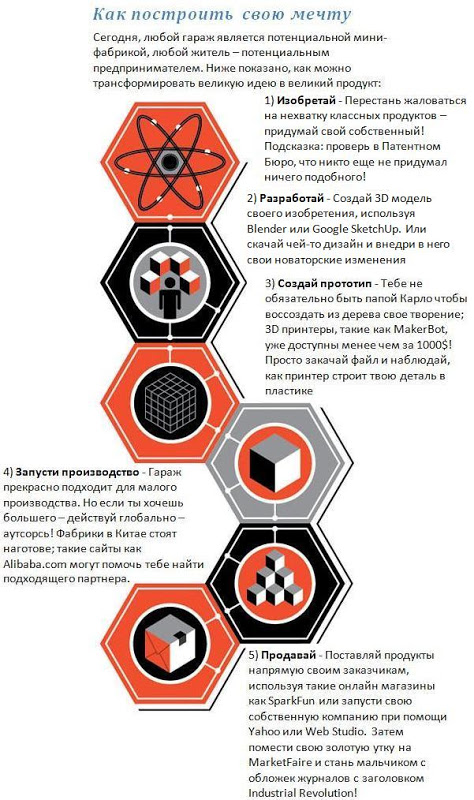

Industrial revolution. Part 4. How to build your dream

The following is a translation of a new part of the fascinating article in the Next Industrial Revolution, Atoms Are the New Bits by Wired magazine . Last time I talked about Rally Fighter , virtual mini-factories and a 3D printer for $ 1000 ; today you’ll learn how to transform your great idea into a great product, in other words, how to build your dream!

The following is a translation of a new part of the fascinating article in the Next Industrial Revolution, Atoms Are the New Bits by Wired magazine . Last time I talked about Rally Fighter , virtual mini-factories and a 3D printer for $ 1000 ; today you’ll learn how to transform your great idea into a great product, in other words, how to build your dream! To see how innovation was created in the 20th century, see the movie Flash of Genius . The film, based on real events, begins in the sixties, and tells the sad story of the invention of a car windshield wiper, working with a pause. Inventor ProfessorBob Kearns , - closes in his workshop until he receives a working prototype. Instead of selling the technology to the auto giants, Kearns decides to establish his own company in order to independently manufacture wipers. Ford signs a contract to install its invention on one of the new models. That means Kearns needs a factory! He rents a huge building and fills it with assembly lines, loaders, and other heavy equipment - the classic scene of the industrial age.

As Kearns approaches the launch of his plant, Ford suddenly withdraws from the deal. Having no prospects for profit, the factory closes without releasing a single wiper.

Eighteen months later, Kearns, returning home in the rain, suddenly sees a new Ford Mustang turning around the corner. The wiper passes through the glass, then freezes, then passes again. His brilliant idea was simply stolen! Kearns is depressed and will soon go crazy, and so on until the end of the film (in fact, the “real” Kearns sued Ford and Chrysler for copyright infringement and, after several years of litigation, sued about $ 30 million).

Kearns would have done differently today. As before, he would build the first prototype himself. But, instead of building a factory, he would order a case in one company, and an electronic filling in another. After which he would pay the Chinese manufacturer to assemble everything together. Wipers would be delivered directly to customers - automobile companies, and the entire process of setting up production would take several months, not years. Kearns could fulfill his dream and create a company without fighting windmills.

To see how this model is already working in the real world, go to the TechShop website of the do-it-yourself network of work platforms, where you can use the most advanced tools for rapid prototyping for only $ 100 per month.

To see how this model is already working in the real world, go to the TechShop website of the do-it-yourself network of work platforms, where you can use the most advanced tools for rapid prototyping for only $ 100 per month.Most recently, at a factory in Menlo Park, California, we saw Michael Pineo , a former manager of an artificial diamond company, design a special chamber for the production of colorless diamonds. And in the corner is the base of the landing module for the rocket, developed by a team that competes for the Google Lunar X Prize. At the other table, Stefan Weiss, vice president of Interoptix, together with one of their colleagues, assemble printed circuit boards for managing electrical networks. They produce batches of 50 units in size, which, according to Weiss, "still does not reach the factory, but enough to not be called a garage." On the devices is the sign of ABB - a giant engineering company. Customers may never know that their devices were made manually at a common production site.

It is an atomic age incubator. When the founder of TechShop, Jim Newton , was looking for a director for his enterprise, he quickly decided that Mark Hatch, the former head of Kinko, is like no one else suitable for this position. Similar to Kinko, which made printing more affordable by creating a national network of service centers, TechShop wants to make production more affordable. Now TechShop already has two additional production sites: in Darham, North Carolina and Bevearton, Oregon, and plans to open hundreds more. One site is located in San Francisco, in a building that previously occupied the largest edition of the San Francisco Chronicle, which significantly reduced its size. The irony is that the grains of the industry of the future sprout on the ashes of the industry of the past.

After lunch, Hatch makes an excursion into the history of production. In the era of industrialism, Karl Marx feared that, with the advent of factories, the artisan would no longer be able to afford the tools to do his job. The economy of mass production has supplanted individual production. The advantage of this approach is lower prices and quality products, and the disadvantage is their uniformity. Together with large retail chains, the market began to dominate the fruits of mass production - goods created for everyone.

However, today the means of production are becoming so cheap that many people can afford them. For example, modern machines that used to cost $ 150,000 can now be bought for $ 4,000 thanks to Chinese copies. Any garage is now potentially a high-tech factory. Marx would be pleased.

Blogger Jason Kottke pondered what to call this new class of entrepreneurs. Boutique is too defiant, and indie is not entirely true. As Kottke notes, the following terms have been proposed at present: "craftsman, artisan, studio, atelier, dojo, temple, and disco business." But it seems no one has hit the nail on the head.

Therefore, he proposed the term "small batch", which is most often used for bourbon. This term can mean a business for which product quality is more important than market size. Rather, they will do what they like, than launch mass production.

In order to take a look at an example of this approach, let's go to the neighborhood of Seattle, where you can meet Villa Chapman from BrickArms . Occupying a small area, BrickArms fills the gaps in the Lego product line, doing what the toy giant does not dare to produce: weaponsStarting with the AK-47 and ending with grenades that look like they were taken directly from Halo 3. Although they are more complex than the regular Lego component, their quality remains at the level of other Lego components. BrickArms products are sold online to thousands of fans — children and adults who want to create scenes that are more interesting than standard sets.

Lego manufactures products on an industrial scale with a team of developers working in a secret building in Billund, Denmark. Initially, engineers produce prototypes that are shipped to specific stores. Then, after approval, they are launched into mass production.

Chapman works on a different scale. He designs toys using SolidWorks, which can create the design of the part, the opposite of the one used for the production of molds. It sends the file to the Taig 2018 Mini Machine , which costs less than $ 1,000. The machine grinds a mold from aluminum billets. Then he puts it in a casting machine, melts several balls of resin and fills the mold. A few minutes later, the finished prototype is obtained. If fans like the prototype, Chapman contacts a local manufacturer to replicate the steel mold and a company that will manufacture a batch of several thousand toys.

Chapman works on a different scale. He designs toys using SolidWorks, which can create the design of the part, the opposite of the one used for the production of molds. It sends the file to the Taig 2018 Mini Machine , which costs less than $ 1,000. The machine grinds a mold from aluminum billets. Then he puts it in a casting machine, melts several balls of resin and fills the mold. A few minutes later, the finished prototype is obtained. If fans like the prototype, Chapman contacts a local manufacturer to replicate the steel mold and a company that will manufacture a batch of several thousand toys.Why not make ready-made toys directly in China? Chapman says that this could be done, but it would lead to "time delays and worse quality of the material." Moreover, as he says, “if your molds are in China, who knows what can happen to them if you do not use them? They can be used, for example, for the manufacture of toys, which will then be sold on the secondary market, which you will not even suspect ”

Chapman’s three sons pack toys, which he then sells directly to customers. Today, BrickArms has resellers in the UK, Australia, Sweden, Canada, and Germany. The business began to grow so fast that in 2008 Chapman left his 17-year career as a software engineer. Now he calmly provides for his family of five, solely through the sale of toy weapons. “Now I earn a lot more thanks to BrickArms than when I worked as a programmer.” Life is Beautiful!

To be continued…