The second life of rings and brooches: how to quickly recreate jewelry using 3D technology

Restoring damaged objects or reconstructing lost objects is one of the great features of 3D scanning and subsequent modeling in specialized software. The use of 3D scanners in jewelry is especially important , where the transfer of the smallest details of products, reproduction of their complex shapes and textures is required.

3D technologies also serve the high purposes of preserving the cultural heritage, as they allow you to quickly and efficiently restore or recreate historical values and works of art, including archaeological finds.

Today we will talk about one such project, carried out by iQB Technologies. It included the following steps:

- creation of digital copies of valuable jewelry found during archaeological excavations;

- printing master models of products on a 3D printer;

- casting jewelry from precious metals in a jewelry workshop.

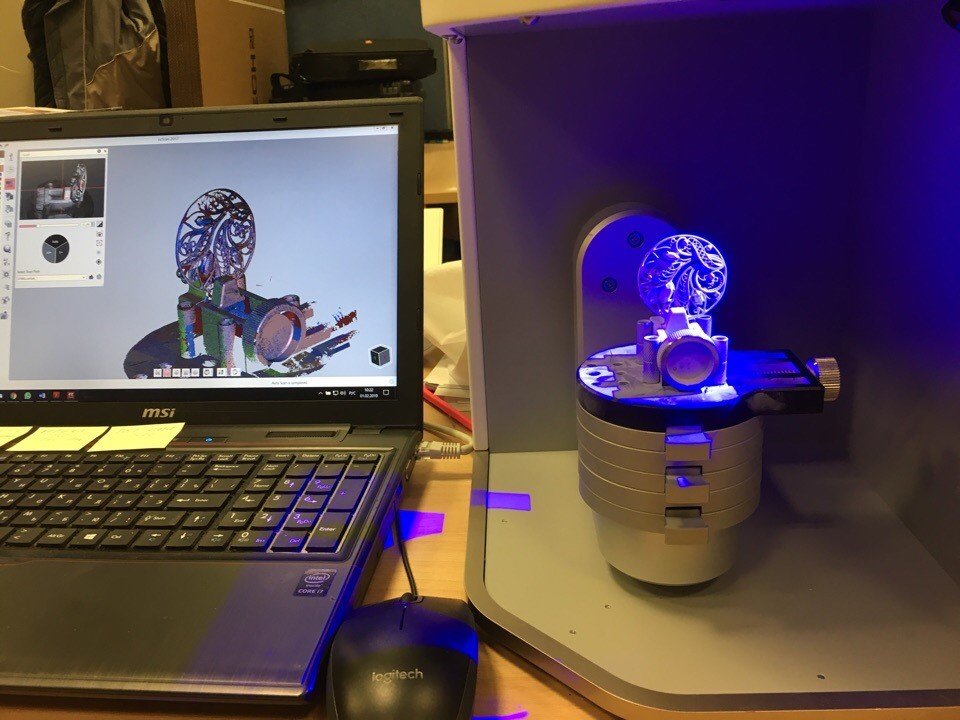

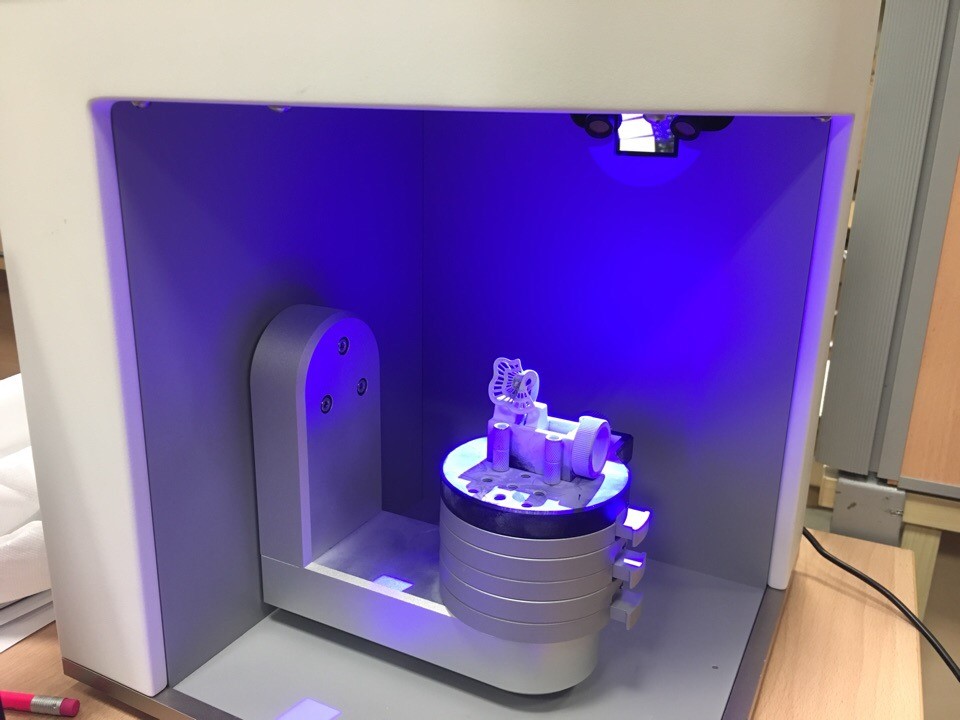

Solutionix D700 Stationary 3D Optical Scanner

The task of product recovery is traditionally solved by means of reverse engineering (reverse engineering). To implement the ideas of reverse engineering , machine vision is increasingly being used, which allows non-contact measurements of objects with the highest accuracy and detail for a short period of time. Machine vision systems mean modern 3D scanners that work with objects of almost any size, whether it be a building or a room, an assembly unit or a jewelry ring.

To solve this problem, we used a 3D scanner of a well-known South Korean manufacturer Solutionix, whose industrial line allows us to obtain a digital 3D model of objects ranging in size from 1 to 30 cubic meters. see ModelSolutionix D700 is the best fit for the role of a non-contact jewelry measurement system.

A 3D scan of two jewelry discovered by archaeologists - rings and brooches - took a total of one hour of work. As a result, digital 3D models of high accuracy were obtained with an error not exceeding 10 microns, which is ten times thinner than a human hair.

Three-dimensional mathematical models of products are stored in a digital archive in the format necessary for the user. Digital archiving saves time, and access to files can be obtained anywhere in the world, which is convenient for remote work.

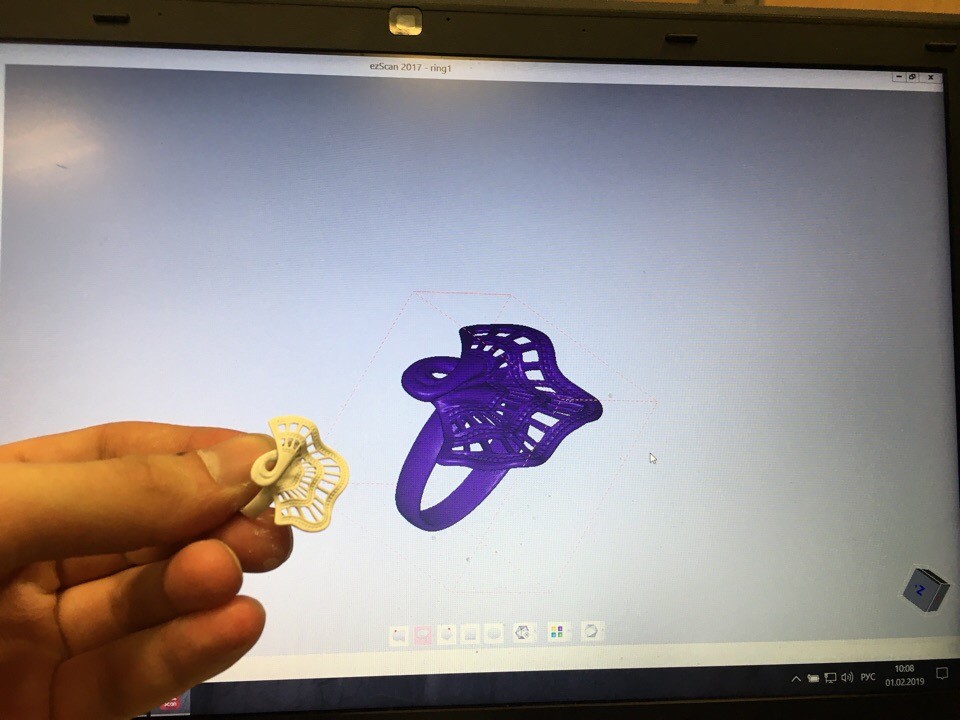

Ring and its 3D model

One of the advantages of working with the Solutionix D700 3D scanner is the simplicity of the EZscan software interface and the operations that the operator needs to do to get the result. Most operations are performed in automatic mode - just place the scan object in the working area of the 3D scanner and select a measurement automation program available to the user.

However, for the embodiment of rings and brooches in precious metals and with stones, it was necessary to obtain a master model for casting . This has been made possible thanks to additive technologies, namely a photopolymer 3D printer. It took the 3D printer about four hours to create the master models.

Ring, brooch and printed master models

As a result, products were obtained that are most similar to those found during excavations. The only thing left was to hand them over to the jeweler for casting from the corresponding precious metals. Thus, historical values found a second life in the form of jewelry, precisely recreated thanks to modern technologies of 3D scanning and 3D printing . And the whole process from scanning to receiving casting models took only five hours.