Raise3D N1 Dual Review from REC

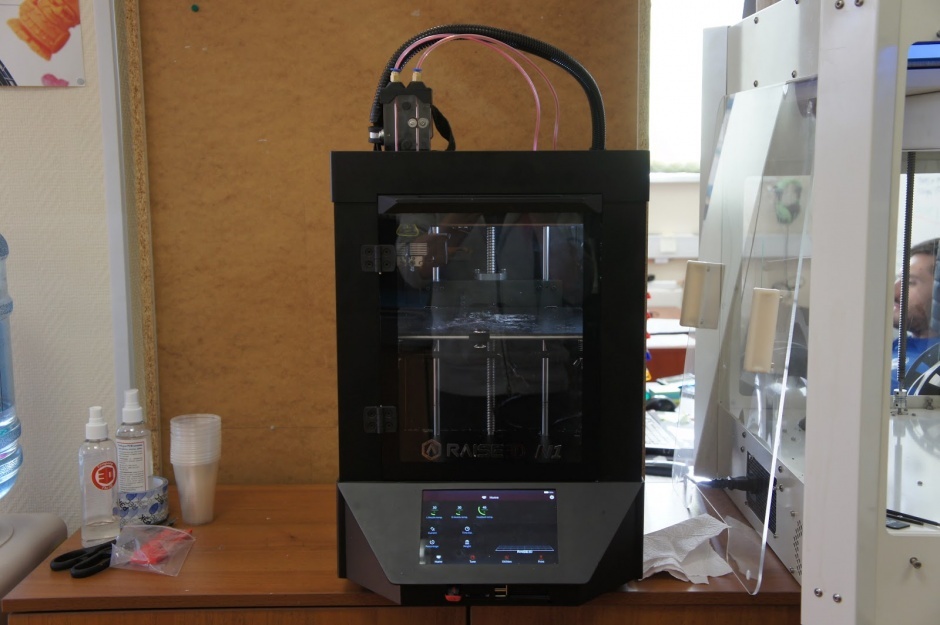

Hello! Meet the review of the 3D-printer Raise 3D N1 Dual. This is an amazing two-extruder 3D printer from China.

General

1. External dimensions - 362x529x651 mm.

2. The print area is rectangular, 205x205x205 mm.

3. The weight is 22 kg (as stated, we did not measure, but it seems easier).

4. The maximum movement speed of the head is 150 mm / s.

5. The minimum layer is 0.01, the base nozzle is 0.4 mm.

6. The package includes a thermal desk, a color LCD touch screen with its own interface, removable mounting frames for coils, 4 usb.

7. It is stated by the manufacturer that Raise 3D prints with many polymers and can heat the extruder up to 300 degrees.

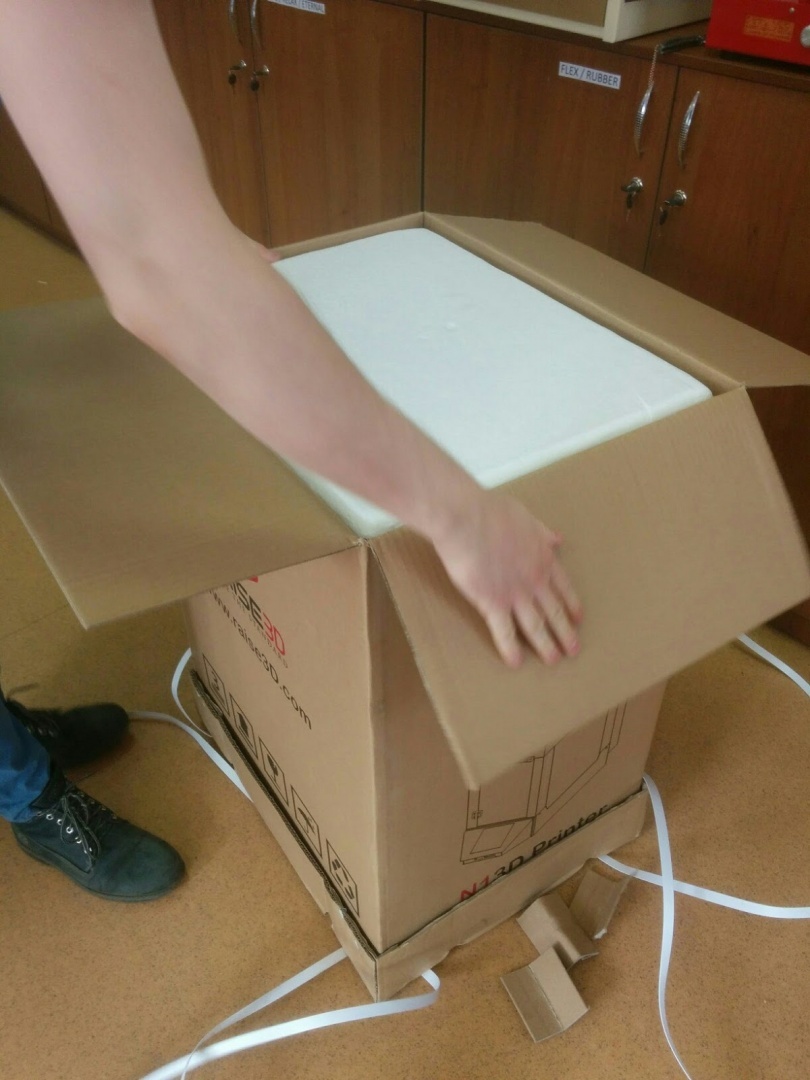

Packaging and equipment The

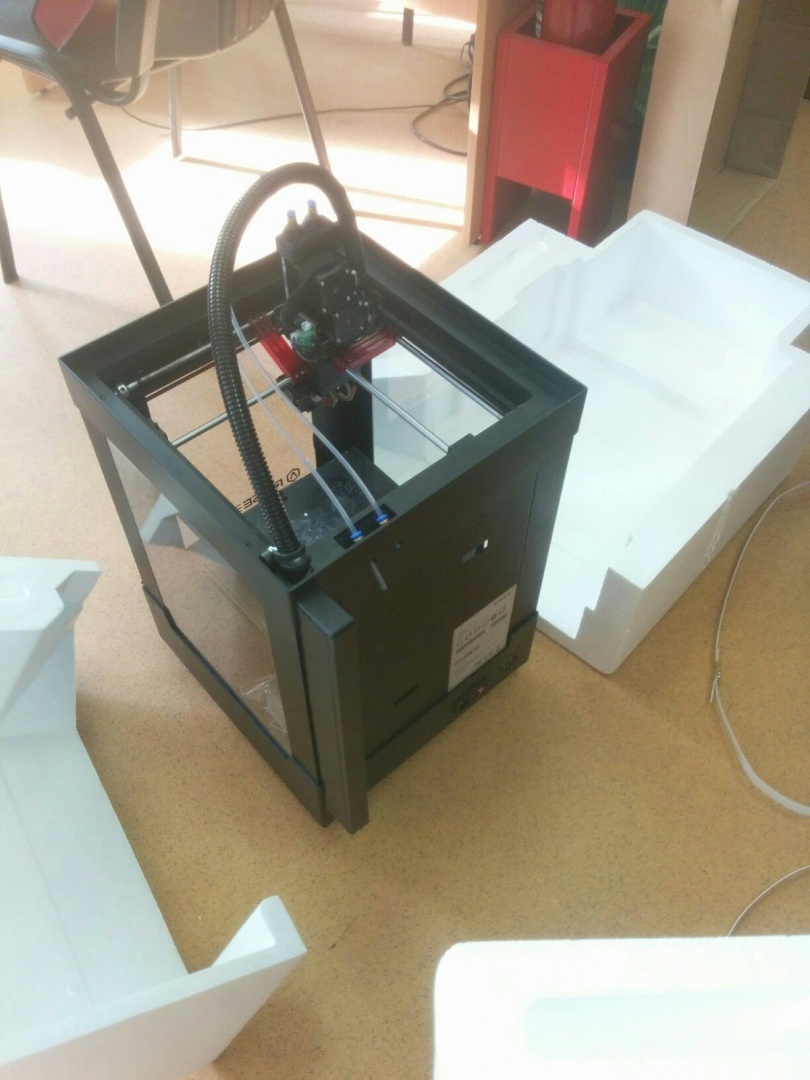

printer is packed really soundly. Large pieces of foam that protect the printer.

The package includes a great instruction, two branded holder for the coils, power cable, USB flash drive, two plastic coils, a set of hexagons, and a couple of nice little things.

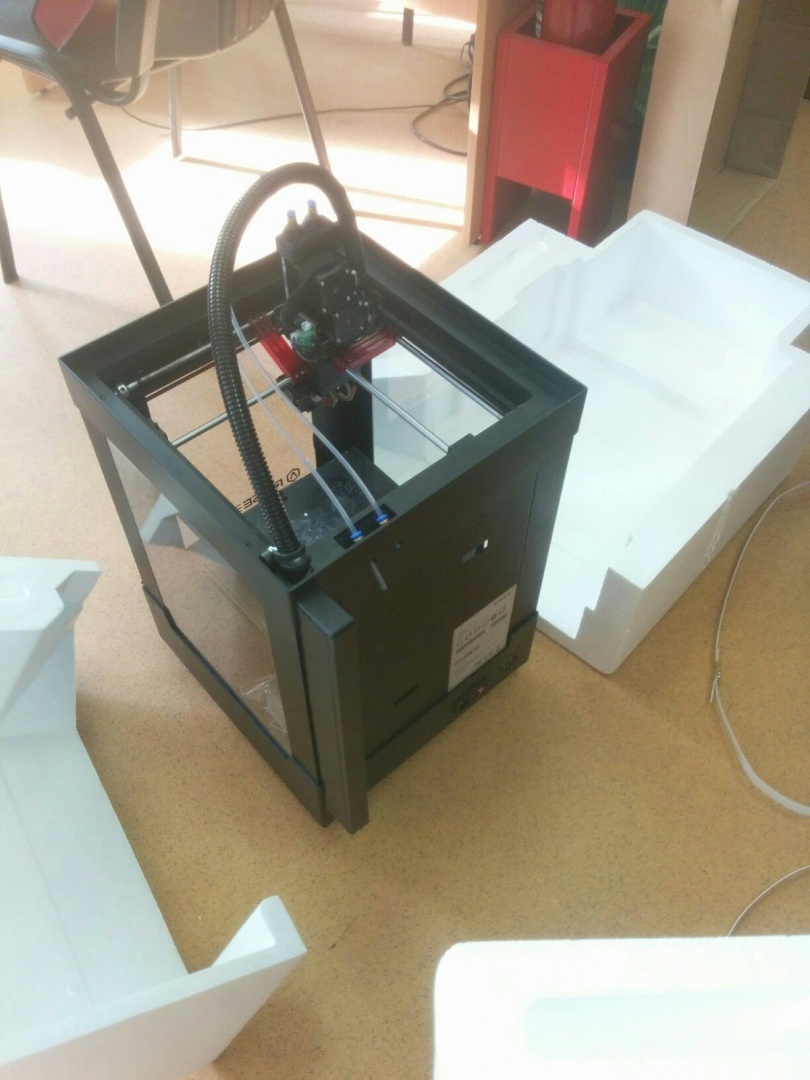

Appearance and technical nuances The

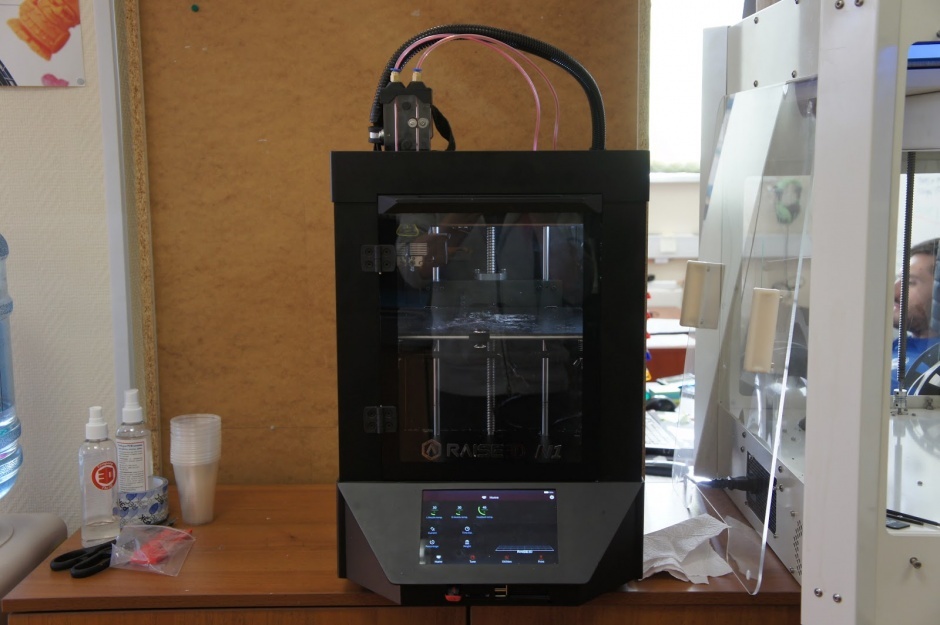

printer has a very aesthetic, durable and rigid body.

The dashboard and connectors are conveniently located for the user.

Touch screen with clear and stylish design. For beginners 3D printing this solution will be extremely convenient.

It displays the process and print settings, impressive.

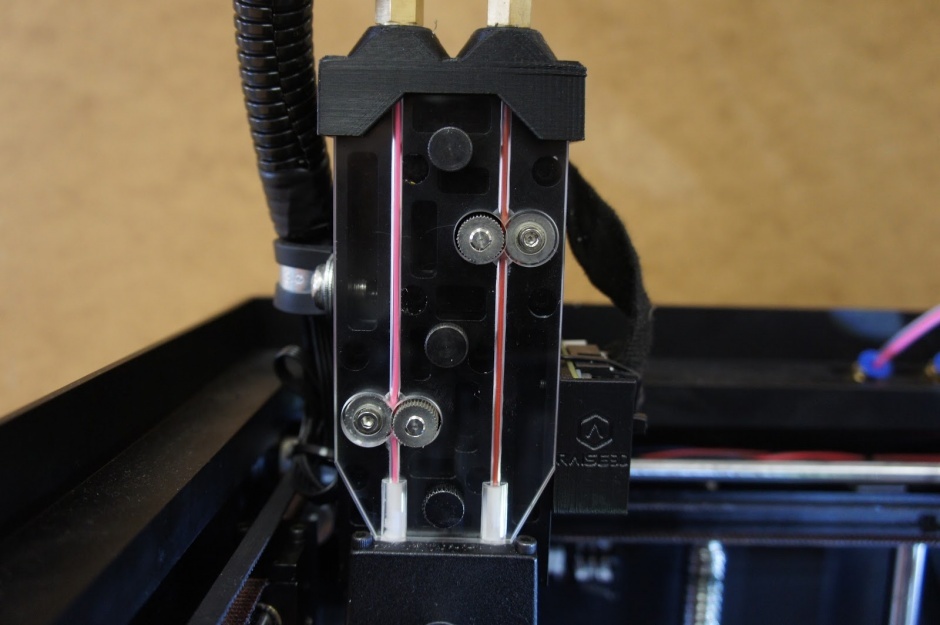

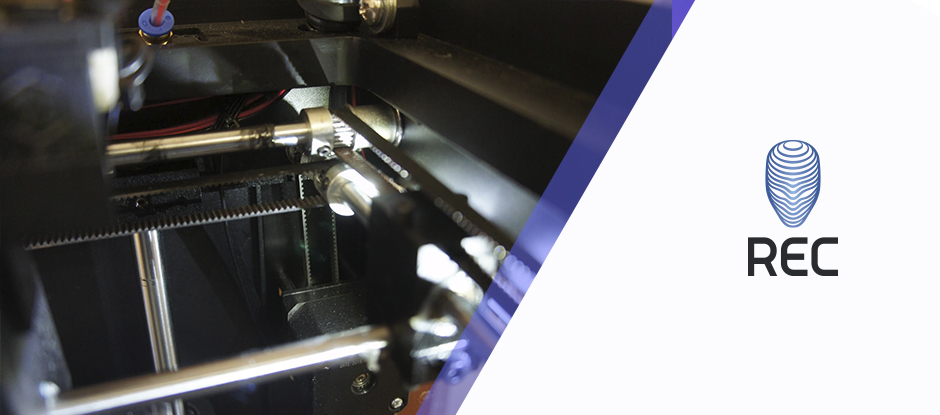

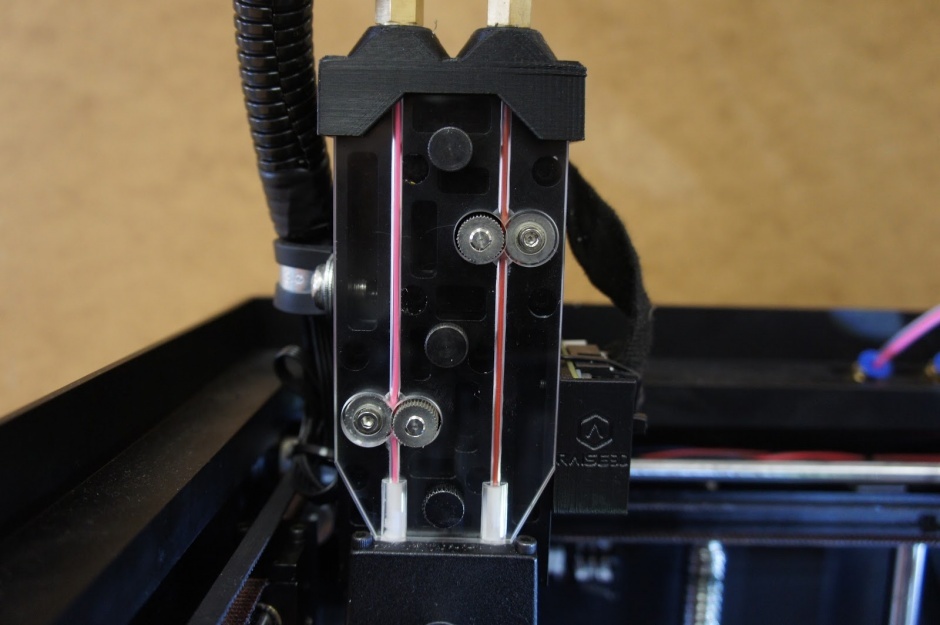

Two parallel extruders - many say such a scheme is “dead” and, as a rule, does not work. Check it out.

The print head is somewhat similar to the Ultimaker head, with one exception, the pushing mechanism is located on it, moreover, it has a “rectifier” for the rod. This creates a more confident and accurate bar feed at the hot end by reducing filament stress due to bending.

The first impression of the motors piled on the head is not the best idea.

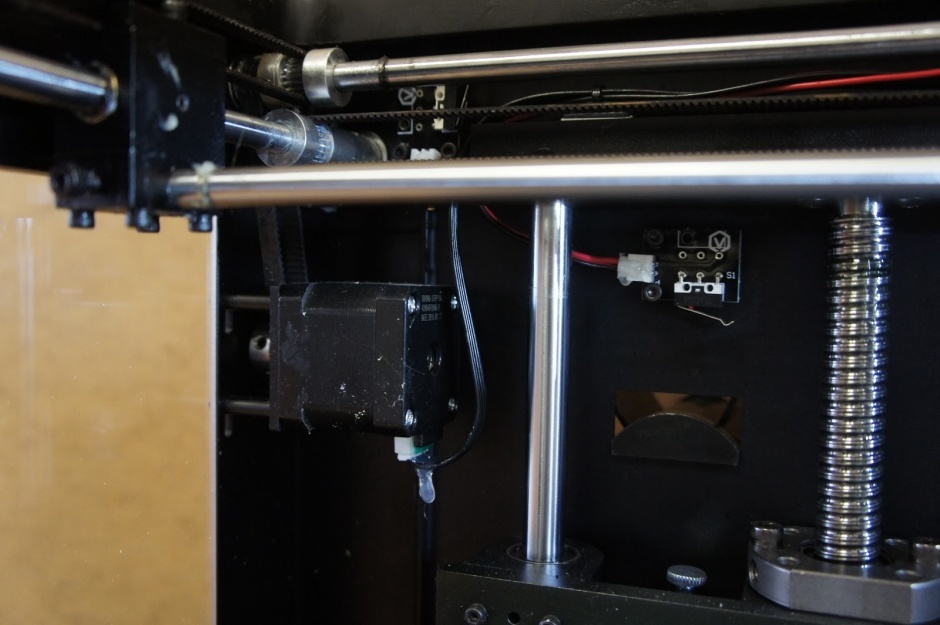

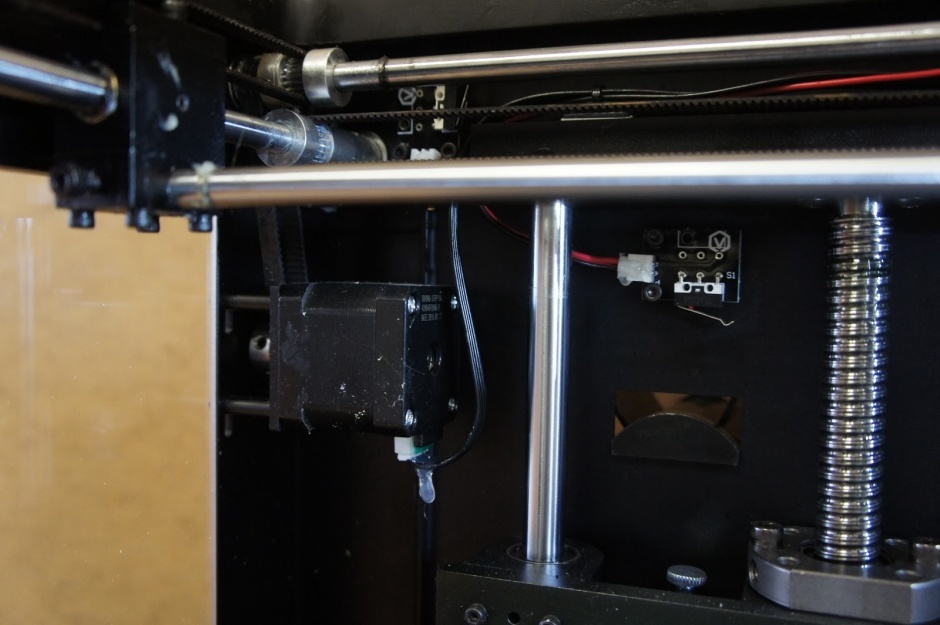

As for the kinematics, this Cartesian scheme is well executed and again copies Ultimaker. Many good components and custom parts made of metal and molded plastic.

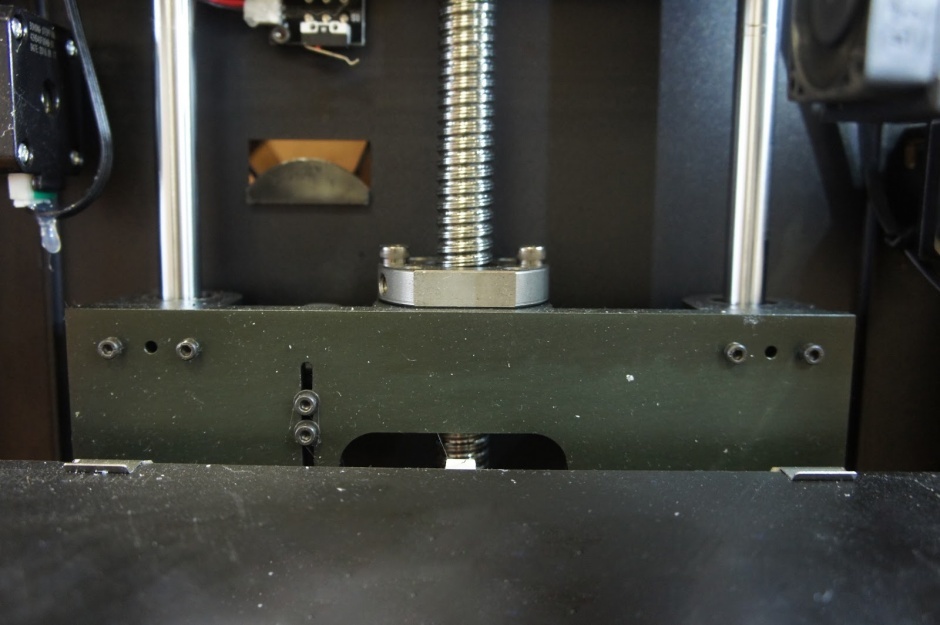

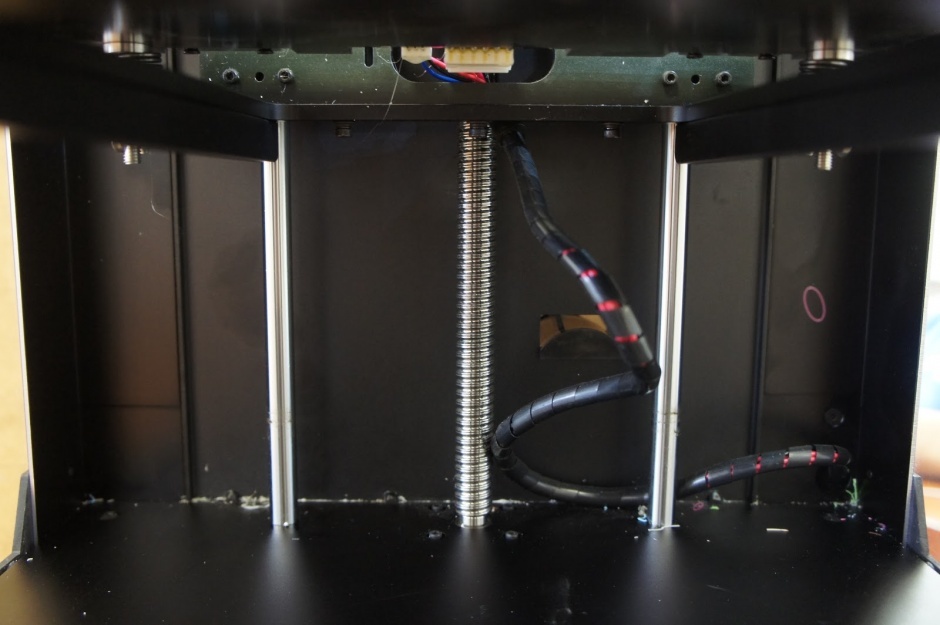

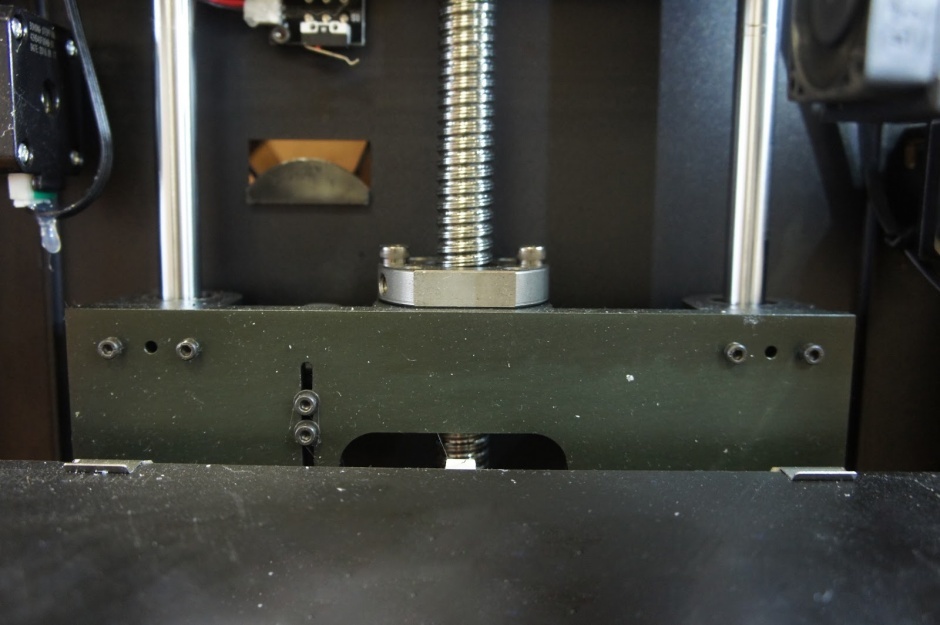

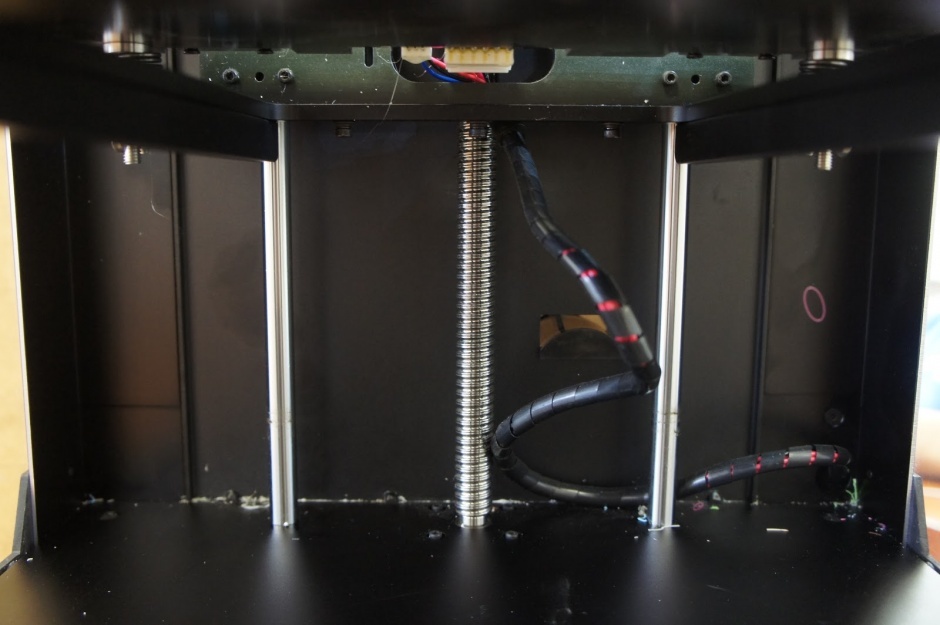

As for the table itself, it is located on shafts and ball screws with sufficient thickness. Does not play and does not bend.

The table is regulated by four bolts - not very cool, but a classic.

BY

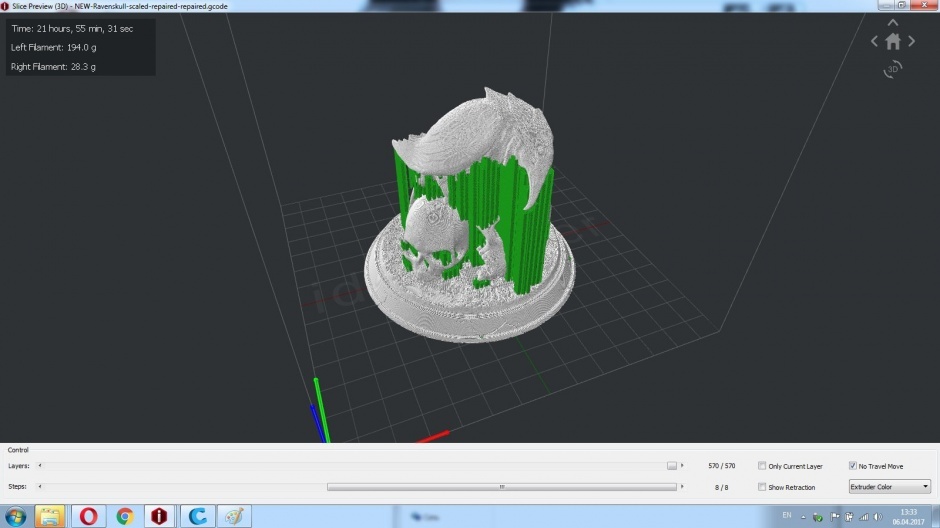

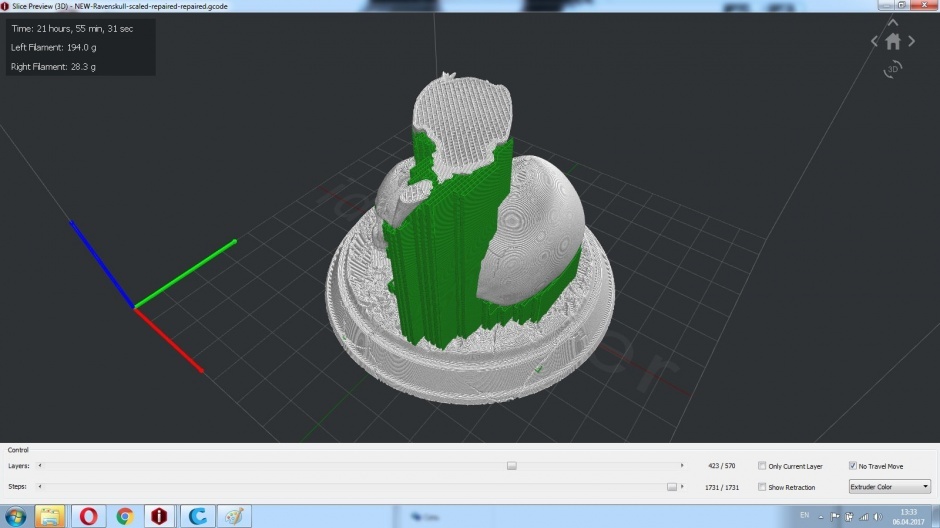

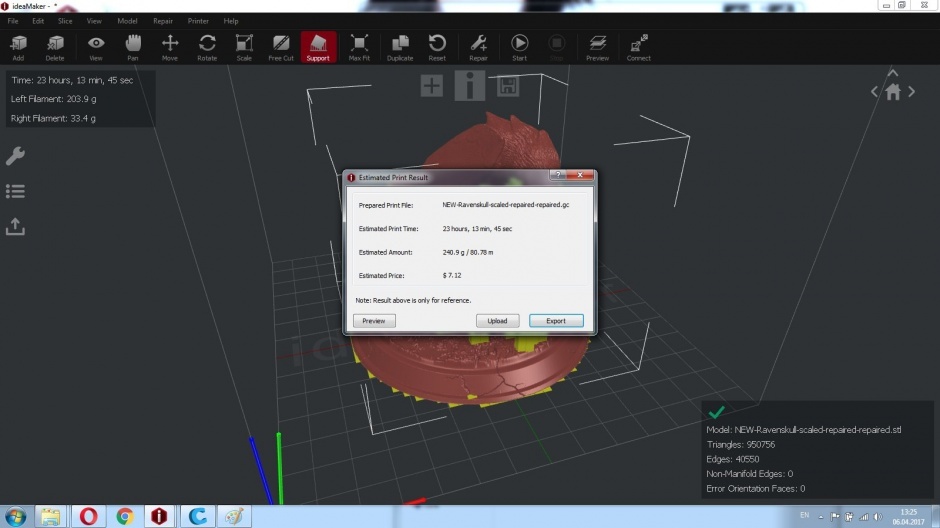

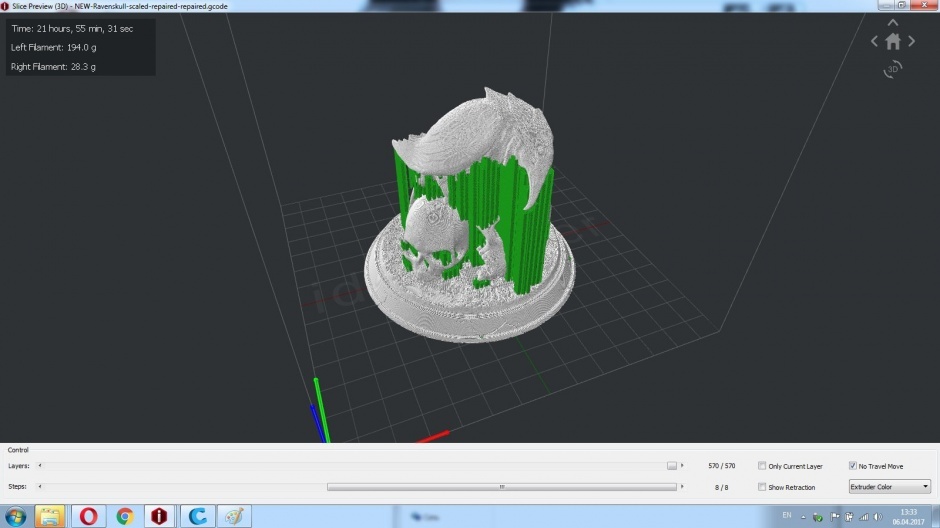

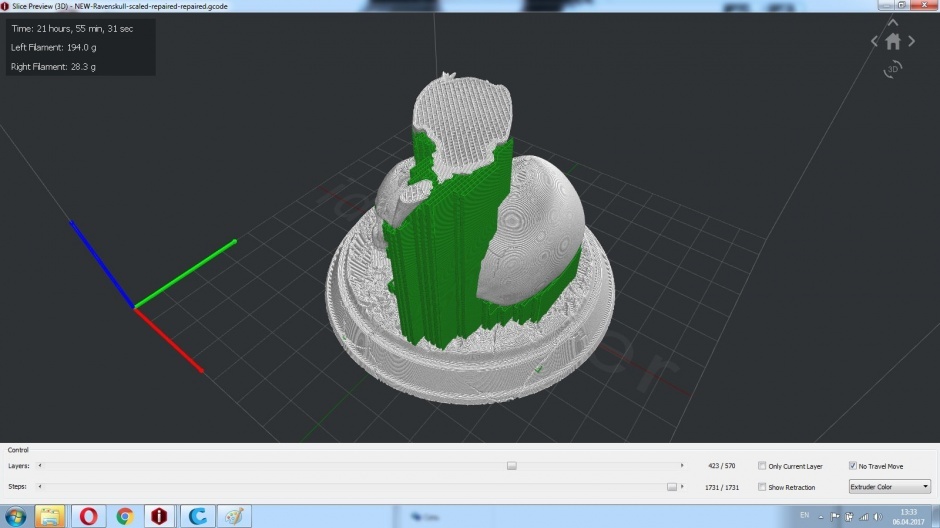

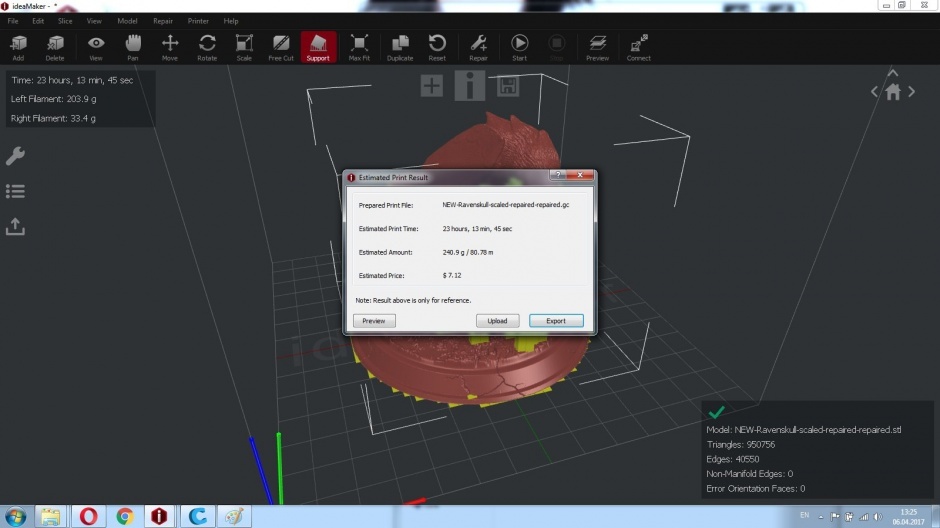

The program is called IdeaMaker - comes bundled with the printer or downloaded from the manufacturer’s website. It is a bit more complicated than the Cura interface, but it is easy to understand. Very pleased with the ability to quickly and easily visualize the printing process.

If necessary, you can use another slicer and fill the g-code into the ideal maker, but we have not tested this functionality.

Print

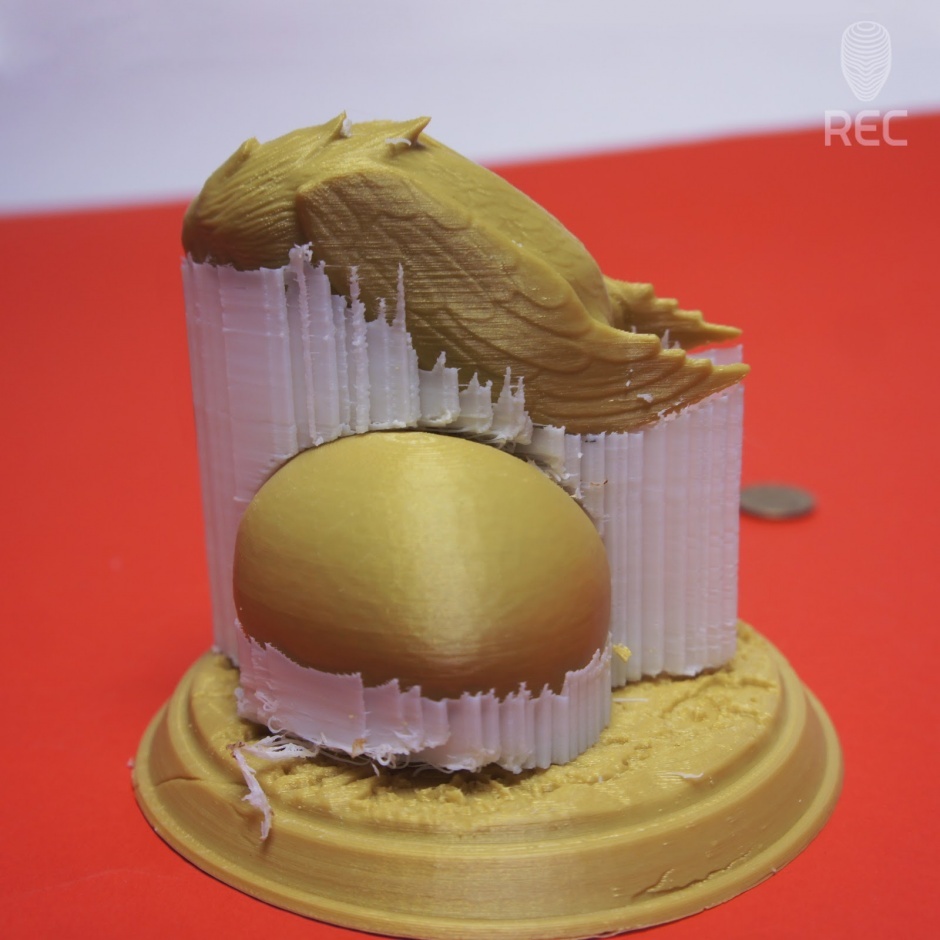

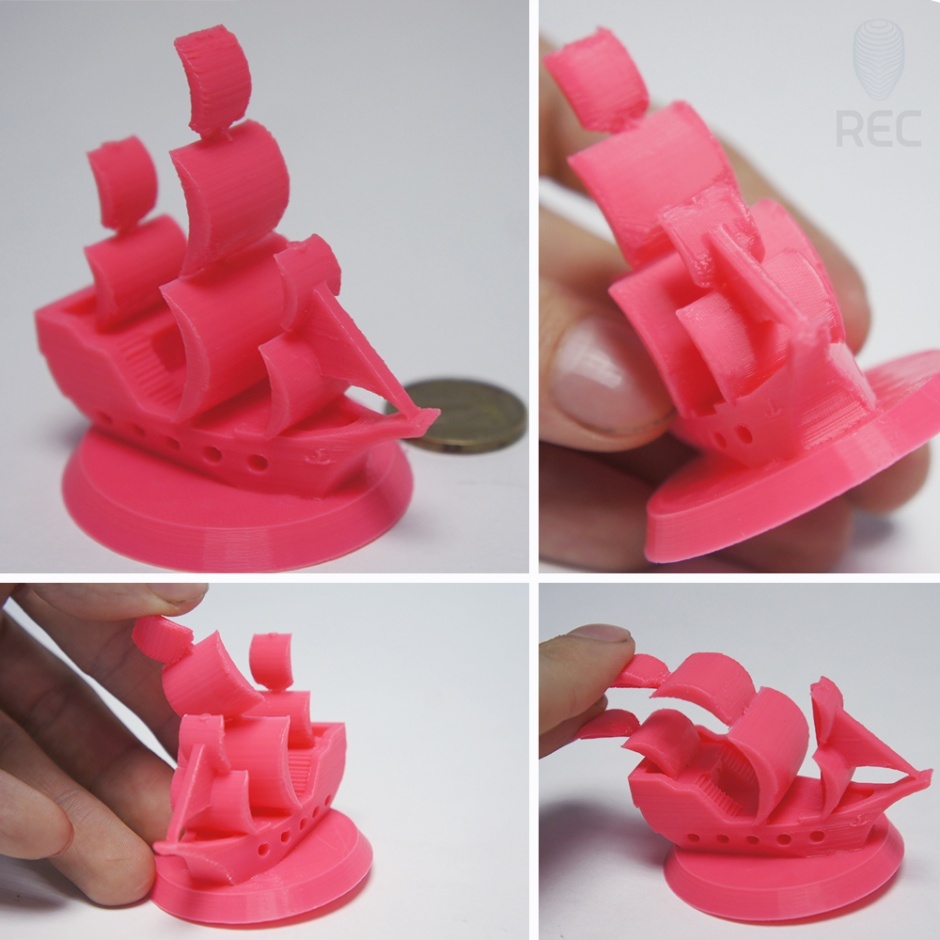

REC ABS and RELAX. These are the very first attempts to print on this device: a

layer of 0.15 mm

REC PLA

layer of o.1 mm

REC ABS and REC PLA

0.1 mm layer, problems with applying materials of different temperature conditions did not arise

REC FLEX

The result of Flex exceeded expectations, the height of the layer 0.15 mm

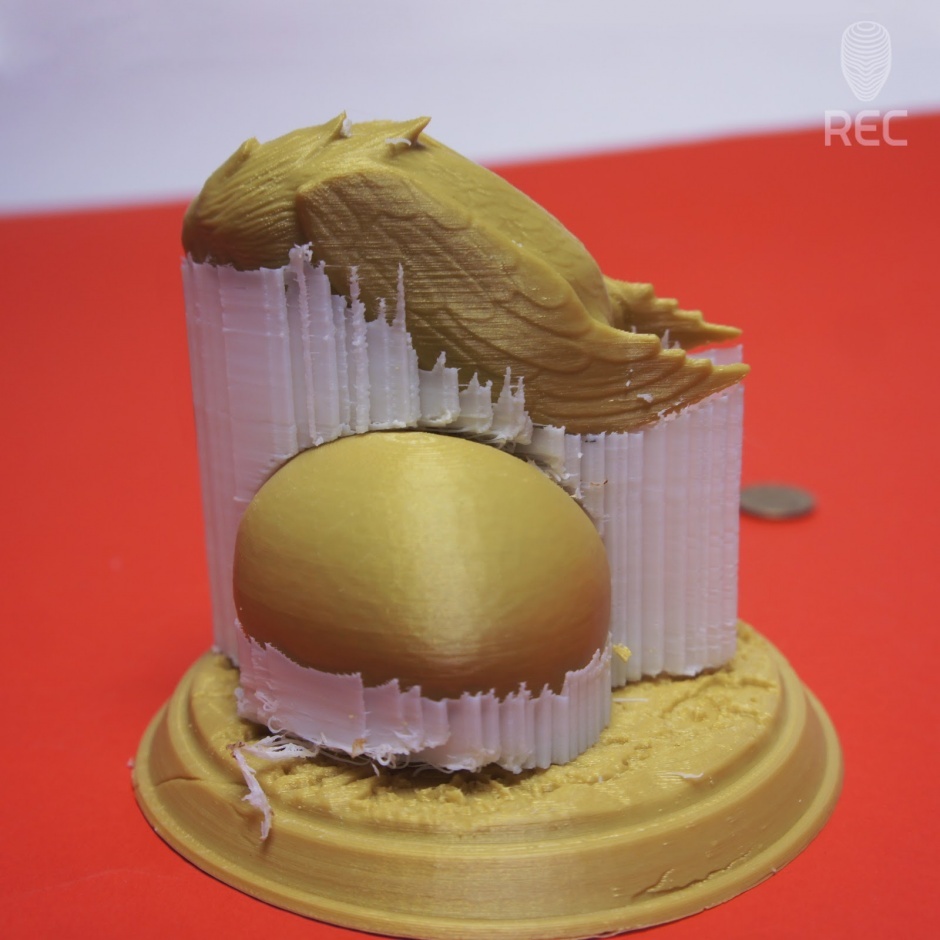

REC ABS + REC HIPS

Printing time 16 hours. layer 0.15 mm.

As you can see from the photos, the printer prints very confidently and qualitatively with a large amount of materials. Unfortunately, REC RUBBER does not apply to them - for this extruder the bars are too soft and we didn’t manage to adjust the printing correctly for a stable result.

As for the calibration of the nozzles - on this printer it is quite simple, (for this there is only one bolt that corresponds to the height of each nozzle from each other) compared to other printers with a similar layout of extruders.

Simply we park the printer to zero, unscrew the screw holding the right nozzle, and when it comes out and touches the table - we twist it back.

Identified one problem with printing, which will be discussed below.

pros

1) Two extruders with a filament guide, you can print many different filaments

2) Large table with a good Z axis

3) Stylish case with a rigid frame

4) Incredibly steep display with the ability to track progress

5) Many connectors

6) Good and convenient software

7 ) The printer is very noob friendly

8) Reliable packaging, equipment and instructions

9) Built-in battery and memory, when the power is turned off, the printer will remember where it finished printing. When the power appears again, the device continues to print as if there was no interruption.

10) The printer is quite quiet, as it is assembled on the meringues of good components.

11) It is possible to connect via the Internet and search for models

Minuses

1) The printer is a little less stable in its result than we would like, quite often when printing, the extruder motors on the print head heat up so much that they soften the bar. Thus, it ceases to be pushed into the hot end and the printing process ceases to be carried out correctly. It happens more often on PLA plastic than on ABS and PET-g, but it happens to them. Additional cooling of the motors of the extruder is necessary, since they heat up to 60-70 degrees, and sometimes more.

2) Flash drives stick out very much, it is easy to touch - to break the port and break the seal

3) There is a small bug with the display of the printing process on the monitor, if there is a column for cleaning the nozzles, the model's progress is not shown or is very late, the failure does not always happen and it is not proved that this is not a problem of our sample.

4) A comparable low print speed due to heavy printhead, although the printer can not be called slow.

5) Low airflow for the part, with PLA plastic when printing small models at low speed PLA flows around.

6) The power wires to the extruder itself fly out of the fasteners in spite of the nice corrugation, not critical but unpleasant.

7) The irregularity of the magnetic clamp on the door of the print chamber is a bit annoying, of course it is a nagging, but considering how often you have to deal with the door, you pay attention to it.

Conclusion

Chinese printer Raise 3D N1 Dual can be called a new generation 3D printer because it sets a kind of bar: “high-quality touchscreen display, enclosed case, two extruders, autonomy to restart printing, convenient software.” At the same time, technically, the printer is a good set made and well-proven technical solutions - the simplest system of two nozzles, a kind of synthesis of Bowden and direct extruder, kinematics from Ultimaker.

The device showed itself as an almost omnivorous printer capable of solving many problems.

By right, versatility is one of the distinguishing features of this go.

Of course, this model has not been without some flaws, but there are quite a few of them, the same goes for software.

The Raise 3D N1 Dual 3D printer is perfect for both professionals and beginners altogether, it gives quite a lot of versatile features and is very easy to use, thanks to the software and the interface on the device itself.

General

1. External dimensions - 362x529x651 mm.

2. The print area is rectangular, 205x205x205 mm.

3. The weight is 22 kg (as stated, we did not measure, but it seems easier).

4. The maximum movement speed of the head is 150 mm / s.

5. The minimum layer is 0.01, the base nozzle is 0.4 mm.

6. The package includes a thermal desk, a color LCD touch screen with its own interface, removable mounting frames for coils, 4 usb.

7. It is stated by the manufacturer that Raise 3D prints with many polymers and can heat the extruder up to 300 degrees.

Packaging and equipment The

printer is packed really soundly. Large pieces of foam that protect the printer.

The package includes a great instruction, two branded holder for the coils, power cable, USB flash drive, two plastic coils, a set of hexagons, and a couple of nice little things.

Appearance and technical nuances The

printer has a very aesthetic, durable and rigid body.

The dashboard and connectors are conveniently located for the user.

Touch screen with clear and stylish design. For beginners 3D printing this solution will be extremely convenient.

It displays the process and print settings, impressive.

Two parallel extruders - many say such a scheme is “dead” and, as a rule, does not work. Check it out.

The print head is somewhat similar to the Ultimaker head, with one exception, the pushing mechanism is located on it, moreover, it has a “rectifier” for the rod. This creates a more confident and accurate bar feed at the hot end by reducing filament stress due to bending.

The first impression of the motors piled on the head is not the best idea.

As for the kinematics, this Cartesian scheme is well executed and again copies Ultimaker. Many good components and custom parts made of metal and molded plastic.

As for the table itself, it is located on shafts and ball screws with sufficient thickness. Does not play and does not bend.

The table is regulated by four bolts - not very cool, but a classic.

BY

The program is called IdeaMaker - comes bundled with the printer or downloaded from the manufacturer’s website. It is a bit more complicated than the Cura interface, but it is easy to understand. Very pleased with the ability to quickly and easily visualize the printing process.

If necessary, you can use another slicer and fill the g-code into the ideal maker, but we have not tested this functionality.

REC ABS and RELAX. These are the very first attempts to print on this device: a

layer of 0.15 mm

REC PLA

layer of o.1 mm

REC ABS and REC PLA

0.1 mm layer, problems with applying materials of different temperature conditions did not arise

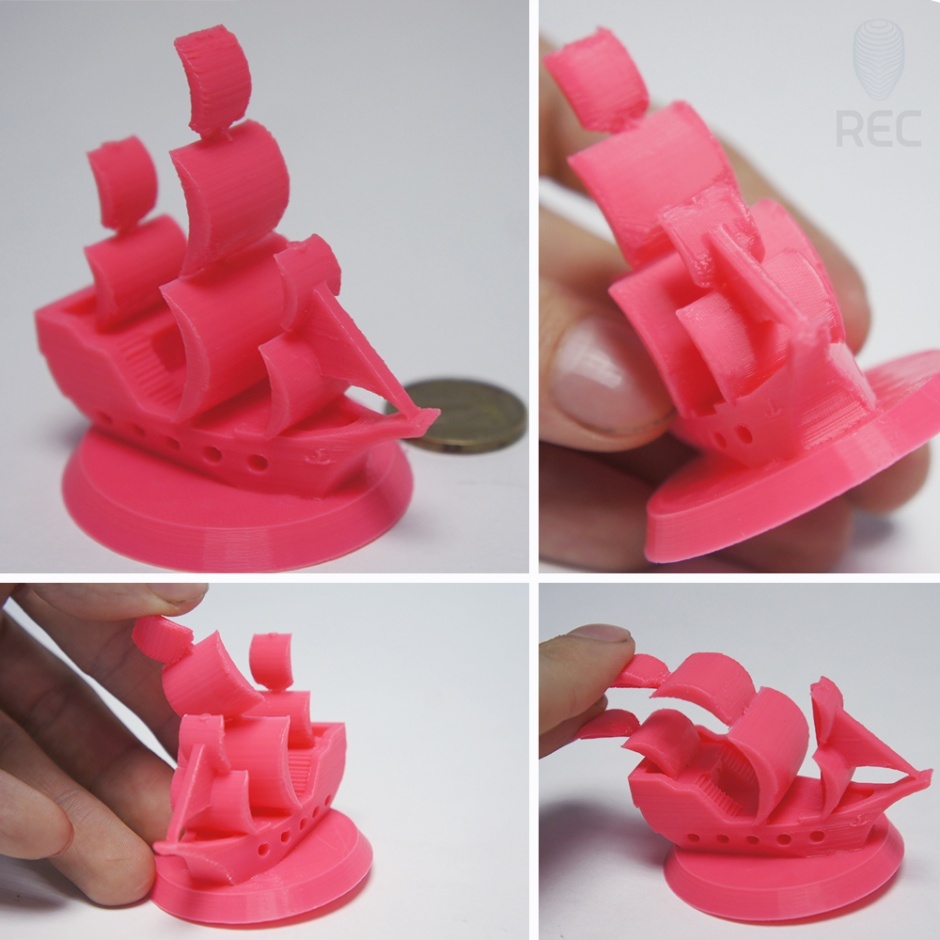

REC FLEX

The result of Flex exceeded expectations, the height of the layer 0.15 mm

REC ABS + REC HIPS

Printing time 16 hours. layer 0.15 mm.

As you can see from the photos, the printer prints very confidently and qualitatively with a large amount of materials. Unfortunately, REC RUBBER does not apply to them - for this extruder the bars are too soft and we didn’t manage to adjust the printing correctly for a stable result.

As for the calibration of the nozzles - on this printer it is quite simple, (for this there is only one bolt that corresponds to the height of each nozzle from each other) compared to other printers with a similar layout of extruders.

Simply we park the printer to zero, unscrew the screw holding the right nozzle, and when it comes out and touches the table - we twist it back.

Identified one problem with printing, which will be discussed below.

pros

1) Two extruders with a filament guide, you can print many different filaments

2) Large table with a good Z axis

3) Stylish case with a rigid frame

4) Incredibly steep display with the ability to track progress

5) Many connectors

6) Good and convenient software

7 ) The printer is very noob friendly

8) Reliable packaging, equipment and instructions

9) Built-in battery and memory, when the power is turned off, the printer will remember where it finished printing. When the power appears again, the device continues to print as if there was no interruption.

10) The printer is quite quiet, as it is assembled on the meringues of good components.

11) It is possible to connect via the Internet and search for models

Minuses

1) The printer is a little less stable in its result than we would like, quite often when printing, the extruder motors on the print head heat up so much that they soften the bar. Thus, it ceases to be pushed into the hot end and the printing process ceases to be carried out correctly. It happens more often on PLA plastic than on ABS and PET-g, but it happens to them. Additional cooling of the motors of the extruder is necessary, since they heat up to 60-70 degrees, and sometimes more.

2) Flash drives stick out very much, it is easy to touch - to break the port and break the seal

3) There is a small bug with the display of the printing process on the monitor, if there is a column for cleaning the nozzles, the model's progress is not shown or is very late, the failure does not always happen and it is not proved that this is not a problem of our sample.

4) A comparable low print speed due to heavy printhead, although the printer can not be called slow.

5) Low airflow for the part, with PLA plastic when printing small models at low speed PLA flows around.

6) The power wires to the extruder itself fly out of the fasteners in spite of the nice corrugation, not critical but unpleasant.

7) The irregularity of the magnetic clamp on the door of the print chamber is a bit annoying, of course it is a nagging, but considering how often you have to deal with the door, you pay attention to it.

Conclusion

Chinese printer Raise 3D N1 Dual can be called a new generation 3D printer because it sets a kind of bar: “high-quality touchscreen display, enclosed case, two extruders, autonomy to restart printing, convenient software.” At the same time, technically, the printer is a good set made and well-proven technical solutions - the simplest system of two nozzles, a kind of synthesis of Bowden and direct extruder, kinematics from Ultimaker.

The device showed itself as an almost omnivorous printer capable of solving many problems.

By right, versatility is one of the distinguishing features of this go.

Of course, this model has not been without some flaws, but there are quite a few of them, the same goes for software.

The Raise 3D N1 Dual 3D printer is perfect for both professionals and beginners altogether, it gives quite a lot of versatile features and is very easy to use, thanks to the software and the interface on the device itself.