Three-dimensional modeling in the modern world

Today I will tell you what 3D modeling is, what it is like, where it is used and what it is eaten with. This article is primarily aimed at those who have just heard from the bottom of their ears what 3D modeling is, or just trying their hand at this. Therefore, I will explain the maximum "on the fingers."

I myself am a technical specialist and have been working with 3D models for more than 10 years, I have worked in more than 10 different programs of different classes and purposes, as well as in various industries. In this regard, a certain helicopter view has accumulated in this industry, with which I wanted to share with you.

3D modeling has firmly entered our lives, partially or completely rebuilding some types of business. In each industry in which 3D modeling has brought its changes, there are both its own specific standards and unspoken rules. But even within the same industry, the number of software packages can be so many that it is very difficult for a beginner to figure out and navigate where to start. Therefore, for starters, let's look at what types of 3D-modeling are and where they are used.

We can distinguish 3 large industries that today are impossible to imagine without the use of three-dimensional models. It:

With the first we come across almost every day. These are films, animation and 90% of computer games. All virtual worlds and characters are created using the same principle - polygonal modeling .

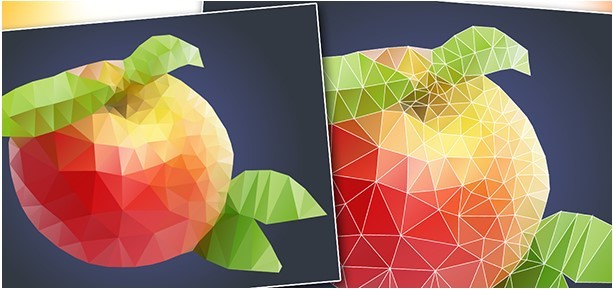

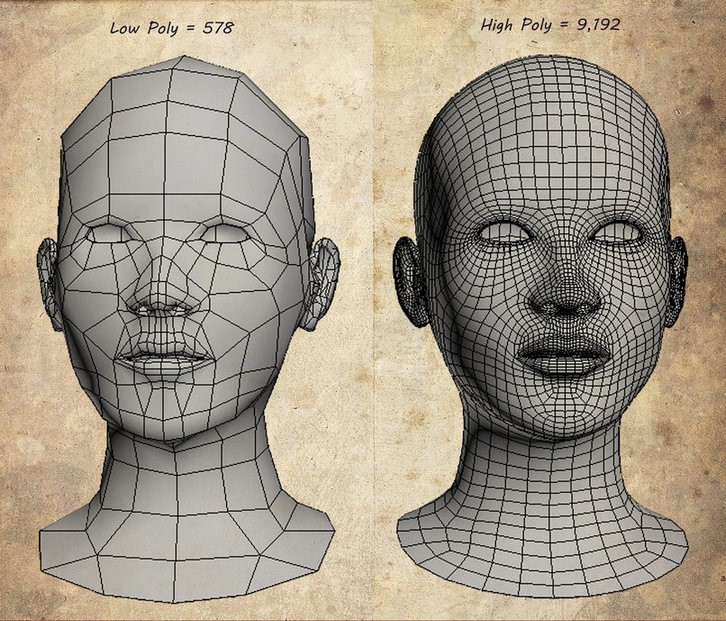

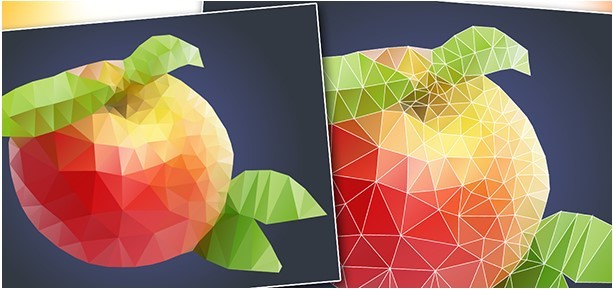

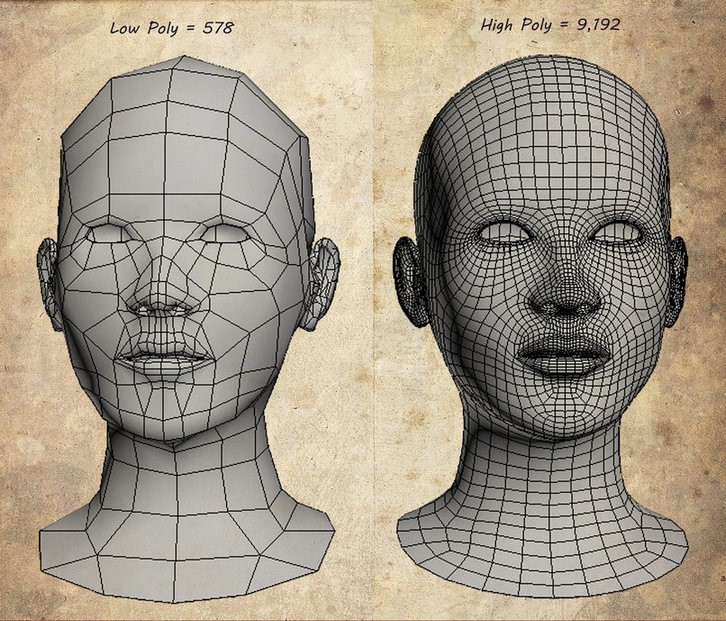

Polygons are called these triangles and quadrangles.

The more polygons per model area, the more accurate the model. However, this does not mean that if the model contains few polygons (low poly), then this is a bad model, and the person’s hands are not from there. The same thing, it cannot be said that if the model Over999999 has polygons (High poly), then this is cool. It all depends on the destination. If, for example, we are talking about massively multiplayer games, then imagine what it will be like for your computer when you need to process 200 characters around, if all of them are high poly?

Polygonal modeling occurs by manipulating polygons in space. Pulling, rotating, moving, etc.

Autodesk (known to many for its AutoCAD product, but about it later) is a pioneer in this industry.

Products of the Autodesk 3Ds Max , and the Autodesk Maya , the de facto industry standard. And I began my acquaintance with 3D models as a 15-year-old teenager with 3Ds Max.

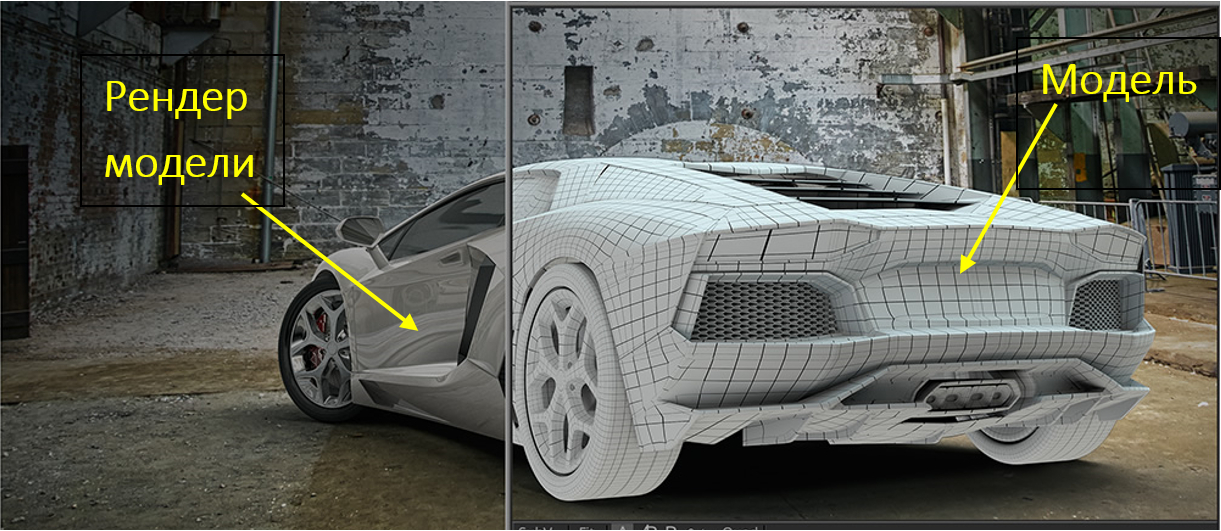

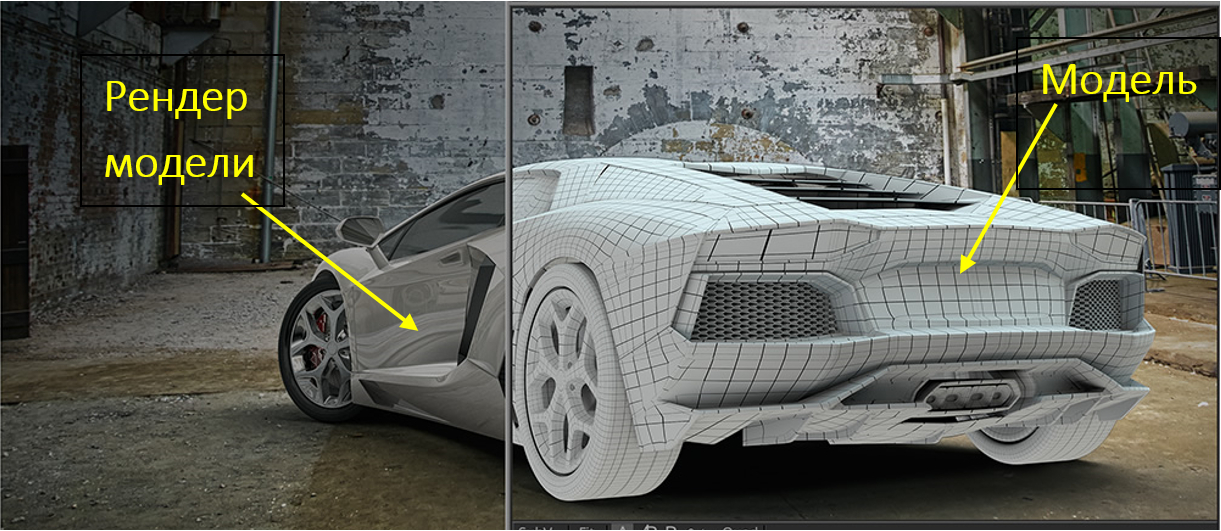

What do we get when we make such a model? We get a visual IMAGE. Gamers sometimes say, "I fell through the textures" in the game. In fact, you fall through the polygons that these textures are superimposed on. And the fall into infinity occurs precisely because there is nothing behind the image. Basically, the resulting images are used for RENDER (final image rendering), in the game / in the movie / for pictures on the desktop.

Actually, at one time I also tried to “blind” something to make a cool render (then it was much more difficult).

Speaking of modeling. There is such a direction as 3D-sculpting.In fact, the same polygonal modeling, but aimed at creating basically complex biological organisms. It uses other polygon manipulation tools. The process itself is more like minting than 3D modeling.

If the polygonal model is made in the form of a closed volume, such as the same sculptures, then thanks to modern 3D printing technology (which can be found in almost any shape), they can be realized.

In fact, this is the only way for polygonal 3D models to be in the real world. From the above it can be concluded that polygonal modeling is necessary exclusively for creative people (artists, designers, sculptors). But this is not unique. For example, another major area of application for 3D models ismedicine , namely surgery. You can grow a prosthetic bone instead of a crushed one. For example, the lower jaw for a turtle.

I don’t have a medical education and I have never modeled anything for medicine, but given the nature of the forms of the model, I’m sure that polygonal modeling is used there. Medicine has now taken a very long step, and as the following video shows, almost everything can be repaired (there would be money).

Of course, using polygonal modeling, it is possible to build all these restoring and reinforcing elements, but it is impossible to control the necessary gaps, sections, take into account the physical properties of the material and manufacturing technology (especially the shoulder joint). For such products, industrial design methods are used.

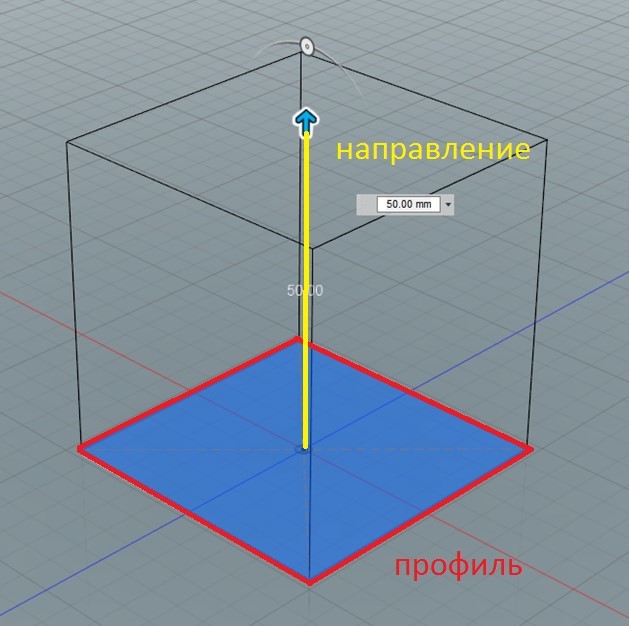

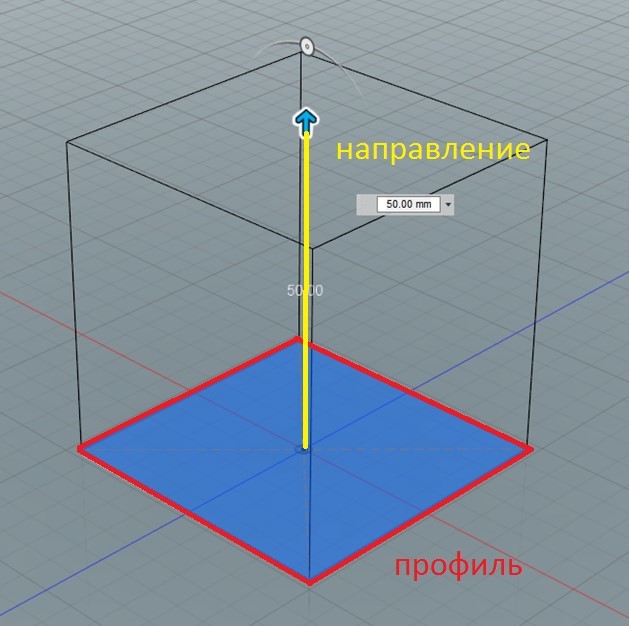

Correctly they are called: CAD (Computer Aided Design System) or in English CAD (Computer-Aided Design) . This is a fundamentally different type of simulation. It is on him that I have been specializing for 8 years. And it is about him that I will tell you in the future. How is this method different from polygonal? The fact that there are no polygons. All forms are integral and are built on the principle of profile + direction.

The basic type is solid modeling . From the name you can understand that if we cut the body, inside it will not be empty. Solid modeling is available in any CAD system. It is great for designing frames, gears, engines, buildings, planes, cars, and everything that is obtained through industrial production. But in it (unlike polygonal modeling) it is impossible to make a model of a package with products from a supermarket, a copy of a neighbor's dog or crumpled things on a chair.

The purpose of this method is to obtain not only a visual image, but also measurable and working information about the future product.

CAD is an accurate tool and when working with CAD, you must first imagine in your headmodel topology. This is an action algorithm that forms the shape of the model. Here, just in terms of topology, it is possible to distinguish an experienced specialist from a curved one. Not always conceived topology and complexity of the form can be implemented in a solid body, and then an integral part of industrial design comes to our aid - surface modeling .

Topology in surfaces is 10 times more important than solid-state modeling. Invalid topology - model crash. (I remind you that this article is also overview for beginners, I do not paint the nuances here). Mastering the topology of surfaces at a high level closes 70% of the issues in industrial modeling. But for this you need to practice a lot and constantly. Ultimately, the surfaces are still locked into a solid model.

Over time, an understanding of the most convenient method when modeling a particular product comes. It is full of life hacks, and each specialist has his own.

IMPORTANT: using CAD without a specialized education is not productive! I myself have watched many times how creative people or handymen tried to design. Yes, of course, they modeled something, but all this was a "spherical horse in a vacuum."

When modeling in CAD, in addition to topology, you must have design skills. Know the properties of materials, and production technology. Without this, it’s the same as to hammer nails with a pillow, or to iron with a vacuum cleaner.

In CAD, we get an electronic-geometric model of the product .

(I remind you that with polygonal modeling we get a visual image)

From it you can:

I think for now this is enough for you. We made out:

I hope you were interested!

I myself am a technical specialist and have been working with 3D models for more than 10 years, I have worked in more than 10 different programs of different classes and purposes, as well as in various industries. In this regard, a certain helicopter view has accumulated in this industry, with which I wanted to share with you.

3D modeling has firmly entered our lives, partially or completely rebuilding some types of business. In each industry in which 3D modeling has brought its changes, there are both its own specific standards and unspoken rules. But even within the same industry, the number of software packages can be so many that it is very difficult for a beginner to figure out and navigate where to start. Therefore, for starters, let's look at what types of 3D-modeling are and where they are used.

We can distinguish 3 large industries that today are impossible to imagine without the use of three-dimensional models. It:

- Entertainment industry

- Medicine (surgery)

- Industry

With the first we come across almost every day. These are films, animation and 90% of computer games. All virtual worlds and characters are created using the same principle - polygonal modeling .

Polygons are called these triangles and quadrangles.

The more polygons per model area, the more accurate the model. However, this does not mean that if the model contains few polygons (low poly), then this is a bad model, and the person’s hands are not from there. The same thing, it cannot be said that if the model Over999999 has polygons (High poly), then this is cool. It all depends on the destination. If, for example, we are talking about massively multiplayer games, then imagine what it will be like for your computer when you need to process 200 characters around, if all of them are high poly?

Polygonal modeling occurs by manipulating polygons in space. Pulling, rotating, moving, etc.

Autodesk (known to many for its AutoCAD product, but about it later) is a pioneer in this industry.

Products of the Autodesk 3Ds Max , and the Autodesk Maya , the de facto industry standard. And I began my acquaintance with 3D models as a 15-year-old teenager with 3Ds Max.

What do we get when we make such a model? We get a visual IMAGE. Gamers sometimes say, "I fell through the textures" in the game. In fact, you fall through the polygons that these textures are superimposed on. And the fall into infinity occurs precisely because there is nothing behind the image. Basically, the resulting images are used for RENDER (final image rendering), in the game / in the movie / for pictures on the desktop.

Actually, at one time I also tried to “blind” something to make a cool render (then it was much more difficult).

Speaking of modeling. There is such a direction as 3D-sculpting.In fact, the same polygonal modeling, but aimed at creating basically complex biological organisms. It uses other polygon manipulation tools. The process itself is more like minting than 3D modeling.

If the polygonal model is made in the form of a closed volume, such as the same sculptures, then thanks to modern 3D printing technology (which can be found in almost any shape), they can be realized.

In fact, this is the only way for polygonal 3D models to be in the real world. From the above it can be concluded that polygonal modeling is necessary exclusively for creative people (artists, designers, sculptors). But this is not unique. For example, another major area of application for 3D models ismedicine , namely surgery. You can grow a prosthetic bone instead of a crushed one. For example, the lower jaw for a turtle.

I don’t have a medical education and I have never modeled anything for medicine, but given the nature of the forms of the model, I’m sure that polygonal modeling is used there. Medicine has now taken a very long step, and as the following video shows, almost everything can be repaired (there would be money).

Of course, using polygonal modeling, it is possible to build all these restoring and reinforcing elements, but it is impossible to control the necessary gaps, sections, take into account the physical properties of the material and manufacturing technology (especially the shoulder joint). For such products, industrial design methods are used.

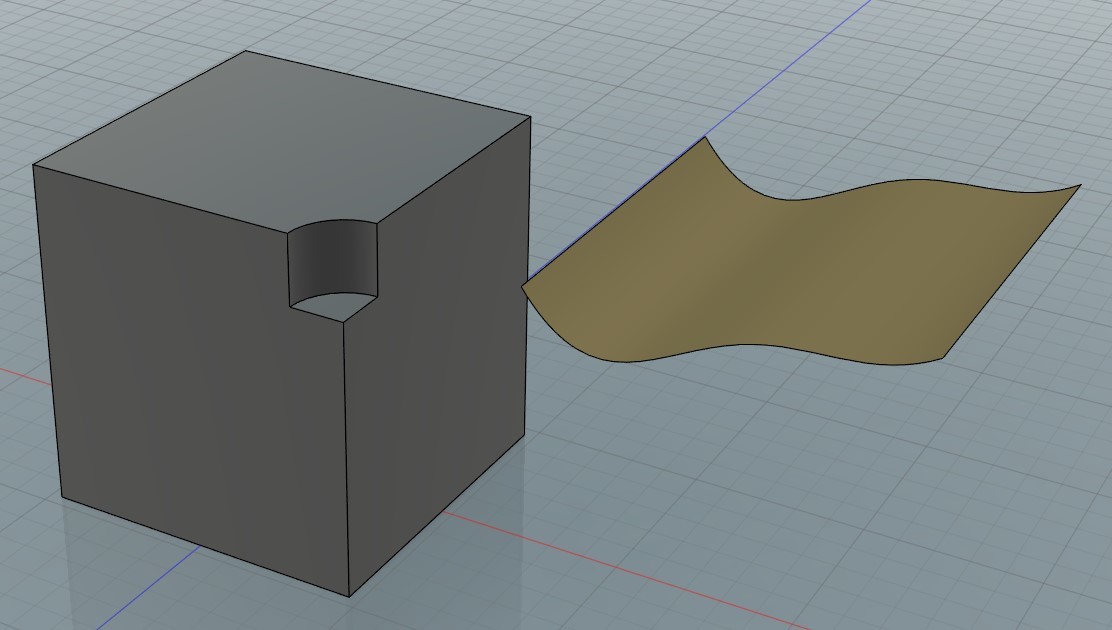

Correctly they are called: CAD (Computer Aided Design System) or in English CAD (Computer-Aided Design) . This is a fundamentally different type of simulation. It is on him that I have been specializing for 8 years. And it is about him that I will tell you in the future. How is this method different from polygonal? The fact that there are no polygons. All forms are integral and are built on the principle of profile + direction.

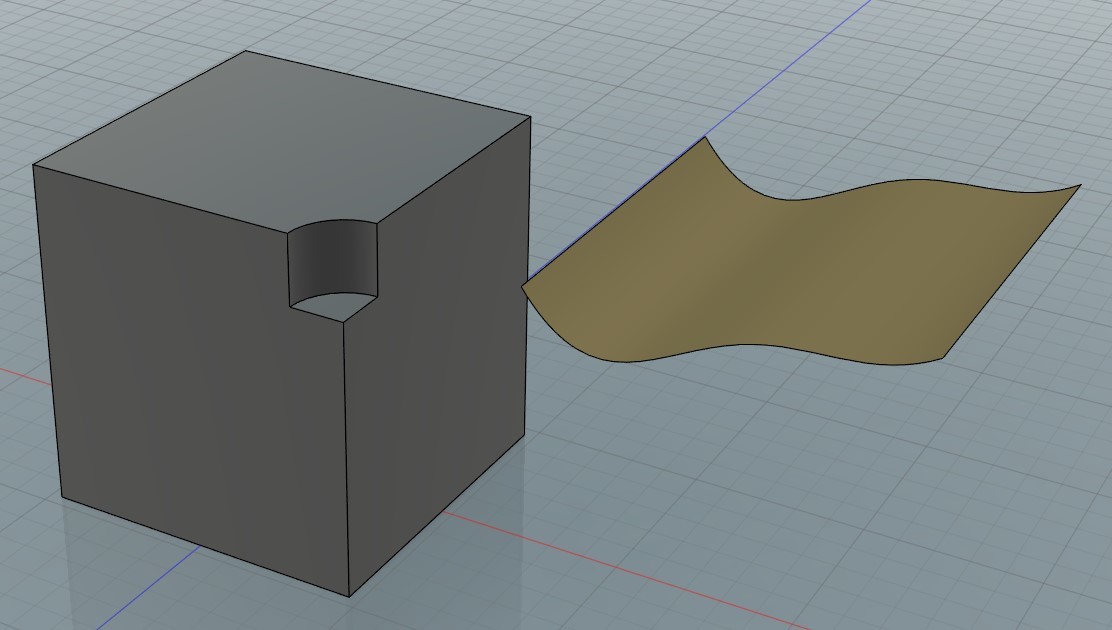

The basic type is solid modeling . From the name you can understand that if we cut the body, inside it will not be empty. Solid modeling is available in any CAD system. It is great for designing frames, gears, engines, buildings, planes, cars, and everything that is obtained through industrial production. But in it (unlike polygonal modeling) it is impossible to make a model of a package with products from a supermarket, a copy of a neighbor's dog or crumpled things on a chair.

The purpose of this method is to obtain not only a visual image, but also measurable and working information about the future product.

CAD is an accurate tool and when working with CAD, you must first imagine in your headmodel topology. This is an action algorithm that forms the shape of the model. Here, just in terms of topology, it is possible to distinguish an experienced specialist from a curved one. Not always conceived topology and complexity of the form can be implemented in a solid body, and then an integral part of industrial design comes to our aid - surface modeling .

Topology in surfaces is 10 times more important than solid-state modeling. Invalid topology - model crash. (I remind you that this article is also overview for beginners, I do not paint the nuances here). Mastering the topology of surfaces at a high level closes 70% of the issues in industrial modeling. But for this you need to practice a lot and constantly. Ultimately, the surfaces are still locked into a solid model.

Over time, an understanding of the most convenient method when modeling a particular product comes. It is full of life hacks, and each specialist has his own.

IMPORTANT: using CAD without a specialized education is not productive! I myself have watched many times how creative people or handymen tried to design. Yes, of course, they modeled something, but all this was a "spherical horse in a vacuum."

When modeling in CAD, in addition to topology, you must have design skills. Know the properties of materials, and production technology. Without this, it’s the same as to hammer nails with a pillow, or to iron with a vacuum cleaner.

In CAD, we get an electronic-geometric model of the product .

(I remind you that with polygonal modeling we get a visual image)

From it you can:

- Make drawings

- Using it, you can write a program for CNC machines,

- It can be parameterized (this is when changing 1 parameter you can change the model without alteration)

- It is possible to carry out strength and other calculations.

- It can also be sent to 3D printing (and the quality will be better)

- Make a render.

I think for now this is enough for you. We made out:

- 2 main types of modeling.

- Dismantled the industry application.

- We examined the capabilities of each method and its purpose.

- We examined the basic types of modeling in CAD and some nuances.

I hope you were interested!