Lockheed Martin patents 3D printing with diamond

- Transfer

Products of any shape! The author wanted to insert a diamond tyrannosaurus, but Google did not find a suitable picture. Photo source: Crystal Fox

Lockheed Martin, one of the largest aerospace manufacturers in the world, filed a patent on April 4 for a new 3D printing technology - 3D printing with artificial diamond.

Material from 3dprintingindustry.com has been translated for you by the Top 3D Shop .

In a patent application, inventor David G. Findley describes a new 3D printing process using a ceramic binder polymer and a nanoparticle filler to create synthetic diamond objects of almost any shape imaginable.

About technology

David G. Findley:

“The method consists in layer-by-layer application of layers of ceramic powder and bonding them with a previously dissolved polymer.

After completion of the layer-by-layer construction, the object is heated, at least, to the polymer decomposition temperature, which is lower than the powder sintering temperature. ”

Image: US Patent and Trademark Office, Lockheed Martin

Although the printer is likely to be primarily used to make drills, cutters, and possibly even light armor, its appearance could be great news for jewelers who can create diamonds in practice. any form.

About Lockheed Martin

Quiet supersonic device for NASA. Source: Lockheed Martin

Lockheed Martin, headquartered in Bethesda, Maryland, USA, is an international security and aerospace company with approximately 98,000 employees worldwide. The company is engaged in research, design, development, production, integration and support of modern technological systems, products and services.

US Air Force F-35 fighter. Source: nationalinterest.org

What else is common with 3D printing and diamonds

Photo: georgeherald.com

De Beers Technologies diamond technology experts have invested in two Stratasys 3D printing systems, Fortus 360mc and Dimension 1200, to increase the production of parts for the diamond industry.

The company used to cover its 3D printing needs with third-party artists, but the addition of two machines means around-the-clock production at its diamond research center in Maidenhead, UK.

3D printers are used to create automated methods for checking and sorting diamonds, for prototyping parts of new equipment.

De Beers Technologies Senior Mechanical Engineer Andrew Portsmouth:

“Whenever I get an idea, my first thought is“ will it work? ” Now we can print the prototype overnight, test it the next day, find out the characteristics and shortcomings, make changes and print the corrected one by the next morning to repeat all the tests. It’s impossible to put into words how much 3D printing speeds up development. ”

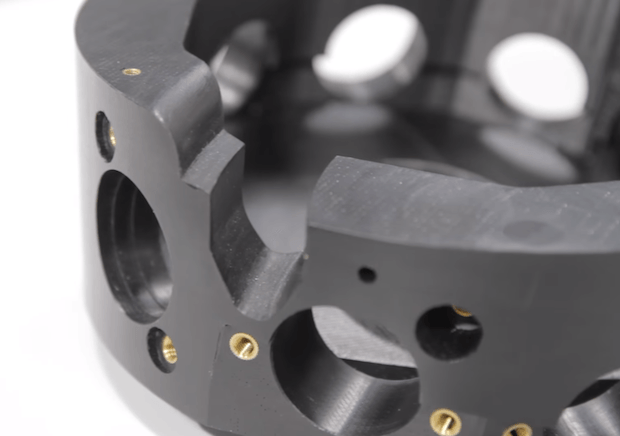

The body of the optical measuring cell. Image: tctmagazine.com

One of the equipment components, the body of the optical measuring cell (pictured above), cannot be created without 3D printing.

“The design features of this case give it many advantages in use, but these same features mean that it is impossible to make it in other ways than 3D printing,” Andrew explained.

“The production of this part on Fortus 360mc resulted in a cost reduction of 3-4 times compared with the previous processing method, simply because it is a much cheaper process.”

What do you think Lockheed Martin will print with artificial diamond?

What other applications besides instrumental and jewelry can this technology be found? Share your opinion in the comments.