Popularly about the genealogy of 3D printers. Who is who?

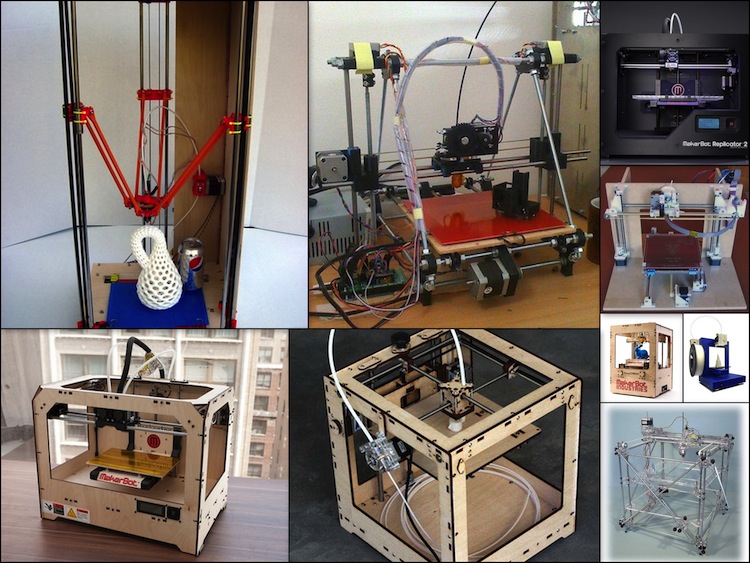

The situation with 3D printers is reminiscent of the situation with Linux distributions, especially for a beginner. A huge pile of designs under code names, half of which are supplied assembled, half must be assembled as a designer from parts, and for another half all the details must be found by yourself, and even work with a file. By the way, where the third half came from is also unclear. Let's try to figure it all out.

Since the printer prints a three-dimensional object, its head (extruder) must somehow move in three coordinates. In order not to get confused, they are called standardly - X, Y, Z. If you are standing “face to face” with the printer, then the X coordinate is the movement of the head closer or further to you, Y - left and right, and Z - up and down . Of course, it is not necessary to move the head - you can move the platform itself with the object under the fixed head. And you can do both, move the extruder along one axis, and the platform along the other. Sobsvenno, most often they do it. Assembling 4 engines (for the Z axis it is better to use two engines - gravity-s) next will be more difficult and more expensive in overhead than to put them in different places.

It includes those printers where the print head moves along the X axis, and the platform along the Y and Z axes. It is very small, and most of it (if in pieces, up to probably 95%) is made up of a Chinese printer UP!

A very interesting printer, according to reviews - the older version prints fine out of the box. The younger version ( Up! Mini ) is really scolded. Own good software with convenient support generation (open source doesn’t yet), which can be easily separated. The famous bearing was printed on it. The only minus is completely closed, so you can forget about entertainment in the form of a fine adjustment of the conversion parameters, as well as about alternative programs.

Such a small variety follows some design complication - it is more difficult to move a platform with a printed object along two axes simultaneously. Nevertheless, for some reason, the Chinese are doing this.

The second, most numerous group:

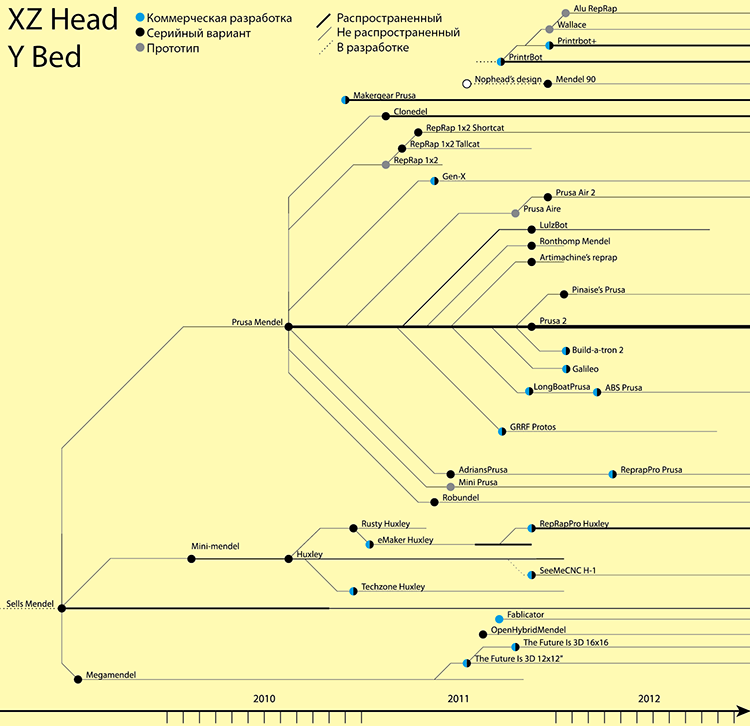

The platform moves along the Y axis, and the extruder moves along the XZ axis.

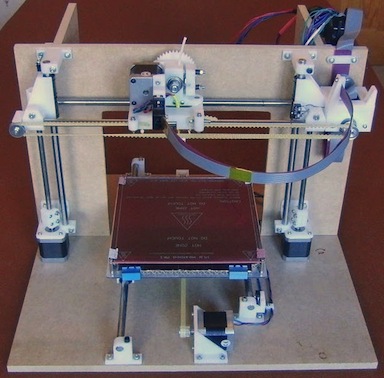

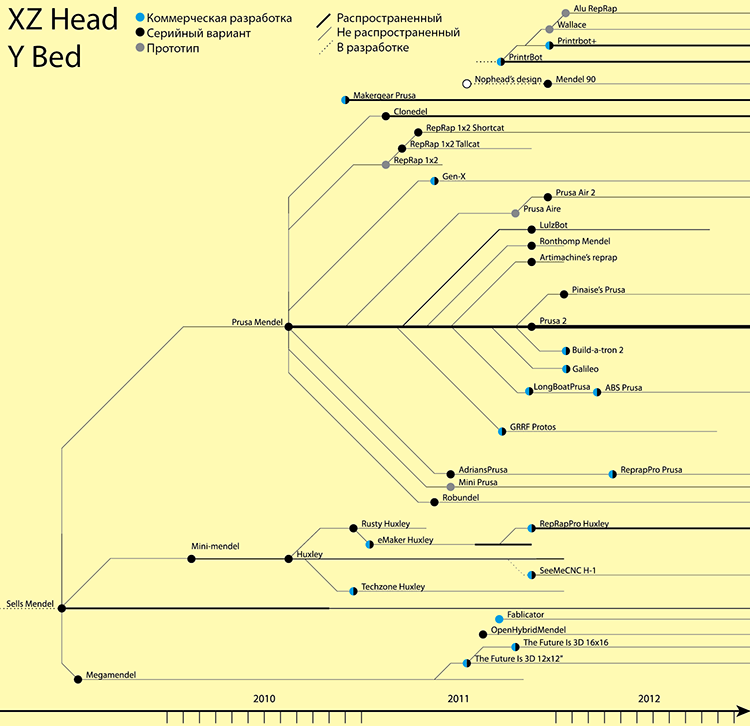

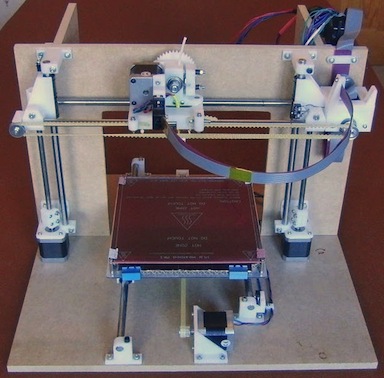

The core of the group is the most popular homemade printer Prusa Mendel at the moment - the version of the "classic" Mendel from Josef Prusa. The author slightly simplified the design, making it more repeatable and repairable. In particular, he added a second engine for the Z axis, immediately removing all the problems with the belt drive to two studs. This design, unfortunately, also has problems - with the random movement of one axis, the symmetry of the plane of the head and platform is broken.

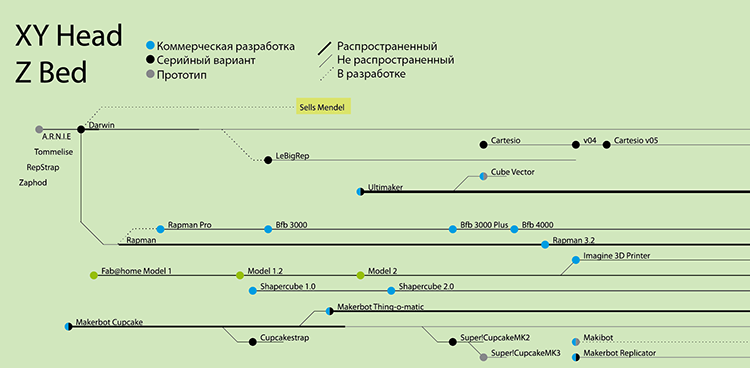

Due to its simplicity, the printer is very widespread (a thick black line in the diagram), both in the form of various assembly kits for home use, and in the form of commercially successful off-the-shelf printers, usually sold assembled, and already configured. One example is the Russian development of Gen-X from SKB Kiparis . True, recently they are busy with a seriously updated version of the printer - Picaso , so Gen-X sales are stopped.

The printer can be identified by its characteristic triangular profile - the frame is based on two triangular elements.

Similar profiles are used in the classic mendel, but you most likely will not see it.

The ease of assembly of such a printer has its drawbacks - low frame rigidity on some axes. Part of the problem is to be solved by the MendelMax design - from a different profile and with additional mountings.

It should also be noted that the Mendel-90 construction , which is quite popular in the post-Soviet space , is named after two wooden panels made of plywood or other easily processed material located at right angles. Aesthetes can make plexiglass. This design has a positive effect on print accuracy and ease of calibration - due to the small number of vibrations.

It became popular because of the ease of assembly - it is easier to fasten two planks of plywood than to find parts for a frame. Yes, and you can cut them from any furniture maker or on a laser machine. Or a manual jigsaw.

The third group:

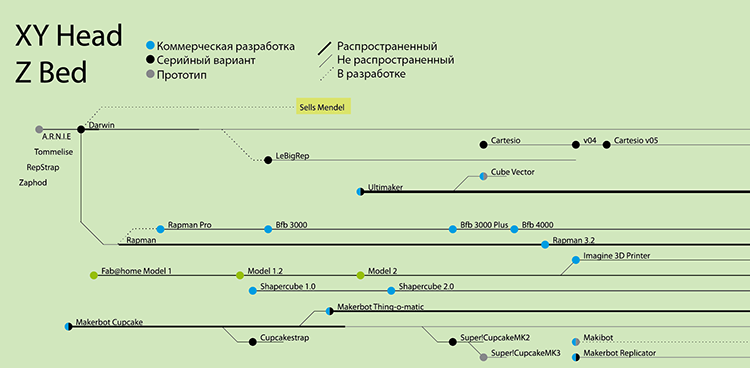

It is not the first one in that plan that the platform moves up and down (in the printing process - down) - along the Z axis. And the print head with the extruder - along the other two axes, respectively.

This group includes the “grandfather” of all printers - the Darwin project , from which Mendel once budded . Being not very successful, but frankly terrible in assembly and configuration, the printer, however, gained some popularity, and gave life to Mendel Prusa .

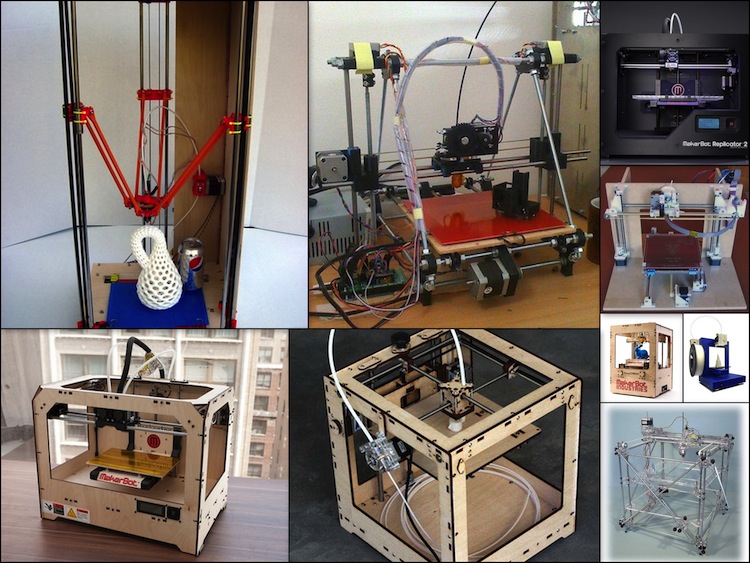

The two most common printer manufacturers in this group are RapMen and Ultimaker . Here's RapMen :

Recognized by its square design with crosses on its sides.

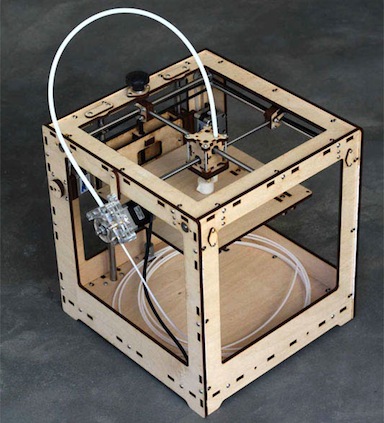

And here is Ultimaker:

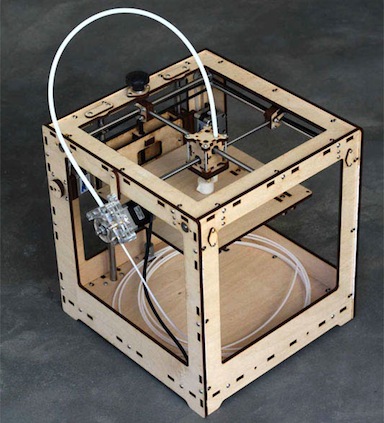

Characteristic features - body made of laser-cut wooden pieces. Sold as assembly kits. Here, for example, dude just collects it. According to reviews - good quality and speed, but a complicated assembly. Complicated regarding - there are more problems with the mendel, but here everything is ready - the file is needed minimally.

And the most popular is of course the Makerbot printer family . The first printer, Cupcake , was, like Ultimaker, made of a wooden profile, had two extruders and the ability to print in two colors.

The next - Thing-o-matic was like a two-drop water trip to the Ultimaker . Stop. We look at the diagram. This is Ultimaker.similar to Thing-o-matic , but not vice versa - the second was released earlier.

In fact, this is a step backward compared to Cupcake - a smaller working area, and without a second extruder. But cheaper. Therefore, it also became popular - as it turned out, the cost outweighs the ability to print in two colors.

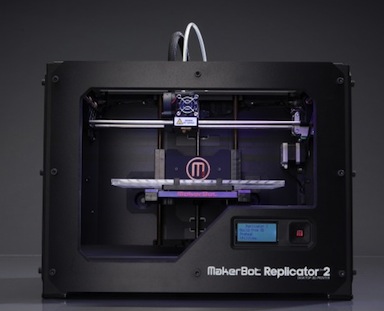

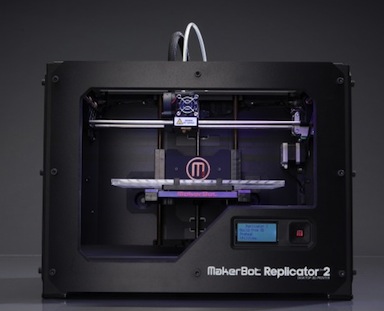

Well, finally, Makerbot Replicator and Replicator 2 - "the most advanced home 3D printer ", so unloved (read UPD) by Joseph Prusa. The reason is simple - before getting Makerbot's investmentHe was a supporter of OpenSource, and after that they focused on selling Replicator 2, refusing to post the source code, some of which was developed by the community. Well, and not forgetting to grab a bunch of open source 3D models, which they essentially sell with the printer. In general, fu to be. But the printer is good. Separately sold version with two extruders.

Oh yes, there is still the FAB @ Home project . This is a project that has been developed since 2006, capable of printing everything that gets into the syringe - silicone, chocolate, glue, etc. But quite complicated and expensive.

Group 5 - delta printers, and a prototype cemetery.

Delta printers are printers in which only the print head moves. It would seem that there are pluses everywhere - and three engines of everything is needed, and the setup is simple, and the drawings are simple. Only something goes wrong - there are no models on the market. Only prototypes .

There, nearby - a bunch of devices that constantly receive prizes at exhibitions and shine in the news, but which most likely will not see the series. Sleep well, unborn .

So what to take? If for self-assembly - then Mendel-90, or Mendel Prusa. The second is good in that you can choose the degree ofinadequate use of the file to taste - from a complete assembly based on parts from printers to buying a complete set that can only be assembled. Despite the fact that there are more optimal designs, and somewhere easier to assemble - there are enough of these printers in Russia, in every major city there are a couple that well affects support - you can always ask for advice. Well, or Ultimaker - in complexity it will be about the same as assembling the tested Mendel whale.

If you don’t want to collect, then take any commercial one - for which there is enough money:

If you do not have an account on Habrahabr, you can read and comment on our articles on the siteBoxOverview.com

Since the printer prints a three-dimensional object, its head (extruder) must somehow move in three coordinates. In order not to get confused, they are called standardly - X, Y, Z. If you are standing “face to face” with the printer, then the X coordinate is the movement of the head closer or further to you, Y - left and right, and Z - up and down . Of course, it is not necessary to move the head - you can move the platform itself with the object under the fixed head. And you can do both, move the extruder along one axis, and the platform along the other. Sobsvenno, most often they do it. Assembling 4 engines (for the Z axis it is better to use two engines - gravity-s) next will be more difficult and more expensive in overhead than to put them in different places.

Group One:

It includes those printers where the print head moves along the X axis, and the platform along the Y and Z axes. It is very small, and most of it (if in pieces, up to probably 95%) is made up of a Chinese printer UP!

A very interesting printer, according to reviews - the older version prints fine out of the box. The younger version ( Up! Mini ) is really scolded. Own good software with convenient support generation (open source doesn’t yet), which can be easily separated. The famous bearing was printed on it. The only minus is completely closed, so you can forget about entertainment in the form of a fine adjustment of the conversion parameters, as well as about alternative programs.

Such a small variety follows some design complication - it is more difficult to move a platform with a printed object along two axes simultaneously. Nevertheless, for some reason, the Chinese are doing this.

The second, most numerous group:

The platform moves along the Y axis, and the extruder moves along the XZ axis.

The core of the group is the most popular homemade printer Prusa Mendel at the moment - the version of the "classic" Mendel from Josef Prusa. The author slightly simplified the design, making it more repeatable and repairable. In particular, he added a second engine for the Z axis, immediately removing all the problems with the belt drive to two studs. This design, unfortunately, also has problems - with the random movement of one axis, the symmetry of the plane of the head and platform is broken.

Due to its simplicity, the printer is very widespread (a thick black line in the diagram), both in the form of various assembly kits for home use, and in the form of commercially successful off-the-shelf printers, usually sold assembled, and already configured. One example is the Russian development of Gen-X from SKB Kiparis . True, recently they are busy with a seriously updated version of the printer - Picaso , so Gen-X sales are stopped.

The printer can be identified by its characteristic triangular profile - the frame is based on two triangular elements.

Similar profiles are used in the classic mendel, but you most likely will not see it.

The ease of assembly of such a printer has its drawbacks - low frame rigidity on some axes. Part of the problem is to be solved by the MendelMax design - from a different profile and with additional mountings.

It should also be noted that the Mendel-90 construction , which is quite popular in the post-Soviet space , is named after two wooden panels made of plywood or other easily processed material located at right angles. Aesthetes can make plexiglass. This design has a positive effect on print accuracy and ease of calibration - due to the small number of vibrations.

It became popular because of the ease of assembly - it is easier to fasten two planks of plywood than to find parts for a frame. Yes, and you can cut them from any furniture maker or on a laser machine. Or a manual jigsaw.

The third group:

It is not the first one in that plan that the platform moves up and down (in the printing process - down) - along the Z axis. And the print head with the extruder - along the other two axes, respectively.

This group includes the “grandfather” of all printers - the Darwin project , from which Mendel once budded . Being not very successful, but frankly terrible in assembly and configuration, the printer, however, gained some popularity, and gave life to Mendel Prusa .

The two most common printer manufacturers in this group are RapMen and Ultimaker . Here's RapMen :

Recognized by its square design with crosses on its sides.

And here is Ultimaker:

Characteristic features - body made of laser-cut wooden pieces. Sold as assembly kits. Here, for example, dude just collects it. According to reviews - good quality and speed, but a complicated assembly. Complicated regarding - there are more problems with the mendel, but here everything is ready - the file is needed minimally.

And the most popular is of course the Makerbot printer family . The first printer, Cupcake , was, like Ultimaker, made of a wooden profile, had two extruders and the ability to print in two colors.

The next - Thing-o-matic was like a two-drop water trip to the Ultimaker . Stop. We look at the diagram. This is Ultimaker.similar to Thing-o-matic , but not vice versa - the second was released earlier.

In fact, this is a step backward compared to Cupcake - a smaller working area, and without a second extruder. But cheaper. Therefore, it also became popular - as it turned out, the cost outweighs the ability to print in two colors.

Well, finally, Makerbot Replicator and Replicator 2 - "the most advanced home 3D printer ", so unloved (read UPD) by Joseph Prusa. The reason is simple - before getting Makerbot's investmentHe was a supporter of OpenSource, and after that they focused on selling Replicator 2, refusing to post the source code, some of which was developed by the community. Well, and not forgetting to grab a bunch of open source 3D models, which they essentially sell with the printer. In general, fu to be. But the printer is good. Separately sold version with two extruders.

Oh yes, there is still the FAB @ Home project . This is a project that has been developed since 2006, capable of printing everything that gets into the syringe - silicone, chocolate, glue, etc. But quite complicated and expensive.

The fourth group is represented only by the late McWire.

A pity, the design was interesting , and a lot of material was accumulated on it.Group 5 - delta printers, and a prototype cemetery.

Delta printers are printers in which only the print head moves. It would seem that there are pluses everywhere - and three engines of everything is needed, and the setup is simple, and the drawings are simple. Only something goes wrong - there are no models on the market. Only prototypes .

There, nearby - a bunch of devices that constantly receive prizes at exhibitions and shine in the news, but which most likely will not see the series. Sleep well, unborn .

Summary

So what to take? If for self-assembly - then Mendel-90, or Mendel Prusa. The second is good in that you can choose the degree of

If you don’t want to collect, then take any commercial one - for which there is enough money:

If you do not have an account on Habrahabr, you can read and comment on our articles on the siteBoxOverview.com

Only registered users can participate in the survey. Please come in.

Want a series of articles on 3D printing and an overview of the printer?

- 3.3% Come on, come on tablets and phones 55

- 52% YES! Bullied tablets and phones 849

- 29.5% Come on both this and that. 483

- 15% I am a UFO, I am violet 245