Capabilities of container data centers: ready-made switching center in Myanmar in 50 days

Building a telecommunications infrastructure is a difficult task when there are no conditions, experience or specialists for this. However, in this case, you can use ready-made solutions, such as container data centers. In this post, we talk about how the Campana data center was created in Myanmar, which today is one of the main switching nodes in the region and provides the connection of submarine cables coming from different countries. About how it works and how the data center was created - read under the cut.

When it comes to building a new data center, the customer expects to receive the whole solution from a single supplier, and also wants to get guarantees that all this will work without complaints.

In such cases, we use container data centers. They can be brought directly to the customer’s site and mounted as soon as possible, having the equipment installed according to pre-prepared schemes, as well as taking advantage of the solutions originally laid down.

Campana MYTHIC Co Ltd. Today it is a major telecommunications operator in the region. In fact, this is the first private company in Myanmar that serves international traffic - it provides gateway support, signaling, IP address translation and so on. Campana provides a competitive connection of the Internet spaces of Myanmar, Thailand and Malaysia, as well as the exchange of traffic with India. The company needed a reliable data center, requiring minimal maintenance, and in the shortest possible time. That is why it was decided to use a ready-made infrastructure based on Delta solutions.

Training

Since Myanmar did not have enough specialists to test and deploy the infrastructure, all preliminary work was carried out in China. The company's employees prepared all the equipment and carried out not only its initial setup, but also testing for compatibility and docking of the containers themselves. Agree, it would be a shame to bring containers to another country, but encounter inconsistencies, a lack of fasteners or other troubles. For this, a test assembly of the container data center was conducted in Yangzhou.

When the trailers with containers arrived in Myanmar (Yangon city), they were unloaded and collected at the place of constant operation. For the installation of containers, a special column foundation was prepared to raise the data center above ground level, while also providing the possibility of ventilation of the data center from below. Testing, delivery and installation of the structure took only 50 days - it took so much to build the infrastructure on an almost empty site.

Full data center

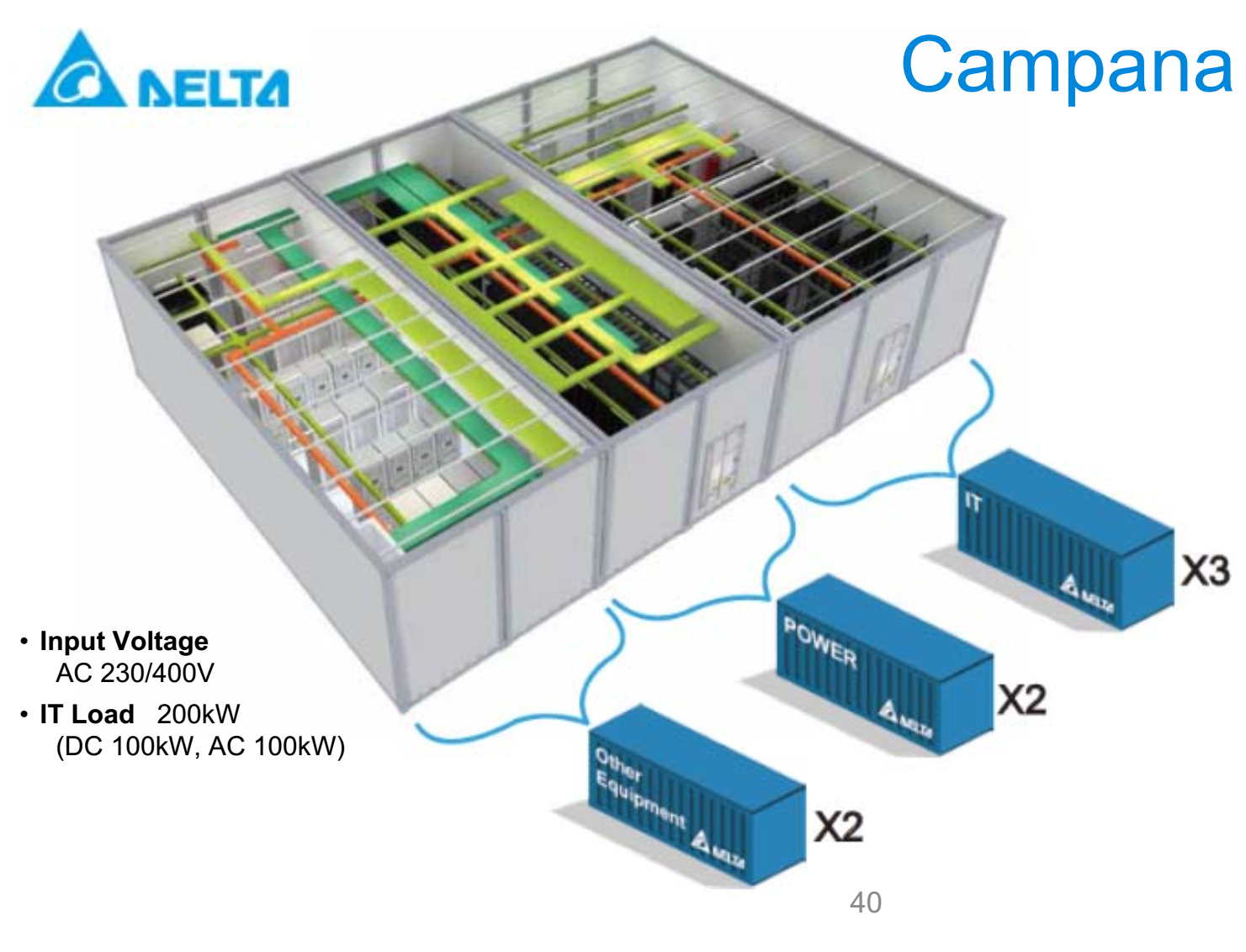

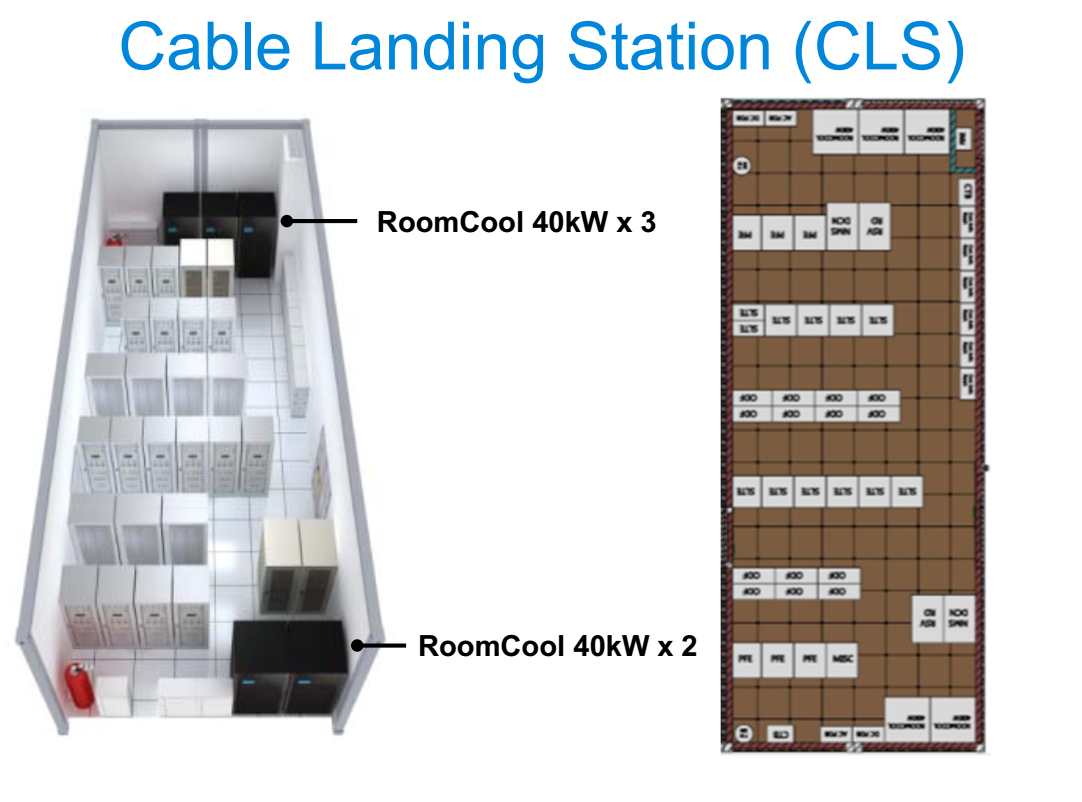

Campana data center has 7 containers that have been combined into three functional areas. In the first room, consisting of two combined containers, is CLS (Cable Landing Station). It contains switching equipment that provides routing of incoming and outgoing Internet traffic.

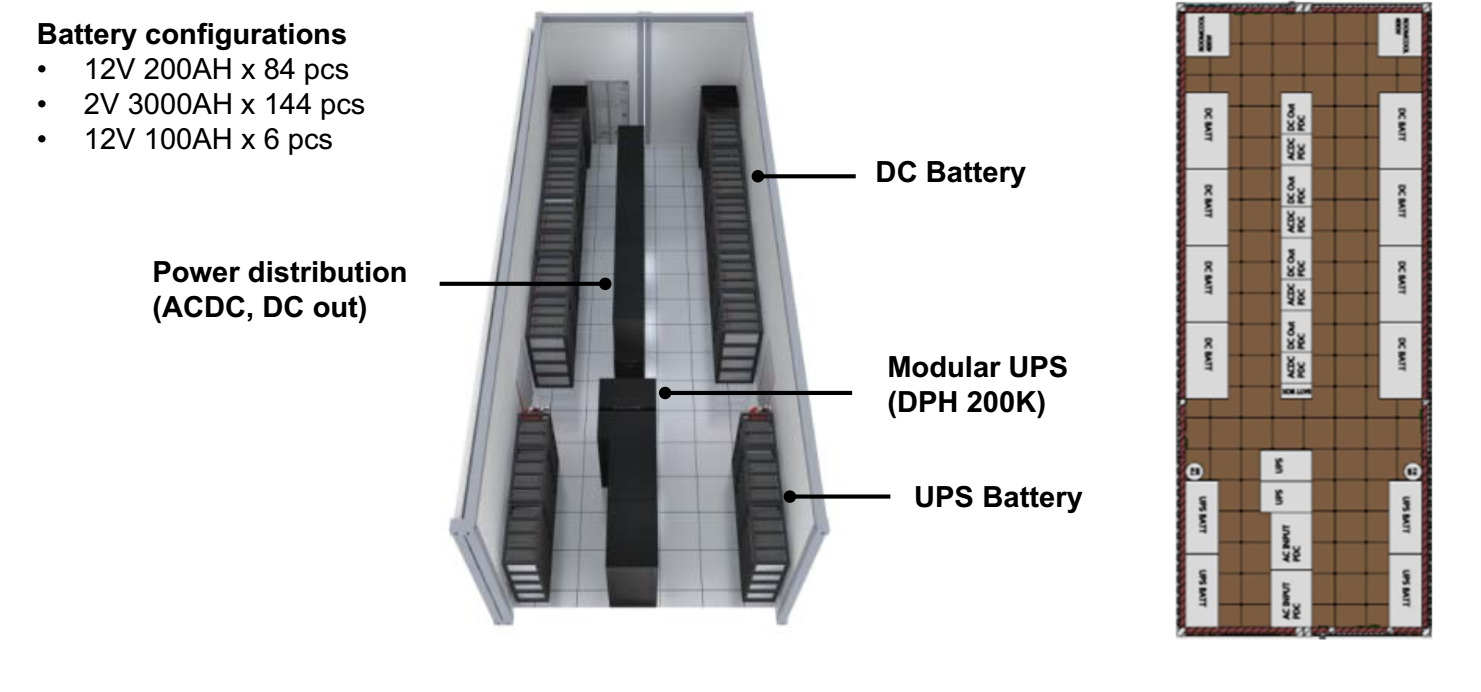

The second room, also made up of two containers, is the power room. Here are the Delta distribution cabinets connected to 230 V and 400 V power supply networks, as well as uninterruptible power supplies that provide autonomous operation of loads up to 100 kW.

The third room is designed to accommodate the IT load. Campana also provides Colocation services for customers in the region. As a result, those who have placed their loads in the new data center receive the fastest access to international traffic exchange channels.

Equipment placement

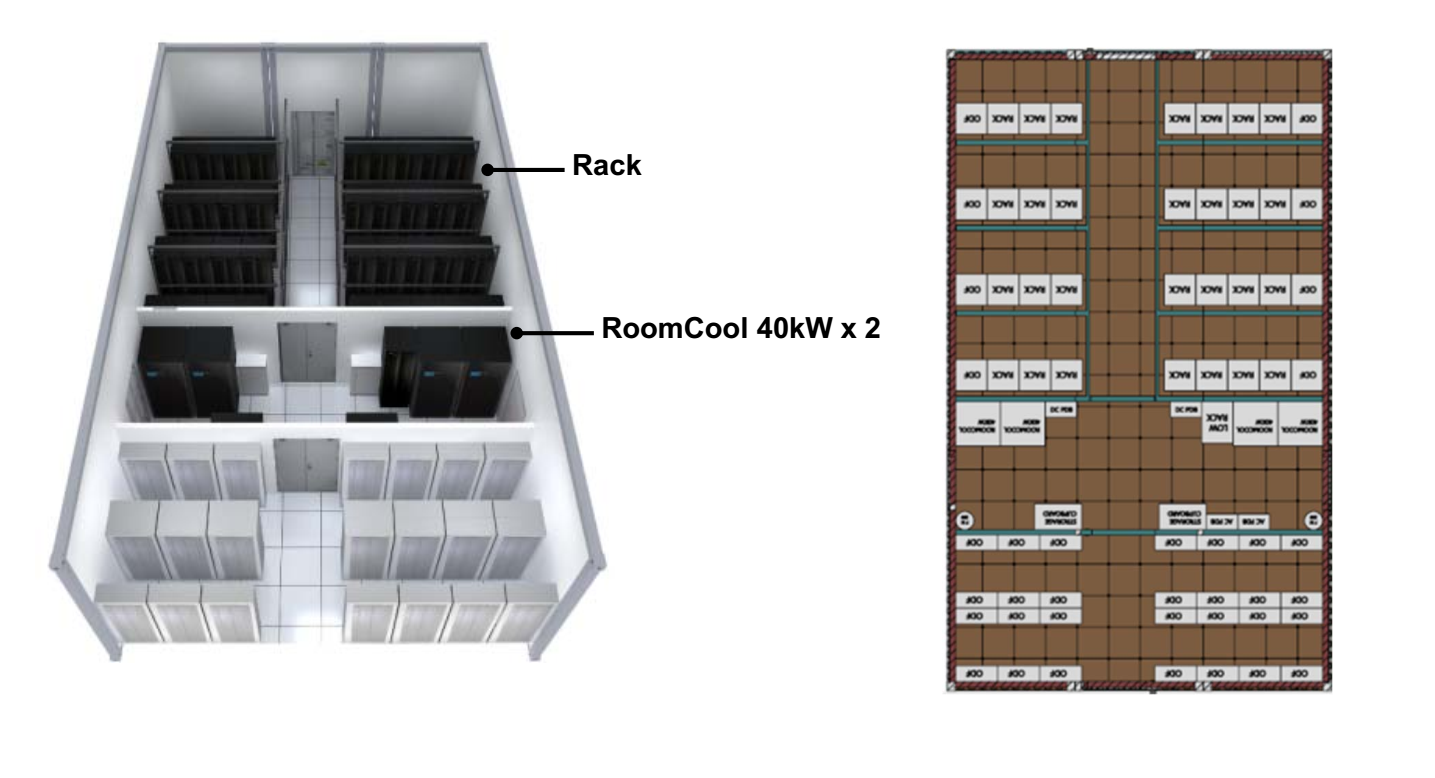

To cool the CLS cable station, five Delta RoomCool air conditioners, 40 kW each, were used. They were installed at different ends of the zone to provide efficient air cooling for the switching equipment. The layout of the equipment in the CLS is as follows:

Given the problems associated with the instability of power supply (which are typical for many regions), a lot of batteries were installed in the power zone: six 12V batteries per 100 Ah *, as well as 84 batteries at 200 Ah * and 144 batteries with a voltage of 2V and power 3000 A * H Distribution systems are installed in the center of the room, and batteries and uninterruptible power supplies are installed at the edges.

The room with server equipment is divided into two zones, between which the same RoomCool air conditioning units with a capacity of 40 kW are installed, as in the CLS. At the first stage, two air conditioners are enough for the Campana data center, however, as you add new racks with servers, their number can be increased without changing the topology of the hall.

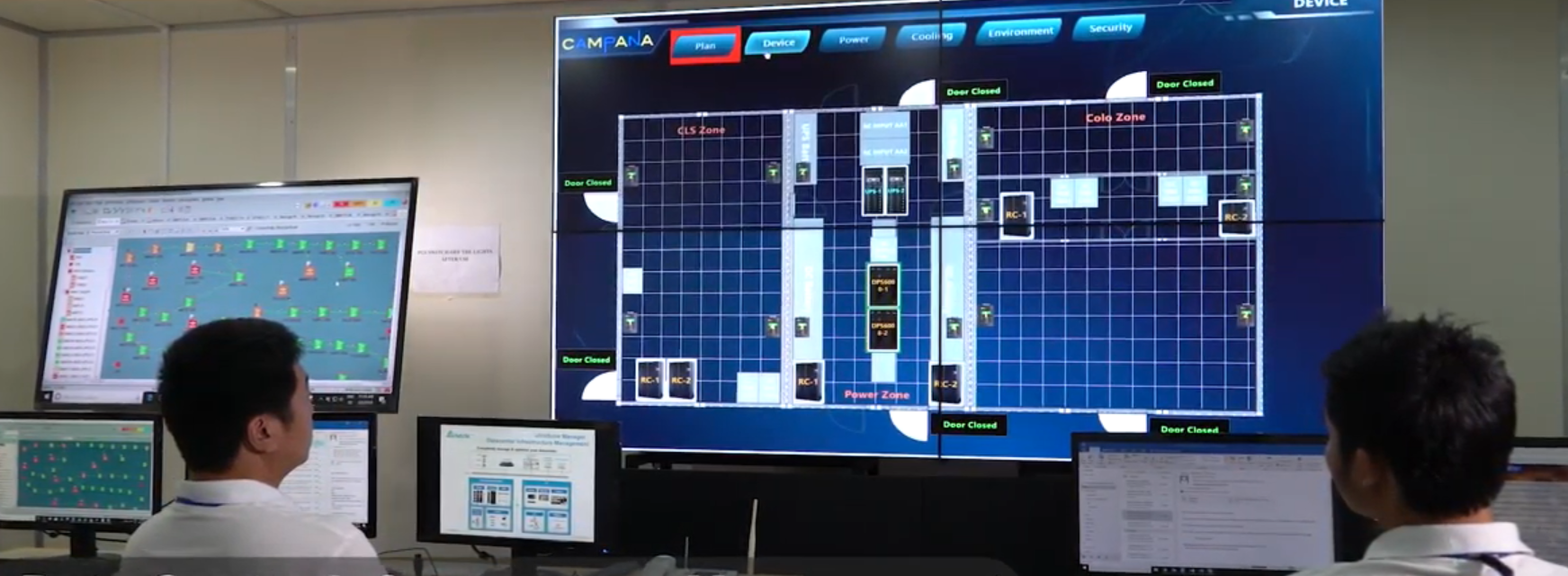

To control the entire complex, Delta InfraSuite software is used, which allows operators to control the temperature of each rack with equipment, as well as change the parameters of power consumption.

Result

In less than 2 months, a data center was built from containers in Myanmar, which today is the main traffic exchange platform in the country. At the same time, given that we are talking about a country with a hot climate, where it makes little sense to apply concepts such as FreeCooling, we managed to achieve the PUE (Power Usage Efficiency) parameter of 1.43. This was made possible mainly due to adaptive cooling for all types of loads. Also, the presence of built-in ventilation systems made it possible to regulate the supply of cold and the removal of hot air through the rooms.

A short video about the construction of the data center can be seen here .

Such a container data center can be created in any other region, including Russia. However, for the midland and northern regions, PUE levels may be even lower due to colder ambient air.

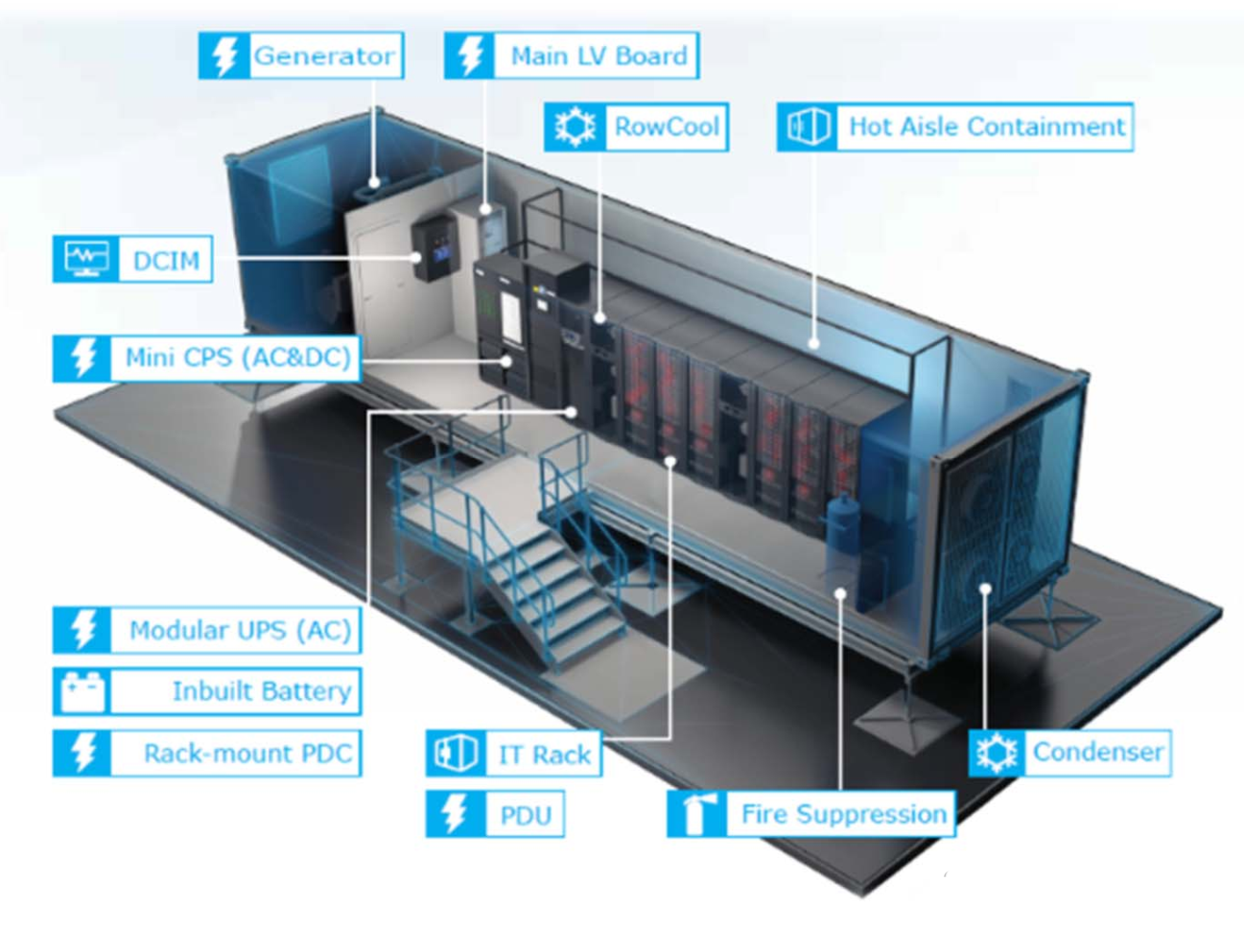

The typical design of a modular data center in a container implies the placement of a similar load and power systems, and also makes it possible to place IT systems with a capacity of up to 75 kW per one container - that is, up to 9 full-fledged racks. Today, Delta container data centers can meet the requirements of Tier II or Tier III, as well as be accompanied by a room with generators and a fuel reserve of 8-12 hours of operation. Versions with anti-vandal protection are available for installation in remote areas, which do not require any external infrastructure, except for incoming cables.