Juicero Juicer - quality, but too complicated and expensive product

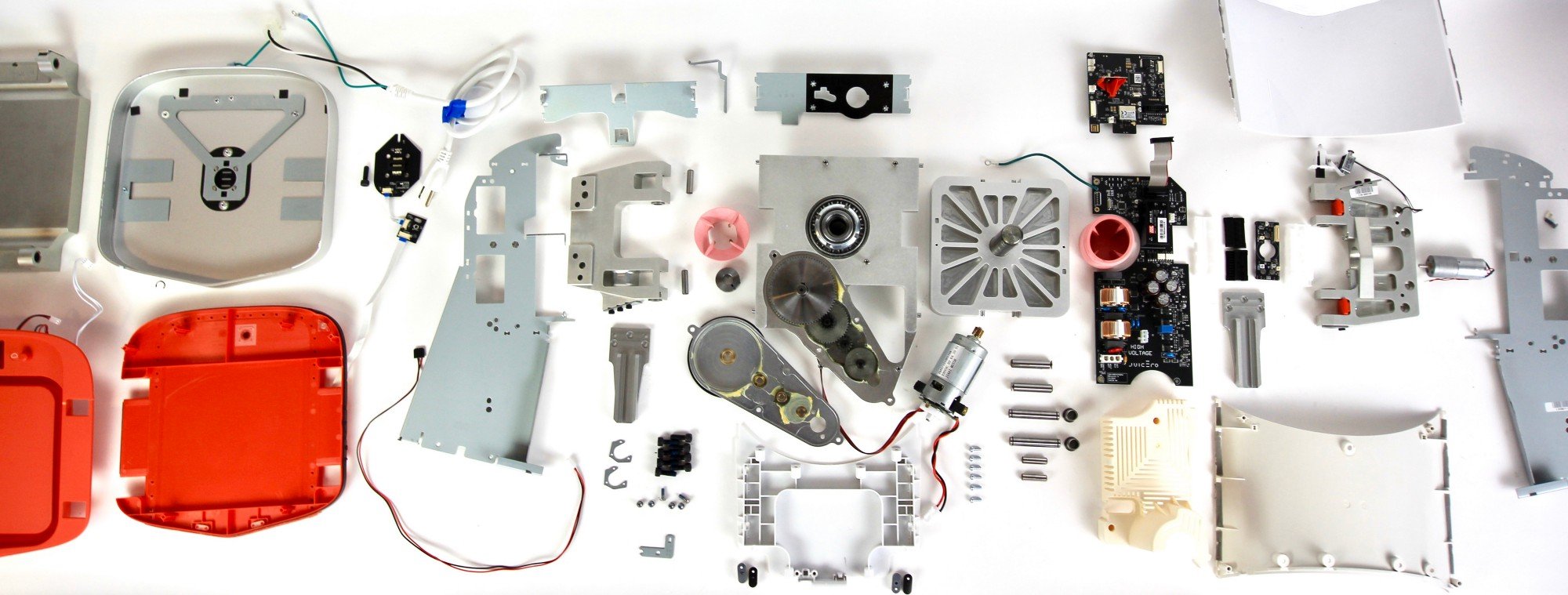

Disassembled Juicero Juicer. Source: bolt.io

Last week , an article about an “innovative” Juicero juicer that collected more than $ 120 million during a crowdfunding campaign was published in Geektimes . This juicer, as the developers said, develops enormous pressure to squeeze the maximum amount of juice out of a special bag of vegetables or fruits. The cost of the device at the beginning of sales was $ 699, now, however, the price has been reduced to $ 399. As it turned out, the juice from the packages for Juicero can be squeezed without any problems. The creators of the juicer said that there would still be people who would like to get fresh juice "using their phone" (the device is controlled wirelessly) without unnecessary worries and troubles.

Most Web users blamed developers for fraud, calling them scammers. The craftsmen from the Bolt site decided to disassemble the device to see if the juicer complies with the quality and functionality declared by its creators. Looking ahead, you should immediately say that yes. Moreover, according to the craftsmen who disassembled the device, it turned out to be too complicated, although perfectly designed. What can be in a normal, let and wireless juicer?

Under the white plastic hides the base of the metal. Immediately noticeable that the engineers treated with attention to every detail. The materials that were used are obviously not cheap.

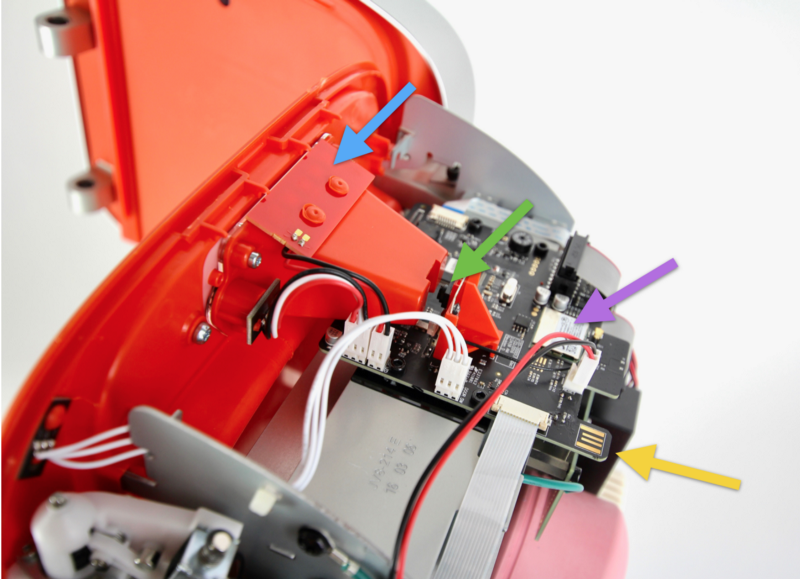

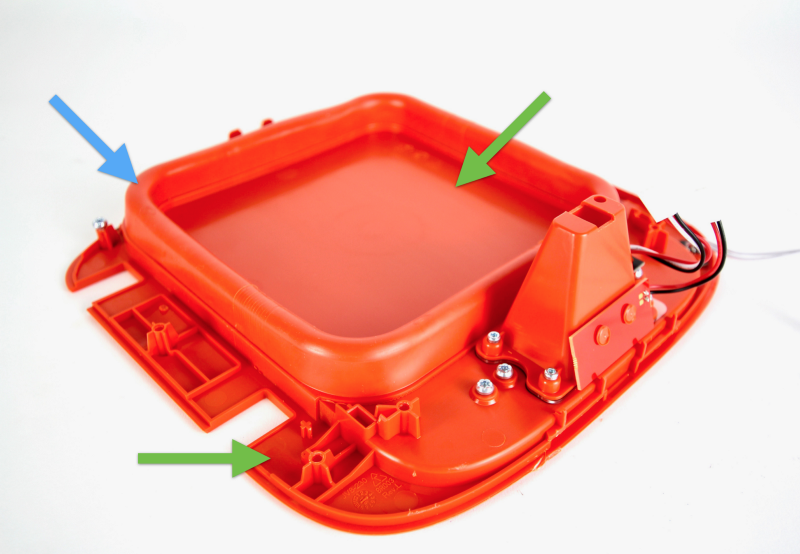

Under the case also hides a board that ensures the operation of the device in a wireless network. It uses the TI CC3200 chipset, plus there is a camera for reading a bar code (indicated by a blue arrow) and a control system based on the STM32F407 ARM processor. By the way, the firmware can be updated using a USB cable (the connector is shown with a yellow arrow).

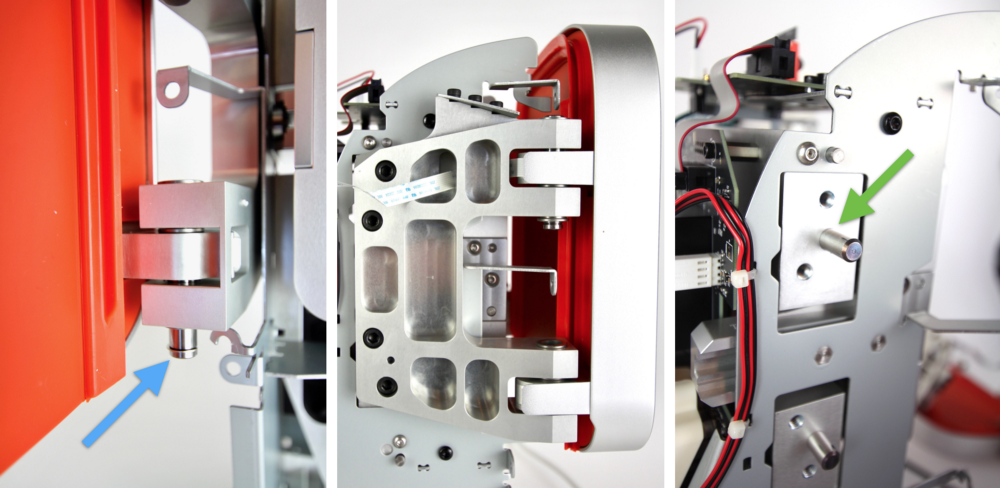

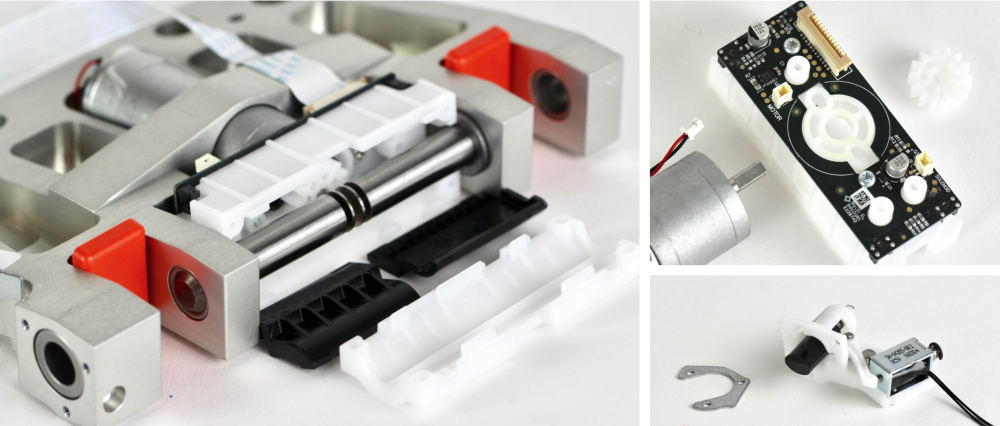

In order to withstand the pressure produced by the engine with the transmission, the developers have made the main working parts massive. They are made of aluminum.

All parts are placed inside a relatively massive metal case (mount shown by blue arrows). The yellow arrow shows a cunning mechanism that locks the door when squeezing the juice out (this mechanism will be discussed in more detail below), the green arrow points to a metal plate that squeezes the juice out of the bags.

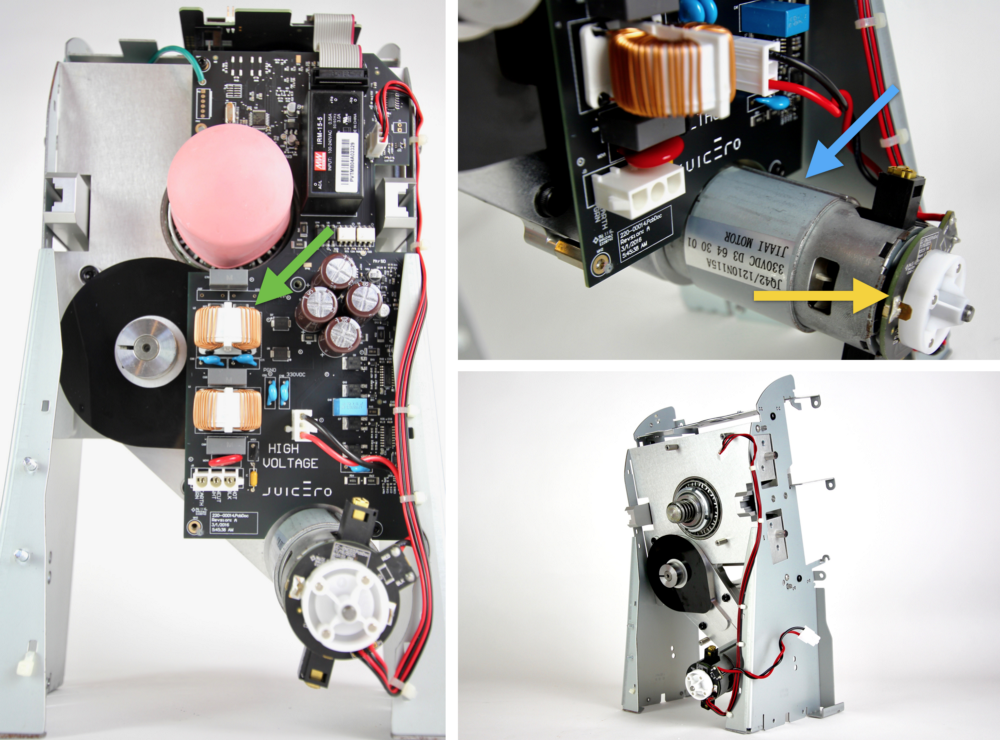

The electro-mechanical part is well designed too. Inside there is a transformer from 120/240 to 330 volts. According to those who disassembled the device, the custom power system of the juicer is excellent, but it “pulled” additional funds and risks during certification.

The electric motor JQ42-1210N1 is indicated by a blue arrow. It is produced by Jiaai Motor Company. The yellow arrow shows the custom angle sensor from Juicero.

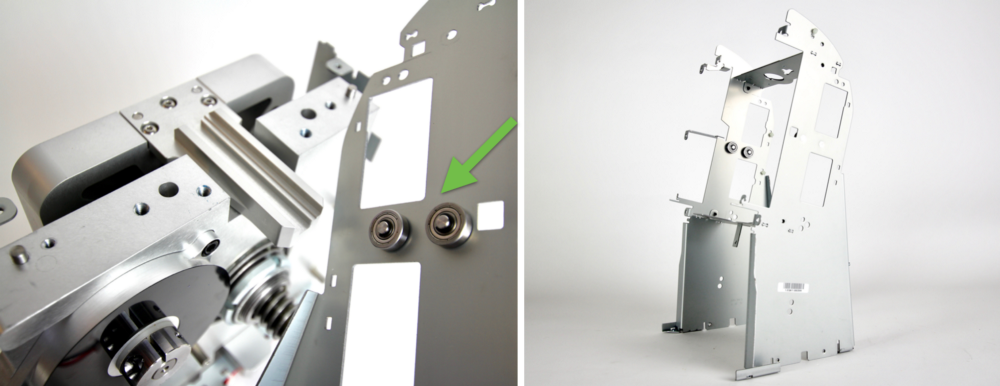

If you remove all the details from the metal frame, special fasteners open to ensure that the mechanism slides when squeezing out the juice. Those who disassembled the device, they say that everything is done just perfect. Engineering thought obviously worked well, and no one was sorry for the money for the construction and materials.

All parts are high quality and expensive , including the gear system and even bearings. Only the drive shaft with bearings, according to craftsmen who have studied the design of the juicer, can cost about $ 35.

What's wrong here

Without a doubt, the task to save in the development and assembly of the device to the developers did not stand. Designed device quality. Systems are complex, carefully assembled. Once again, it can be repeated that all this is very expensive.

There are many non-standard parts and systems. Having calculated the price of the parts used in the assembly of the juicer, it can be assumed that their total price is about half the cost of the device. For example, the plastic part shown below costs about $ 4-6. And this is plastic, and in fact metal, machined parts are much more expensive.

But in many cases the question arises: “Why?”. Why so many difficulties in order to get an ordinary press, at least a radio-controlled? For example, only in order to keep the door closed, such systems and elements are used:

- Massive aluminum base;

- 10 molded parts;

- 1 solenoid;

- Motor and control board;

- 2 stamped steel parts;

- 2 non-standard locating pins;

- 4 sleeves;

- The mechanism itself is constipation;

- A pile of screws, connectors, cables. Connecting materials.

Once again - this is all in order to keep the door closed.

And once again - all this most complicated technique is needed in order to squeeze the juice out of the package. A similar operation can be performed with your own hands without great pressure. Yes, some of the liquid will remain in the package, but not so much.

The developers explain this by saying that a person does not press immediately on the entire package, but on certain points, developing considerable pressure on a small area. The juicer produces pressure over the entire area of the bag at the same time, and it takes much more effort to squeeze out the juice than with the hands

As mentioned above, the entire set of parts for the price goes in half the cost of a juicer. The rest is marketing, the cost of forming an ecosystem (contracts with farmers, logistics, product processing, etc.). Little remains and developers.

In general, the developers have created a perfectly assembled, perfectly functioning apparatus with an ecosystem of products and a built-in supply chain, which ... is too expensive for the real Central Asian of this juicer. Yes, geeks bought and bought it, but not in the amount that could be if the juicer were created based on the needs of real consumers. As far as can be judged, the project itself is not a scam, since everything is prepared too well and efficiently. The developers simply created their product based on their own preferences, rather than the needs of potential buyers.

It is impossible to name the failed project, because it raised $ 120 million. But it is unlikely that it will exist for any length of time, despite its entire ecosystem and two-year product preparation by developers.

The juicer itself is a kind of Goldberg machine - it performs its task, but it is extremely complicated. But in reality, the juicer is not needed at all - the juice can be squeezed out of the package by hand without any machinery. So maybe the Juicero representatives will simplify everything, and start selling their bags of fruit or vegetable filling, modifying them to squeeze out the juice with your hands?