Scientists have printed a soft heart that works like a real

Over the past few years, the science and art of prosthetics has rapidly developed, and research in the field of soft robotics has been particularly interesting. The same methods that are used in the design of roboruki help to create more complex and subtle designs, including the heart.

A quality artificial heart is a necessity: about 26 million people worldwide suffer from heart failure, and there are not enough organs from donors. Artificial blood pumping pumps help reduce the waiting time until the patient receives the donor's heart or restores its own work.

Today, effective robots that completely replace such an important organ as the heart do not exist. However, there are useful developments that partially compensate for the function of the heart. For example, a soft robotic clutch, developed by researchers at Harvard University and Boston Children's Hospital, is made exactly along the contours of the heart and surrounds it, and then reduced in time with the natural rhythm, helping the body to cope with work in conditions of heart failure.

In Switzerland, scientists managed to create an artificial human heart, as close as possible to the real one. Silicone model developed by doctoral student Nicholas Cors (Nicholas Cohrs) under the guidance of Wendelin Stark (Wendelin Stark), professor of functional materials inSwiss Higher Technical School Zurich .

There are many reasons why scientists seek to recreate the natural forms and functionality of the heart in an artificial implant. In the pumps that are used now, there are drawbacks: their metal and plastic mechanisms in some cases are difficult to integrate with natural tissues after transplantation, and the patient has no physiological pulse. Therefore, the goal of scientists is to create such an artificial heart, which is as close as possible to the organic heart.

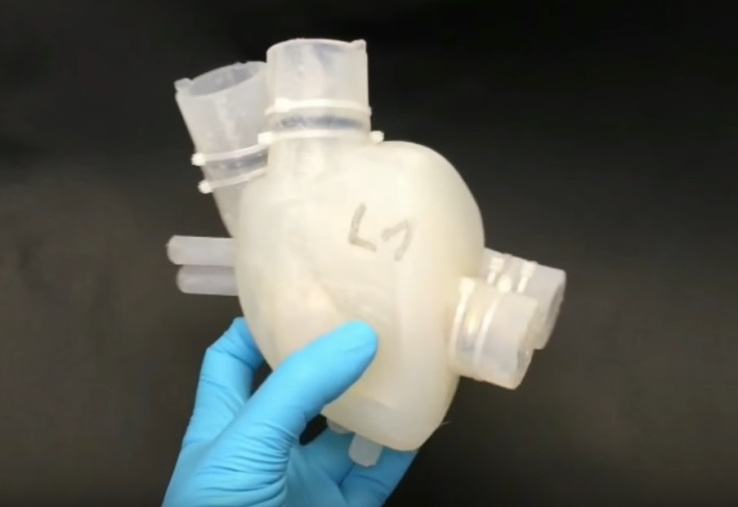

The researchers printed a soft artificial silicone heart using wax casting technology to create a complex internal structure while maintaining the softness and flexibility of the starting material. The heart itself is a monoblock, so there is no need to worry about how the mechanical parts of the heart will interact with the tissues of the body, with the exception of the input and output arteries through which blood will flow to the implant.

Such a heart of 679 cm 3 weighs 390 grams. For comparison, the average weight of a human heart is 331 grams. The model consists of a right and left ventricle, which are separated not by a septum, but by an additional camera. Compressed air passes through this chamber, which pumps liquid from one chamber to another, simulating the contraction of a person’s heart muscles.

Another group of researchers appreciated the work of this artificial heart. Scientists have confirmed that it works and contracts like a human heart. Nevertheless, he still has a problem: now the model withstands about 3 thousand blows - 30-45 minutes of continuous work, and then the material does not withstand deformation.

Kors explains that their goal was not to present a heart ready for implantation, but to set a new direction for the development of artificial hearts. Of course, they plan to significantly increase the strength and performance of the material.

All work was done at the University of Medicine Zurich as part of the Zurich Heart Project. In total, there are 20 research groups from different institutions of Zurich and Berlin. Some studies focus on improving existing blood pumps, for example, reducing blood damage caused by the operation of the mechanical parts of the pump. The other team is exploring elastic membranes and other biocompatible materials and surfaces.

It also developed an environment for testing artificial hearts, with which you can simulate the human cardiovascular system. The Kors team used it for their development process, which also included working with a fluid comparable in viscosity to human blood.

doi: 10.1111 / aor.12956