Scientists have developed a chip for planning the movement of robots in real time

If you have ever watched how the demo versions of robots work, you probably noticed that the robot can “hang” for a long time before continuing. One might think that in this way the robot reflects on at what point and on what path to move. This assumption is not far from the truth: at this moment the processor handles motion planning operations, which often takes a lot of time.

Researchers at Duke University have found a way to speed up the movement planning of robots by a factor of three using the one-twentieth power required for this today. Their solution is based on a specialized processor that can perform the most labor-intensive part of the work — checking all possible collisions in the entire range of the robot’s movement — with high efficiency.

Traffic planning, for example, for a robotic arm primarily involves the creation of a probabilistic route map. It is a graph consisting of points in a space free from obstacles with lines-edges connecting these points so that each movement between them does not lead to a collision. In fact, the motion planner selects the start and end point on the chart, and then determines the most efficient way to move to get from one point to another.

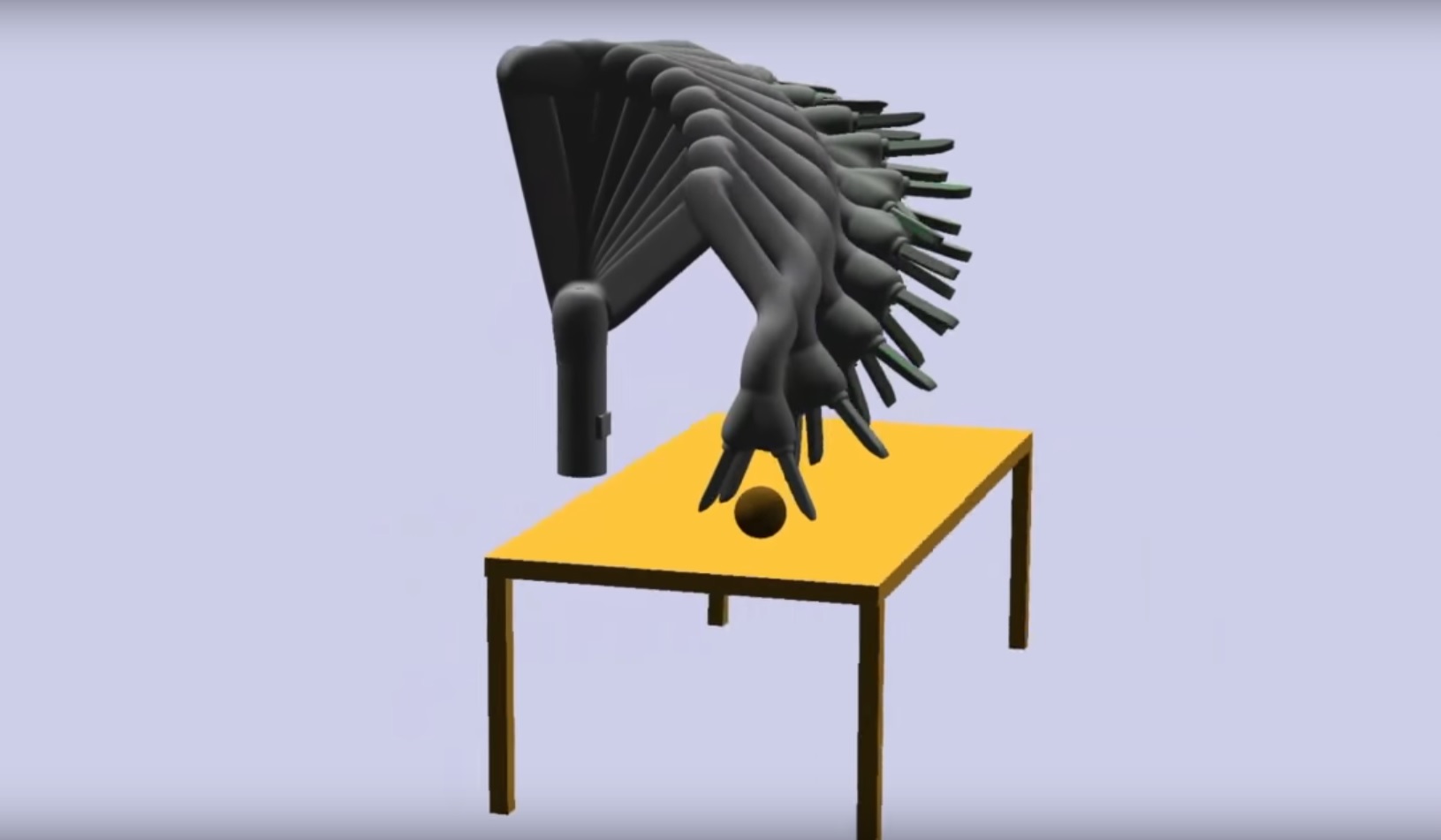

Motion planning algorithms are looking for the best way from one point to another, which allows to avoid obstacles (to the left). Probabilistic route map with edges connecting points in free space (right).

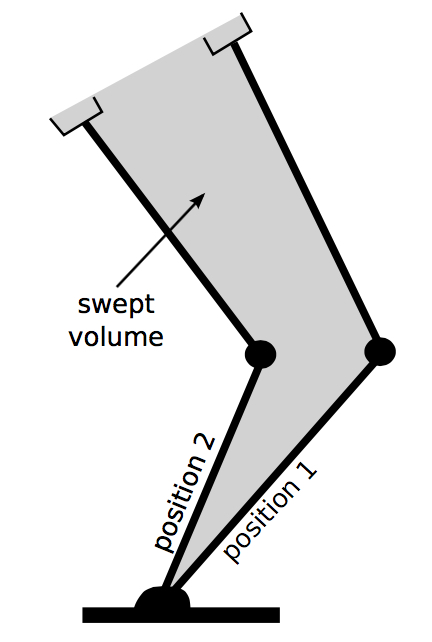

In theory, it sounds simple enough, but in practice you need to take into account the fact that you are working with a robotic arm. And when the hand moves from one point to another, the forearm may encounter an obstacle. The area in which the robot arm moves is called the “displacement”.

The working volume is the space in which the robot changes its position from one position to another.

The results of the study showed that the detection of obstacles takes more than 99% of the computational time. Preliminary calculations are made when the robot is configured. You create one map, which consists of about 150 thousand edges, describing possible trajectories of the robot, while avoiding self-collisions and collisions with things that do not change their position, for example, sex.

150,000 edges is too much for the prototype system of the Duke University team system. A more reasonable number is close to 1000, so the researchers had to find a way to reduce their number.

To speed up and simplify the whole process, the researchers first modeled about 10,000 scenarios with different numbers of randomly positioned obstacles of different sizes, and then checked which edges on the map are used by the system for motion planning. Rarely used edges were removed from the map. After several iterations, cutting and re-checking the results in one example, the number of edges was less than a thousand. At the same time, the reduction did not affect the ability to solve two main problems of the movement planner - slow processing speed and high power consumption.

Limiting the number of edges on the map to some acceptable value is very important because the capabilities of the processor that handles scheduling operations are limited. In this case, the processor - a programmable logic integrated circuit ( FPGA ) - is programmed with an array of collision detection circuits, each of which corresponds to one edge on the card. Thus, the size of the card is limited by the number of such schemes that can fit on the FPGA - a maximum of several thousand.

Technology scientists from Duke University work by breaking the workspace into thousands of voxels. Then, the algorithm determines whether a pre-programmed motion path of the object is laid in one of the voxels. Thanks to FPGA technology checks thousands of routes at the same time, and then stitches the shortest path using the remaining safe options. The robot can only execute it.

At the output, the scientists received a significant acceleration: no matter how many edges are on the card, the processing speed of the entire FPGA card was 50 nanoseconds per pixel. In one particularly complex example, the processing took slightly more than 0.6 ms. The scheduler, which worked on the basis of a quad-core Intel Xeon processor with a clock frequency of 3.5 gigahertz, coped with this task in 2.738 ms. Conventional processors consume about 200-300 watts of electricity during motion planning, and the development of scientists from Duke University - less than 10 watts.

Now industrial robots do not use motion planners. When it comes, for example, to a conveyor assembly of cars using robots, the environment is planned in such a way that robots can blindly repeat the same movements over and over again. They simply do not have the opportunity to make a mistake: parts of the car every time are in the same place, and the robots are kept in special boxes, fencing them off from people. But if the robot will use real-time motion planning algorithms, neither people wandering past nor conveyor fails to interfere with it - the robots will do their job with the usual precision.

Real-time traffic planning saves time and engineering costs for the environment surrounding the robot. Scientists have been studying planning technology for the past 30 years, and recent advances make it possible to create an improved movement plan in a few seconds. Existing approaches, with some exceptions, rely on the capabilities of central processors or faster, but also more energy-intensive graphics processors. According to scientists, the central processor is good at solving different types of problems, but it cannot compete with a processor specially designed for only one specific task.

Dinesh Manocha, a professor at the University of North Carolina at Chapel Hillwho is working on a real-time motion planner on GPUs agrees that FPGA has a serious potential to increase the efficiency of motion planning. He is confident that the development of scientists will find its practical application in the near future: robots are increasingly used in new, uncertain conditions, the role of traffic planning will only increase with time.

Startup Realtime Robotics will commercialize technology scientists. As part of this project, the FPGA will be replaced with specialized integrated circuits ( ASIC ), which can unite more than 100 thousand edges. Such an upgrade will allow robots to work in a wide variety of environments.