Overview of high temperature FDM plastics for industrial 3D printing

The scope of application of additive technologies is wide: on one pole - desktop printers "only PLA", for decorative use, on the other - plants for direct printing with metals, between them - equipment and materials in the assortment. In order to understand what materials are necessary to obtain a solid and lightweight detail, we move from personal to industrial printing. PLA, ABS, SBS - consumables that are familiar to all printers. PETG, nylon, polycarbonate - rather exotic. But this is not the most serious materials.

Where do you need superplastic?

Plastics with outstanding properties are very useful in space. No, it’s impossible to print out a plastic rocket engine yet, the heat resistance is not even close, but it will fit perfectly for various parts around. An example is Stratasys and the “climate control” of Atlas V missiles. 16 printed parts instead of 140 metal parts are faster, easier, cheaper. And this is not a theoretical project, it has already flown into space.

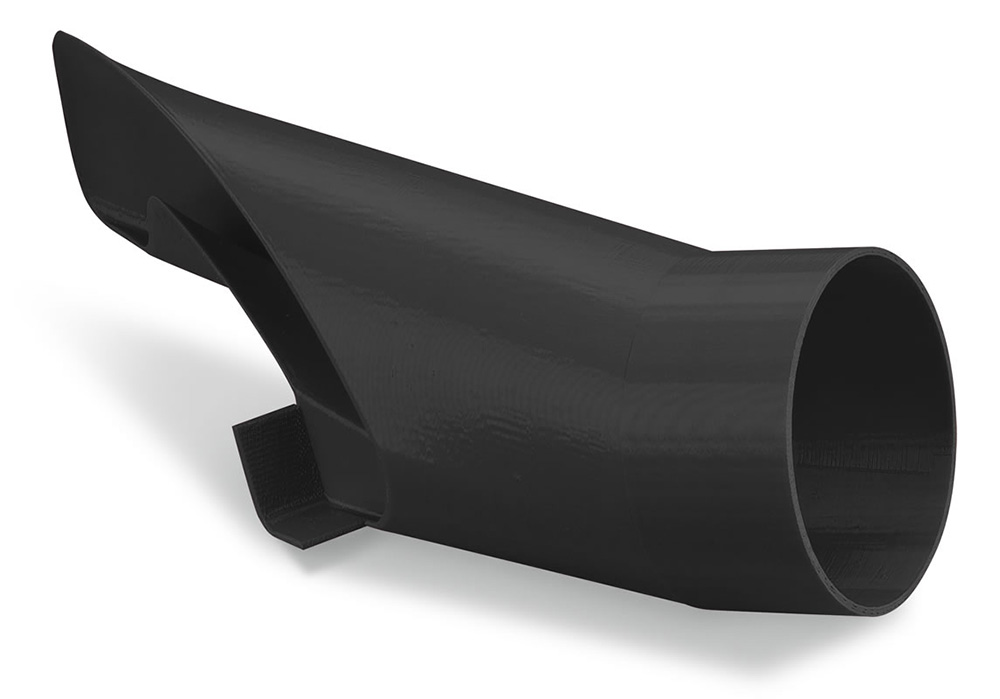

Another example is aviation. Flight altitude is lower, but the application is more massive. Here, too, there is a reason to reduce the mass of parts, to switch to plastic where it is possible. It is used in aircraft construction and direct printing with metals, when it comes to engine components or parts of the fuselage frame, but less loaded structural elements, such as interior ventilation and interior elements, should be made of plastic. This trend is developed, for example, by Airbus.

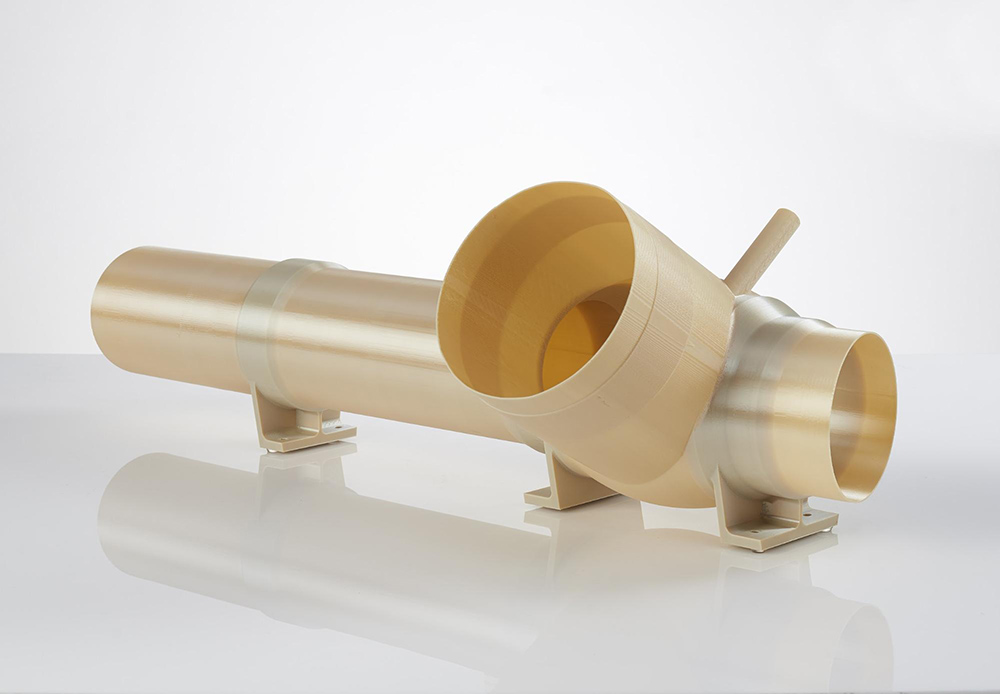

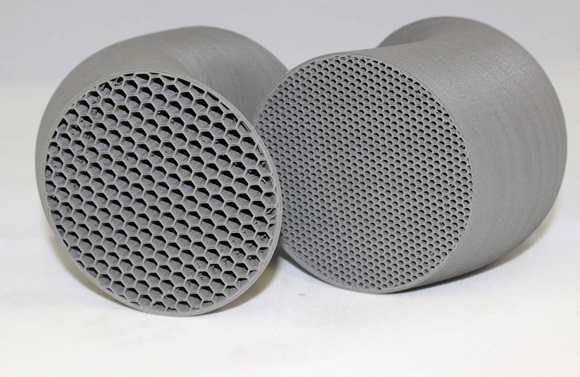

We descend from heaven to earth: here the mass is no longer so critical, other properties of engineering plastics are interesting. Resistance to aggressive chemistry and high temperature, the ability to create structures inaccessible to classical methods. At the same time - lower price, in comparison with the metal press. Printed products are used in medicine, oil and gas industry, chemical industry. As an example, a mixing unit with a complex channel structure, made for a sectional illustration.

Difference from usual plastics

Why not to launch PLA into space and not to make ventilation grates of the aircraft cabin from ABS? A number of requirements are applied to engineering plastics related to resistance to high and low temperatures, fire resistance, and mechanical strength. As a rule, all at once. So, “floating” when interacting with the PLA environment or perfectly burning ABS it is undesirable to launch into the sky.

Now to what plastics are actually used in industrial printing using FDM / FFF technology. Polycarbonate

Filaments

Polycarbonate is a plastic with high impact resistance and transparency that is widespread in the industry. It is also produced for the needs of FDM printing. The material holds the temperature better than ABS, is resistant to acids, but is sensitive to UV radiation and collapses when exposed to petroleum products.

Pure Polycarbonate, PC

The maximum operating temperature for polycarbonate products is 130 ° C. Polycarbonate is biologically inert, products from it withstand sterilization, it allows you to print packaging and auxiliary equipment for medicine.

- Stratasys PC , PC-ISO for Fortus printers. The first one is for general use, the second one is certified for biocompatibility, for medical use.

- Intamsys PC ;

- Esun ePC ;

- SEM PC ;

- PrintProduct PC ;

ABS / PC

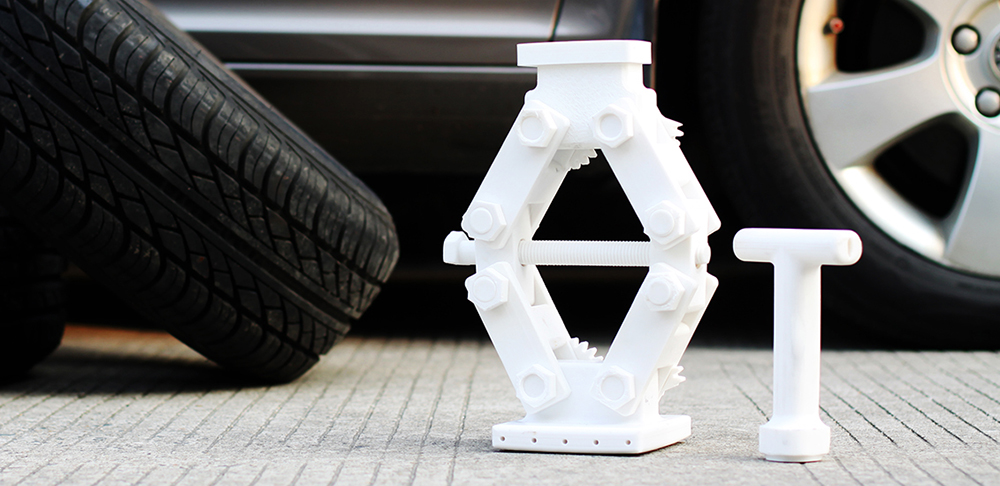

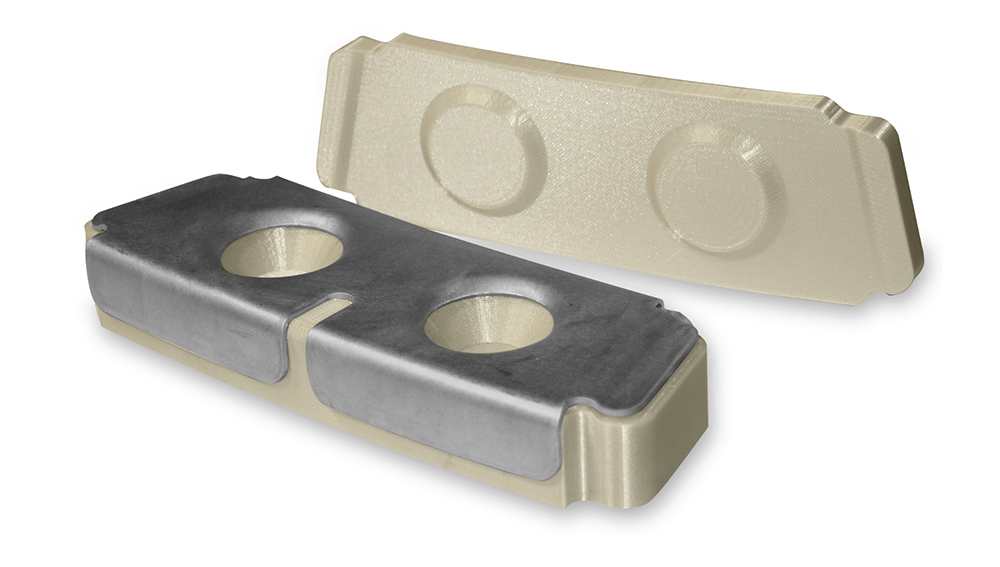

The polycarbonate and ABS alloy combines the abrasive and paint features of ABS with higher impact resistance and operating temperature. Keeps strength at low temperatures - up to -50 ° C. Unlike pure PC, it is better to apply in cases when it is necessary to eliminate the layered structure of the part by grinding or sandblasting. Application: production of housings and controls for single-piece and small-scale production, replacement of serial plastic parts in equipment, parts of which are no longer produced.

Polyamide based filaments

Polyamides are used in the manufacture of synthetic fibers; this is a popular printing material using the selective laser sintering method (SLS). For printing on FDM / FFF technology, polyamide-6 (capron), polyamide-66 (nylon) and polyamide-12 are mainly used. Common features of polyamide based filaments include chemical inertness and anti-friction properties. Polyamide-12 is more flexible and resilient than PA6 and PA66. The working temperature is about 100 ° C, individual modifications - up to 120.

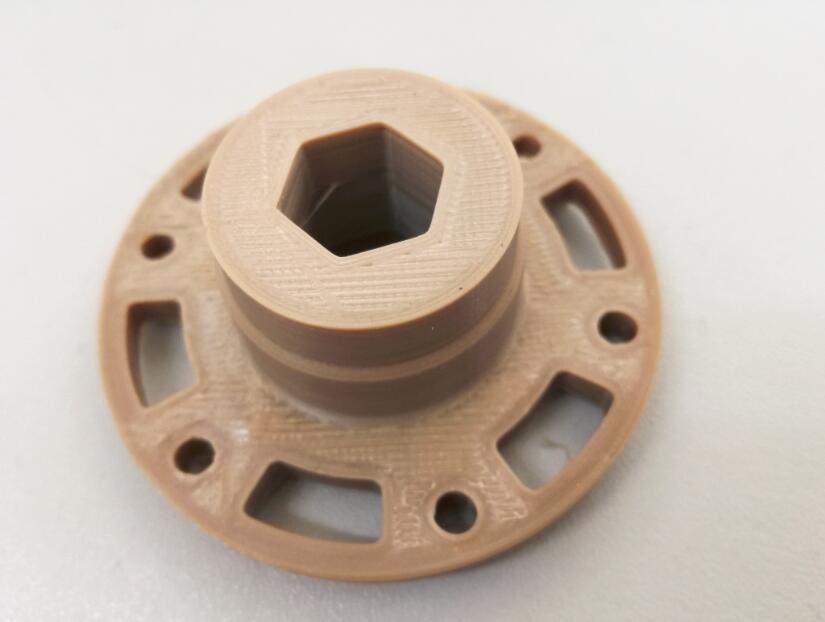

First of all, gears are printed from polyamide. The best material for this purpose, with which you can work on a regular 3D-printer with a closed camera. Resistance to abrasion allows you to make thrust, cams, sleeve sleeves. In the line of many manufacturers are present composite filaments based on polyamide, with even greater mechanical strength.

- Stratasys Nylon 6 , Nylon 12 , Nylon 12CF . The latter - with a filler in the form of carbon fiber.

- Intamsys Nylon , PA6.

- Taulman Nylon 618 , Nylon 645 - based on PA66 and PA6 respectively. Nylon 680 - approved for use in the food industry. Alloy 910 is a polyamide based alloy with reduced shrinkage.

- PrintProduct Nylon , Nylon Mod , Nylon Strong ;

- REC Friction ;

- BestFilament BFNylon .

We turn to the most interesting.

You can work with polycarbonate or polyamide on a regular 3D printer. With the filaments described below it is more difficult, they require other extruders and maintaining the temperature conditions in the working chamber, that is, you need special equipment for printing with high-temperature plastics. There are exceptions - for example, in NASA, for the sake of experiment, modernized Lulzbot TAZ, popular in the USA, to work with high-temperature filaments.

Polyetheretherketone, PEEK

The operating temperature of PEEK products reaches 250 ° C, short-term heating up to 300 is possible - figures for reinforced filaments. PEEK has two disadvantages: high price and moderate impact resistance. The rest is pluses. Plastic self-extinguishing, heat-resistant, chemically inert. Medical equipment and implants are produced from PEEK. Abrasion resistance allows printing of machine parts from it.

- Intamsys PEEK ;

- Apium PEEK ;

- Roboze PEEK , Carbon PEEK . The second is carbon fiber reinforced.

Polyetherimide, PEI

He is Ultem. The family of plastics developed by SABIC. The characteristics of PEI are more modest than those of PEEK, but the cost is noticeably lower. Ultem 1010 and 9085 - Stratasys basic materials for printing functional parts. PEI is in demand in the aerospace industry - the mass is much less in comparison with aluminum alloys. The operating temperatures of the products, depending on the modification of the material, reach 217 ° C according to the manufacturer’s information and 213 according to the test results of Stratasys.

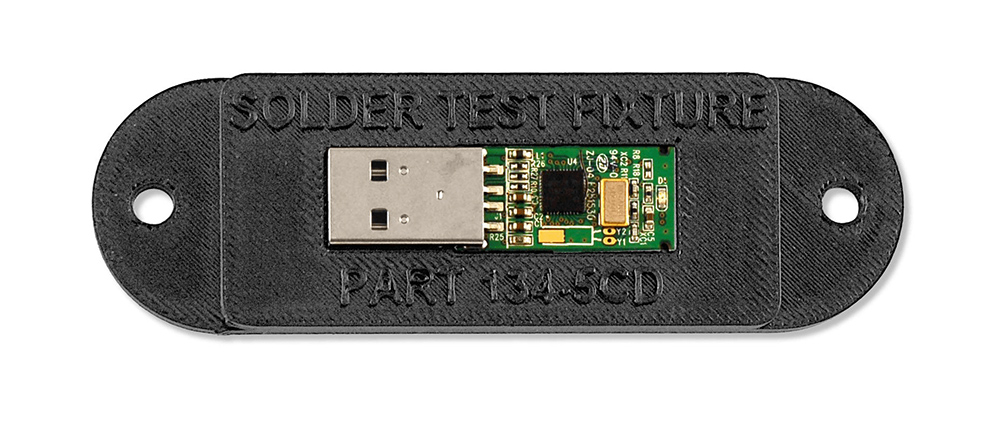

The advantages of PEI are the same as those of PEEK - chemical and temperature resistance, mechanical strength. It is this material that Stratasys promotes as a partial replacement for the metal in the aerospace industry, for UAVs, the manufacture of tooling for molding, rapid printing of functional parts in the pilot production.

The components of the Atlas V rocket cooling system and the plastic parts for Airbus liners, cited as an example at the beginning of the review, are made from Ultem 9085.

- Stratasys Ultem 1010 and 9085 , for Fortus 450mc and 900mc printers.

- Intamsys Ultem 1010 and 9085 ;

- Roboze Ultem AM9085F ;

- Apium PEI 9085 .

Polyphenylsulfone, PPSF / PPSU

Another material that combines in its properties temperature resistance, mechanical strength and resistance to chemical attack. Stratasys PPSF is certified for aerospace and medical applications. Positioned as a raw material for the production of auxiliary medical devices, it can be sterilized in steam autoclaves. Used in the manufacture of parts for laboratory installations in the chemical industry.

Polysulfone, PSU

Less common compared to PPSU, has similar physical characteristics, chemically inert, self-extinguishing. Operating temperature - 175 ° C, up to 33% cheaper compared to PPSU.

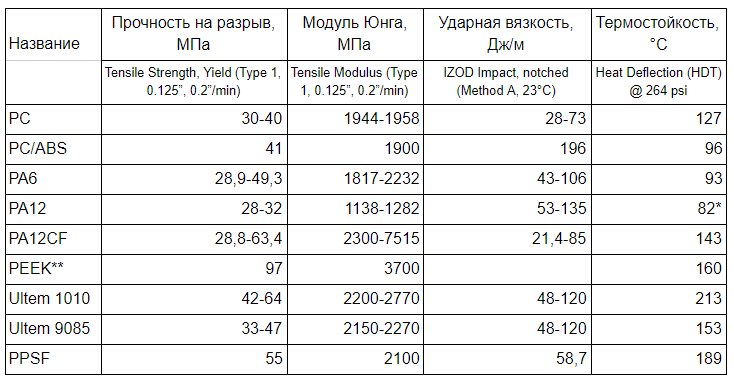

Comparison of filament characteristics

* calcination for 2 hours at 140 ° C.

** Apium PEEK 450 natural, no impact test results obtained by similar methods. Heat resistance indicated for unfilled PEEK.

Data is given for Stratasys filaments, with the exception of PEEK. If a range of values is indicated, then the tests were carried out along and across the layers of the part.

About composite filaments

Most materials for FDM printing have composite versions. If we talk about PLA, then it adds powders of metals or wood, to change the aesthetic properties. Engineering filaments are reinforced with carbon fiber to increase the rigidity of the part. The effect of such additives on the properties of plastic depends not only on their quantity, but also on the size of the fibers. If the fine powder can be considered a decorative additive, the fibers already significantly change the characteristics of the plastic. By itself, the word Carbon in the name of the material does not mean outstanding properties, you need to look at the test results. For example: Stratasys Nylon12CF has almost twice the tensile strength when tested along layers than Nylon12.

An exotic option - the implementation of continuous reinforcement from Markforged. The company offersreinforcing filament for joint FDM printing with other plastics.

Other specific properties

Engineering plastics are not only high temperature resistance and mechanical strength. For enclosures or boxes for storing electronic devices, as well as in working conditions with flammable volatile liquids, materials with antistatic properties are necessary. In the Stratasys lineup this is, for example, ABS-ESD7.

Conventional ABS is not UV resistant, which limits its use without a protective coating in the open air. As an alternative, the ASA is proposed, whose characteristics are close to ABS, except for the presence of UV resistance.

The original alternative

Plastic can replace metal in many areas, as it surpasses it in lightness, heat and electrical insulation, resistance to reagents. But before the physical indicators of metal products printouts from the best FDM-filaments do not reach.

The chemical giant BASF offers the Ultraduse 316LX FDM filament, with a mass fraction of stainless steel of 80%. The part is printed on an FDM printer, and then placed in a furnace where the bonding plastic is burned out and the metal is sintered. The part received in such a way goes much cheaper than that produced by the method of direct printing with metal. With an FDM printer and a suitable oven, no new equipment is needed.

Note that a similar solution is offered by the company Virtual Foundry - its Filamet, with bronze or copper powder, is baked in the same way. The choice of metal hints at decorative rather than engineering use.

In AIM3D own implementation of this principle - the printer ExAM 255 does not work with a filament, but with granules. This makes it possible to use raw materials for FDM printing, which are commonly used in MIM, Metal Injection Molding. For sintering parts, the company offers an ExSO 90 furnace . You can also print with plastic granules, which is usually cheaper than using traditional filaments.

Special engineering engineering plastics

To summarize In a nutshell: the considered consumables differ from the usual materials in high temperature printing, which requires the use of special equipment, and serious heat resistance and mechanical strength of the manufactured parts. To work with such filaments, 3D printers with an extruder operating temperature of 350 ° C and a thermally stabilized working chamber are needed. Experts Top 3D Shop will help you with the selection of industrial 3D-printer and plastics to solve the most interesting problems.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks: