To see through. How to study subjects without breaking them?

For almost five thousand years, mankind has studied its products using only the senses: blacksmiths listened to the sound of Damascus steel, architects of the Great Pyramids gropingly evaluated the smoothness of the blocks. We did not know how to explore man-made objects without disassembling or breaking them until the 19th century, until the history of Non-Destructive Inspection (NDI) technologies began.

The story of non-destructive testing began, of course, with destruction.

In 1854, a brand new steam boiler exploded in a factory in Hartford (Connecticut). The explosion destroyed the workshop and claimed 21 lives. In the era of steam engines, boilers often burst, although they were produced with a huge margin of safety. Engineers could only vaguely suspect the existence of microcracks and metal fatigue. The explosion in Hartford for the first time forced the authorities to establish a regular commission, which was to inspect steam boilers. It was then that engineers around the world thought about how to get inside what cannot be removed and disassembled.

The subsequent scientific and technological revolution by the middle of the 20th century equipped us with a whole arsenal of non-destructive research techniques designed to prevent and prevent a variety of troubles. Among these techniques are x-rays, magnetic resonance imaging (MRI), electromagnetic radiation, computed tomography and even cosmic rays. Much is known about the application of these technologies in medicine, safety and manufacturing, so we decided to talk about the most non-trivial tasks that NDI helps us and our colleagues in other areas.

1. How X-Ray Helps 3D Printing

If we can "enlighten" any object, then why not capture its three-dimensional model, and then not make a copy of it? Engineers at Toshiba IT & Control Systems Corporation (ITC) have created the most accurate x-ray that can deliver finished 3D models in HD quality for 3D printing - the TX Lamino. It got its name from laminography - the technology of layer-by-layer X-ray examination of objects, which is laid in its foundation.

TX Lamino “shines through” an object from different viewing angles, which helps to see details or defects that cannot be detected by viewing a 2D image. The machine is equipped with a nanofocus x-ray generator, that is, it can focus the rays at an optical point with a diameter of less than 1 μm, or rather, in the case of TX Lamino, 0.25 μm. This allows you to examine very small objects in detail. The 4-megapixel camera, which produces four times sharper images than conventional x-rays with a 1-megapixel camera, helps nanofocus.

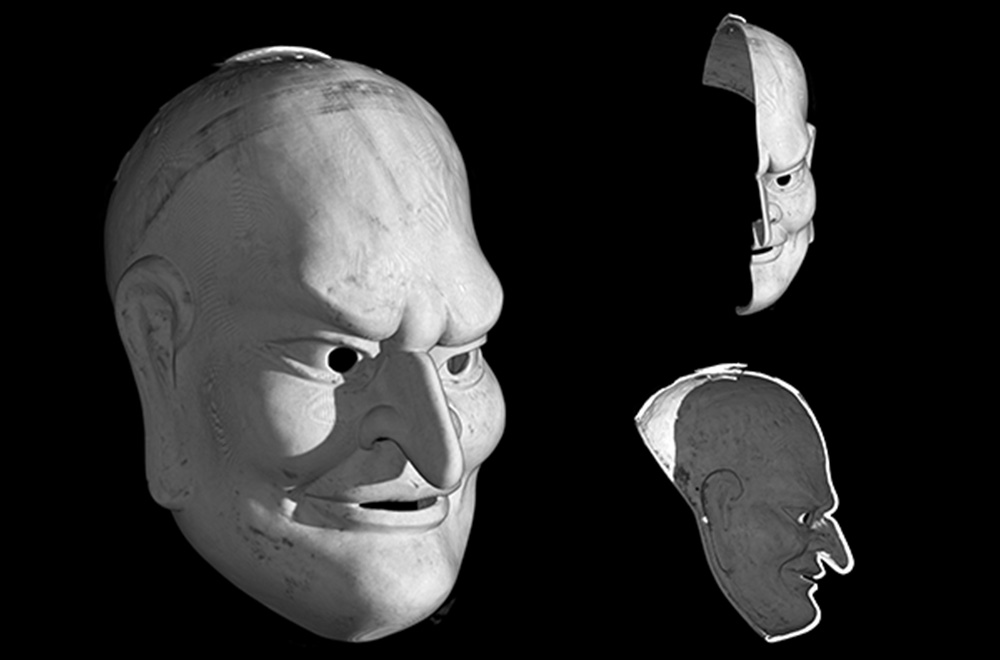

The device TX Lamino. With it, you can create an accurate 3D model of any item. Source: Toshiba ITC

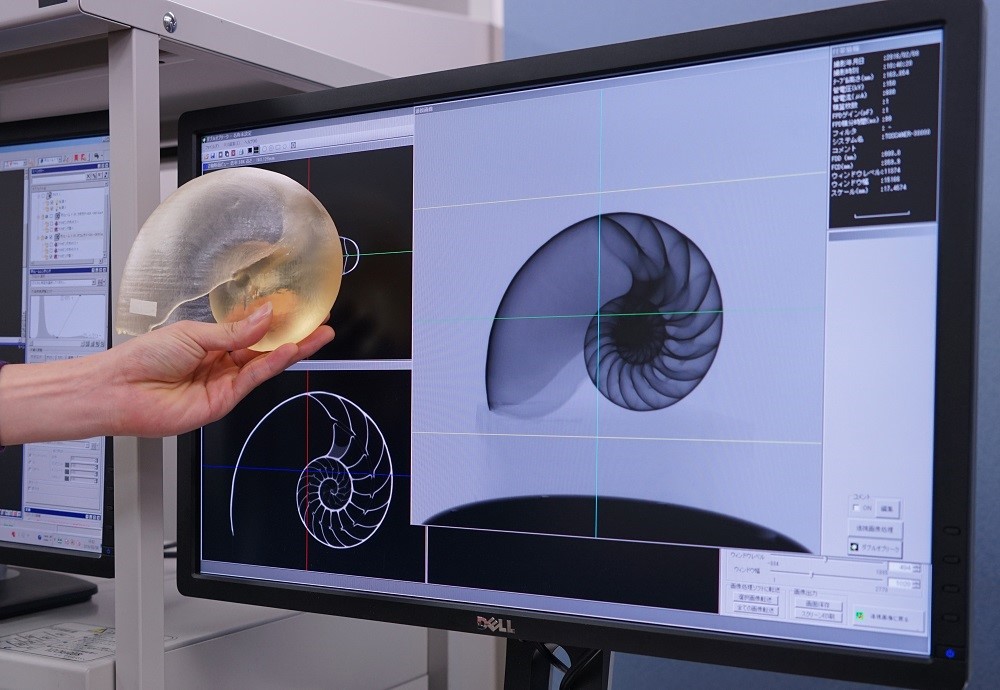

The device TX Lamino. With it, you can create an accurate 3D model of any item. Source: Toshiba ITCThe X-ray takes layered images of the subject, and then combines them into a realistic 3D model, which can be viewed on the monitor in 4K resolution. Moreover, if necessary, any of the photo layers can be studied separately from the others in 2D. For example, a shell of a mollusk can be “decomposed” into layers.

Source: YouTube channel Toshiba News and Highlights

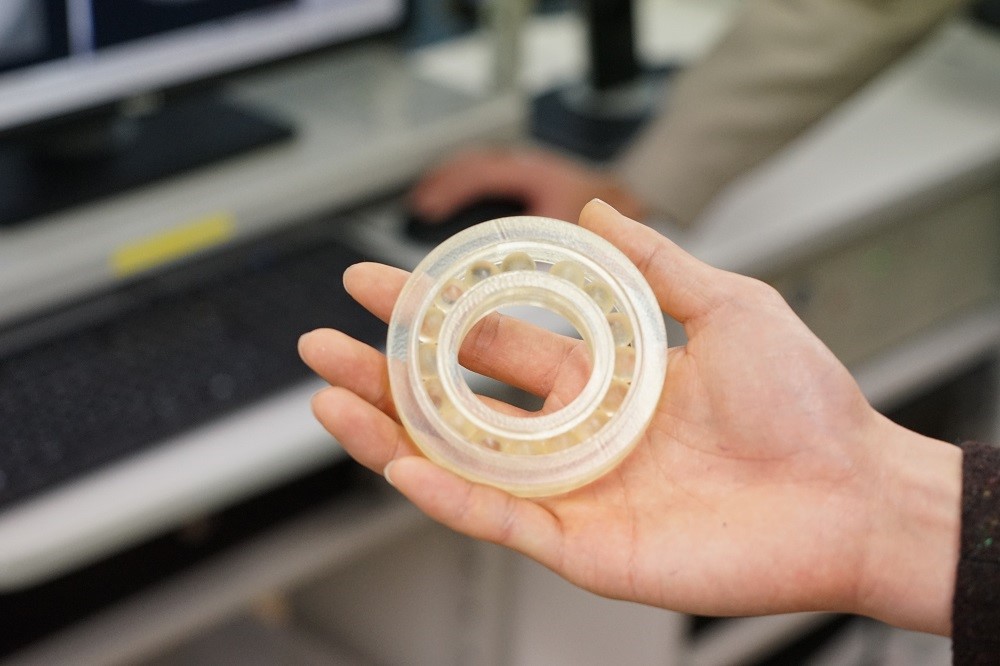

Then the model can be turned into a real object on a 3D printer, and its internal structure will be absolutely identical to the original, even if we are talking about, say, an engine part with moving parts. For example, with the help of TX Lamino it was possible to create a polymer copy of a ball bearing with a rotating ring.

3D print of engine parts made with TX Lamino. Source: Toshiba

And that bearing. Source: Toshiba ITC

And that same clam shell. Source: Toshiba

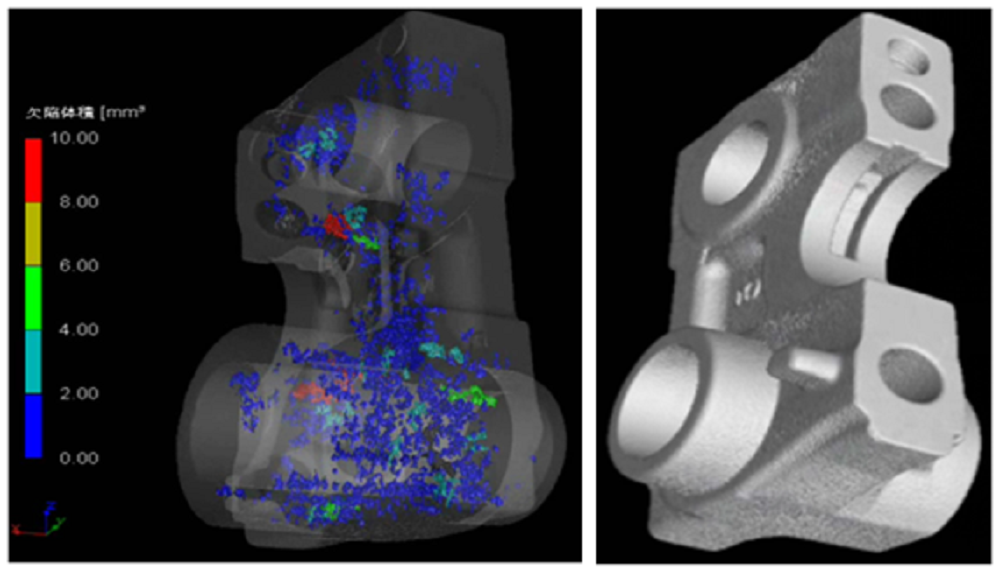

The technology, which allows us to literally see through any object, helps us at Toshiba cope with less original tasks, in particular with quality control. Take, for example, cars. Any defect in important components and mechanisms creates a risk to human life and health. And far from all defects we see with the naked eye. Our industrial systems, combining X-ray and advanced imaging technologies, identify these problems.

At first glance, any metal disc seems completely solid. In reality, this is not so. A defective part may contain a myriad of air bubbles, which over time will lead to breakage. You can see them only "at gunpoint" x-rays.

Aluminum car part. On the left is an X-ray image that shows clusters of air cavities and their size, differentiated by color. On the right is a 3D model. Source: Toshiba

However, while a 3D scanner is not capable of living creatures - a sea shell or aluminum blank can be shone through as much as you want, and living organisms, especially those that cannot be opened without breaking once and for all, say, insects, from and / or intense exposure deteriorate.

2. How to save the life of a Drosophila fly

NDI insects have a complex relationship. It is almost impossible to get a clear three-dimensional image of a fly: the insect is constantly moving, and for a high-quality image you need the complete rest of the scanned. In addition, invertebrates can hardly tolerate large doses of radiation, and for a good 3D image, you need a lot of pictures, so for insects such a photo shoot becomes deadly. Moreover, even if the model survives shooting, radiation will negatively affect her growth, reproduction and life expectancy, which interferes with long-term research.

Our colleagues at the University of Western Ontario in Canada solved this problem with carbon dioxide. The fact is that insects have the ability to survive during oxygen starvation. Their natural reaction to a lack of oxygen is a dream during which the invertebrate remains motionless for some time.

With this in mind, such an NDI method was developed: photomodels are conveniently placed in a small round-shaped chamber - on a polystyrene substrate. It is installed under the x-ray source. Then CO2 is injected into the insect chamber, which puts them into a state of sleep.

At this moment, a computer tomograph (CT) starts to work, similar to those used to scan people. The main difficulty at this stage was the CT settings. Scientists always make the inevitable compromise: the lower the radiation dose, the worse the image quality, and vice versa. Canadian scientists have come to the conclusion that to get good 3D images of sleeping insects, radiation is enough, which is 80 times weaker than what leads to their sterilization. As it turned out, adult flies, Colorado beetles, caterpillars quite coped with a 7-hour stress test for hypoxia and radiation, and then quickly came to their senses.

Three-dimensional computed tomography (resolution - 20 microns) of a male moth. On the left is the first photo shoot, on the right - in four days. He is alive, though tired. Source: BioMed Central Ltd

However, absolute peace does not always guarantee the success of NDI, especially if we are not interested in the structure of the subject of study, but, for example, in the inscription in it.

3. How to read books using NDI

Perhaps the dream of all students will soon come true - to receive information from a closed book without clairvoyance. For this, a group of scientists from MIT called for help the very real forces of electromagnetism and terahertz radiation (the average between infrared and microwave). Terahertz waves are well known to safety experts: different chemicals absorb different frequencies of TG radiation in different ways.

When TG rays pass through ink and blank paper, the touch receiver receives a different imprint of intensity - this is the way to read books or scrolls without unrolling them - it is very useful when the sheets stick together and / or become very fragile, which is often the case with old books, to which researchers need access. The process is organized as follows: a TG emitter generates ultrashort radiation pulses per book, and the built-in camera sensor reads their reflection from tiny air pockets with a width of 20 microns, which are between the pages of the book. The response from letters and blank pages looks different, allowing you to distinguish between the inscription.

Source: YouTube Channel MIT Media Lab

But not so simple. Most of the radiation is either reflected or absorbed by the book, and other particles do not bounce away from air bubbles, but from other pages, creating a false signal. To separate false signals from true ones, you need to know the distance from the receiver to a specific page of the book. Now an algorithm developed by scientists can theoretically distinguish between writing at a depth of up to 20 pages. But in practice, at about a depth of nine pages, the energy of the reflected signal becomes so small that it is no longer possible to distinguish it from noise. So for now, we can read newspapers rather than books, although research is ongoing. In addition, there are tasks for NDI from the era of preliterate history.

4. Did the Neanderthal play the flute?

In addition to medical issues, the invention of Wilhelm Roentgen helps to solve historical problems. For example: could Neanderthals play the flute?

Scientists were thinking about the bone of a cave bear found in the cave Divye Babe (Slovenia). Two holes were made in it, and at the break points, the outlines of two more are visible. Together they form a row, like a flute. The find is 43 thousand years old, so some scientists believe that we found a Neanderthal product, while others see in the bone scraps of a hyena feast, whose fangs could make such neat holes.

Neanderthal Flute from Divier Babier. The author of the holes is either a Neanderthal or a cave hyena. Source: Sporti / Wikimedia Commons

To thoroughly examine the “flute”, scientists used computed tomography (CT): an x-ray illuminated the bone from different angles, and the computer combined the images into a three-dimensional image. It turned out that there really are a lot of traces of eating animals on the bone, but not all can be clearly attributed to the effects of the jaws. Then, using the obtained images, the scientists reconstructed a copy of the “flute”.

As it turned out, you can really play it: the instrument produces up to 2.5 octaves in a sequence of melodies on a 12-tone scale. “Neanderthal flute” under the power of legato, staccato, frullato, glissando and other methods of performance.

It is not so difficult to enlighten a small flute with X-ray, but there are more historical monuments. Much more. How to be with them?

5. From heaven to earth: how cosmic rays helped to make an “X-ray” of the pyramid

Almost all of our all-seeing technologies remain "nearsighted": the "vision" of radars, x-ray machines, and ultrasound does not extend further (deeper) than a few meters. And you need more! With about such thoughts in 2016, a group of Japanese scientists from Nagoya University looked at the Cheops pyramid with a volume of 2.5 million cubic meters. They decided to scan this object with cosmic rays, which are born by sources of high energies, say, supernova explosions. Passing through the Earth’s atmosphere, cosmic rays turn into secondary particles - muons. They have a very high penetrating ability: to overcome even 1 kilometer of limestone blocks is not a problem for them.

Matter absorbs more muons than void. To "catch" particles, the Japanese set special traps inside the famous chambers of the pyramid. Bright muon prints indicated a previously unknown cavity above the Great Gallery of the Cheops Pyramid. A space 30 meters long resembles the shape of a large gallery. As Egyptologists suggest, cosmic rays helped to find the technical room - the cavity reduces the pressure of the blocks on the arches of the Great Gallery.

By the way, the same technology is now used by Russian scientists in Derbent: they are trying to understand whether the cross-shaped structure, completely hidden underground, was the oldest Christian church in Russia or just a reservoir.

Source: Euronews

What will happen next?

We believe that in the near future non-destructive testing technologies will be combined with other advanced developments:

- Big Data will help us collect and interpret much more information than a live radiologist can absorb;

- neural networks will make NDI more proactive: we will be able to build a system for mass testing of products, parts, assemblies at the production stage, which does not require a direct human assessment;

- The direct result of these operations will be implemented automatically using 3D printing . The processed analysis results will serve as “food” for 3D printers, which immediately eliminate the shortcomings or improve the product in the conveyor mode.