Which laser machine to buy? Review of reliable laser machine Raylogic 11G

Good day, everyone , 3Dtool company with you .

Today we would like to show you and tell a little about the Raylogic 11G laser machines .

The 11G series is a large line of universal laser machines with a wide range of technical specifications and working field sizes. You can pick up the machine exclusively for your current needs, without the need to overpay for the functionality that you do not use.

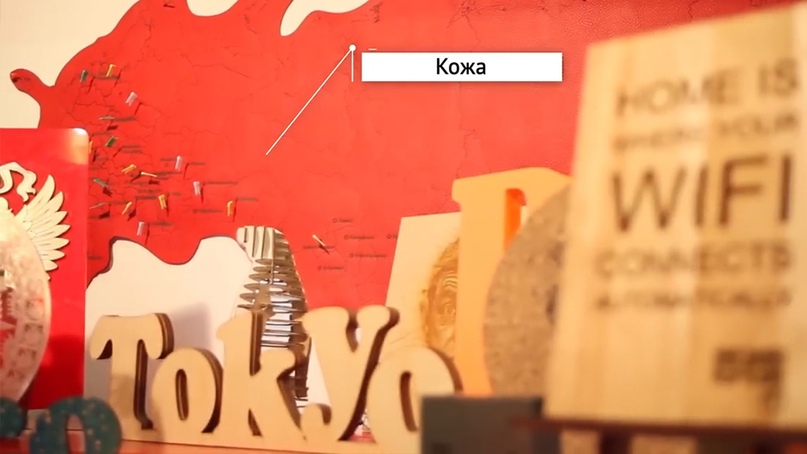

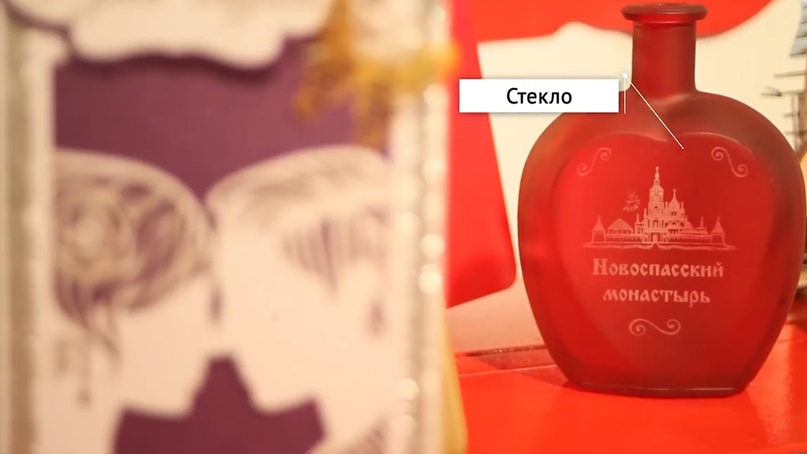

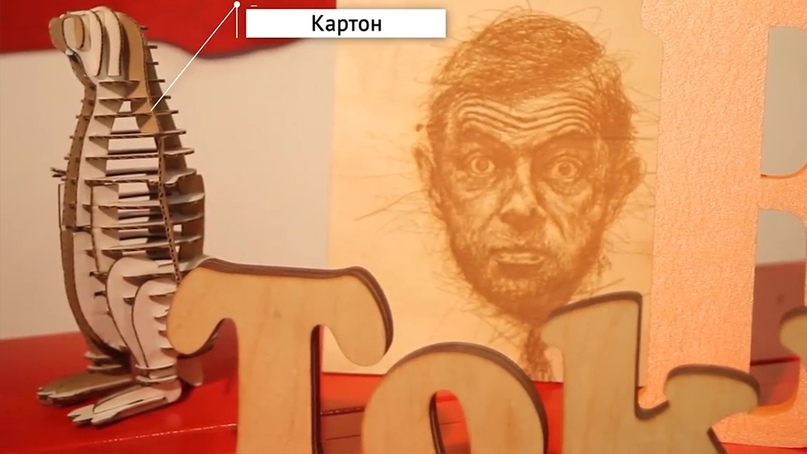

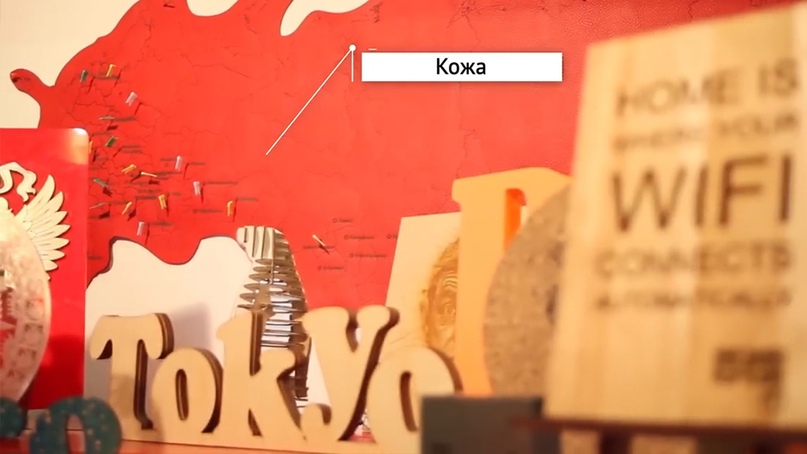

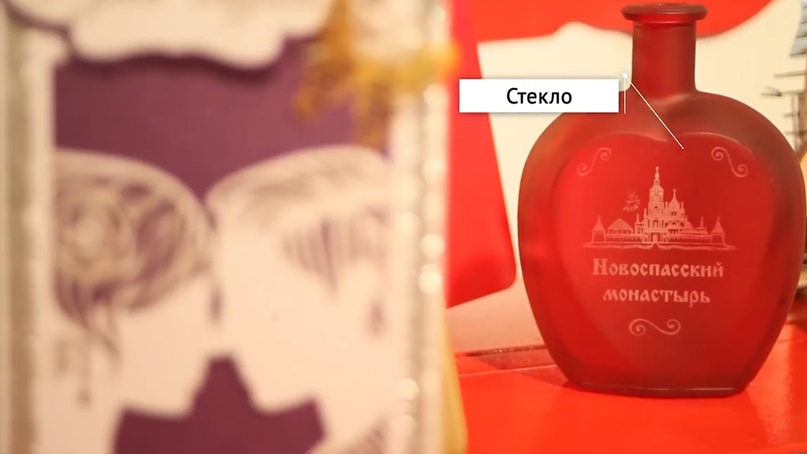

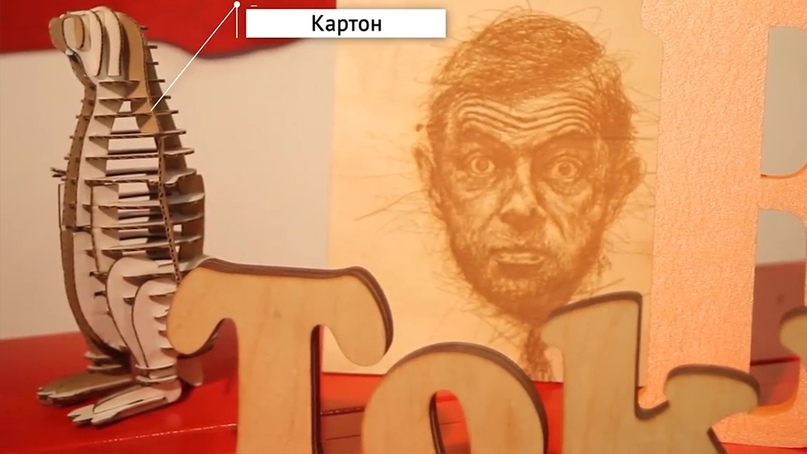

These machines work with a variety of materials: leather, wood, plywood, plexiglas, polystyrene foam, glass, paper, cardboard, izolon, mirror.

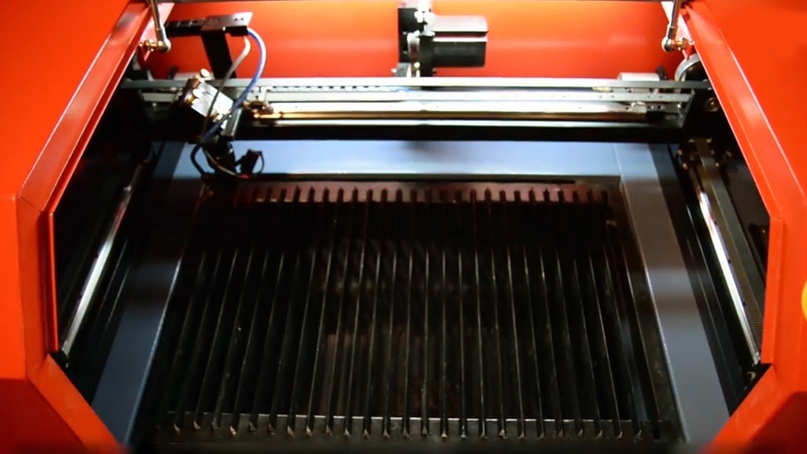

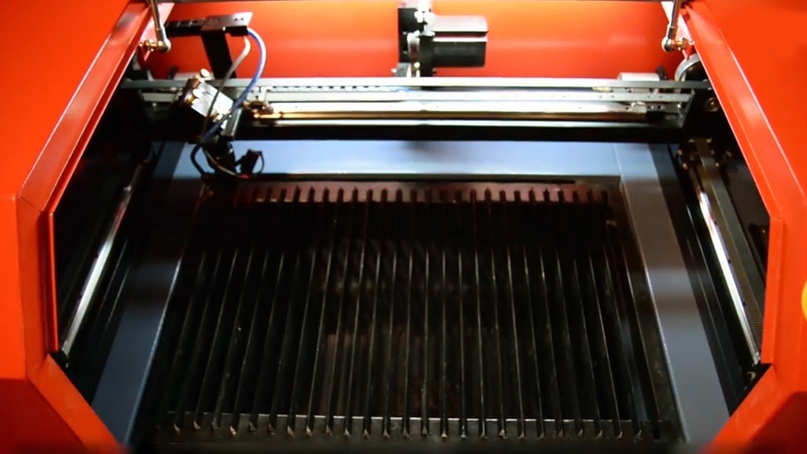

In the basic configuration, an electric screw lift table is installed on a stepper motor with a power reserve of up to 250 mm along the Z axis.

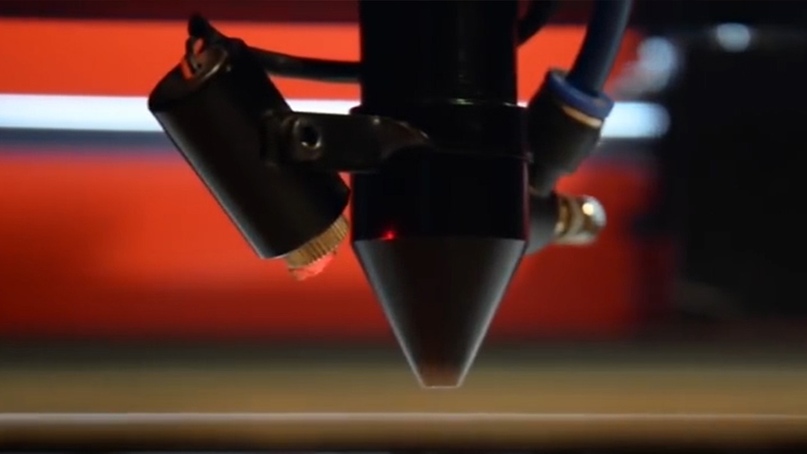

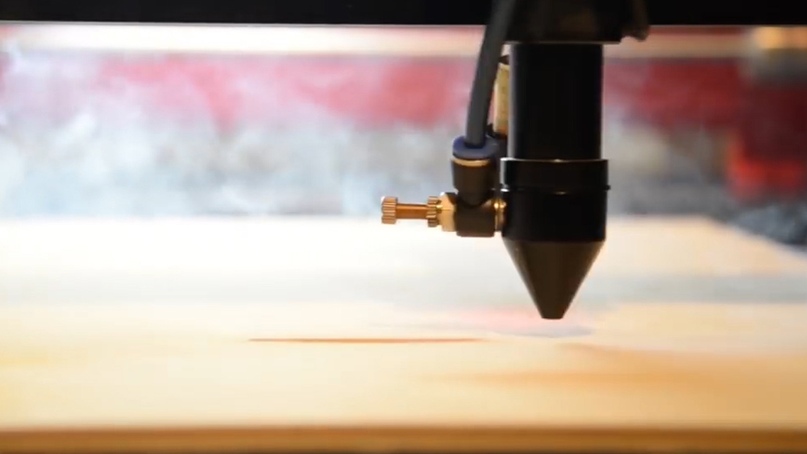

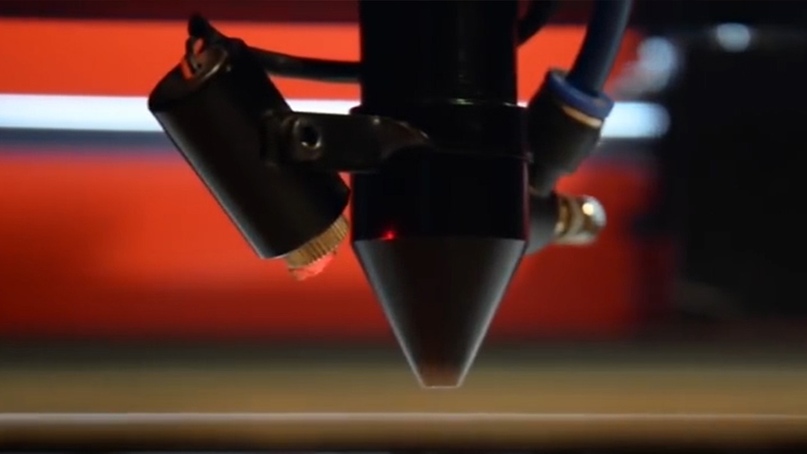

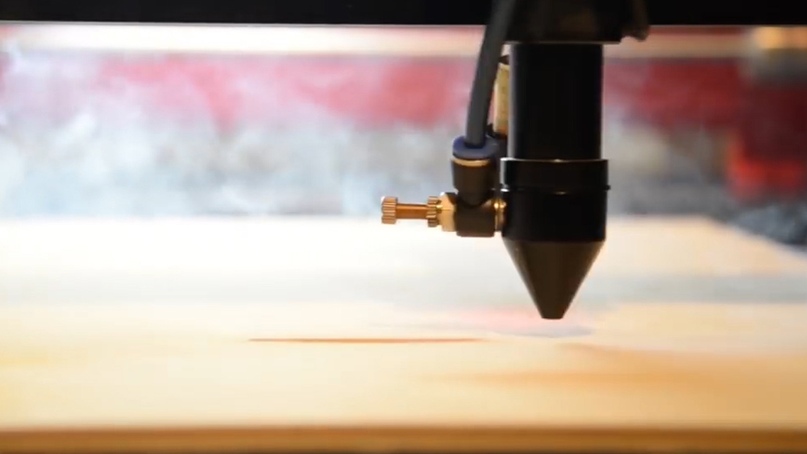

For precise positioning and setting the “zero” or origin, a laser pointer is mounted on the nozzle.

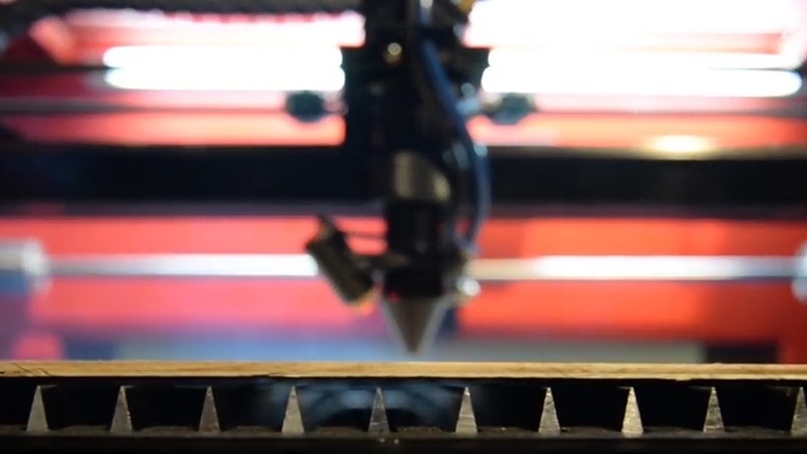

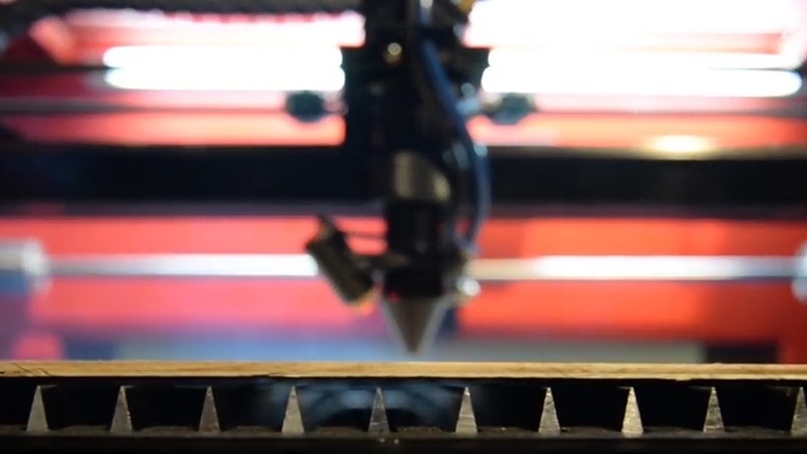

Rack table - the optimal solution for cutting sheet materials. As an additional option, you can purchase a “cellular table” for cutting fine or soft materials.

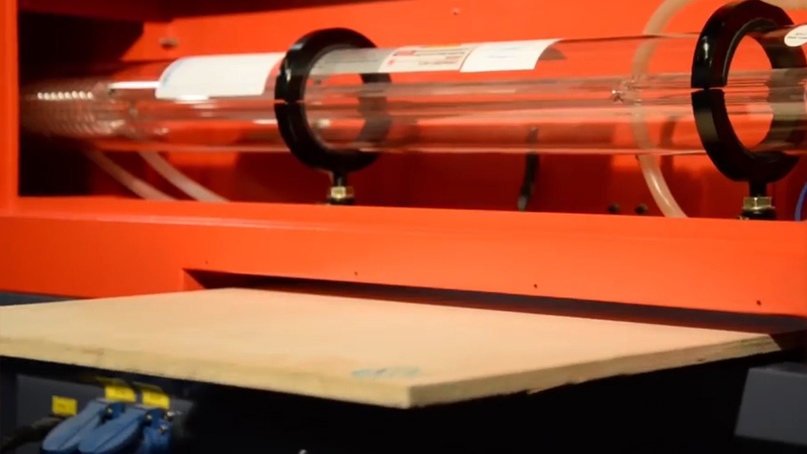

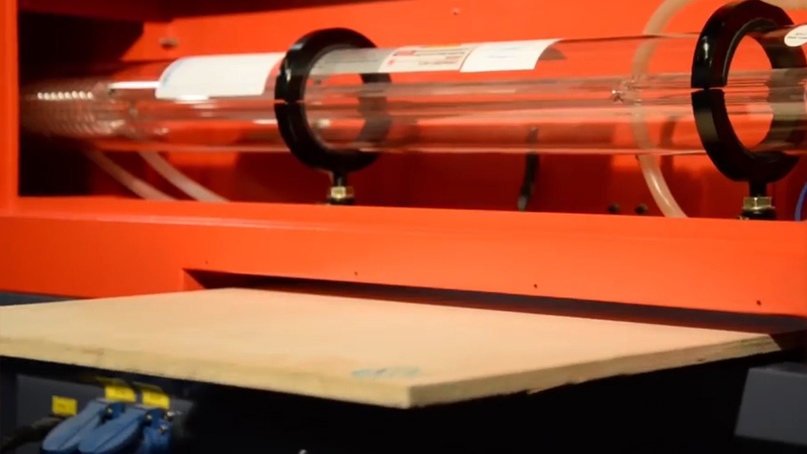

For any Raylogic 11G laser machine, you can increase the radiator power to a higher one, even for models with a working field of 500 x 300 (mm). The laser tubes are interchangeable and if you buy a model with a 40k watt tube, you can easily replace it with a more powerful one. For example, 100 watt.

The set comes expander box emitter, in case of a possible upgrade.

The entire model range of Raylogic machines has through windows for pulling sheet materials. Those. If you work, for example, with a sheet of plywood 2 meters long, you will not need to cut it into several pieces to fit the sheet into the machine.

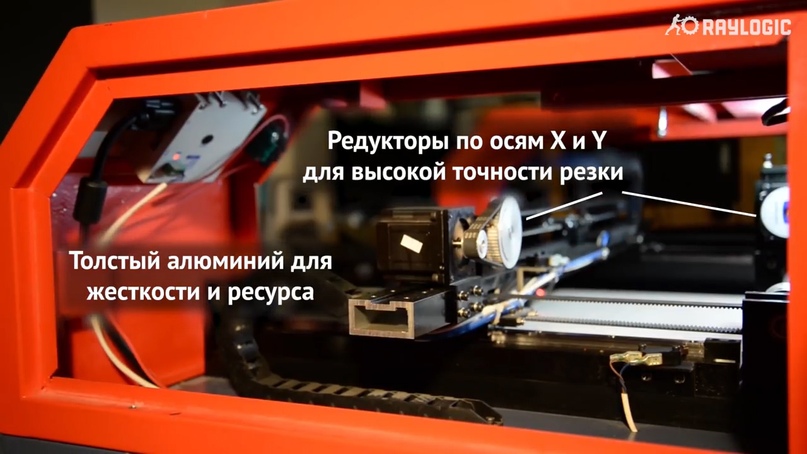

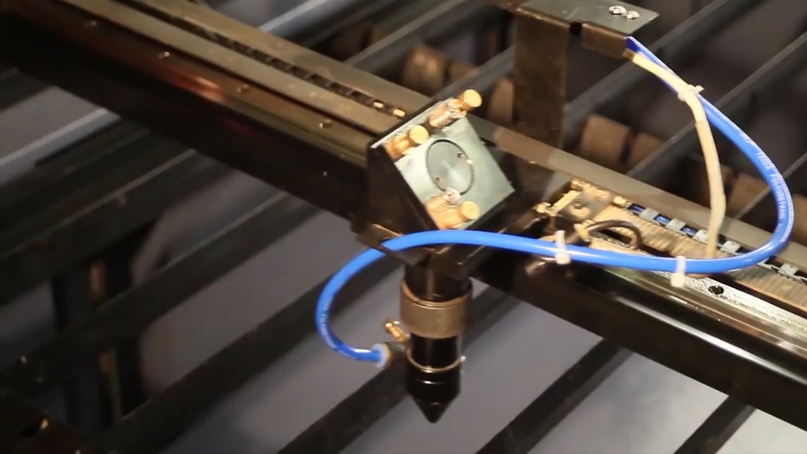

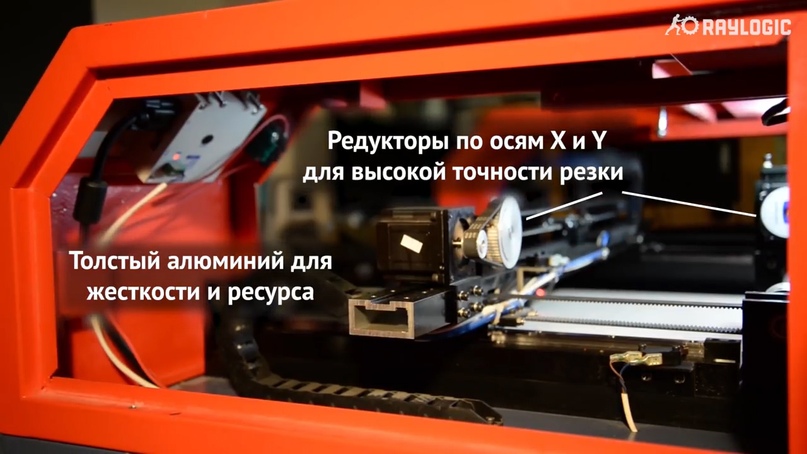

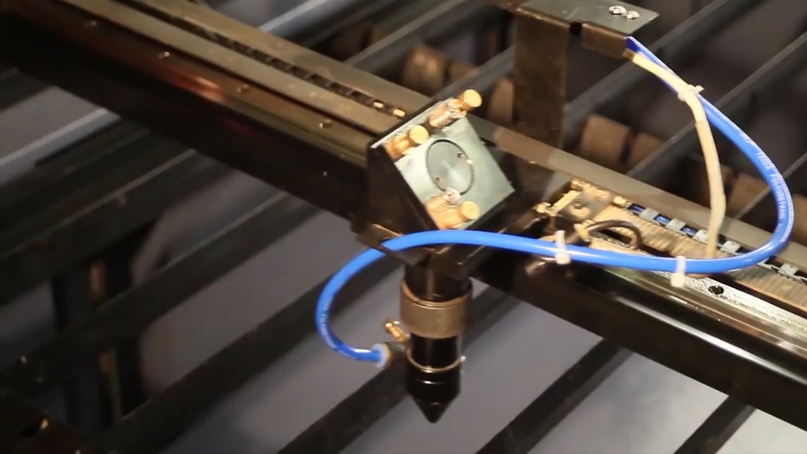

Installed gearboxes on the X and Y axes to improve the accuracy of positioning and cutting. The portal and the bases for rail guides are made of thick aluminum for rigidity. Not at a loss to the weight and durability of the machine mechanics.

It is possible to connect a mouse and keyboard to control the interface. This greatly increases the convenience and speed of work.

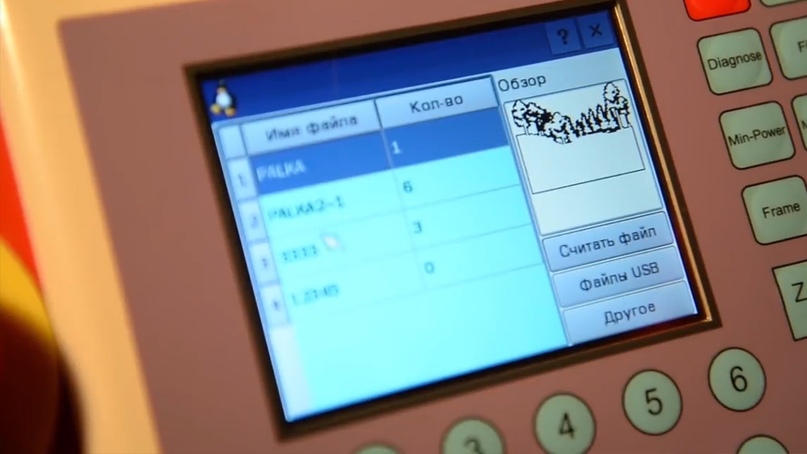

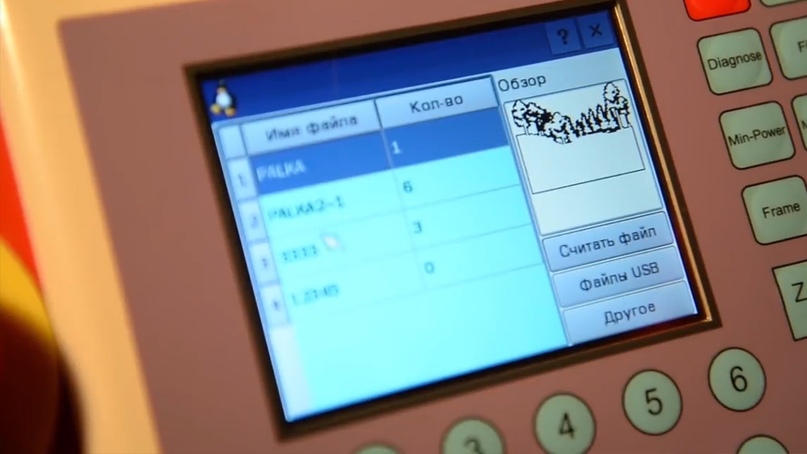

The Russified display and software facilitate the training of new operators.

Tasks can be saved to the machine memory via USB, USB flash drive or local network.

The machine can consistently cut and engrave one task with multiple layers and settings. Preparation of tasks is carried out in the programs "Corel Draw" (using a plug-in), or "Laser Works".

Lifting table allows you to handle bulk products up to 250 mm. Also, it is possible to complete the machine with a rotary table. What will allow to process cylindrical objects.

Steel rail guides with metal hardness of 58 - 64 HRC, ensure durability and wear resistance of the machine kinematics.

The machine is also equipped with a two-zone exhaust system. The smoke is pulled down and out of the working area. Some equipment comes with a separate swirl hood.

Optionally, a set of flaps with remote control is installed to regulate exhaust zones.

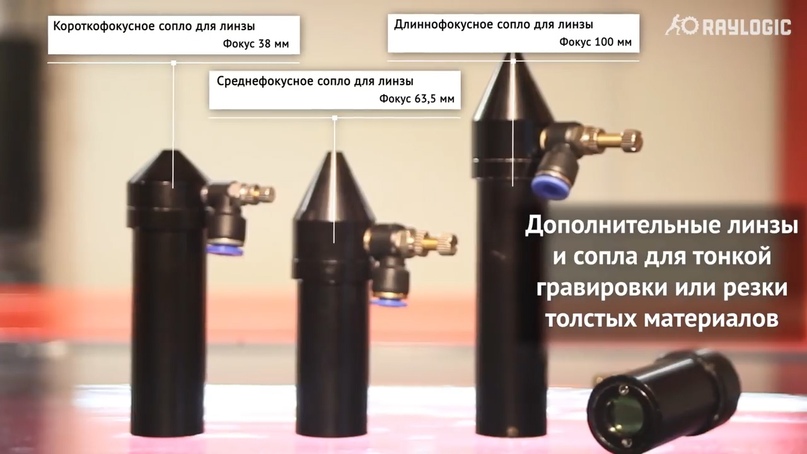

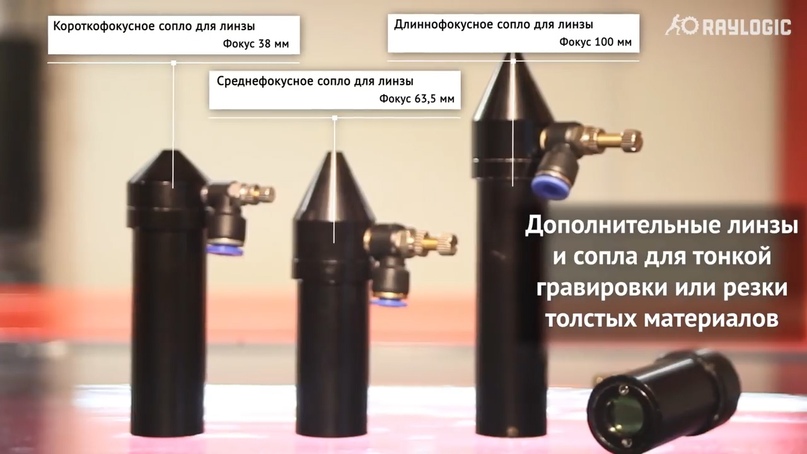

The set also comes with additional lenses and nozzles for fine engraving or cutting of thick materials. They change quickly and quite conveniently.

Summarizing all the above, I would like to add that these machines have long been represented on the Russian market and have proven to be reliable and easy-to-use machines. A wide range of Raylogic allows you to select the machine for the tasks of a particular business or production. The cost of machine tools as of 2018 starts from 260-000 rubles. I am glad that in Russia there is a full-fledged service center, with a warehouse of spare parts. The issues related to maintenance and warranty repairs are resolved quickly and efficiently.

To view the catalog of Raylogic laser machines, please click here .

General catalog of CNC laser machines - 3dtool.ru/category/chpu/lazernye-stanki

Today we would like to show you and tell a little about the Raylogic 11G laser machines .

The 11G series is a large line of universal laser machines with a wide range of technical specifications and working field sizes. You can pick up the machine exclusively for your current needs, without the need to overpay for the functionality that you do not use.

These machines work with a variety of materials: leather, wood, plywood, plexiglas, polystyrene foam, glass, paper, cardboard, izolon, mirror.

In the basic configuration, an electric screw lift table is installed on a stepper motor with a power reserve of up to 250 mm along the Z axis.

For precise positioning and setting the “zero” or origin, a laser pointer is mounted on the nozzle.

Rack table - the optimal solution for cutting sheet materials. As an additional option, you can purchase a “cellular table” for cutting fine or soft materials.

For any Raylogic 11G laser machine, you can increase the radiator power to a higher one, even for models with a working field of 500 x 300 (mm). The laser tubes are interchangeable and if you buy a model with a 40k watt tube, you can easily replace it with a more powerful one. For example, 100 watt.

The set comes expander box emitter, in case of a possible upgrade.

The entire model range of Raylogic machines has through windows for pulling sheet materials. Those. If you work, for example, with a sheet of plywood 2 meters long, you will not need to cut it into several pieces to fit the sheet into the machine.

Installed gearboxes on the X and Y axes to improve the accuracy of positioning and cutting. The portal and the bases for rail guides are made of thick aluminum for rigidity. Not at a loss to the weight and durability of the machine mechanics.

It is possible to connect a mouse and keyboard to control the interface. This greatly increases the convenience and speed of work.

The Russified display and software facilitate the training of new operators.

Tasks can be saved to the machine memory via USB, USB flash drive or local network.

The machine can consistently cut and engrave one task with multiple layers and settings. Preparation of tasks is carried out in the programs "Corel Draw" (using a plug-in), or "Laser Works".

Lifting table allows you to handle bulk products up to 250 mm. Also, it is possible to complete the machine with a rotary table. What will allow to process cylindrical objects.

Steel rail guides with metal hardness of 58 - 64 HRC, ensure durability and wear resistance of the machine kinematics.

The machine is also equipped with a two-zone exhaust system. The smoke is pulled down and out of the working area. Some equipment comes with a separate swirl hood.

Optionally, a set of flaps with remote control is installed to regulate exhaust zones.

The set also comes with additional lenses and nozzles for fine engraving or cutting of thick materials. They change quickly and quite conveniently.

Summarizing all the above, I would like to add that these machines have long been represented on the Russian market and have proven to be reliable and easy-to-use machines. A wide range of Raylogic allows you to select the machine for the tasks of a particular business or production. The cost of machine tools as of 2018 starts from 260-000 rubles. I am glad that in Russia there is a full-fledged service center, with a warehouse of spare parts. The issues related to maintenance and warranty repairs are resolved quickly and efficiently.

To view the catalog of Raylogic laser machines, please click here .

General catalog of CNC laser machines - 3dtool.ru/category/chpu/lazernye-stanki