Why not use a computer UPS to power a gas boiler?

A year ago, I tried to understand why ordinary car batteries cannot be used instead of specialized in uninterruptible power supplies. In that article , several horror stories from sellers of specialized rechargeable batteries were considered, as well as measurements were made of the capacity of two batteries, each of which consists of four car batteries that had worked in the UPS for a year. Unfortunately, I did not guess to make such a measurement immediately after the installation of fresh batteries, but I promised to repeat the measurement a year later so that you can understand how much the capacity of the batteries decreased in a year. I planned to do this in the form of a comment with updated data, but during the measurement I noticed that while the UPS is running on batteries - the boiler connected to it - does not work.

A year ago, when the UPS was installed, the gas boiler was as simple as possible, minimum electronics, manual ignition. Actually, manual ignition was the only minus of the boiler, because when the electricity was disconnected, the boiler extinguished the torch for safety reasons, and was unable to light it back. This problem was solved by the UPS, but there was still a problem: with a strong gust of wind, the torch could just blow out. This did not happen often, but it did cause some inconvenience. And about six months ago, it was decided to replace the boiler with a slightly more “smart” one, with the possibility of automatic ignition of the burner, as well as with the turbine, which creates the traction necessary for the boiler operation, as a result of which there is no need to use a long exhaust pipe.

There was one fundamental difference between the old and the new boiler - phase dependence. In the new boiler, it was necessary to connect the phase to L, zero to N, otherwise the boiler will ignite the burner and extinguish it almost immediately, giving the error "It is impossible to light the burner." There was a suggestion that during the transition to the battery, the UPS reverses the phase and zero, so the boiler stops working. An indicator screwdriver with a neon-tube showed that there is a phase on both wires coming out of the UPS. The voltmeter showed that there is a voltage of 150V between the phase and the ground, and between the zero and the ground it is 90V, and, well, between the phase and the zero, respectively, their sum. This alignment is clearly not satisfied with the boiler.

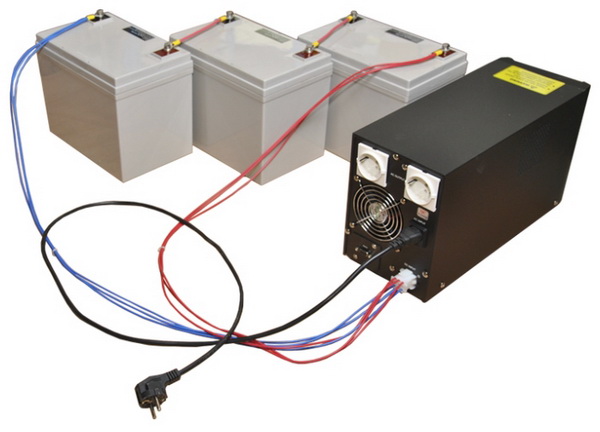

It became interesting what sellers of specialized UPSs for boilers write about this. After all, from the side the difference between the UPS for the boiler and for the computer look about the same as the battery for the car and for the UPS. The main difference between them, probably, is that some of the wires for connecting the batteries are long, designed for external batteries, while others are short. But is this a reason to raise the price by 2-3 times for the same power? Not to mention the fact that for the purposes of DIY you can buy used UPS, written off due to the expiration of the warranty period, at a price of 10 times cheaper than the same specialized UPS for a boiler.

Quite often, one can read that off-line (line-interactive) UPSs are not suitable for powering boilers because they have too long a time to switch from external power to battery. But in reality it is easy to check. It is enough to pull out the power plug of the boiler from the outlet and insert it back. The switching time took half a second, but the boiler not only did not report an error, but did not even notice that there was a shutdown at all. And in what time did the line-interactive UPS do the switching? 5-10, maybe even 50ms, but in any case it will be less than a manual shutdown.

But off-line UPS have no voltage stabilization function. Although some models have 1–2 steps for correcting the output voltage, but switching is usually performed using a relay and is well suited for situations where the voltage is consistently high or low. But if the voltage is constantly walking, then the UPS will rather quickly use up the relay resource, especially if they operate at maximum power. In this case, it is necessary to install a voltage regulator before the UPS, or immediately put an on-line UPS, which, regardless of the input voltage, will always try to keep a stable voltage at the output.

The cheapest and simplest computer UPSs, when running on batteries, generate a non-sinusoidal waveform at the output, because the shape and frequency of the input voltage is not very important for the switching power supplies. But the gas boiler contains in its design at least a circulation pump, which will almost certainly not like the “modified sine wave”, and at least it will work, but with a terrible roar. I do not know how such a mode of operation affects the life of its service, but it sounds scary, and there is a strong desire to turn it off.

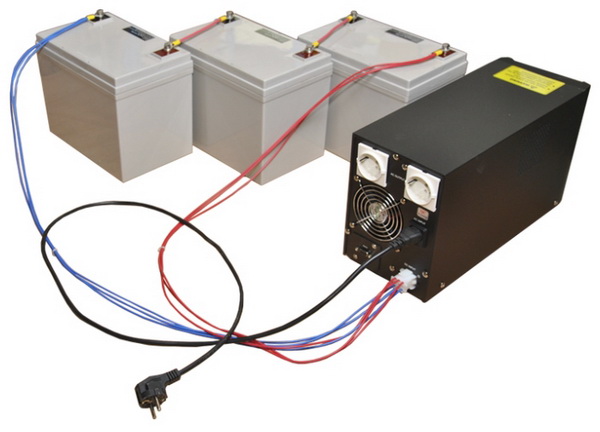

But, anyway, there are quite a few UPSs for PCs on sale that generate the “right sine” output. Some manufacturers add such models to the name “Smart”, but in any case, it is worth paying attention to the characteristics of the device, namely, the “Output waveform” column. But even if the UPS is off-line and output “sine wave approximation”, you can buy an inverter with enough power to operate the boiler, and connect it to the UPS battery, the result is a cheap on-line UPS with a suitable waveform. In this case, instead of the UPS, you can take a charger for batteries of a suitable type.

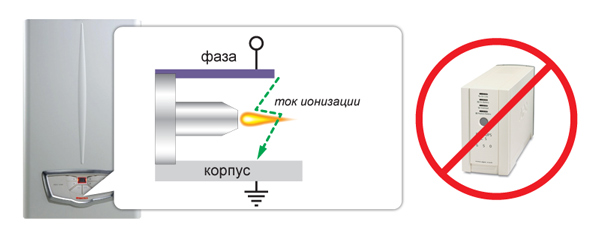

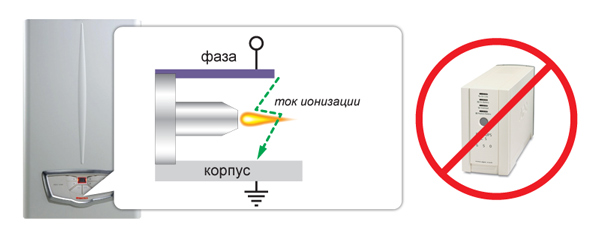

And now the fun part. Automatic ignition boilers have a flame sensor to turn off the gas in case the lighter broke and could not ignite it. These sensors can be either mechanical (in the case of manual-start boilers) or electric, and in the second case they can react to heat, radiation or ionization. And in the case of ionization flame sensors, there are problems when feeding them from the UPS. In general, the problem is solved very simply: you need to connect zero before the UPS with zero after the UPS. And it's all.

However, there is one caveat: if the UPS is connected to the mains with a plug, then it is desirable to conduct a zero with a separate wire directly from the outlet, otherwise you can insert the plug to the wrong side (you can of course put a small automatic switch on the jumper between zeros than fix). And of course, it is assumed that if it is a private house, then it has a ground loop and it is connected to the neutral wire (up to the RCD, if any), i.e. zero grounding is performed (if the circuit is not TT!), and of course the boiler itself is grounded. After the UPS, the wire that performs the function of zero for mains supply is selected as zero.

For some reason, along with this item, a computer UPS such as% Company% Back Power 500 is constantly given as an example, in which the battery has a capacity of 7Ah, and the battery life is specifically limited by a jumper to 5 minutes, due to the fact that the transformer used during operation battery so hot that the plastic case is deformed. In spite of this, even such a weak UPS can operate for a long time on batteries, just need to replace the battery with a more capacious one and add active cooling. In my case, such a UPS worked from a car battery for 20 hours supporting PC operation with consumption in the region of 150W. Simply put, the backup time does not depend on the UPS, but on the capacity of the batteries.

The following item often emerges from the previous point: once the battery was at the 7Ah out of the box, and now it was set to 70Ah, the charger will not be able to give more current and fully charge the battery. Partly, the statement is true, the charger in the UPS does indeed have a limit on the maximum current with which it can charge the battery, but this does not mean that it will not be able to charge the battery. Just charging time will increase. Of course, this can be a problem if electricity is given on a schedule, several hours a day, and the batteries simply do not have time to charge. But in this case, nothing prevents parallel with the UPS to connect to the same battery a more powerful charger (or solar controller, for example). The main thing to remember is that in the instructions for the charger,

There is an opinion that it is better to take a UPS with a battery voltage of 12V and connect several batteries in parallel to increase the total capacity than to take a 24 / 48V UPS and connect the same batteries in series. The argument is usually given the need to balance the batteries if they are connected in series, but it is overlooked that each battery consists of 6 cells, the balancing of which in principle is not provided by the battery design, and it works somehow. In my case, 4 batteries of 12V are connected to two UPSs, after two years of use, the difference in voltages on the batteries was less than a tenth of a volt.

In some UPSs, calibration is performed by pressing a button on the front / rear panel, on others it can be performed only from the service menu when connected via RS232 / USB to a PC, and somewhere it is not provided in principle. But it is believed that if you do not perform the calibration, the UPS will not fully charge the battery, and even with an increase in battery capacity, you will be working on them as little as with old batteries. Although in reality it is not. Without calibration, the UPS will not correctly display the remaining battery capacity as a percentage, but this will not affect in any way when the UPS decides that the batteries are completely empty. This can only affect the equipment, the connection is connected to the interface connector of the UPS, and depending on the settings, after a certain level of percentage balance of the battery capacity, it disables this equipment on command.

In my case, the APC Smart 3000 UPS was calibrated about a year ago, but in spite of the fact that the batteries did not change, the graph of battery capacity as a percentage and voltage shows that the UPS is aping for the first one. From it you can see that from 100% to 23%, the UPS just linearly reduces the percentage, regardless of the voltage on the batteries, then the charge "freezes" by 23% for several hours, and then gradually decreases to 11%. Unfortunately, I didn’t manage to wait until it was completely discharged, I had to supply external power, and at that moment something strange began. Judging by the schedule, the voltage on the battery began to rise, the charge went, and the charge percentage went down to the opposite, until it dropped to 1%, and only then began to rise smoothly, depending on the voltage on the battery. Perhaps so that the UPS does not lie,

As a conclusion, I would like to give the results of measuring the capacity of batteries. In the new plate, the number of discharge-charge cycles was replaced by battery life, but since the UPS parameters were not monitored 100% of the time, according to the monitoring opinion, the net hours were not recorded in brackets. The refrigerating and freezing chambers were disconnected from the first UPS, which, when simultaneously started, the starting current exceeded the maximum power of the UPS and led to its shutdown. Two PCs were connected to the second UPS, one of which works around the clock, because it is called a server.

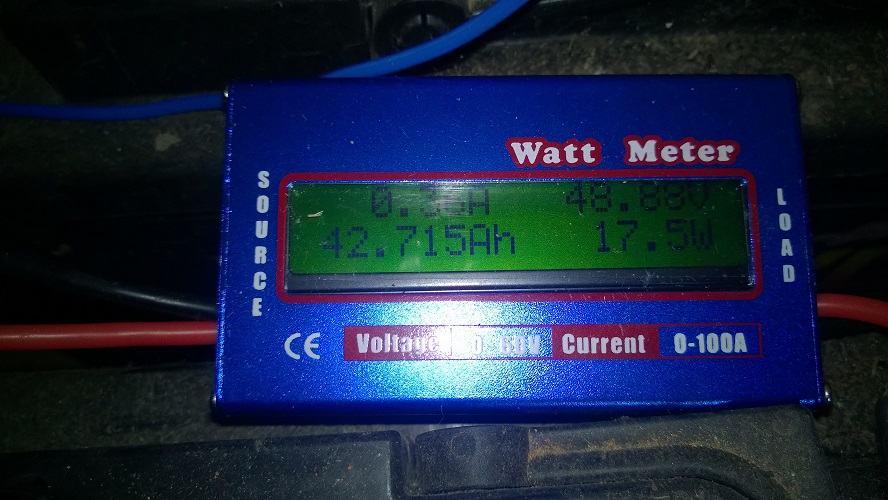

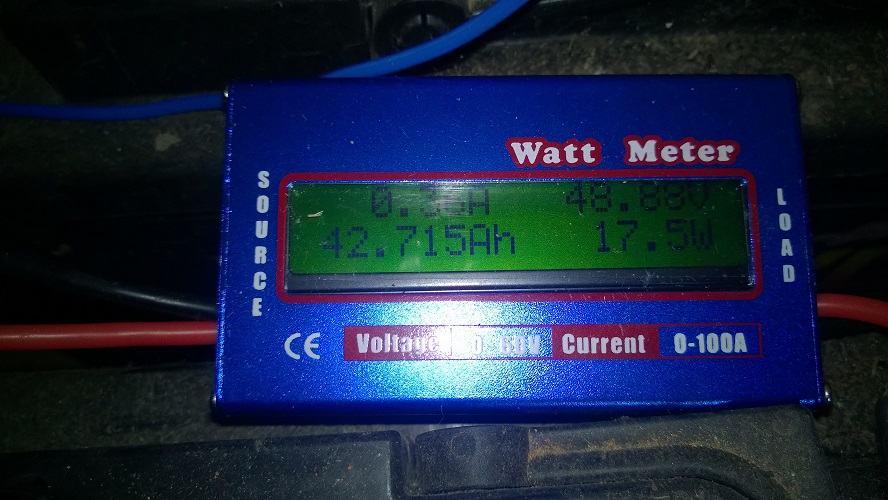

The measurements were made with a slightly updated version of the Chinese wattmeter, which looks similar to the same one with which the measurements were made last time, but unlike it has a little greater accuracy due to the use of high-quality shunt instead of a stack of SMD resistors. Due to the fact that the discharge of the battery of the first UPS took too long, I decided at the end to connect the refrigerating chamber as an additional load, but during its launch, the battery dramatically reduced the voltage and the UPS decided that “everything”, although the voltage was “under” and “without” the load, it can be seen that without powerful consumers, the UPS could still work on batteries, it was also possible that the watt-meter was not connected with very thick wires (18 AWG), and because of the voltage drop on them, the UPS saw the battery voltage lower than it actually was.

In general, it can be noted that the capacity not only did not decrease, but even increased in the case of the first UPS. This is partly due to the fact that this year he worked in a sparing mode, almost all the time he was connected to the network (in the first year it was disconnected from the network every day), and two powerful loads were removed from it. In general, the article turned out slightly chaotic, but I hope for someone it will be useful, and of course I will listen to criticism with pleasure, as well as answer questions in the comments.

A bit of background

A year ago, when the UPS was installed, the gas boiler was as simple as possible, minimum electronics, manual ignition. Actually, manual ignition was the only minus of the boiler, because when the electricity was disconnected, the boiler extinguished the torch for safety reasons, and was unable to light it back. This problem was solved by the UPS, but there was still a problem: with a strong gust of wind, the torch could just blow out. This did not happen often, but it did cause some inconvenience. And about six months ago, it was decided to replace the boiler with a slightly more “smart” one, with the possibility of automatic ignition of the burner, as well as with the turbine, which creates the traction necessary for the boiler operation, as a result of which there is no need to use a long exhaust pipe.

There was one fundamental difference between the old and the new boiler - phase dependence. In the new boiler, it was necessary to connect the phase to L, zero to N, otherwise the boiler will ignite the burner and extinguish it almost immediately, giving the error "It is impossible to light the burner." There was a suggestion that during the transition to the battery, the UPS reverses the phase and zero, so the boiler stops working. An indicator screwdriver with a neon-tube showed that there is a phase on both wires coming out of the UPS. The voltmeter showed that there is a voltage of 150V between the phase and the ground, and between the zero and the ground it is 90V, and, well, between the phase and the zero, respectively, their sum. This alignment is clearly not satisfied with the boiler.

Let them talk

It became interesting what sellers of specialized UPSs for boilers write about this. After all, from the side the difference between the UPS for the boiler and for the computer look about the same as the battery for the car and for the UPS. The main difference between them, probably, is that some of the wires for connecting the batteries are long, designed for external batteries, while others are short. But is this a reason to raise the price by 2-3 times for the same power? Not to mention the fact that for the purposes of DIY you can buy used UPS, written off due to the expiration of the warranty period, at a price of 10 times cheaper than the same specialized UPS for a boiler.

To power the boiler you can use only On-line bespereboynik

Quite often, one can read that off-line (line-interactive) UPSs are not suitable for powering boilers because they have too long a time to switch from external power to battery. But in reality it is easy to check. It is enough to pull out the power plug of the boiler from the outlet and insert it back. The switching time took half a second, but the boiler not only did not report an error, but did not even notice that there was a shutdown at all. And in what time did the line-interactive UPS do the switching? 5-10, maybe even 50ms, but in any case it will be less than a manual shutdown.

But off-line UPS have no voltage stabilization function. Although some models have 1–2 steps for correcting the output voltage, but switching is usually performed using a relay and is well suited for situations where the voltage is consistently high or low. But if the voltage is constantly walking, then the UPS will rather quickly use up the relay resource, especially if they operate at maximum power. In this case, it is necessary to install a voltage regulator before the UPS, or immediately put an on-line UPS, which, regardless of the input voltage, will always try to keep a stable voltage at the output.

“Pure sine” is required to power the heating boiler

The cheapest and simplest computer UPSs, when running on batteries, generate a non-sinusoidal waveform at the output, because the shape and frequency of the input voltage is not very important for the switching power supplies. But the gas boiler contains in its design at least a circulation pump, which will almost certainly not like the “modified sine wave”, and at least it will work, but with a terrible roar. I do not know how such a mode of operation affects the life of its service, but it sounds scary, and there is a strong desire to turn it off.

But, anyway, there are quite a few UPSs for PCs on sale that generate the “right sine” output. Some manufacturers add such models to the name “Smart”, but in any case, it is worth paying attention to the characteristics of the device, namely, the “Output waveform” column. But even if the UPS is off-line and output “sine wave approximation”, you can buy an inverter with enough power to operate the boiler, and connect it to the UPS battery, the result is a cheap on-line UPS with a suitable waveform. In this case, instead of the UPS, you can take a charger for batteries of a suitable type.

Correct phasing is necessary for correct heating of the boiler.

And now the fun part. Automatic ignition boilers have a flame sensor to turn off the gas in case the lighter broke and could not ignite it. These sensors can be either mechanical (in the case of manual-start boilers) or electric, and in the second case they can react to heat, radiation or ionization. And in the case of ionization flame sensors, there are problems when feeding them from the UPS. In general, the problem is solved very simply: you need to connect zero before the UPS with zero after the UPS. And it's all.

However, there is one caveat: if the UPS is connected to the mains with a plug, then it is desirable to conduct a zero with a separate wire directly from the outlet, otherwise you can insert the plug to the wrong side (you can of course put a small automatic switch on the jumper between zeros than fix). And of course, it is assumed that if it is a private house, then it has a ground loop and it is connected to the neutral wire (up to the RCD, if any), i.e. zero grounding is performed (if the circuit is not TT!), and of course the boiler itself is grounded. After the UPS, the wire that performs the function of zero for mains supply is selected as zero.

UPS to power the heating boiler must have a long reserve

For some reason, along with this item, a computer UPS such as% Company% Back Power 500 is constantly given as an example, in which the battery has a capacity of 7Ah, and the battery life is specifically limited by a jumper to 5 minutes, due to the fact that the transformer used during operation battery so hot that the plastic case is deformed. In spite of this, even such a weak UPS can operate for a long time on batteries, just need to replace the battery with a more capacious one and add active cooling. In my case, such a UPS worked from a car battery for 20 hours supporting PC operation with consumption in the region of 150W. Simply put, the backup time does not depend on the UPS, but on the capacity of the batteries.

UPS charger is not designed for such a large battery capacity

The following item often emerges from the previous point: once the battery was at the 7Ah out of the box, and now it was set to 70Ah, the charger will not be able to give more current and fully charge the battery. Partly, the statement is true, the charger in the UPS does indeed have a limit on the maximum current with which it can charge the battery, but this does not mean that it will not be able to charge the battery. Just charging time will increase. Of course, this can be a problem if electricity is given on a schedule, several hours a day, and the batteries simply do not have time to charge. But in this case, nothing prevents parallel with the UPS to connect to the same battery a more powerful charger (or solar controller, for example). The main thing to remember is that in the instructions for the charger,

It is better to connect the batteries in parallel than in series

There is an opinion that it is better to take a UPS with a battery voltage of 12V and connect several batteries in parallel to increase the total capacity than to take a 24 / 48V UPS and connect the same batteries in series. The argument is usually given the need to balance the batteries if they are connected in series, but it is overlooked that each battery consists of 6 cells, the balancing of which in principle is not provided by the battery design, and it works somehow. In my case, 4 batteries of 12V are connected to two UPSs, after two years of use, the difference in voltages on the batteries was less than a tenth of a volt.

It is important to replace the battery after a more capacious calibration.

In some UPSs, calibration is performed by pressing a button on the front / rear panel, on others it can be performed only from the service menu when connected via RS232 / USB to a PC, and somewhere it is not provided in principle. But it is believed that if you do not perform the calibration, the UPS will not fully charge the battery, and even with an increase in battery capacity, you will be working on them as little as with old batteries. Although in reality it is not. Without calibration, the UPS will not correctly display the remaining battery capacity as a percentage, but this will not affect in any way when the UPS decides that the batteries are completely empty. This can only affect the equipment, the connection is connected to the interface connector of the UPS, and depending on the settings, after a certain level of percentage balance of the battery capacity, it disables this equipment on command.

In my case, the APC Smart 3000 UPS was calibrated about a year ago, but in spite of the fact that the batteries did not change, the graph of battery capacity as a percentage and voltage shows that the UPS is aping for the first one. From it you can see that from 100% to 23%, the UPS just linearly reduces the percentage, regardless of the voltage on the batteries, then the charge "freezes" by 23% for several hours, and then gradually decreases to 11%. Unfortunately, I didn’t manage to wait until it was completely discharged, I had to supply external power, and at that moment something strange began. Judging by the schedule, the voltage on the battery began to rise, the charge went, and the charge percentage went down to the opposite, until it dropped to 1%, and only then began to rise smoothly, depending on the voltage on the battery. Perhaps so that the UPS does not lie,

Conclusion

As a conclusion, I would like to give the results of measuring the capacity of batteries. In the new plate, the number of discharge-charge cycles was replaced by battery life, but since the UPS parameters were not monitored 100% of the time, according to the monitoring opinion, the net hours were not recorded in brackets. The refrigerating and freezing chambers were disconnected from the first UPS, which, when simultaneously started, the starting current exceeded the maximum power of the UPS and led to its shutdown. Two PCs were connected to the second UPS, one of which works around the clock, because it is called a server.

| Parameter | Battery number 1 | Battery number 2 |

|---|---|---|

| Model | BRAVO 6CT-90VL | Tyumen Batbear 75 |

| Capacity max. current | 90Ah, 760A | 75Ah, 610A |

| Cost at the time of purchase (unit) | 2200 rub | 2400 rub |

| installation date | November 9, 2014 | November 11, 2014 |

| UPS | APC Smart-UPS 3000VA, 2700W, 230V, 50Hz pure sine | |

| Load | gas boiler, floor heating pump, water well pump, lighting | lighting, refrigerator, server, pc |

| Battery life per year | 25 hours (from 238 days) | 120 hours (from 182 days) |

| Calibration done | not | Yes |

| Date of control measurement | September 24, 2016 | September 28, 2016 |

| Check digit | 18 hours 30 minutes 42.7 Ah | 7 hours 30 minutes, 58.2Ah |

| Voltage after discharge | 46.6V under load, 48.8V without load | 45.6V under load, 46.8V without load |

| Control charge | 12 hours, 42.9 Ah | 14 hours, 54.0 Ah |

| Voltage after charge | 55.2V plus or minus 0.05V for battery | |

| Electrolyte level | Slight decrease in level, still above plates | |

The measurements were made with a slightly updated version of the Chinese wattmeter, which looks similar to the same one with which the measurements were made last time, but unlike it has a little greater accuracy due to the use of high-quality shunt instead of a stack of SMD resistors. Due to the fact that the discharge of the battery of the first UPS took too long, I decided at the end to connect the refrigerating chamber as an additional load, but during its launch, the battery dramatically reduced the voltage and the UPS decided that “everything”, although the voltage was “under” and “without” the load, it can be seen that without powerful consumers, the UPS could still work on batteries, it was also possible that the watt-meter was not connected with very thick wires (18 AWG), and because of the voltage drop on them, the UPS saw the battery voltage lower than it actually was.

In general, it can be noted that the capacity not only did not decrease, but even increased in the case of the first UPS. This is partly due to the fact that this year he worked in a sparing mode, almost all the time he was connected to the network (in the first year it was disconnected from the network every day), and two powerful loads were removed from it. In general, the article turned out slightly chaotic, but I hope for someone it will be useful, and of course I will listen to criticism with pleasure, as well as answer questions in the comments.