Microelectronics for space and military

Possible, many of you thought after the situation with Phobos-Grunt - what is so special about microchips for space and why do they cost so much? Why can not put protection against cosmic radiation? What is the story of the arrest of people who exported chips from the United States to Russia? Where are all the polymers?

Possible, many of you thought after the situation with Phobos-Grunt - what is so special about microchips for space and why do they cost so much? Why can not put protection against cosmic radiation? What is the story of the arrest of people who exported chips from the United States to Russia? Where are all the polymers? I will try to answer these questions in this article.

Disclaimer: Information obtained from open sources and may not be entirely accurate. I personally do not work with military electronics, and whoever works, those articles cannot write. I will be glad to supplement and correct the article.

Additional requirements for space and military chips

First of all, increased requirements for reliability (both the crystal itself and the case), resistance to vibration and overloads, humidity, the temperature range are much wider, because military equipment and at -40C should work, and when heated to 100C.

Then - resistance to the damaging factors of a nuclear explosion - EMR , a large instantaneous dose of gamma / neutron radiation. Normal operation at the time of the explosion may not be possible, but at least the device must not irreparably fail.

And finally - if the microcircuit is for space - the stability of parameters as the total dose of radiation is slowly set and survival after meeting with heavy charged particles of cosmic radiation (more on this below).

Why do military love ceramic-metal cases?

They found out for a long time , it seems that earlier (in Soviet times) plastic did not stand the test of thermal cycling, it was porous (i.e. it was gaining moisture), and it could not tolerate negative temperatures.

And finally - this is an easy way to reduce the percentage of fakes, because you can’t buy microchips in the metal-ceramic case on the market.

But ceramics also have disadvantages - it is more expensive, less vibration resistance and, in general, from large accelerations, the wire, by which the contact pads on the chip are connected to the terminals of the microcircuit, can fall off (in the plastic case, the wire is "supported" along the entire length with plastic).

About Chip Categories

In the west, microcircuits are divided into categories commercial, industrial, military and space.

Commercial - ordinary, most widespread microcircuits for home and office products, usually designed for the temperature range 0..75C.

Industrial / Military - the same conventional microcircuits, but with additional testing, designed for a slightly wider temperature range (-40..125С for example) and optionally in a ceramic-metal case (microcircuits that did not pass additional tests can be sold as Commercial).

Space - radiation-resistant microcircuits for space applications, there is already a metal-ceramic case rather the rule. There are significant restrictions on the sale of Military and especially Space microchips to sworn friends - you need to get special permissions, and if they sell them to us, it’s only for civilian vehicles (for example, conditionally civilian GLONASS).

In Russia, everything is divided somewhat differently: microcircuits are sold with acceptance 1 (the so-called acceptance of quality control department - the technical control department, when the factory tests the chips), acceptance 5 (customer acceptance, in the case of the military, the military representative controls the tests) and acceptance 9 (when only the most qualified personnel are involved in the work - for space and nuclear power plants). Acceptance of 5/9 in itself does not mean that the microcircuit is radiation-resistant - resistance to special factors is indicated in the (non-public) documentation for the microcircuit.

These additional tests, the ceramic case and small-scale production (when the development cost is divided not by 1 million microchips, but by 100) and lead to the fact that the military / space microchip costs at least 10 times more than the civilian one, and the maximum - maybe 100 ' $ 000 apiece.

However, not every microcircuit can be supplied to the Russian military equipment - there is a list of domestic (“domestic” includes Belarusian microcircuits from Integral) electronic components that can be used to create equipment where everything is listed by name. If a plant creates a new microcircuit, then it cannot be used until it gets to this list. For general development and assessment of how much domestic industry produces, you can look at the list of 2010 here , and2011 .

The use of imported microcircuits requires individual permission (with the corresponding formal bureaucracy that there are no domestic analogues, but as they appear - we will definitely use them).

How radiation affects microcircuits

In "pieces of particles" cosmic radiation consists of 90% of protons (i.e., hydrogen ions), 7% of helium nuclei (alpha particles), ~ 1% heavier atoms and ~ 1% electrons. Well, stars (including the sun), galactic nuclei, the Milky Way - abundantly illuminate everything not only with visible light, but also with x-ray and gamma radiation. During outbreaks in the sun - radiation from the sun increases by 1000-1'000'000 times, which can be a serious problem (both for people of the future and current spacecraft outside the Earth’s magnetosphere).

There is no neutron in cosmic radiation for an obvious reason - free neutrons have a half-life of 611 seconds and turn into protons. Even the sun cannot reach a neutron, unless with a very relativistic speed. A small amount of neutrons flies from the earth, but these are trifles.

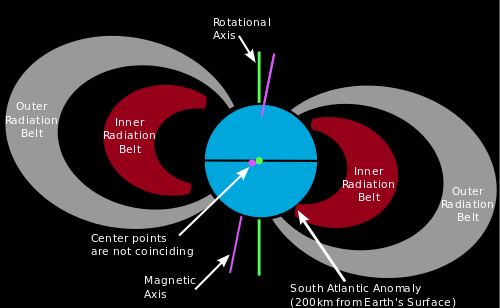

There are 2 belts of charged particles around the earth - the so-called Van Allen radiation belts: at an altitude of ~ 4000 km from protons, and at an altitude of ~ 17 000 km from electrons. Particles there move in closed orbits, captured by the magnetic field of the earth. There is also a Brazilian magnetic anomaly - where the internal radiation belt comes closer to the ground, up to a height of 200km.

Electrons, gamma and X-rays

When gamma and x-ray radiation (including secondary radiation, obtained due to the collision of electrons with the apparatus body) passes through the microcircuit, the charge gradually accumulates in the gate dielectric of the transistors, and accordingly the parameters of the transistors begin to slowly change - the threshold voltage of the transistors and the leakage current. An ordinary civilian digital microcircuit may already stop working normally after 5000 rad (however, a person may stop working after 500-1000 rad).

In addition, gamma and X-ray radiation makes all pn junctions inside the microcircuit work like small “solar cells” - and if radiation in space is usually insufficient to greatly affect the microcircuit's operation, gamma and X-ray flux may already be enough during a nuclear explosion to disrupt the chip due to the photoelectric effect.

Then - flash / EEPROM memory. Someone may still remember old UV-erased memory chips:

To reduce the cost, a version without a quartz window was also released, which was considered once-programmable. But craftsmen still managed to wash it - with X-ray radiation. Exactly the same effect exists in space - radiation erases data in eeprom / flash memory slowly, so everyone actively explores FRAM / MRAM memory for space applications (Integral and Angstrom do this for us). The memory on fired and shorted jumpers - fuse and antifuse is not erased from radiation either, Micron understands this. In the West, however, they fly on a cheap near-civil eeprom, and generally have no problems.

In a low orbit of 300-500 km (where people fly), the annual dose can be 100 rad or less, accordingly, even for 10 years, the dose received will be portable by civilian microcircuits. But in high orbits> 1000km, the annual dose can be 10'000-20'000 rad, and conventional microcircuits will gain a lethal dose in a matter of months.

Heavy charged particles (TZZ) - protons, alpha particles and high-energy ions

This is the biggest problem of space electronics - TZZs have such high energy that they “pierce” the microcircuit through (together with the satellite’s body) and leave a “loop” of charge . In the best case this can lead to a software error (0 become 1 or vice versa - single-event upset, SEU), in the worst case it can lead to thyristor latching(single-event latchup, SEL). In a latched chip, the power is shorted to ground, the current can go very large, and lead to the burning of the chip. If you manage to turn off the power and connect it before combustion, then everything will work as usual.

Perhaps this was exactly what happened with Phobos-Grunt - according to the official version, non-radiation-resistant imported memory chips failed at the second turn, and this is possible only because of the TZZh (according to the total dose of radiation in low orbit, a civil chip could have been work).

It is the snap that limits the use of conventional ground-based circuits in space with all sorts of software tricks to increase reliability.

There are several ways to deal with snapping:

1) Monitor the current consumed, and quickly distort the power

2) Use chips on a sapphire substrate (Silicon-on-sapphire, SOS, in a more general form Silicon-on-insulator, SOI) - this eliminates the formation of bipolar parasitic transistors and, accordingly, snapping. Nonetheless, there may still be software errors. Silicon-on-sapphire wafers are expensive, difficult to process, and they have limited use in the civilian sector - accordingly, production is expensive.

3) Use the so-called triple-well process - it also greatly reduces the possibility of snapping the microcircuit due to the additional isolation of transistors with a pn junction, but does not require any special plates or equipment and, accordingly, the production itself is much cheaper than silicon on sapphire.

Historically, in the USSR and Russia, they worked more with silicon on sapphire, and in the west they try to use ordinary silicon with triple-well as much as possible (to combine with commercial products and reduce cost), but they also do SOS / SOI as needed.

Neutrons + 10 B

Boron is used for doping silicon and in the form of borosilicate glass to isolate metal layers. The problem is that natural boron for 20% consists of Boron-10, which reacts very well with neutrons with the release of alpha particles directly in the heart of the chip. This led to errors in the operation of microcircuits, especially memory.

Neutrons are obtained as secondary radiation, or fly from the earth, as we recall in space radiation they are not.

10 B + n → [ 11B] → α + 7 Li + 2.31 MeV.

This is one of the problems that could be solved - using only the 11 B isotope for the production of microcircuits . Now neutrons pass through the microcircuit almost unhindered without causing errors. By the way, this property of boron is used for emergency shutdown of nuclear reactors - boric acid enriched in the 10 B isotope is poured into it - alpha particles are not a problem there.

Let's move on to a couple of interesting myths:

And let's turn the satellite into radiation protection, and we will put civilian microcircuits

Nature looks with a grin at the toy accelerators of elementary particles of beastmen - at the large hadron collider they (or rather will) achieved miserable energies of 7 TeV for protons, and 574 TeV for lead ions. And with galactic cosmic rays, particles with an energy of 3 * 10 20 eV sometimes fly to us , i.e. 300000000 TeV. Where such particles come from is another question, because this is above the theoretical limit of the energy of cosmic particles of Graisen - Zatsepin - Kuzmin . In human-readable units, this is about 50J, i.e. in one elementary particle, energy is like that of a bullet of a small-caliber sports pistol.

When such a particle collides with, for example, a lead atom of radiation protection, it simply tears it to shreds. The fragments will also have gigantic energy, and will also tear to shreds everything in their path. Ultimately - the thicker the protection of heavy elements - the more fragments and secondary radiation we get. Lead can only greatly weaken the relatively soft radiation of terrestrial nuclear reactors.

A high-energy gamma radiation has a similar effect - it is also capable of tearing heavy atoms to shreds due to the photonuclear reaction .

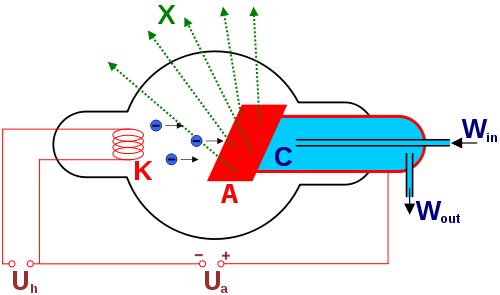

Finally, let's take a look at the design of the x-ray tube:

Electrons from the cathode fly towards the anode of heavy metal, and when they collide with it, X-ray radiation is generated due tobremsstrahlung . When the electron of cosmic radiation flies to our ship, then our radiation protection will turn into such a natural X-ray tube, next to our delicate microcircuits.

Because of all these problems, radiation protection from heavy elements, like on earth, is not used in space. They use protection mainly consisting of aluminum, hydrogen (from various polyethylenes, etc.), because it can be broken down only into subatomic particles - and this is much more complicated, and such protection generates less secondary radiation.

But in any case, there is no protection against TZCh, moreover - the more protection - the more secondary radiation from high-energy particles, the optimal thickness is about 2-3 mm of Aluminum. The most difficult thing is the combination of hydrogen protection and slightly heavier elements (the so-called Graded-Z ) - but this is not much better than pure "hydrogen" protection. In general, cosmic radiation can be attenuated by about 10 times, and that’s all.

Another myth is that modern technical processes are less radiation-resistant.

The chance of getting an error in a particular transistor is proportional to its volume, and it quickly decreases with a decrease in technology (because transistors become not only smaller in area, but also thinner). In addition, an abnormal increase in radiation resistance with modern thicknesses of gate dielectrics (3 nm or less) was noted.

In general, on modern stable technical processes (65nm or less), microcircuits withstanding a radiation dose of 1 million rad are obtained routinely, which exceeds all reasonable requirements for resistance. Resistance to snapping-in and program errors - achieved through triple-well and special architectural solutions.

About soft errors (single-event upset)

Those. when due to the TZZ we had a distortion of the memory contents or the logic worked incorrectly.

Fighting this remains only in architectural ways - by majority logic (when we connect 3 copies of each block we need at a certain distance from each other - then 2 correct answers “overpower” one wrong one, using more error-resistant memory cells (out of 10 transistors, instead of the usual 6), using error correction codes in memory, cache and registers, and many others.

But it’s impossible to completely get rid of errors - after all, it may be lucky for us and the TZCh (or rather, a whole fan of secondary particles) will go exactly along the chip, and almost 5% of the chip may fail ... Here we need a highly reliable system of several independent computers, and their correct programming.

How to develop space and military chips

From the previous article, we already know that microcircuits do not grow on trees; developing them is long and expensive. This fully applies to military and space microcircuits. The situation here, however, is exacerbated by small-scale production - and on its own initiative it becomes extremely difficult for the plant to develop anything: it’s a conditional investment of $ 1 million to develop, and customers only need 10 microchips. How much do you need to sell them for? 100'000 $? 200'000 $?

Therefore, the state finances OCD for the development of microcircuits needed by the industry, and these OCDs are dark. For example, you can look at the list of OCD of one Integral (by the way, there are already small FPGAs there). That’s how the domestic ARM appeared - Milander, fulfilling OCD, bought a license for Cortex-M3,He made a microcontroller for the military and produced it in the right quantity, and then released it in the civilian version (and plastic case), at a competitive price.

Of course, not everything can be developed at a reasonable cost. One of the sore spots is the large FPGA. The FPGA chip itself is not difficult to develop, but software for synthesis can be very complicated. In such cases, it may be advantageous to purchase imported microcircuits in the form of plates with a large margin, their testing and packaging. Probably this is how the domestic FPGA 5576XC4T and 5576XC3T appeared - which are software compatible with Altera but have a different pinout.

In general, now the Russian electronics industry can develop and produce any military and space microelectronics (especially after the acquisition of new Micron equipment in 2007 and 2011), but for this someone needs to order and finance this development, taking into account the development and manufacturing time of several years. Or directly, or through the state OKR. So if you hear in the interview of some leader the words “Well, a poor backward domestic industry does not make us the necessary microcircuits”, this should be understood as “I’m too lazy to finance or knock out financing to create all the necessary microcircuits”.

But of course, a lot of equipment made 5-15 years ago is built on imported key components - this is the result of our lost 90s, when everything was very sad in microelectronics (however, as everywhere else at that time). Forced use of imported components in the 90s and early 2000s is certainly bad and dangerous, but the choice was simple - either we make it on import or we don’t do it at all. In recent years, it seems that they have taken proper steps to rectify the situation with domestic military electronics, and it will be more and more difficult to find excuses for using imported components.

And we must remember that war is won first of all on the economic front. Whoever spends resources more efficiently wins. Therefore, it’s difficult to blame the defense industry for not developing “for ourselves” absolutely everything that the whole Western world is developing together — compromises are everywhere needed.

There are similar problems with military electronics in the West - military microcircuits are also expensive there due to small-scale production (for example, RAD750 - $ 200 thousand), and the recent scandal over the massive supply of counterfeit microcircuits for military equipment was not a good life .

About bookmarks

Very often you hear about "bookmarks" - a magic button that can turn off imported chips. Of course, everything is not so simple - the electronica is still protected from external radio signals, and you still have to manage to give the signal.

But what’s possible is to reduce the reliability of the chips we supply. As you know, reliability is already 10 years old as a result of a compromise with speed and heat dissipation. And the ways to increase and decrease reliability are very well studied: for example, it’s enough not to add 1% copper to aluminum compounds, or to anneal the chip not in deuterium, but in hydrogen - and the service life will be reduced by 10 times. Whether this will detect testing is another question.

In addition, the use of imported components in key systems is a dependency that can be expensive (and already expensive, because you have to buy such components with a margin). Well, by buying microcircuits abroad - we help foreign enterprises solve their problems with small-scale

production. There is some danger in the manufacture of microcircuits at domestic factories, if masks are manufactured abroad - not only can they be theoretically copied and studied, masks can be modified - companies like Chipworksquite capable of this (for example, you can reduce reliability by disrupting the operation of majority logic or damaging the operation of error correction structures). It will be very difficult to detect such modifications - I’m not sure that the finished masks are thoroughly verified with their electronic original.

What is the story of the arrest of people selling chips from the US to Russia?

By itself, exporting from the United States even military / Space class microcircuits is not a problem - this can be done quite legally with the passage of the appropriate bureaucracy. The problem is the provision of forged end-use documents in order to avoid unnecessary difficulties in obtaining the necessary permits.

The list of microcircuits (page 20, probably incomplete, at least a couple of items at the beginning of the list) caused bewilderment of everyone - there were no space ones, of the coolest - EV10AQ190CTPY - Quad 10-bit 1.25 Gsps ADC.

But the most important thing in this story is that all these comrades and companies were monitored from the very beginning - all correspondence, conversations and so on. Accordingly, we read the previous section of the article on “bookmarks” and a possible decrease in reliability.

Is being discussedtopic here (only for registered users).

Summary

The use of civilian microcircuits in space is limited by the snapping effect, and possibly at best in low orbits. In high orbits and in deep space - we need special radiation-resistant microcircuits, because there we are deprived of protection of the earth’s magnetic field, and a meter of lead will not save us from high-energy particles of cosmic radiation.

In imported microcircuits, bookmarks with remote shutdowns are unrealistic, but it is quite possible to reduce reliability and service life.

After the dark decade of the 90s, in recent years, relatively complex domestic microcircuits have finally begun to appear - microcontrollers, FPGAs (small ones, large ones, from imported plates with their own packaging and testing), processors ( Comdivs, Elbrus, MTsST R500, Milandrovskie ARM-s). Work is underway on conditionally “breakthrough” military technologies (rad. FRAM).

So if the world does not end this year, less and less military and space equipment will come out with Made in Taiwan microcircuits, and less often automatic interplanetary stations will plow the expanses of the ocean.

I will be glad to hear about errors and additions - they will certainly be needed here.