On rails behind clouds: how to wash glass in a skyscraper

Wash the window, replace the damaged facade glass - the tasks seem to be simple, but when it comes to buildings with a height of 400 m, the level of complexity of even the most simple operations grows many times.

Climber behind the facade glass of the Lakhta Center tower, project archive

The taller and larger the building, the more stringent the requirements for clean windows, and the more difficult it is to keep the facade in order. At the dawn of skyscraper building, this problem was solved in the classical way, since the buildings themselves were close in design to ordinary houses, so he opened the window and wiped it with a cloth moistened with soap and water from the outside.

True, there are many windows. For example, in the Empire State Building there are 6514 of them. And higher. Therefore, there were eight washers, and they completely serviced the facade in two weeks, after which they left for the next cleaning round. The safety of the pioneers of industrial mountaineering was provided by a leather belt clinging to special hooks on the outside of the frame.

Technology is safer than in the previous photo. But with modern skyscrapers such a trick will not work. The facades are completely glass; most often there are no windows that open. So the washer-climbers work either from the roof, or from special technological hatches located at certain levels of skyscrapers.

However, for truly large buildings, this method is not suitable or is used only at certain points of the facade. Low productivity, high risks, and load capacity in a couple of human forces is not enough, for example, to replace a damaged facade element. Therefore, real supertalls are equipped with integrated SOFs , or in the international version of BMU. As a rule, such systems are mini-cranes that lift platforms or cradles, and move along facades along rails installed on the roof or on special technological sites.

Such a system is integrated into the design of the 310-meter tower "Eurasia" in Moscow City.

The additional complexity for the designers of the SOF was the geometry of the building, sharply narrowing at the level of the 51st floor. To work with two vertical planes at once, the lift is equipped with a telescopic boom with a reach of 19 m and a special system of fastening to the facade soft rope system. The carrying capacity of the cradle is 240 kg, the lifting speed is 8 m / min.

The Eye Tower is also equipped with a similar mechanism - here the geometry of the facades is simpler, respectively, and the SOF too.

There are more exotic options, for example - monorail facade systems that move along the profile of aluminum alloy. A small platform, 1-2 meters in length, suspended on ropes, moves along the guide profiles. But such systems are not installed on buildings above 80 m.

In the tallest buildings, the SOFs are entire multilevel complexes. For example, such as at Burj Khalifa in Dubai. The tallest building in the world is 828 m, 162 floors and 142 thousand m2 of glass facades.

The SOF of this giant is based on a special rail system integrated into the construction of a skyscraper and located on three floors - the 40th, 73rd and 109th. 12 cradles weighing 1.5 tons each move on rails. Starting from 110 floors, the rail system becomes too heavy to use and the facades of the upper floors are cleaned from ordinary suspended cradles.

A similar system serves the facade of the 315-meter tower of the Bank of China, located in Hong Kong. At the level of the 70th floor, guide rails run along the entire perimeter of the building, along which a working platform with a cradle moves.

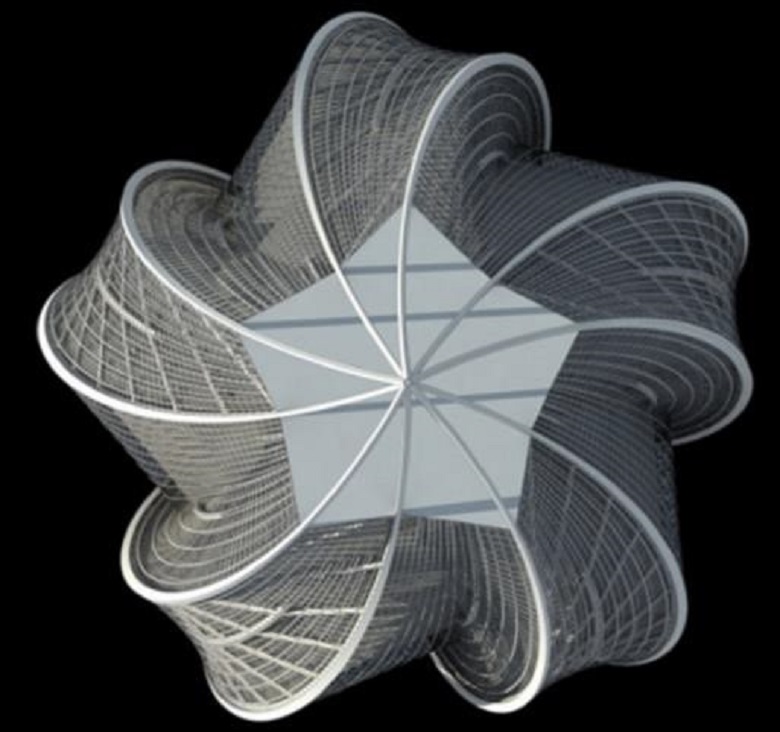

But be that as it may, the principle of all these systems is the same - a crane and a cradle. And they are suitable only for straight facades. Not for those like the tower of the Lakhta Center.

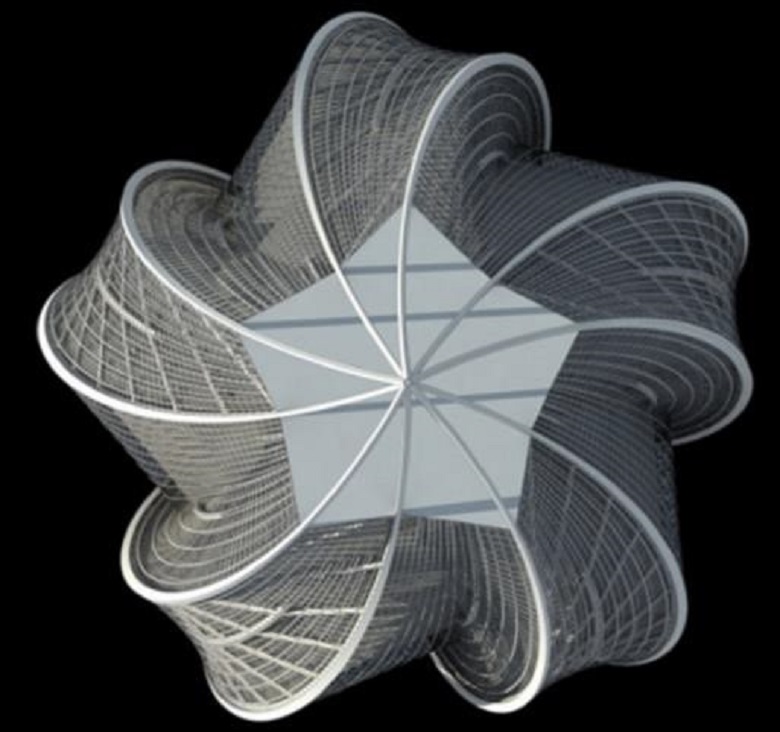

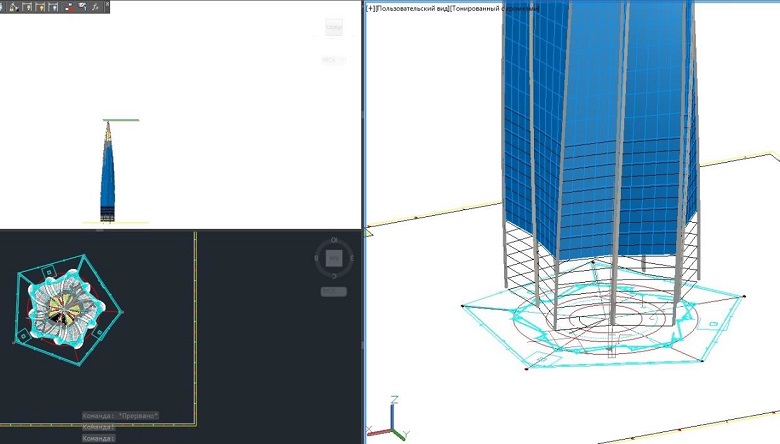

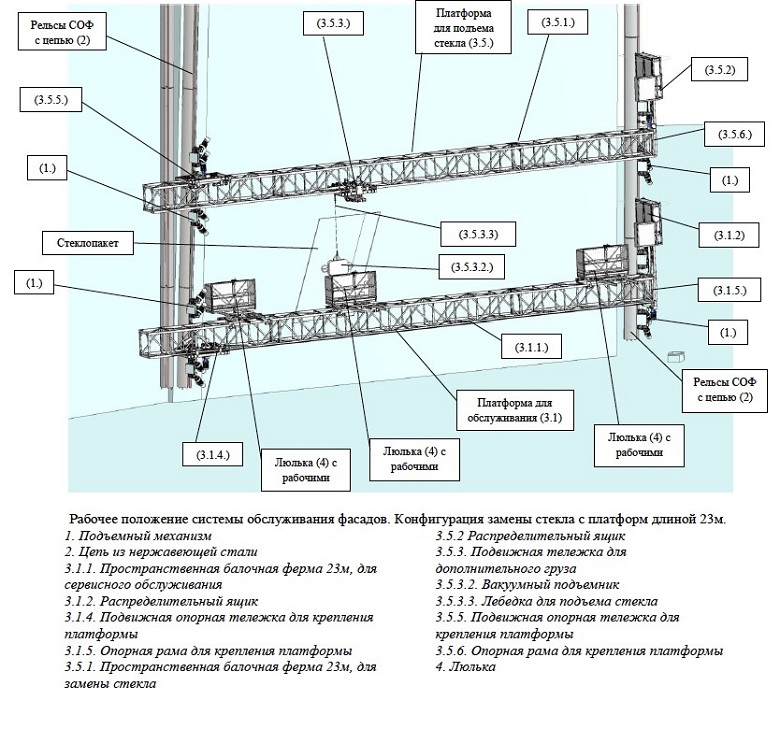

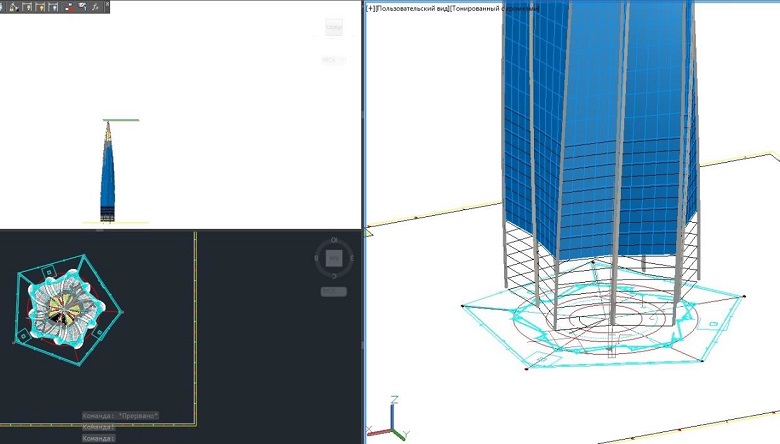

You can’t hang the cradle on the crane here, so for the St. Petersburg supertall we had to develop a completely new SOF. In fact, this is a real rail transport, but vertical. On the edges of the facade of the building from the 3rd to the 89th floor, 15 rail tracks are installed. Each track is made up of 87 rails exactly one floor long, that is, 4.2 m.

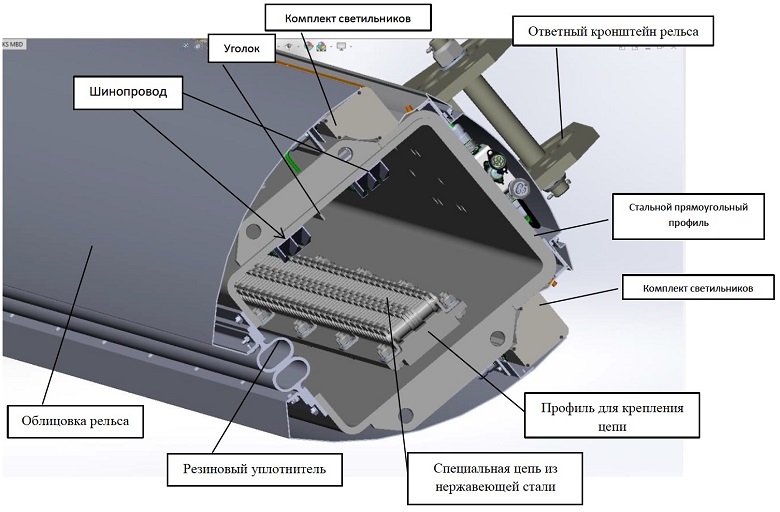

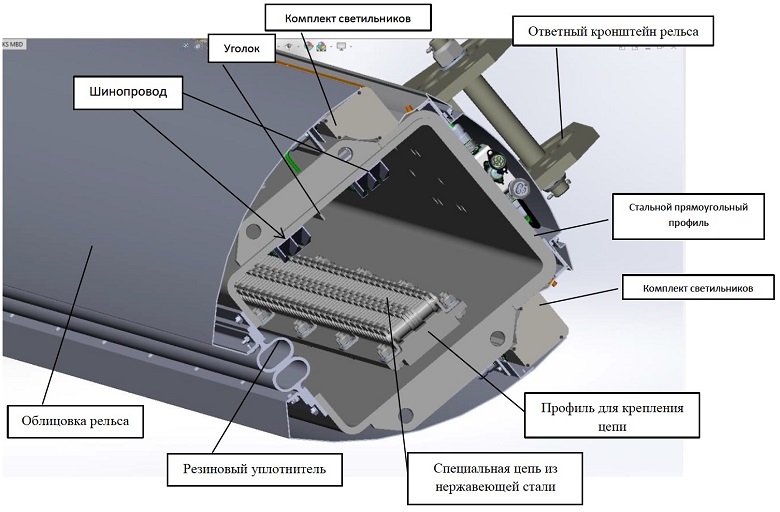

The rail itself is a rather complicated structure, which integrates a busbar for power supply (approximately, like in the subway), a facade lighting system and a stainless steel chain .

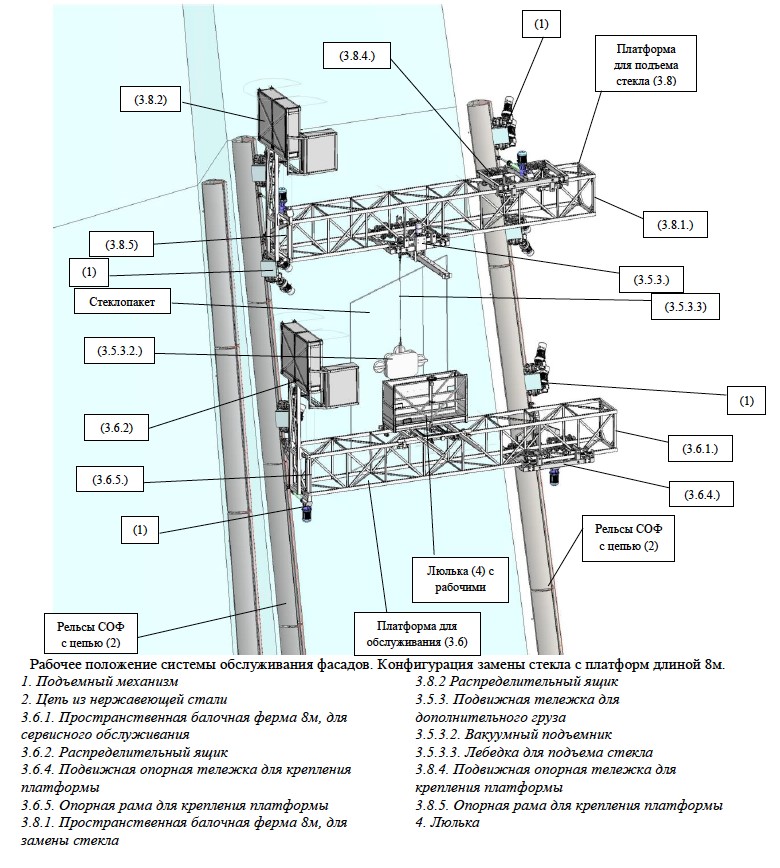

It is for this chain that the sprockets of the hoisting mechanisms equipped with four engines will cling - two at the top and bottom.

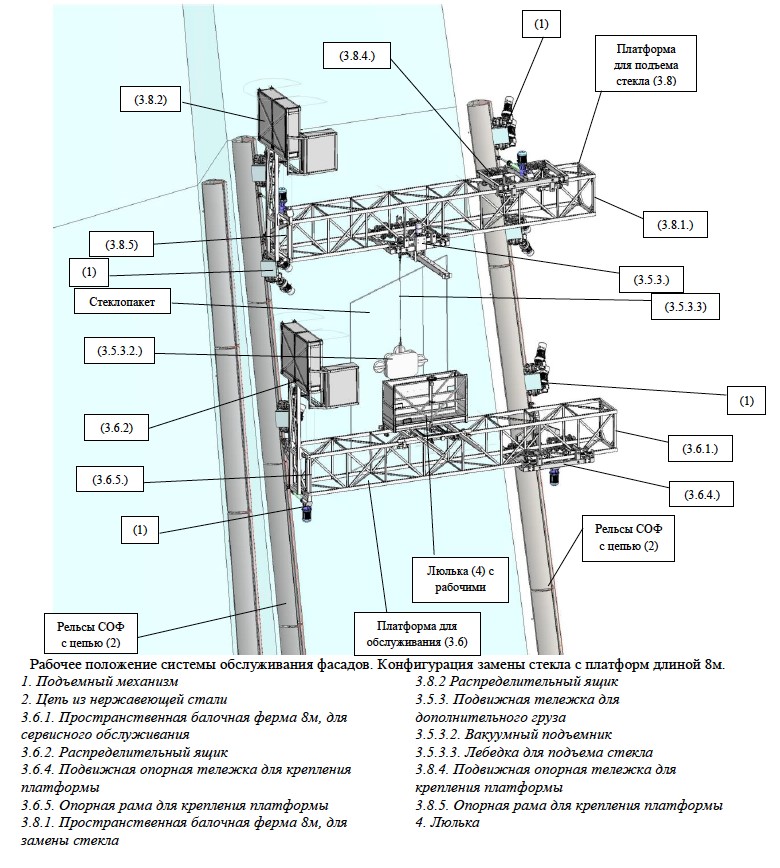

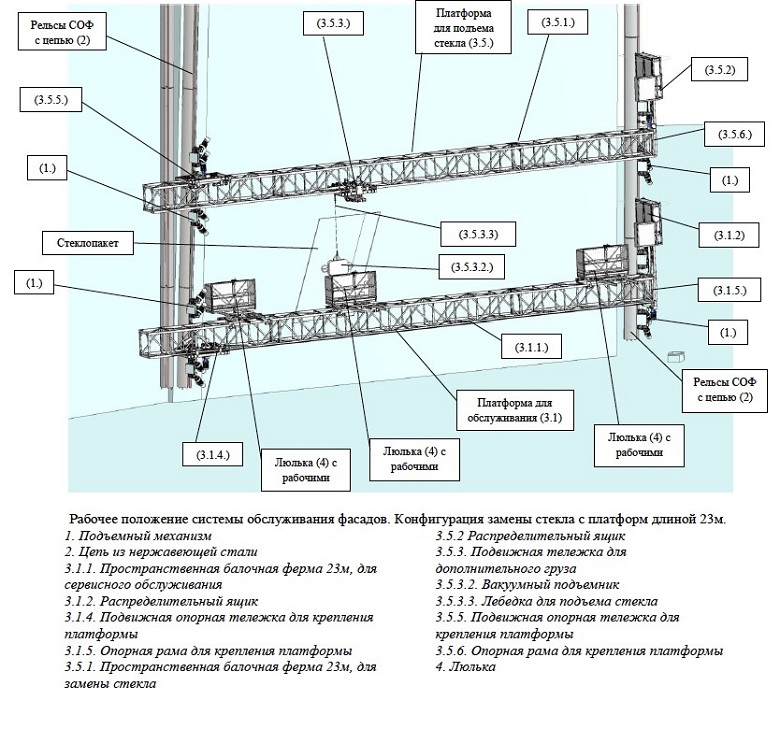

Between the lifting mechanisms mounted on two edges of the tower with rails, a platform is fixed. A platform with a length of 23 m is designed to work on wide planes between the corners - three cradles are installed here for transporting people or facade elements. On narrow planes, an 8-meter platform will be used, accommodating one cradle.

There are eight platforms in the “garages” of Lakhta Center - four large and two small for transporting people and one each in size for moving windows. At the same time, seven platforms can simultaneously work on the facades.

Due to the complexity of the tower’s geometry, the distance between the rails and the angle of inclination of the platform will constantly change when moving. Therefore, the SOF control system will have to constantly monitor the position of the platform and adjust it, accelerating or slowing down the movement of lifting mechanisms.

Obviously, despite the grandeur of the Lakhta Center tower, servicing its facades using one of the most advanced SOFs in the world will be convenient and quite simple. Another thing is to mount it. 15 ribs with 87 rails on each - this is more than 1.3 thousand rail elements. And each industrial climbers install virtually manually.

In solving this unique problem, several more paired engineering puzzles had to be simultaneously solved. And the very first one is how to deliver a rail weighing about 1.3 tons to the installation site when the cranes working on the tower construction are already dismantled? The solution was found in the experience of railroad workers who use track laying machines, building paths ahead of them, along which they move on.

The rails to the installation site on the facade of the Lakhta Center skyscraper are delivered by a special conveyor-conveyor, he is also a freight elevator. It is driven by a winch installed on the 89th floor.

The elevator-conveyor moves on a 14-mm metal cable, which may well damage the glass of the facade, and already mounted rails. In order to prevent this from happening, rollers are installed every five floors in which the cable is laid. Special guides had to be installed for climbing ropes, which due to this follow the bend of the building.

Actually, here the most difficult part begins. After a special device on the conveyor feeds the rail to the facade, two climbers must get four mounting tabs into the hole of the lower rail - as in the designer. Only an element of the designer weighs more than a ton and hangs at a 300-meter height. Moreover, due to the bending of the building, it is necessary to fix it “on a break”. So climbers, also hanging not at right angles and without a reliable fulcrum, have to sweat even during the initial installation operation.

Then you need to connect the cables and wires of adjacent rails to each other, lower the mounted structure to the only point of its attachment to the skyscraper structures, combine the rail mounting axis with the bracket in four planes, which often do not coincide due to the rail turning and the inclination of the facade. After that, the fasteners are tightened with a rigidly fixed force with torque wrenches. To prevent threaded connections from “souring” over time, they are lubricated with graphite grease.

Installation of just one rail can take up to 10 hours, that is, a whole shift. Yes, even getting to the place of work is not easy. Above level 30, climbers descend from the top of the tower to the mounting point. To do this, go up to 82 floors by elevator. Then on foot from the 82nd to the 87th and back - down - this time already outside the tower by cables. To the 20th level it is 30-40 minutes in the summer and 1.5-2 hours in the winter.

So it’s easier to go up to level 20 from below. Well, it's easier - just faster. But physical training for such an attraction in a person should be extraordinary. Not every climber is able to climb 80 meters on a rope on his hands and then install a rail weighing a ton for a few more hours.

Work on the facade is going on around the clock. Someone likes to work at night, though the whole installation is in the light of flashlights. Someone prefers a day when, albeit noisy, but the visibility is excellent.

When the wind force exceeds 10 m / s, the work stops. In winter - taking into account temperature and wind. With minus -15 below, above, with a strong wind, it can be -25. Without wind, the top / bottom temperature difference is 1.5-2 degrees. Climbers work on the tower to -20.

Climbers will remain regular “guests” of the Lakhta Center even after the SOF is launched. After all, the rails of the system do not go above level 89 - they are decorative on the spire. So all outdoor elements located there will be served by industrial climbers.

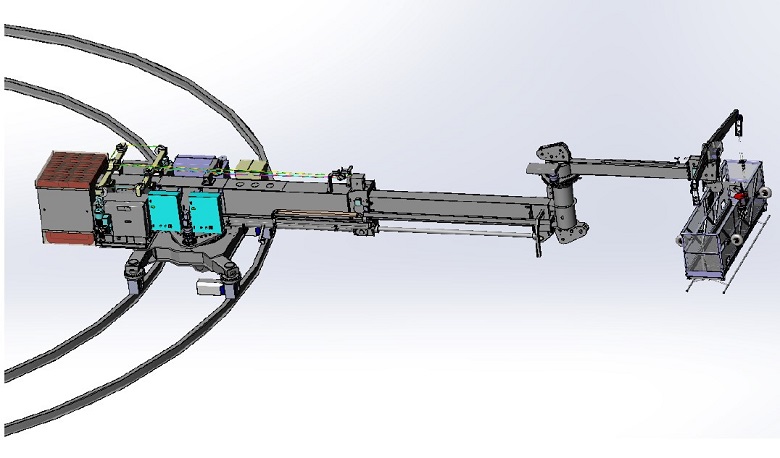

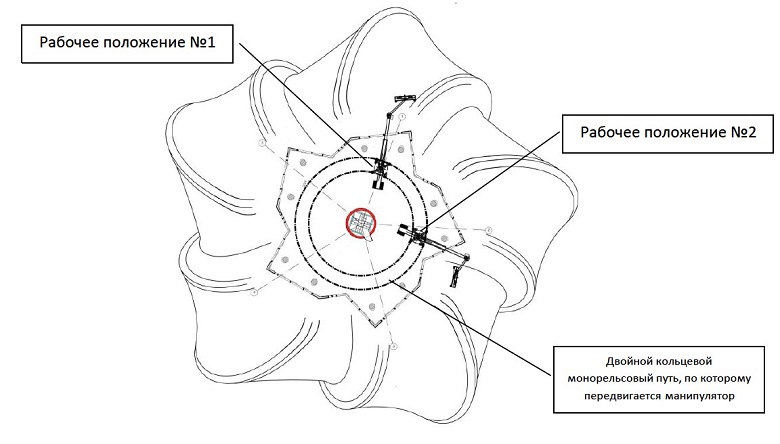

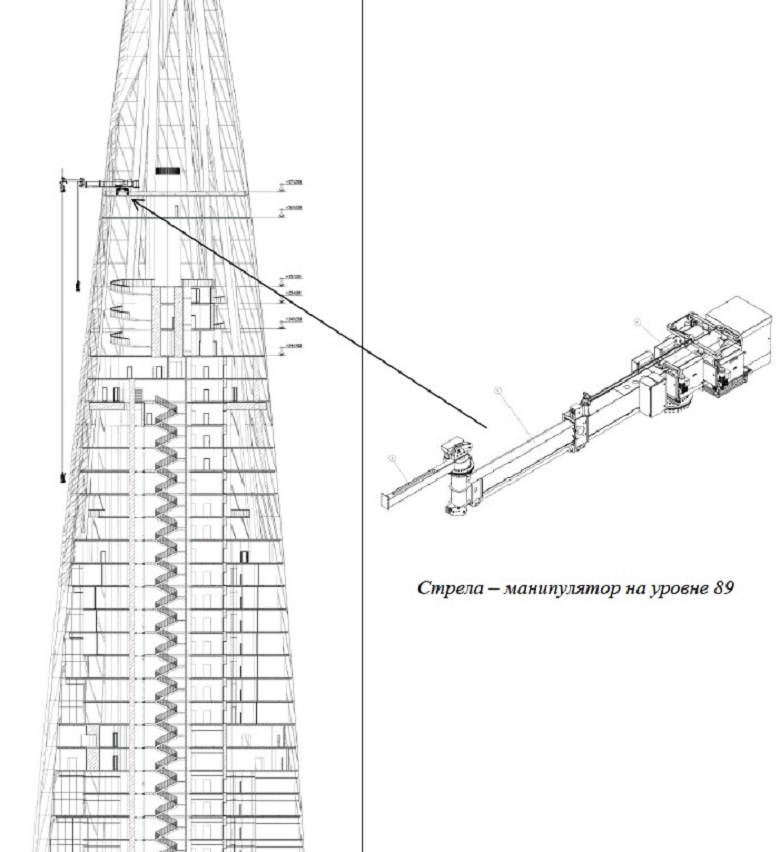

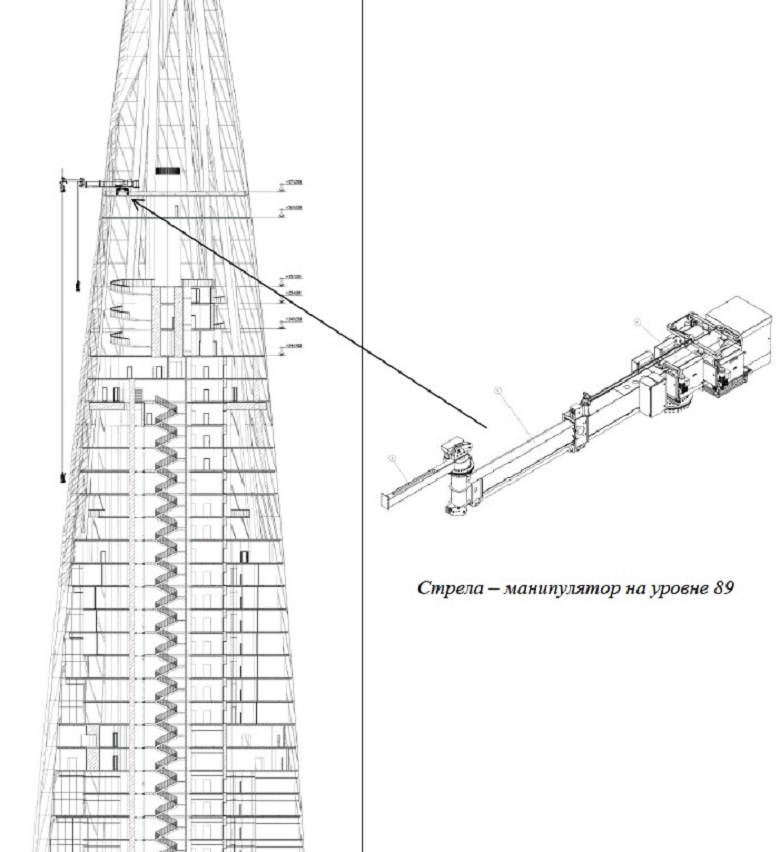

Their work is not the only addition to the main SOF. At the 89th level, there is a crane-mounted crane, traditional for skyscrapers with straight facades, with a lifting capacity of 1 ton and moving along rails.

The manipulator will service sections of the facade inaccessible to platforms, in emergency situations it will become a means of evacuating workers from the SOF platforms.

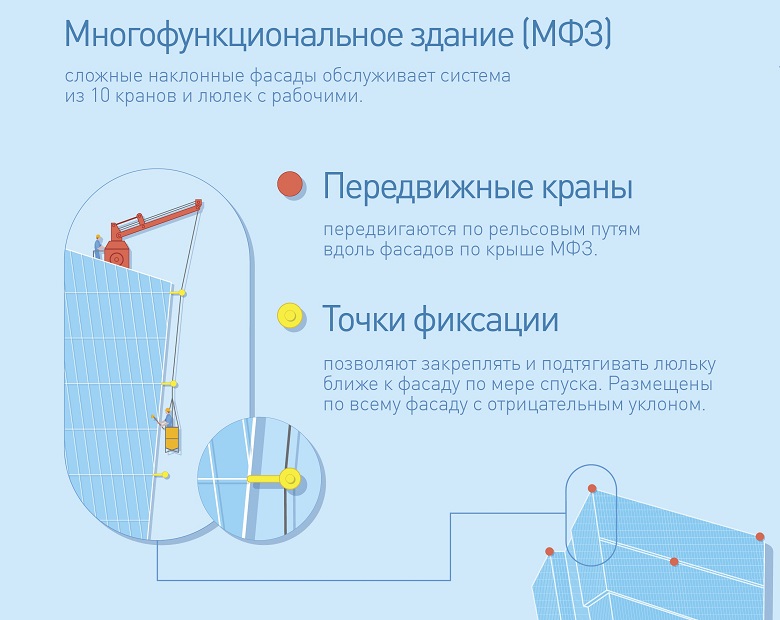

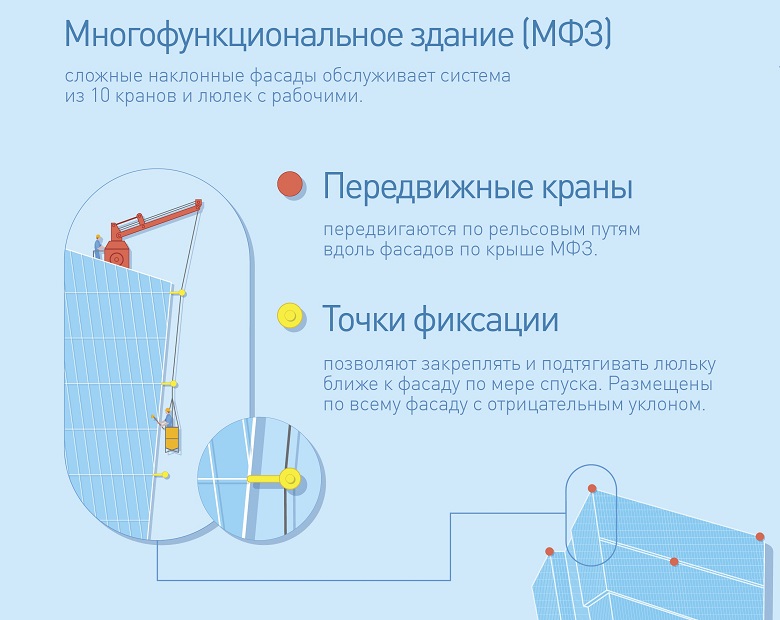

Approximately the same principle will serve and the facades of the multifunctional building. SOF MFZ form two mobile cranes with a reach of 4.37 m, six cranes with a reach of more than 10 m and two cranes with a boom of 12.5 m for the atrium facades.

***

For help in preparing the material, we thank Alexander Luchin, the head of the facades and structural design department of the building of the Lakhta Center project office tower, Ildar Nasypov and Yegor Lapin, employees of the Tetrostroy contract organization

Climber behind the facade glass of the Lakhta Center tower, project archive

SUPERCLING EVOLUTION

The taller and larger the building, the more stringent the requirements for clean windows, and the more difficult it is to keep the facade in order. At the dawn of skyscraper building, this problem was solved in the classical way, since the buildings themselves were close in design to ordinary houses, so he opened the window and wiped it with a cloth moistened with soap and water from the outside.

True, there are many windows. For example, in the Empire State Building there are 6514 of them. And higher. Therefore, there were eight washers, and they completely serviced the facade in two weeks, after which they left for the next cleaning round. The safety of the pioneers of industrial mountaineering was provided by a leather belt clinging to special hooks on the outside of the frame.

Technology is safer than in the previous photo. But with modern skyscrapers such a trick will not work. The facades are completely glass; most often there are no windows that open. So the washer-climbers work either from the roof, or from special technological hatches located at certain levels of skyscrapers.

However, for truly large buildings, this method is not suitable or is used only at certain points of the facade. Low productivity, high risks, and load capacity in a couple of human forces is not enough, for example, to replace a damaged facade element. Therefore, real supertalls are equipped with integrated SOFs , or in the international version of BMU. As a rule, such systems are mini-cranes that lift platforms or cradles, and move along facades along rails installed on the roof or on special technological sites.

Such a system is integrated into the design of the 310-meter tower "Eurasia" in Moscow City.

The additional complexity for the designers of the SOF was the geometry of the building, sharply narrowing at the level of the 51st floor. To work with two vertical planes at once, the lift is equipped with a telescopic boom with a reach of 19 m and a special system of fastening to the facade soft rope system. The carrying capacity of the cradle is 240 kg, the lifting speed is 8 m / min.

The Eye Tower is also equipped with a similar mechanism - here the geometry of the facades is simpler, respectively, and the SOF too.

There are more exotic options, for example - monorail facade systems that move along the profile of aluminum alloy. A small platform, 1-2 meters in length, suspended on ropes, moves along the guide profiles. But such systems are not installed on buildings above 80 m.

In the tallest buildings, the SOFs are entire multilevel complexes. For example, such as at Burj Khalifa in Dubai. The tallest building in the world is 828 m, 162 floors and 142 thousand m2 of glass facades.

The SOF of this giant is based on a special rail system integrated into the construction of a skyscraper and located on three floors - the 40th, 73rd and 109th. 12 cradles weighing 1.5 tons each move on rails. Starting from 110 floors, the rail system becomes too heavy to use and the facades of the upper floors are cleaned from ordinary suspended cradles.

A similar system serves the facade of the 315-meter tower of the Bank of China, located in Hong Kong. At the level of the 70th floor, guide rails run along the entire perimeter of the building, along which a working platform with a cradle moves.

But be that as it may, the principle of all these systems is the same - a crane and a cradle. And they are suitable only for straight facades. Not for those like the tower of the Lakhta Center.

METRO ON THE WALL

You can’t hang the cradle on the crane here, so for the St. Petersburg supertall we had to develop a completely new SOF. In fact, this is a real rail transport, but vertical. On the edges of the facade of the building from the 3rd to the 89th floor, 15 rail tracks are installed. Each track is made up of 87 rails exactly one floor long, that is, 4.2 m.

The rail itself is a rather complicated structure, which integrates a busbar for power supply (approximately, like in the subway), a facade lighting system and a stainless steel chain .

It is for this chain that the sprockets of the hoisting mechanisms equipped with four engines will cling - two at the top and bottom.

Between the lifting mechanisms mounted on two edges of the tower with rails, a platform is fixed. A platform with a length of 23 m is designed to work on wide planes between the corners - three cradles are installed here for transporting people or facade elements. On narrow planes, an 8-meter platform will be used, accommodating one cradle.

There are eight platforms in the “garages” of Lakhta Center - four large and two small for transporting people and one each in size for moving windows. At the same time, seven platforms can simultaneously work on the facades.

Due to the complexity of the tower’s geometry, the distance between the rails and the angle of inclination of the platform will constantly change when moving. Therefore, the SOF control system will have to constantly monitor the position of the platform and adjust it, accelerating or slowing down the movement of lifting mechanisms.

Obviously, despite the grandeur of the Lakhta Center tower, servicing its facades using one of the most advanced SOFs in the world will be convenient and quite simple. Another thing is to mount it. 15 ribs with 87 rails on each - this is more than 1.3 thousand rail elements. And each industrial climbers install virtually manually.

VERTICAL

In solving this unique problem, several more paired engineering puzzles had to be simultaneously solved. And the very first one is how to deliver a rail weighing about 1.3 tons to the installation site when the cranes working on the tower construction are already dismantled? The solution was found in the experience of railroad workers who use track laying machines, building paths ahead of them, along which they move on.

The rails to the installation site on the facade of the Lakhta Center skyscraper are delivered by a special conveyor-conveyor, he is also a freight elevator. It is driven by a winch installed on the 89th floor.

The elevator-conveyor moves on a 14-mm metal cable, which may well damage the glass of the facade, and already mounted rails. In order to prevent this from happening, rollers are installed every five floors in which the cable is laid. Special guides had to be installed for climbing ropes, which due to this follow the bend of the building.

Actually, here the most difficult part begins. After a special device on the conveyor feeds the rail to the facade, two climbers must get four mounting tabs into the hole of the lower rail - as in the designer. Only an element of the designer weighs more than a ton and hangs at a 300-meter height. Moreover, due to the bending of the building, it is necessary to fix it “on a break”. So climbers, also hanging not at right angles and without a reliable fulcrum, have to sweat even during the initial installation operation.

Then you need to connect the cables and wires of adjacent rails to each other, lower the mounted structure to the only point of its attachment to the skyscraper structures, combine the rail mounting axis with the bracket in four planes, which often do not coincide due to the rail turning and the inclination of the facade. After that, the fasteners are tightened with a rigidly fixed force with torque wrenches. To prevent threaded connections from “souring” over time, they are lubricated with graphite grease.

Installation of just one rail can take up to 10 hours, that is, a whole shift. Yes, even getting to the place of work is not easy. Above level 30, climbers descend from the top of the tower to the mounting point. To do this, go up to 82 floors by elevator. Then on foot from the 82nd to the 87th and back - down - this time already outside the tower by cables. To the 20th level it is 30-40 minutes in the summer and 1.5-2 hours in the winter.

So it’s easier to go up to level 20 from below. Well, it's easier - just faster. But physical training for such an attraction in a person should be extraordinary. Not every climber is able to climb 80 meters on a rope on his hands and then install a rail weighing a ton for a few more hours.

Work on the facade is going on around the clock. Someone likes to work at night, though the whole installation is in the light of flashlights. Someone prefers a day when, albeit noisy, but the visibility is excellent.

When the wind force exceeds 10 m / s, the work stops. In winter - taking into account temperature and wind. With minus -15 below, above, with a strong wind, it can be -25. Without wind, the top / bottom temperature difference is 1.5-2 degrees. Climbers work on the tower to -20.

SOF +

Climbers will remain regular “guests” of the Lakhta Center even after the SOF is launched. After all, the rails of the system do not go above level 89 - they are decorative on the spire. So all outdoor elements located there will be served by industrial climbers.

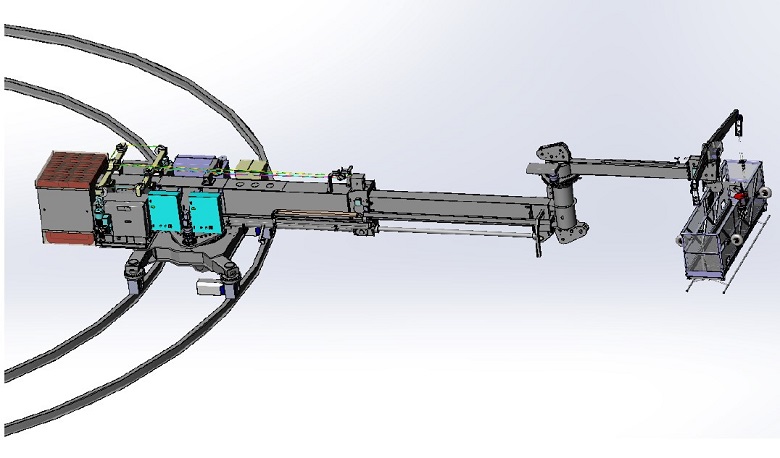

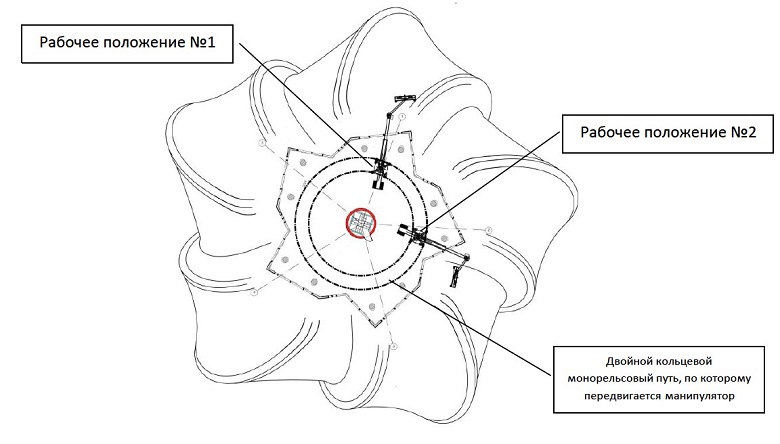

Their work is not the only addition to the main SOF. At the 89th level, there is a crane-mounted crane, traditional for skyscrapers with straight facades, with a lifting capacity of 1 ton and moving along rails.

The manipulator will service sections of the facade inaccessible to platforms, in emergency situations it will become a means of evacuating workers from the SOF platforms.

Approximately the same principle will serve and the facades of the multifunctional building. SOF MFZ form two mobile cranes with a reach of 4.37 m, six cranes with a reach of more than 10 m and two cranes with a boom of 12.5 m for the atrium facades.

***

For help in preparing the material, we thank Alexander Luchin, the head of the facades and structural design department of the building of the Lakhta Center project office tower, Ildar Nasypov and Yegor Lapin, employees of the Tetrostroy contract organization