How do we collect TV boxes

How to take a step towards such a fashionable concept today as import substitution? In fact, it is easy if you already have relevant experience in the development and production of a domestic product. We have such experience. For more than a year, the assembly production of television set-top boxes has been operating in Yekaterinburg.

It was 2018, when weighed all the pros and cons, we began work on a business plan for the future production of television set-top boxes and worked closely on preparing the premises for the assembly shop. Prior to this, a full production cycle of hardware was deployed at our partners' factory in China, and software development and circuitry work were carried out within the NAG company.

Before continuing the story, let us dwell on what the production process is, which we had to master. At first glance, it might seem that the assembly of such a seemingly simple and compact device should not present any special difficulties.

It would seem: what is there? The case, the board and a few "goodies" on it, and then, most importantly, carefully put everything in a box, "dilute" the components and send it to a happy customer. But it turned out to be a little more complicated. And before starting work on the project, we decided to see how the assembly process was delivered to our colleagues in China.

To assemble one Vermax console, it is necessary to assemble 27 elements in a certain and strict sequence, since even some small structural parts of the device consist of several smaller ones. In China, each such operation is performed by one person, and this whole “conveyor machine” from human hands is quite successfully doing the job. Unfortunately (or fortunately), we could not afford such a quantity of human resources, and the area of our workshop is insufficient to accommodate such a quantity of workers. Therefore, I had to make great efforts before assembling the assembly line in accordance with our requests and capabilities. Some processes had to be automated and optimized so that one person could perform several assembly operations. But more on that later, because before you start collecting,

Room

The main criteria when choosing a room for the assembly line were its proximity to the head office of the company and the capacity sufficient to accommodate production. Initially, we chose another building near our huge warehouse, and we were ready to demolish the partitions, but then a better idea came up. Fortunately, on the floor of the business center where our office is located in Yekaterinburg, part of the premises was free. It was up to the “small" business - repair and technical equipment in order to turn four concrete walls into a real workshop with protection against static electricity.

When the room was finally ready, we purchased all the necessary equipment and approved the layout of it. It turned out like this:

Later, it was decided to slightly change the assembly steps and methods of transferring operations. This allowed us to significantly save space. Now, in the room where one line was originally located, two can be accommodated. This opens up prospects for us to scale production as necessary without opening a second workshop, although sooner or later we will have to go for it.

Production stages

In production, each person is assigned to a specific post at which specific assembly operations are performed. Each post is numbered, so let's start, as usual with Post No. 1.

Boards come in two hundred pieces in boxes from the SMT line. Each board is packaged in a separate package.

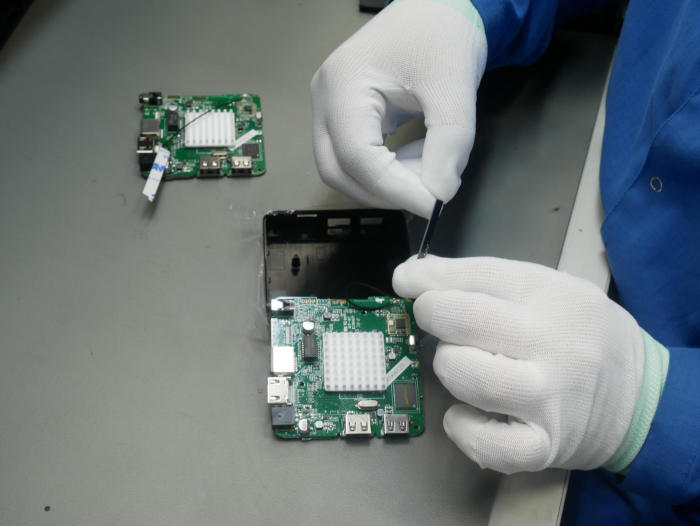

At the first post, there is a visual inspection of the boards for damage, and also the number of pieces in the box with documents is checked. A note is made in the internal logbook, where the serial number and the article number are entered. After that, the boards are unpacked and a radiator is attached to them using heat-conducting glue.

Further, the future prefix will go for verification to Post No. 2, but before that, two USB-drives and a flash-card are inserted into it.

Post two is one of the most important parts of the assembly. Here are rejected fees that could get damaged during transportation. Marriage can be different: from poor-quality soldering to minor breakdowns. And here it is especially worth noting that this is the second test. The first is carried out right at the factory before shipment, and the second after thousands of kilometers of shaking.

By the way, some defects can be detected by a special magnifying glass:

First, the operability of all ports is checked (for which the very same USB-drives and a "flash drive" are necessary). At the same stage, if necessary, the device is flashed.

Six boards are connected simultaneously for verification. It checks the operation of all the functions of the console, for example, such as sound, video, wi-fi, ethernet, bluetooth, overall performance, working with the remote control, etc. We test the sound using a special device with visual indicators of our own development.

Separately, it is worth noting that most tests are carried out automatically - partly using the built-in software in the set-top box, partly using external devices, for example, again our ERD controller.

Further, serviceable boards are transferred to Post No. 3, where the case is partially assembled, as well as antennas are mounted and light barriers are glued. The light barrier is the very element due to which the prefix does not blind the user at night with a bright LED, but only shines with a small light point. For the same reason, by the way, there are no diagnostic diodes on the network card, and the diagnostics themselves are placed in the interface. Therefore, the prefix does not work at night and does not prevent the user in the evening from enjoying watching movies and sleeping.

The semi-assembled prefix continues its movement and moves to Post No. 4. This is probably the most technologically advanced assembly phase. A pneumatic-electric screwdriver is installed here, with which the board is screwed to the top cover.

The screwdriver automatically feeds the screws immediately after the previous screwing is completed. In order to avoid breakdowns and twists, a force is set on the screwdriver with which the screws will be screwed. This saves the very seconds that allowed us to reduce the number of people on the assembly line.

Then the assembler latches the base of the case, and now the prefix can be considered almost assembled. But here there is a nuance. It is important that when you click, the access button to the service menu coincides with the latch of the cover. A trifle, and if necessary, service work will be unpleasant.

The case is assembled and it remains only to stick on the rubber legs. By the way, an interesting story is connected with them, which once again emphasizes the advantage of its own assembly. One of our major customers asked to replace the rubber legs of the console with ones that would not dirty the surface of white furniture. We fulfilled the request as soon as possible and the new batch of consoles no longer left black traces. If this request had to be transmitted to a factory in China, its resolution would take months.

At the next post, the prefix is packed in a box, and with it the components that a particular client needs. This is one of the advantages of our customization. For example, a client runs his business in the eastern city of Russia, where the population still has a large number of old televisions. “Tulips” (RCA ports) are relevant for them. So, the consoles will be equipped with “tulips”. In general, the set of components is standard: a remote control, batteries, a power supply unit and an HDMI cable, the set-top box itself, an instruction manual and further on the customer list.

At the next stage, the prefix is placed in a box. The transportation film is removed, and instead the end of the console is glued with a protective film.

The whole thing is packed in a bag and placed in a box on which an individual barcode is glued.

After labeling, all boxes are weighed. Weighing is necessary to control the availability of all components in the box. If the difference in weight from the standard values turns out to be significant, then the collectors have to open the boxes and transfer them to control.

After, each number is entered into the database and the computer forms a barcode of the box. It is in this box that the supplier will go to twenty, already assembled and fully equipped, consoles.

Well, then, everything is simple. A certain number of prefixes are sent directly from the boxes for manual unpacking and control, and some of them are sent to the oven of our own production to be sure of the reliability of the assembled device.

Why do we need these "troubles"?

Actually, why do we need all this trouble with our own assembly? Why hire employees and invest if hundreds of hands are ready to do the job somewhere out there in faraway China?

The most important advantage that we obtained by opening our own workshop is a reduction in the terms of customization, which is undoubtedly very important for large telecom operators. The average production time for prefixes in China is 3-4 weeks. A relatively inexpensive delivery takes 1 - 2.5 months. Assembly production allowed us to reduce these terms to one week. Also, we began to produce our own boxes, significantly reducing the cost of the design and making it less time-consuming.

Historically, the NAG worked with a huge number of small operators, so we, including, focus on these companies. There are hundreds of providers in Russia whose needs for consoles do not exceed two thousand per year. As a rule, such companies cannot afford to immediately pay for large batches of equipment, which means that they actually have no opportunity to customize the hardware for themselves, because it is simply not profitable for the manufacturer. For such companies, we have already developed a special offer that will solve their need for consoles and get a custom solution.

Prospects

Already, the number of consoles collected per day varies from 600 to 720 pieces. In the near future, to increase the number of assembly posts in order to reduce the time spent on some operations. This will allow us to significantly increase the volume of devices collected per day. Today, we can already cover the needs for set-top boxes for the operator during the day.