing the strength of the current, you can calculate the internal resistance, which is obviously used in rapid tests. On this “just a current-voltage characteristic” ends, and the complex process of voltage change in time begins. The current strength will be considered constant, stabilized by the means of the source.

Further on the tape of the recorder, the screen of the oscilloscope with a slow sweep or a diagram from the logger we will see a superposition (superposition) of several responses to the charging effect, the main of which are two. A very slow exponent of the actual useful AM charge, consisting of a superposition of different layers, and another exponent, much faster, resembling a capacitor charge.

Two approaches to the double layer

This is a capacitor, more precisely, an ionistor, sometimes called a parasitic, and often the capacity of a double electric layer. This capacity is complex, since electrolyte separation, as already mentioned, is involved in its formation. But for the first approximation of understanding the promising ways to optimize operational interaction with the CA, it is enough to understand the fact of its existence.

The charging effect causes polarization of the double layer, and different theorists and practitioners have different attitudes to this. Some consider the parasitic ionistor to be a harmful phenomenon that impedes the battery charge as efficient as possible from the point of view of speed, and they suggest that in the intervals between charge pulses a depolarizing effect be performed in the form of a discharge pulse.

Exposure to asymmetric (alternating with a constant component) current, or with the use of a discharge load that is switched on only in pauses or is connected constantly, has been used to charge and restore lead-acid batteries for a long time.

When charging nickel batteries, an asymmetric effect is strongly recommended, and for the experimental restoration of manganese-zinc elements it is necessary, since it prevents the growth of dendrites characteristic of these CITs and causing their emergency failures due to a short circuit.

For SA, active depolarization can make sense in the light of the actualization of the study of the semiconductor properties of sulfated wafers in search of new methods of desulfation and bringing the theoretical base to those already known for many years. On the other hand, the discharge action reduces the efficiency of the charge, and accelerating the latter in this way can reduce the battery life, because the applicability of such methods should be recognized as limited.

For restorative maintenance and express charge with normalized wear, the use of forced depolarization of the double layer can be approved, but not for prevention and everyday charge with priorities for energy efficiency and prolonging battery life.

Magic ionistor

What will happen to a double-layer ionistor if you simply remove the external charge-polarizing effect from the battery by breaking the circuit, for example, with a transistor switch? - It depolarizes (relaxes), discharging and giving up the accumulated charge and energy to the active mass, that is, making a useful SA charge!

Moreover, polarization of the double layer by charge pulses followed by a relaxation pause makes it possible to create a desulfating overvoltage, and if the pulses are short enough, gas generation will not have time to begin! Those oxygen and hydrogen that were released during the overvoltage period will have time to recombine and return to the electrolyte, instead of participating in harmful and dangerous phenomena.

This is the principle of relaxation, impulse or intermittent charge, which allows a whole bunch of dialectic contradictions, for example, the necessity and inadmissibility of overvoltage. The same with the current density: the amplitude of the charging pulse can (and should) be set equal to the double current of the 20-hour discharge, or even higher if there is confidence in the controller algorithm.

Law of energy conservation?

Here the thoughtful reader will be overcome by doubts. The double current of a 20-hour discharge is 0.1C 20 , the same current that is recommended for charging the SA in continuous mode, and charges a fully discharged battery in 10-12 hours.

An intermittent charge implies between pauses of the pause current for assimilation of the charge by the active mass, the influx of ions into its depth, and equalization of the electrolyte density in it. How much then to wait for the completion of the charge? Indeed, the average current, the total charge and energy reported to the battery by the charger, for example, in an hour, when interrupted by pauses, will be lower than in the case of a "normal" continuous supply of current of the same force!

An advanced relaxation memory will charge a fully discharged serviceable battery with a current of 0.1C 20in 8-12 hours, depending on its condition. That is, even faster than if the current was not interrupted. How is this possible, and can this be believed?

The thing is that with classical CC (constant current) charging, the "excess" energy that the active mass does not have time to absorb goes into heating the battery, electrolysis of water, and corrosion of the structure. And the smart memory simply does not serve these extra pendants and joules, waiting for the readiness of the HIT to accept a new portion of the charge, or reducing the parameters of the modulated effect.

This does not mean the efficiency of 100 "or more" percent, the absolute suppression of gas formation and heating, the guarantee of fast charge in any condition of the battery. Worn, sulphated, pre-emergency and emergency batteries can become slightly warm and rustle with bubbles during recovery, which can last a long or very long time, if everything is really bad with one or several banks. Which does not mean at all the extra time and money: the charger is automatic, and it manages electricity in good faith, economically.

But the orders of magnitude increase the likelihood of a successful recovery of the battery, which otherwise would definitely go into junk, creating a burden on the environment and the economy, i.e. your health and wallet, (and more precisely, the resources of freedom of a fruitful happy life). And if we take care of the battery from a young age, we get an increase, in comparison with the traditional practice of charge, its operational characteristics (also being the mentioned resources).

So how to realize this impulse charge?

Today, there are many ways to implement a pulsed or modulated charging action, control it using various feedbacks, devices for their implementation. The relevance is high and growing, there is a continuous improvement, the current and excellent results of which can be used now.

Above, we mentioned the superposition of several (simplified again, the number is actually not integer) electrical signatures in the voltage signal from the battery terminals when a charging pulse is applied. The pause signal is also formed by superimposing signatures of current-forming reactions and side effects in the CA bank. And there are 6 such cans in the most common 12-volt battery, connected in series, and it is most often impossible or inconvenient to connect to the jumpers between them.

Add to this interference pickups, first of all, from the mains and the charger power source itself, and we will understand that the task of analog and digital processing of the electrical signal from the battery terminals to determine the amplitude and time parameters of the optimal charging effect is not trivial. You need to know what to look for, and be able to teach this machine.

You can simply purchase a modern charging and recovery device, but even in this case it is desirable to have an idea of the essence of its work, without which it is difficult to choose the most suitable tool for yourself and use it to the maximum. And you can put your own experiments to the joy and benefit of yourself and the world around you. In any case, it does not hurt to make a brief classification of charging methods and devices.

CC / CV

Constant current, constant voltage — стабилизация или ограничение тока и/или напряжения на заданных уровнях. Может дополняться термокомпенсацией, а также реализацией многоступенчатого заряда, с переключением критериев стабилизации по достижении некоторых условий, таких как: напряжение или ток на клеммах, время с начала заряда, сообщённые АКБ количество электричества или энергия, а в эксплуатационных контроллерах учитывать и предшествовавший разряд АКБ.

Complicating the logic of the operation of such devices can (should) give better compared to simple charging from a stabilized or unstabilized power supply, however, it does not fully resolve the dialectic contradictions mentioned above, does not take into account the intricacies of kinetics, and does not guarantee the adequacy of the charging effect to the current needs of the battery, that is, the ability to take a useful charge, not to mention desulfation.

Swing

If we add to the CC / CV memory the criteria for the termination and renewal of the charge, for example, by the voltage at the terminals, we get one of the simplest methods and devices of intermittent charge, called a “swing”, “two-threshold comparator” or “comparator with hysteresis”, in honor of the main elements. Upon reaching, for example, 14.22 volts, the charger disables the charge, and when the NRC drops to, for example, 13.1V, it resumes. It turns out a relaxation generator.

Thus, a reduction in the charging current at the end, compensation of self-discharge during storage, and an optimizing charge of the deep layers of the AM (“capacity completion”), and desulfating overvoltage, with a significant reduction (prevention) of heating, gas evolution, and corrosion, should be achieved.

The frequency of the swing can be from seconds to hours or more, and they need manual or automated, for example, storing the levels reached by the given battery, tuning, and also thermal compensation. Without careful monitoring by a competent person (who is forced to follow the process) or digitally processing the electrical signatures of the processes occurring in the SA, relying on voltage or current alone, simple swings often do not give the effect that could have been achieved with better control.

The settings of an intermittent and / or modulated (see below) charge that are not suitable for this particular battery may not slow down or reverse, but rather accelerate, aggravate its degradation, for example, short circuit (CI) of individual cans.

Blinker

One of the problems of the swing is the too fast achievement or too long (up to infinity), the expectation of a threshold that is incorrectly set, or ceases to be true during the processes, which can lead to a delay in service and undercharging, and overcharging, with all the consequences. An option to solve this problem is the allocation of a certain time to an impulse and pause.

The simplest intermittent charge devices generally only have a timer (multivibrator, interrupter) for turning the charging current on and off, and they are called flashing lights or blinkers, although blinkers are sometimes called any flash memory, including those that implement a complex algorithm using a microcontroller.

The use of a car corner relay for supplying a charging effect by pulses has been known for a long time, and many have helped to carry out a recharge of accidentally discharged and highly sulfated batteries. These were the first blinkers.

Modulation

But modular charge devices, oddly enough, are both the grandfather rectifier and the automobile or motorcycle generator, again with a rectifier that gives an unbalanced ripple current. How is intermittent charge different from modulated? - The terminological criterion. Where frequencies are below a few hertz, talk about intermittent charge, above - modulated. Both are classified as pulsed, pulsating.

One does not exclude the other, and in cycles with a period of one to hundreds of seconds, the impulse of the charging effect can be a pack of pulses of a higher frequency. This can create both additional opportunities for recharging deep layers, leveling the concentration of reagents and desulfation, as well as difficulties associated, for example, with electromagnetic interference, the influence of wires and connectors, side effects that have yet to be investigated and learned to apply or prevent. Different authors write about different frequencies, taking into account the kinetics of different processes that make up the AM charge or the effect on it.

Already the grandfather rectifier and the auto generator create opportunities for relaxation phenomena in the SA, improving its characteristics in comparison with the forced supply of a stabilized smoothed current or, even worse, withholding the smoothed voltage, (the reason why in the recent past some came to the conclusion that pulse sources are unsuitable power supply, not to be confused with pulse chargers, for battery charge).

Conclusions and Prospects

The study of the reactive characteristics of SAs and their responses to all improving methods of exposure continues to open before us an ever-expanding and deepening spectrum of relaxation, quasi-resonant, resonant and wave phenomena. All this is just excitingly interesting and brings useful benefits.

Today, for example, it is relevant to study the phenomenon of the delay in the propagation of electricity in a lead battery, which leads to the often observed increased wear of extreme (electrically) cans and batteries, and this cannot be attributed to temperature unevenness alone. It is time to develop methods and devices for servicing SA with AM doped with carbon nanotubes, as well as explore the possibilities of creating compact “dry” batteries for lightweight mobile applications on its basis.

In a brief conversation, we did not touch on the discharge characteristics, but the discharge mode can also be controlled. It will soon be necessary to test the possibilities of regenerative braking with the return of energy to the lead traction battery, to study how much power it can receive with advanced process control without harming itself, and also to test the hypothesis that charging impulses can allow the use of more useful capacity By compensating for the known effect of reducing the latter with increasing discharge current.

Lead and sulfuric acid are our good friends, if you treat them sensitively and conscientiously. The magical world of lead-acid batteries is waiting for its researchers, inventors and just all those who benefit from modest massive boxes, freedom and joy!