Drones help to control the progress of excavation during the construction of the hospital

- Transfer

Brasfield & Gorrie, one of the largest private construction companies, uses a 3D model obtained using drones to compare actual excavation work on a construction site with planned targets.

According to this year ’s Goldman Sachs report , the construction sector will have the largest use of drones in the near future. We observed a similar trend when we analyzed user data in the DroneDeploy system when preparing the report “Using drones in industry and commerce”, - in the construction industry, the use of drones grew the fastest. Many were not surprised. Commercial and custom drone models today can easily fly around the construction area and quickly demonstrate the progress of construction on high-resolution maps and on three-dimensional models, which is a very effective solution compared to traditional methods.

However, despite frequent discussions of the benefits of using drones in the construction industry, there are not too many real stories from construction companies that actually use drones.

Therefore, we are pleased to present to you the story from one of the largest private players in the US construction industry, Brasfield & Gorrie, about using drones, in this case for obtaining a height map for the construction of a hospital and comparing it with a construction plan to evaluate performance.

Brasfield & Gorrie began using drones for observation a few years ago, but were forced to temporarily stop due to the need to obtain permission in accordance with the new regulations issued by the United States Federal Aviation Administration (FAA) on December 15, 2015. Today, the company is working with drones in the Virtual Design and Construction (VDC) group, in which 24 employees are engaged in optimizing construction processes by creating a digital model of construction progress.

Hunter Cole, coordinator of visual design, describes the group’s activities in this way: “we are involved in almost all the company's projects that require three-dimensional modeling”. Each regional branch office is equipped with DJI Inspire equipment.

. Be it aerial photography (photo or video), creating detailed 3D models using photogrammetry, drones allow you to quickly, safely and inexpensively collect information at all stages of construction.

During the construction of the hospital on a 61-acre site (24.4 hectares), the local branch of a construction company applied to the VDC group. The subcontractor announced the completion of preparatory earthworks, but the department manager was confident that the results of his work did not correspond to the planning documentation. Therefore, he requested the assistance of the VDC group to clarify the scope of work performed. The coordinator of the group Jesse Creech and field engineer Charles Curtis told us about the future.

“We were asked to find out the difference between the level of the construction site at the current time and the one that was planned,” said Charles Curtis.

Given the size of the construction site, drones were the best choice because measurement of vertical profile by traditional methods is a very long and costly process.

The VDC group hired a local dronebase service provider to fly around the site with the assistance of a licensed pilot. Dronebase circled the site using the Phantom 3 Pro model and the DroneDeploy mobile app to plan and automate the flight. Given the size of the site, it took to make several sorties. All the work took about an hour. Because it was supposed to use the obtained map for a comparative analysis; it was important that when overlaying the existing drawings it exactly coincided with them. To ensure accuracy, Brasfield & Gorrie used ground control points (GCP, ground control points) ( learn more about GCP and map accuracy).

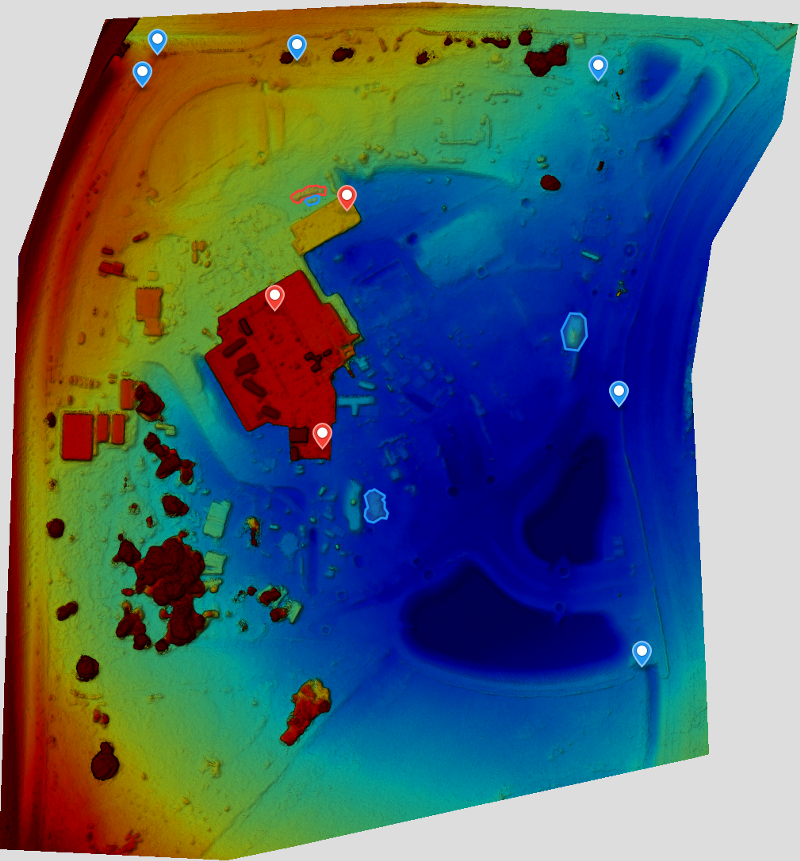

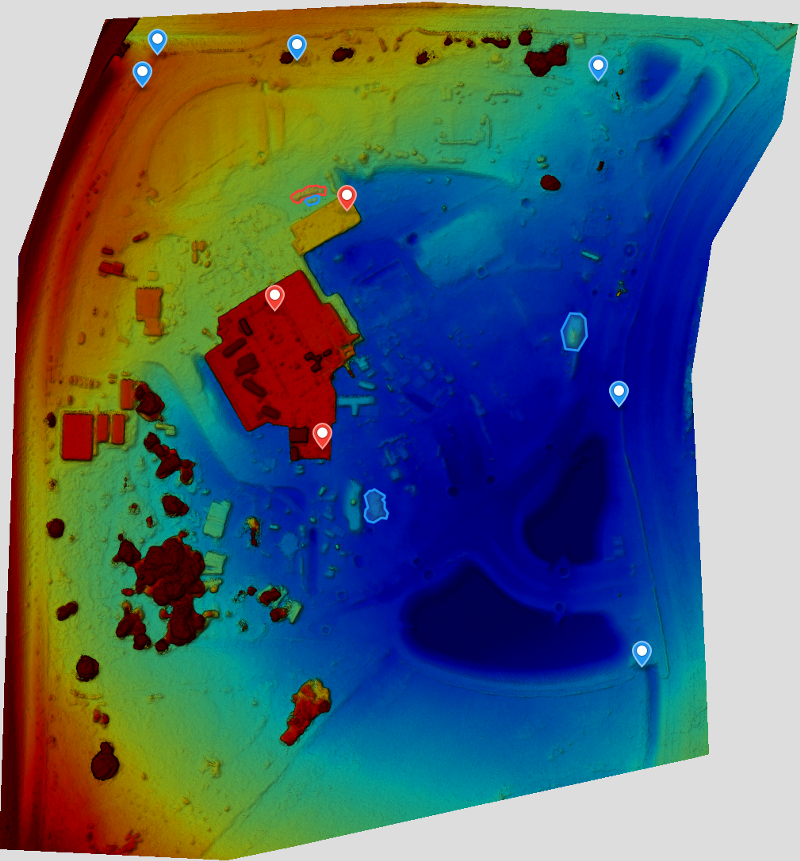

After circling the construction site, Brasfield & Gorrie uploaded the obtained images to the cloud platform DroneDeploy, which on the same day based on them presented an orthomazic map, a vertical profile map and a 3D model.

Ortho-mosaic map ( link to a large map with the possibility of approaching )

Click to view the elevation map .

Click to view the 3D model .

Having received the map from DroneDeploy, Jessie would then have to translate it into the same format in which the planned drawings were made, striving for maximum accuracy (i.e. that the geographic labels match on both maps).

Entering data on ground control points, he made sure that the map was precisely aligned (this is possible using DroneDeploy's Premier plan). Next, Jesse exported the 3D model as a point set to third-party software. And from there I transferred the model to the required coordinate system, which was used to create the drawings (now it can be done with the help of DroneDeploy, just typing in the 4-digit EPSG code, but at that time the VDC team did it through third-party software).

A visual projection of how a vertical profile correlates with a plan, using a three-dimensional point set .

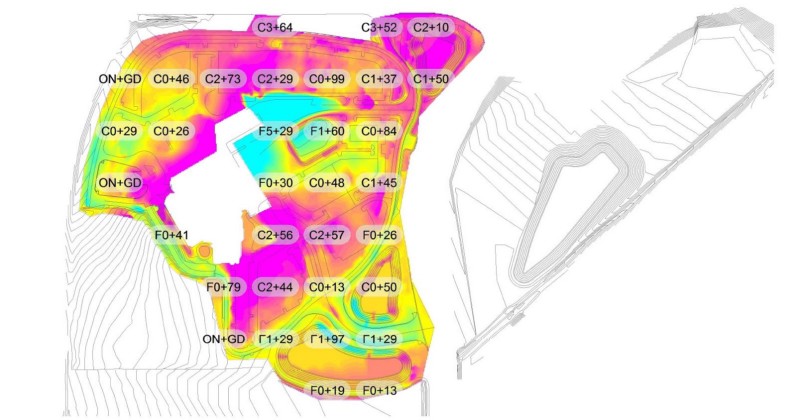

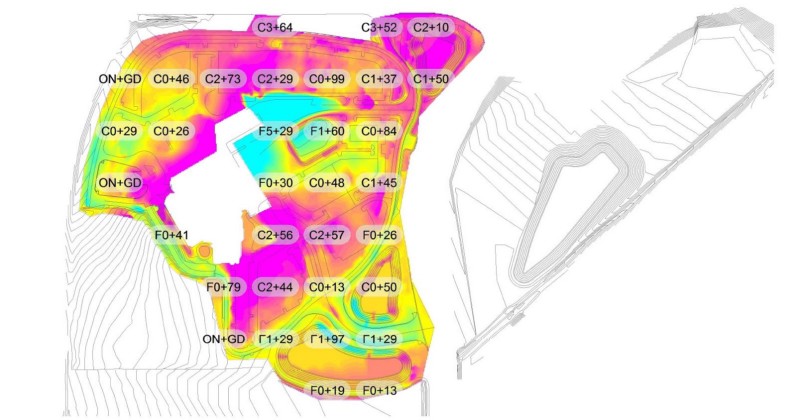

When both models were properly aligned, Jesse was able to compare them. The result was a heat map showing the results of earthworks and their deviations from the plan: the zones marked in green coincide with the plan, blue - too low, pink - too high.

Vertical profile comparison heat map: the zones marked in green coincide with the plan, the blue one is too low, and the pink one is too high.

On the heat map of Jesse, you can clearly see what was done by the subcontractor.

Using drones, VDC was able to evaluate the results of earthworks much faster than if traditional methods were used without losing accuracy.

According to field engineer Charles, this kind of work previously would have required more than 1,000 verification shots.

And even if 1000 shots sound like a lot, the drone easily captures much, much more data, which allows you to create a much more accurate model of the vertical profile of the pad.

The speed of data analysis is in principle comparable to the speed when using other methods, but Charles is confident that the process will improve over time. “We learned a lot from this process, and I feel that in the future we will be able to increase the accuracy and significantly reduce the time for processing and analyzing data,” he said.

Overall, this example illustrated the tremendous time and resource savings that Brasfield & Gorrie can provide for a topographical survey made by drones. “The speed at which a drone can fly around and take detailed pictures saves a lot of time. According to my feelings, we spent three times less time on it than if we did it manually, ”- said Charles. Jesse summed it up:

Have you thought about introducing drones into your construction business? The VDC group from Brasfield & Gorrie can give you some tips:

According to this year ’s Goldman Sachs report , the construction sector will have the largest use of drones in the near future. We observed a similar trend when we analyzed user data in the DroneDeploy system when preparing the report “Using drones in industry and commerce”, - in the construction industry, the use of drones grew the fastest. Many were not surprised. Commercial and custom drone models today can easily fly around the construction area and quickly demonstrate the progress of construction on high-resolution maps and on three-dimensional models, which is a very effective solution compared to traditional methods.

However, despite frequent discussions of the benefits of using drones in the construction industry, there are not too many real stories from construction companies that actually use drones.

Therefore, we are pleased to present to you the story from one of the largest private players in the US construction industry, Brasfield & Gorrie, about using drones, in this case for obtaining a height map for the construction of a hospital and comparing it with a construction plan to evaluate performance.

Drones in Brasfield & Gorrie

Brasfield & Gorrie began using drones for observation a few years ago, but were forced to temporarily stop due to the need to obtain permission in accordance with the new regulations issued by the United States Federal Aviation Administration (FAA) on December 15, 2015. Today, the company is working with drones in the Virtual Design and Construction (VDC) group, in which 24 employees are engaged in optimizing construction processes by creating a digital model of construction progress.

Hunter Cole, coordinator of visual design, describes the group’s activities in this way: “we are involved in almost all the company's projects that require three-dimensional modeling”. Each regional branch office is equipped with DJI Inspire equipment.

. Be it aerial photography (photo or video), creating detailed 3D models using photogrammetry, drones allow you to quickly, safely and inexpensively collect information at all stages of construction.

Excavation work at the hospital construction site

During the construction of the hospital on a 61-acre site (24.4 hectares), the local branch of a construction company applied to the VDC group. The subcontractor announced the completion of preparatory earthworks, but the department manager was confident that the results of his work did not correspond to the planning documentation. Therefore, he requested the assistance of the VDC group to clarify the scope of work performed. The coordinator of the group Jesse Creech and field engineer Charles Curtis told us about the future.

“We were asked to find out the difference between the level of the construction site at the current time and the one that was planned,” said Charles Curtis.

Given the size of the construction site, drones were the best choice because measurement of vertical profile by traditional methods is a very long and costly process.

Flying around the area

The VDC group hired a local dronebase service provider to fly around the site with the assistance of a licensed pilot. Dronebase circled the site using the Phantom 3 Pro model and the DroneDeploy mobile app to plan and automate the flight. Given the size of the site, it took to make several sorties. All the work took about an hour. Because it was supposed to use the obtained map for a comparative analysis; it was important that when overlaying the existing drawings it exactly coincided with them. To ensure accuracy, Brasfield & Gorrie used ground control points (GCP, ground control points) ( learn more about GCP and map accuracy).

After circling the construction site, Brasfield & Gorrie uploaded the obtained images to the cloud platform DroneDeploy, which on the same day based on them presented an orthomazic map, a vertical profile map and a 3D model.

Ortho-mosaic map ( link to a large map with the possibility of approaching )

Click to view the elevation map .

Click to view the 3D model .

Comparison of the plan and the actual state of the construction site

Having received the map from DroneDeploy, Jessie would then have to translate it into the same format in which the planned drawings were made, striving for maximum accuracy (i.e. that the geographic labels match on both maps).

Entering data on ground control points, he made sure that the map was precisely aligned (this is possible using DroneDeploy's Premier plan). Next, Jesse exported the 3D model as a point set to third-party software. And from there I transferred the model to the required coordinate system, which was used to create the drawings (now it can be done with the help of DroneDeploy, just typing in the 4-digit EPSG code, but at that time the VDC team did it through third-party software).

A visual projection of how a vertical profile correlates with a plan, using a three-dimensional point set .

When both models were properly aligned, Jesse was able to compare them. The result was a heat map showing the results of earthworks and their deviations from the plan: the zones marked in green coincide with the plan, blue - too low, pink - too high.

Vertical profile comparison heat map: the zones marked in green coincide with the plan, the blue one is too low, and the pink one is too high.

On the heat map of Jesse, you can clearly see what was done by the subcontractor.

According to the results of the comparison, it became clear that it is necessary to withdraw additional volumes of soil to achieve the required indicators for earthworks.

Faster data collection leads to higher returns.

Using drones, VDC was able to evaluate the results of earthworks much faster than if traditional methods were used without losing accuracy.

According to field engineer Charles, this kind of work previously would have required more than 1,000 verification shots.

“Usually we would use automated tacheometers to compile a grid of height points. I would have to use at least a 50 x 50 grid for a similar site. With an area of 61 acres, it would have taken more than 1,000 individual images with different settings. Combining this with regular work, we would spend many weeks and would seriously get out of schedule. This 1000 shots will not allow us to learn about all the piles of waste land or ditches, so to maintain accuracy we would have to explore all the contours of unspecified parts, which will significantly increase the number of shots, ”says Charles.

And even if 1000 shots sound like a lot, the drone easily captures much, much more data, which allows you to create a much more accurate model of the vertical profile of the pad.

“Getting a lot of points, representing the entire site, in a couple of hours using a drone, is a huge advantage for the budget and the schedule,” said Jesse.

The speed of data analysis is in principle comparable to the speed when using other methods, but Charles is confident that the process will improve over time. “We learned a lot from this process, and I feel that in the future we will be able to increase the accuracy and significantly reduce the time for processing and analyzing data,” he said.

Overall, this example illustrated the tremendous time and resource savings that Brasfield & Gorrie can provide for a topographical survey made by drones. “The speed at which a drone can fly around and take detailed pictures saves a lot of time. According to my feelings, we spent three times less time on it than if we did it manually, ”- said Charles. Jesse summed it up:

“Having spent a little time and money, we were able to find out the result of the excavation work and draw conclusions that in other cases it can be a very expensive and lengthy process. In this case, the ROI is very high. ”

Tips and best ways to use drones in the construction industry

Have you thought about introducing drones into your construction business? The VDC group from Brasfield & Gorrie can give you some tips:

- think through your task beforehand. There are no two identical construction sites, as well as identical difficulties with them. The worst thing you can do is to come to the site without a specific flight plan;

- set goals for yourself. Have an idea of what you will do with the information before you collect it, as this will allow you to select the level of detail needed to complete the task;

- Ensure compliance with the requirements of the US Federal Aviation Administration (FAA). Be prepared to refuse the customer if order fulfillment involves a violation of safety or legislation;

- Enlist the help of these pilots. Brasfield & Gorrie attracted a licensed pilot to work in order to be able to use drones for commercial purposes;

- Explore the market carefully before buying drones - technology is moving fast.